Table of Contents

Advertisement

Operator's Manual

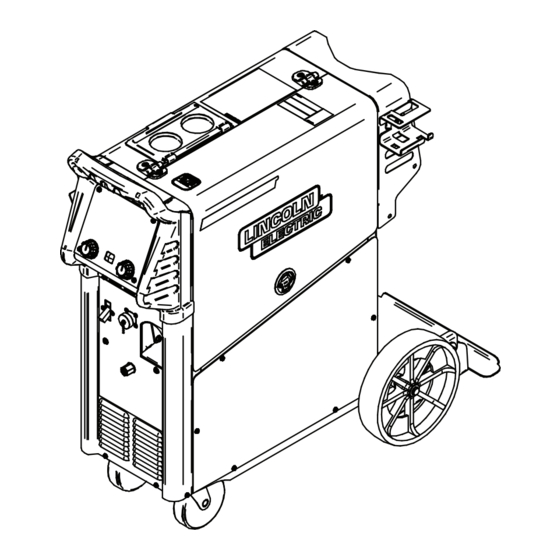

POWER MIG

Register your machine:

www.lincolnelectric.com/register

Authorized Service and Distributor Locator:

www.lincolnelectric.com/locator

Save for future reference

Date Purchased

Code: (ex: 10859)

Serial: (ex: U1060512345)

IM10671-B

|

© Lincoln Global, Inc. All Rights Reserved.

262MP

®

Date Mar - 24

For use with machines having Code Numbers:

13419

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Lincoln Electric POWER MIG 262MP

- Page 1 Operator’s Manual POWER MIG 262MP ® For use with machines having Code Numbers: 13419 Register your machine: www.lincolnelectric.com/register Authorized Service and Distributor Locator: www.lincolnelectric.com/locator Save for future reference Date Purchased Code: (ex: 10859) Serial: (ex: U1060512345) IM10671-B Date Mar - 24 ©...

- Page 2 THANK YOU FOR SELECTING KEEP YOUR HEAD OUT OF THE FUMES. A QUALITY PRODUCT BY DON’T get too close to the arc. LINCOLN ELEC TRIC. Use corrective lenses if necessary to stay a reasonable distance away from the arc. READ and obey the Safety Data PLEASE EXAMINE CARTON AND EQUIPMENT FOR Sheet (SDS) and the warning label DAMAGE IMMEDIATELY...

- Page 3 P.O. Box 351040, Miami, Florida 33135 or CSA Standard W117.2. A Free copy of “Arc Welding Safety” booklet E205 2.a. Electric current flowing through any conductor is available from the Lincoln Electric Company, 22801 causes localized Electric and Magnetic Fields (EMF). St. Clair Avenue, Cleveland, Ohio 44117-1199.

- Page 4 SAFETY ELECTRIC SHOCK ARC RAYS CAN BURN. CAN KILL. 3.a. The electrode and work (or ground) circuits are 4.a. Use a shield with the proper filter and cover plates to protect your electrically “hot” when the welder is on. Do eyes from sparks and the rays of the arc when welding or not touch these “hot”...

- Page 5 SAFETY WELDING AND CUTTING CYLINDER MAY EXPLODE IF SPARKS CAN CAUSE DAMAGED. FIRE OR EXPLOSION. 7.a. Use only compressed gas cylinders containing the correct shielding gas for the process used 6.a. Remove fire hazards from the welding area. If and properly operating regulators designed for this is not possible, cover them to prevent the welding sparks the gas and pressure used.

-

Page 6: Table Of Contents

TABLE OF CONTENTS INSTALLATION .............................SECTION A ® TECHNICAL SPECIFICATIONS – POWER MIG 262 MP....................A.1 INSTALLATION ................................A.2 ® UNCRATING THE POWER MIG 262 MP ........................A.2 LOCATION ................................A.2 TILTING ................................A.2 OUTPUT POLARITY CONNECTIONS ..........................A.3 INPUT POWER, GROUNDING AND CONNECTION DIAGRAM ..................A.3 GUN AND CABLE INSTALLATION..........................A.4 SHIELDING GAS................................A.5 AUXILIARY POWER RECEPTACLES ..........................A.5 OPERATION ..............................SECTION B... - Page 7 ® POWER MIG 262MP INSTALLATION ® TECHNICAL SPECIFICATIONS – POWER MIG 262MP INPUT-SINGLE PHASE ONLY Input Voltage ± 10% Effective Input Amperes* 208/230/460/575 Volts 49.1/44/22.1/17.6 60 Hz RATED OUTPUT Input Voltage/ GMAW GTAW-DC SMAW Phase/Frequency 100% 100% 100% 208/230/460/575/ Amps Amps Amps Amps...

