Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Sherman hobby MIG 200 SMART

- Page 1 Machine Translated by Google V1.1 05/12/23 USER MANUAL...

-

Page 2: General Notes

Machine Translated by Google ATTENTION! Before installing and starting the device, please read this manual 1. GENERAL NOTES The device may be started and operated only after carefully reading this User Manual. Due to continuous technical development of the device, the external appearance and some of its functions may be modified and their operation may differ in detail from the descriptions in the manual and on the box. - Page 3 Machine Translated by Google Preventing poisoning from vapors and gases emitted from the electrode coating and metal evaporation during welding: • Use ventilation and extraction devices installed in places with limited exchange air, • Blow with fresh air when working in confined spaces (tanks), •...

-

Page 4: Technical Parameters

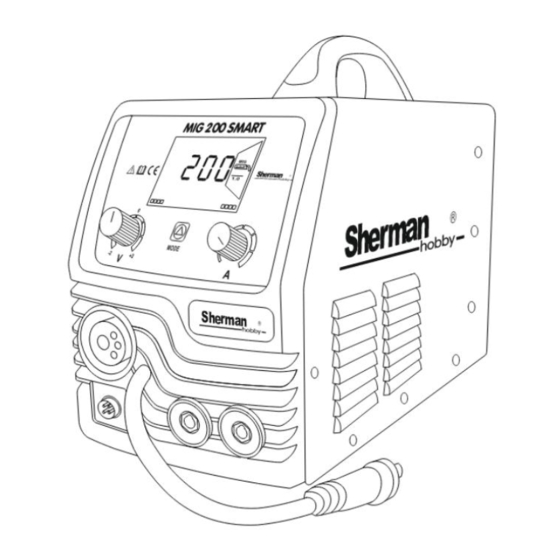

Machine Translated by Google 3. GENERAL DESCRIPTION The synergic MIG 200 SMART welding machine is used for manual welding of steel. Enables welding methods MMA (coated electrode), TIG Lift, and MIG/MAG in synergic mode. By changing the polarity, the device allows MIG/MAG welding using both standard wires shielded with protective gases and self-shielded flux-cored wires. -

Page 5: Preparing The Device For Work

Machine Translated by Google Duty cycle The duty cycle is based on a 10-minute period. A 60% duty cycle means that after 6 minutes of operation, a 4- minute break is required. A 100% duty cycle means that the device can work continuously, without interruption. Attention! Heating tests were carried out at ambient air temperature. - Page 6 Machine Translated by Google 1. MIG gun socket 6. Power switch 2. Spool Gun control socket. 3. Polarity change 7. Shielding gas connection stub. 8. Wire plug spool pin 4. "-" socket 9. Wire feeder 5. "+" socket 10. Spool Gun handle switch 5.1 Connecting the cables 5.1.1 MMA method The ends of the welding cables should be connected to the sockets (4) and (5) located on the front panel so that...

- Page 7 Machine Translated by Google 5.1.3 MIG method 5.1.3.1 Welding under protective gases The power plug of the gun should be connected to the MIG gun socket (1). The gas hose from the reducer should be led and attached to the gas connector (7) located on the rear wall of the device. Place the polarity change plug (3) in the socket (5).

- Page 8 1. The device should only be used in a single-phase power supply system, three-wire, with grounded neutral point. 2. The MIG 200 SMART inverter rectifier is designed to operate with a 230V50 Hz network protected by 20 A time-delay fuses. The power supply should be stable, without voltage drops.

-

Page 9: Operation

Machine Translated by Google D200 spool D100 spool 5.5 Preparing the MIG gun for work Depending on the type of material being welded and the diameter of the electrode wire, attach an appropriate contact tip and wire guide insert to the MIG gun. 6. - Page 10 Machine Translated by Google A – Display The display shows the welding current and the selected welding method. B – Current adjustment knob The knob is used to adjust the welding current. The value of the set current is shown on the display. C –...

-

Page 11: Parameter Settings

Machine Translated by Google MMA welding TIG Lift welding MIG welding with 0.8 wire MIG welding with 1.0 wire MIG welding with self-shielded 0.8 flux-cored wire MIG welding with self-shielded 1.0 flux-cored wire 7. PARAMETER SETTINGS After selecting the MMA and TIG Lift methods, it is possible to adjust the welding current. After selecting the MIG method, the user can adjust the welding current, and the corresponding welding voltage and wire feed speed will be selected automatically depending on the selected wire type and its diameter. - Page 12 Machine Translated by Google 9.2 TIG method Electrode wire Electrode diameter Protective gas Thickness(mm) Welding current (A) (mm) flow (l/min) diameter (mm) 1.0 35 – 45 4 – 6 40 – 70 5 – 8 50 – 85 6 – 8 80 –...

- Page 13 Machine Translated by Google 19ÿ20 0.8,0.9 130ÿ150 19ÿ20 0.8,0.9 High welding speed 22ÿ23 15ÿ20 1.0,1.2 welding speed 60ÿ70 16ÿ17 40ÿ45 10ÿ15 0ÿ8 0.8,0.9 80ÿ90 18ÿ19 45ÿ50 10ÿ15 0.8,0.9 90ÿ100 19ÿ20 45ÿ50 10ÿ15 0.8,0.9 100ÿ130 20ÿ21 45ÿ50 10ÿ15 0.8,0.9 120ÿ150 20ÿ21 45ÿ50 10ÿ15 1.0,1.2...

- Page 14 11. OPERATING MANUAL The MIG 200 SMART welding machine should be operated in an atmosphere free from corrosive ingredients and high dust. Do not place the device in dusty places, near operating grinders, etc. Dust and metallic filings on the control boards, cables and connections inside the device may lead to an electrical short circuit and, consequently, damage to the welding machine.

-

Page 15: Maintenance Instructions

Machine Translated by Google A full list of consumables and spare parts is available on the website www.tecweld.pl and at TECWELD. It is possible to purchase these parts directly. 12. MAINTENANCE INSTRUCTIONS As part of daily maintenance, keep the welding machine clean, check the condition of external connections and the condition of electric wires and cables. - Page 16 Machine Translated by Google If you intend to dispose of this product, do not dispose of it with normal household waste. According to the WEEE directive (Directive 2012/19/EU) in force in the European Union, separate methods of disposal must be used for used electrical and electronic equipment. In Poland, in accordance with the provisions of the Act of September 11, 2015 on waste electrical and electronic equipment, it is prohibited to place waste equipment marked with the crossed-out bin symbol together with other waste.

-

Page 17: Electrical Diagram

Machine Translated by Google 15. ELECTRICAL DIAGRAM... - Page 18 Krzyÿowa 1G POLAND We declare that the following product: Inverter welding machine Trade name: MIG 200 SMART MIG/MMA 200 Type: Manufacturer's trademark: to which this declaration relates complies with the requirements of the following European Union directives and national provisions implementing these directives:...

Need help?

Do you have a question about the MIG 200 SMART and is the answer not in the manual?

Questions and answers