Advertisement

Quick Links

Installation, Operation &

Maintenance

Instructions

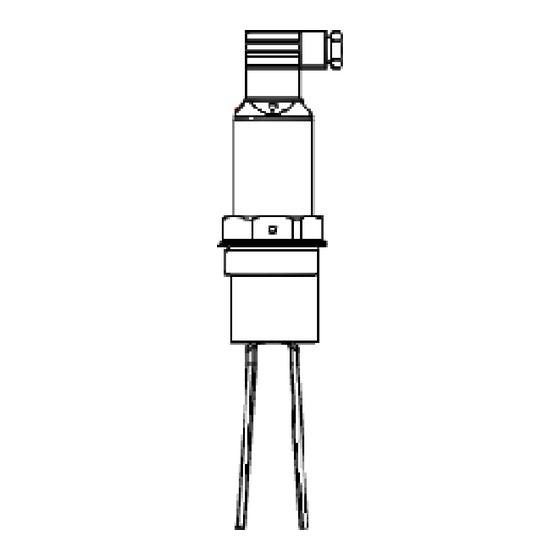

Mini-Vibrating Fork Switch for SOLIDS

Models DMVS (Level Switches)

SAFETY INSTRUCTIONS

Information

...points out useful tips,

recommendations and information

for efficient and trouble-free

operation.

CAUTION!

...indicates a potentially dangerous

situation that can result in light

injuries or damage to equipment or

the environment, if not avoided.

WARNING!

...indicates a potentially dangerous

situation that can result in serious

injury or death, if not avoided.

WARNING!

...identifies hazards caused by

electric power. Should the safety

instructions not be observed, there

is a risk of serious or fatal injury.

WARNING!

...indicates a potentially dangerous

situation that can result in burns,

caused by hot surfaces or liquids, if

not avoided.

WARNING!

...indicates a potentially dangerous

situation in the hazardous area that

can result in serious injury or death,

if not avoided.

Ex applications...special instructions for Ex

applications.

CONTENTS

Foreword

Ambient temperature

•

Process temperature

•

List of standards to which the product conforms

Operating principle

Special conditions of use

Installation

Mounting Position

•

Electrical connections

•

Wiring

•

Operation adjustment

Operation Test

•

Maintenance

Storage

Replacement parts

Warranty

Decommissioning

Disposal

Model code

For the technical characteristics and perfor-

mance of the product, please refer to the Tech-

nical Data Sheet TDS-DMVS-A

Page 1 of 5

FOREWARD

The unit is manufactured, checked and supplied in

accordance with our published specification, and when

installed and used in normal or prescribed applications,

with the lid in place and within the parameters set for

mechanical and electrical performance, will not cause

danger or hazard to life or limb.

Warning: Units must be selected and installed by

suitably

accordance with appropriate codes of practice so

that the possibility of failure resulting in injury or

damage caused by misuse or misapplication is

avoided.

Warning: Before installation check that the

instrument characteristics comply with process

and plant requirements

Warning: The user should ensure the equipment is

suitable for use in the application with aggressive

substances.

Warning: The users attention is drawn to the fact

that, when the unit is 'live' with respect to electrical

or pressure supplies, a hazard may exist if the unit

is opened or dismantled.

Warning: Where any special condition of the

product has been required as identified by the last

4 digits of the part number, follow the necessary

safety instruction for a correct installation.

Ambient temperature

The surface temperature of the instrument is influenced by

the process temperature, electrical working conditions,

installation and environmental. Special attention must be

taken to avoid exceeding the limits specified on table below).

Ambient temperature range

–30 to +70°

Process temperature

Special attention must be taken to avoid exceeding the limits

specified on table below).

Max process temperature at

process connection of the

–40 to +130°C –40 to +266°F

–20 to +90°C

–40 to +120°C –40 to +248°F

LIST OF STANDARDS

This product complies to the below Directives & Standards

Directive:

Conformity Assessment: Module A

Standards:

Directive:

Conformity Assessment: Module A

Standards:

Directive:

Conformity Assessment: Module A

Standards:

www.delta-mobrey.com

IOM-DMVS: DEC 2023

trained

and

qualified

Enclosure type

-22 to +158°F

All model and

Max

process

instrument

temperature

Stainless

–4 to +194°F

PP Flanges

ECTFE

Electromagnetic Compatibility (EMC) - 2014/30/EU

EN 61326-1:2013, EN 61326-2-3: 2013

Low Voltage (LVD) - 2014/35/EU

EN 61010-1:2010/A1:2019/AC:2019

Restriction of Hazardous Substances(RoHS)-2011/65/EU

EN IEC 63000:2018

personnel

in

Advertisement

Summary of Contents for delta-mobrey DMS Series

- Page 1 For the technical characteristics and perfor- Standards: EN 61010-1:2010/A1:2019/AC:2019 mance of the product, please refer to the Tech- Directive: Restriction of Hazardous Substances(RoHS)-2011/65/EU Conformity Assessment: Module A nical Data Sheet TDS-DMVS-A Standards: EN IEC 63000:2018 Page 1 of 5 www.delta-mobrey.com...

- Page 2 • ON HIGH VISCOSITY liquids, where there is risk of material remaining on the fork, the instrument is recommended to be mounted vertically Page 2 of 5 www.delta-mobrey.com...

- Page 3 “H” Level limit switch Connect the unused wire to an unused terminal in the terminal block NPN output “L” Lowe Level limit switch “H” High Level limit switch “L” Low level limit switch “H” Level limit switch Page 3 of 5 www.delta-mobrey.com...

- Page 4 Sales department Warning: returned instrument, must be cleaned from aggressive, harmful , dangerous substances and accompanied by our Cleanliness Certificate duly filled in. Please contact our sales department to arrange any return of instrument. Cable Page 4 of 5 www.delta-mobrey.com...

- Page 5 - Disconnect the instrument from the process publication. No legal liability will be accepted connection. by Delta Mobrey for any errors, omissions or Warning: The process fluid can be hot and amendments. or corrosive. - Plug the process pipe. Page 5 of 5 www.delta-mobrey.com...

Need help?

Do you have a question about the DMS Series and is the answer not in the manual?

Questions and answers