-

Page 8: Installation

® POWER MIG 262MP INSTALLATION INSTALLATION ® UNCRATING THE POWER MIG 262MP Cut banding and lift off cardboard carton. Cut banding holding the Read entire installation section before starting machine to the skid. Remove foam and corrugated packing installation. material. Untape accessories from Gas Bottle Platform. Unscrew the two wood screws (at the Gas Bottle Platform) holding the Safety Precautions machine to the skid. -

Page 9: Output Polarity Connections

® POWER MIG 262MP INSTALLATION FIGURE A.1 OUTPUT POLARITY CONNECTIONS The welder, as shipped from the factory, is connected for electrode positive (+) polarity. This is the normal polarity for GMAW. If negative (–) polarity is required, interchange the connection of the two cables located in the wire drive compartment near the front panel. -

Page 10: Gun And Cable Installation

® POWER MIG 262MP INSTALLATION FIGURE A.5 GUN AND CABLE INSTALLATION The Magnum® PRO 250L gun and cable provided with the ® POWER MIG 262MP is factory installed with a liner for .035- .045" (0.9-1.1 mm) electrode and an .035" (0.9 mm) contact tip. Install the .045”... -

Page 11: Shielding Gas

® POWER MIG 262MP INSTALLATION WARNING SHIELDING GAS For necessary processes. when opening the cylinder valve. Always stand to one side. Customer must provide cylinder of appropriate type shielding gas for the process being used. recommended for the procedure and process being used ®... -

Page 12: Operation

® POWER MIG 262MP OPERATION OPERATION WELDING CAPABILITY SAFETY PRECAUTIONS ® The POWER MIG 262MP is rated at 300 amps @ 29 volts, at Read this entire section of operating instructions before operating a 40% duty cycle based on a ten minute cycle time for GMAW the machine. -

Page 13: Case Front Controls

® POWER MIG 262MP OPERATION CASE FRONT CONTROLS CASE BACK CONTROLS FIGURE B.1 FIGURE B.2 Color LED Screen – Permits visualization of welding process and parameters. The screen features a replaceable screen shield for protecting against dust & dirt. Back Button/Knob – Rotate adjusts value, push to move back to previous selection Home Button –... -

Page 14: Internal Controls

® POWER MIG 262MP OPERATION INTERNAL CONTROLS FIGURE B.3 Wire Drive Tension Pressure Adjustment – Permits increasing or decreasing the pressure applied to the top drive roll. Wire Drive Spindle – Supports a 4-inch or 8-inch spool of wire. The center wing-nut can be adjusted to increase tension on the wire. -

Page 15: Ready.set.weld

® POWER MIG 262MP OPERATION Select Gas Type (If Applicable) READY.SET.WELD™ ® 262MP comes equipped with ™ Ready.Set.Weld which allows the user to easily select the correct welding procedure per their application. Select Process Select Wave Form Type (If Applicable) Select Guided Setup Select Plate Thickness Select Wire Type... - Page 16 ® POWER MIG 262MP INSTALLATION Stick (SMAW) WELDING PROCESSES MENU Select between Soft or Crisp arc MIG (GMAW) / Flux Core (FCAW ) / Gas Soft: Has a less penetrating arc characteristic. For low hydrogen Shielded Flux Core (FCAW-G) types of electrodes (E7018, E8018, E9018, etc) a softer arc is usually desirable.

-

Page 17: Weld Settings

® POWER MIG 262MP OPERATION PREFLOW- Allows a time to be selected for shielding gas to ow after the trigger is pulled, prior to establishing WELD SETTINGS an arc. ® 262MP allows the user to make RUN-IN- Adjusts initial wire feed speed for smooth arc adjustments to the advanced weld parameters via the Weld starting. -

Page 18: Arc Control

® POWER MIG 262MP OPERATION ARC CONTROL ® 262MP allows the user to make adjusts to the welding arc via the Weld Settings screen. Options available are dependent on the welding process you have selected. The table below lists the arc controls available per welding process. ARC CONTROL PROCESS SETTING... -

Page 19: Special Welding Processes

® POWER MIG 262MP OPERATION SPECIAL WELDING PROCESSES PULSE TIG PULSE WELDING Pulse in TIG mode (GTAW) automatically switches the current between the set point current on the main welding screen and the background current. This feature can be used to reduce heat input The pulsed-arc process is a spray transfer process wherein spray and warping of parts. -

Page 20: Drive Rolls

® POWER MIG 262MP OPERATION WIRE REEL LOADING - READI REELS, SPOOLS OR DRIVE ROLLS COILS ® The drive rolls installed with the 262MP have two To Mount a 30 Lb. (14 kg) Readi-Reel Package (Using the Molded grooves one for .035” (0.9mm) wire Solid Steel electrode and the other for .045”... -

Page 21: To Start The Welder

® POWER MIG 262MP OPERATION To Mount 10 to 44 Lb. (4.5-20 kg) Spools (12"/300 mm Diameter) or 14Lb.(6 Kg) Innershield Coils: IDLE ROLL PRESSURE SETTING (For 13-14 lb. (6 Kg) Innershield coils, a K435 Coil Adapter must WARNING be used). ELECTRIC SHOCK can kill. -

Page 22: Wire Drive Configuration

® POWER MIG 262MP OPERATION MAKING A WELD WIRE DRIVE CONFIGURATION CHANGING THE GUN RECEIVER BUSHING 1. Check that the electrode polarity is correct for the process being used, then turn the power switch ON. Tools required: 2. Set desired arc voltage and wire speed for the particular •... -

Page 23: Avoiding Wire Feeding Problems

® POWER MIG 262MP OPERATION AVOIDING WIRE FEEDING PROBLEMS GUN SETTINGS Wire feeding problems can be avoided by observing the following The Gun Settings menu is accessed through the Weld Mode gun handling procedures: Settings -> More Settings -> System Menu. Use this menu to enable/disable Trigger Memory Recall or to con gure a spool gun •... -

Page 24: Options / Accessories

K2910-1 12M to 7F Adapter may be needed to connect some K3676-1 Dual Cylinder Mounting Kit - Used to hold two gas bottle push pull and spool guns to the POWER MIG 262MP’s 12-pin ® connector. The Power MIG 262MP is not dual procedure compatible. -

Page 25: Maintenance

® POWER MIG 262MP MAINTENANCE MAINTENANCE CONTACT TIP AND GAS NOZZLE INSTALLATION Safety Precautions Choose the correct size contact tip for the electrode being used (wire size is stenciled on the side of the contact tip) WARNING sand crew it snugly into the gas diffuser. ELECTRIC SHOCK can kill. -

Page 26: Liner Removal, Installation And Trimming

® POWER MIG 262MP MAINTENANCE LINER REMOVAL, INSTALLATION AND TRIMMING (See Figure D.1) NOTE: The variation in cable lengths prevents the interchange- ability of liners between guns. Once a liner has been cut for a particular gun, it should not be installed in another gun unless it can meet the liner cutoff length requirement. - Page 27 ® POWER MIG 262MP MAINTENANCE See the Gun Calibration procedure in the Gun Settings section for more information.

-

Page 28: Troubleshooting

® POWER MIG 262MP TROUBLESHOOTING TROUBLESHOOTING HOW TO USE TROUBLESHOOTING GUIDE WARNING Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. - Page 29 ® POWER MIG 262MP TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS(S) COURSE OF ACTION OUTPUT PROBLEMS Major physical or electrical damage Do not plug in machine or turn it on. Contact your is evident.

- Page 30 ® POWER MIG 262MP TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS(S) COURSE OF ACTION Output voltage and wire feed is present 1. Remove gun assembly from machine. If If all recommended possible areas of when gun trigger is not pulled (not problem is solved, gun assembly is misadjustment have been checked and the...

- Page 31 ® POWER MIG 262MP TROUBLESHOOTING Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE AREAS OF RECOMMENDED (SYMPTOMS) MISADJUSTMENTS(S) COURSE OF ACTION The wire feed stops while welding. When 1. Check the wire feed drive rolls and motor trigger is released and pulled again the for smooth operation.

- Page 32 POWER MIG 2 2MP TROUBLESHOOTING ® Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION PUSH PULL WIRE FEEDING PROBLEMS CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

- Page 33 POWER MIG 2 2MP TROUBLESHOOTING ® Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION PUSH PULL WIRE FEEDING PROBLEMS POWER MIG 262MP drive rolls ® set too tight. The tension arm should be set at 1 to 1-1/2. Clean or replace contact tip.

- Page 34 POWER MIG 2 2MP TROUBLESHOOTING ® Observe all Safety Guidelines detailed throughout this manual PROBLEMS POSSIBLE RECOMMENDED (SYMPTOMS) CAUSE COURSE OF ACTION PUSH PULL WIRE FEEDING PROBLEMS POWER MIG 262MP drive rolls set ® CAUTION If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

-

Page 35: Diagrams

POWER MIG 2 2MP DIAGRAMS ®... - Page 36 POWER MIG 2 2MP DIAGRAMS ®...

- Page 37 This page intentionally left blank...

- Page 38 WARNING Do not touch electrically live parts or Keep flammable materials away. Wear eye, ear and body protection. electrode with skin or wet clothing. Insulate yourself from work and AVISO DE ground. Spanish PRECAuCION No toque las partes o los electrodos Mantenga el material combustible Protéjase los ojos, los oídos y el bajo carga con la piel o ropa moja-...

- Page 39 WARNING Keep your head out of fumes. Turn power off before servicing. Do not operate with panel open or Use ventilation or exhaust to guards off. remove fumes from breathing zone. AVISO DE Spanish PRECAuCION Los humos fuera de la zona de res- Desconectar el cable de ali- No operar con panel abierto o piración.

- Page 40 Lincoln Electric is a responsive manufacturer, but the de nition of speci cations, and the selection and use of speci c products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Need help?

Do you have a question about the POWER MIG 262MP and is the answer not in the manual?

Questions and answers