Summary of Contents for MAXIMATOR M Series

- Page 1 Air driven high pressure pumps M, M...D, M...-C, MO, MO...D, M...-2, M...-3, M...-ECO, M...- HL, S, S...D, S...-SS, G, G...D, G...-C, G...-2, MSF, GSF, GPD, GPD...-2, GX, DPD Installation and operating manual...

- Page 2 Internet: www.maximator.de Warranty and liability: As a general rule, the “General Terms and Conditions” of Maximator GmbH shall apply. These terms and conditions are available at http://www.maximator.de. Warranty and liability claims shall not be accepted if they can be attributed to one or more of the causes mentioned in this manual or explicitly stipulated below: –...

-

Page 3: Table Of Contents

Contents Contents ..........General information . - Page 4 Contents ........Prerequisites for installation .

- Page 5 Contents ........... . . Removal .

-

Page 6: General Information

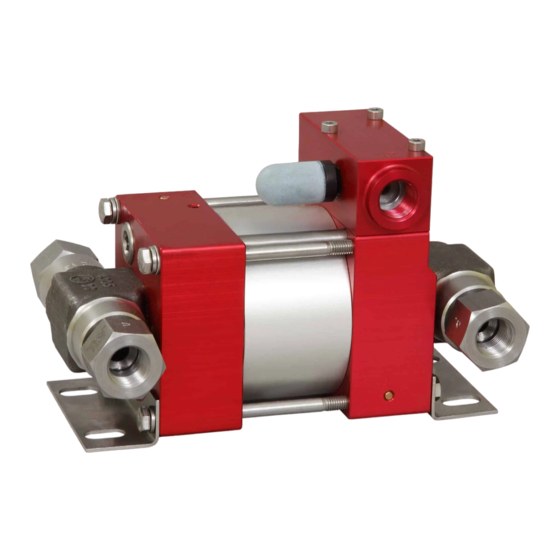

General information Information regarding this manual Maximator compressed air-driven high-pressure pumps can be used for a variety of applications. They are used to deliver oil, water, and other fluids, and pres- surise them to high pressures. This manual applies to all compressed air-driven pump types with the following designations: M, M...D, M...-C, MO, MO...D, M...-... -

Page 7: Rating Plate

General information Rating plate The rating plate is located on the drive unit of the high-pressure pump and con- tains the following information: Fig. 1-1 High-pressure pump rating plate Maximum short-time operating Serial number pressure Pressure ratio High-pressure pump 10 EAC label Type (specifications from the or- 11 Manufacturer contact informa- der code) -

Page 8: Explanation Of Symbols

General information Explanation of symbols DANGER This combination of symbol and signal word indicates a hazardous situation which - if not avoided - may lead to severe injuries or death. WARNING This combination of symbol and signal word indicates a potentially hazardous sit- uation which - if not avoided - may lead to severe injuries or death. -

Page 9: List Of Abbreviations And Formula Signs Used

Tab. 1-2 Formula symbol Qualification of the personnel Qualified personnel are required to work on and with the Maximator high-pres- sure pump safely and properly. Allowing unqualified personnel to work on the high-pressure pump or enter the danger zone creates hazards which could lead to death, severe injuries and significant property damage. - Page 10 General information Qualifications Understands the general mode of operation Understands the detailed mode of operation Able to read and comprehend work-related documents Able to read and comprehend work-related drawings/plans/ documents Possesses comprehensive tech- nical expertise Familiar with the activity-based safety labels utilised Familiar with the technical safe- ty labels utilised Able to identify and adjust safe-...

-

Page 11: Safety And Protection Measures

Safety and protection measures Safety and protection measures The following sections stipulate the residual risks associated with the product, even when used as intended. In order to reduce the risk of personal injuries and material damage, and to prevent hazardous situations, you must observe the safety information listed in this section and the warnings in all other sections of this manual. -

Page 12: Work And Danger Zone

Safety and protection measures Work and danger zone The danger zone comprises the entire area surrounding the product. The hazards associated with the product and the danger zone depend on the application and the installation location. The danger zone should therefore be determined by the user. -

Page 13: Non Obvious Hazards

Safety and protection measures In addition, the following applies to all high-pressure pumps: Leak point Leak type Leak source Pump head / HP cylinder Unexpected Defective pump head Pump head / HP cylinder Unexpected Defective HP cylinder Pump head / HP cylinder Unexpected Seals on the pump head or HP cylinder... -

Page 14: Risk Of Injury Posed By Noise

Safety and protection measures 2.5.2 Risk of injury posed by noise The noise level emitted in the work area depends on the mounting and applica- tion. Assess the risk for the equipment in the risk assessment. 2.5.3 Hazardous operating fluids Improper use of operating fluids can lead to serious accidents resulting in death. -

Page 15: Product Description

Product description Product description Design and function Structure Without control air port With control air port Tab. 3-1 Schematic diagram of a single-acting high-pressure pump Pilot valve lower cap Exhaust port (E) Inlet port (S) Drive air inlet (P High-pressure piston Spool valve Outlet port (P) Air piston... - Page 16 Product description The continuous supply is achieved by means of an internally controlled direction- al valve, the spool valve (8). The spool valve alternately guides the drive fluid to the two sides of the air piston. The spool valve is controlled via two directional valves, the pilot valves (1;...

- Page 17 Product description The individual high-pressure pump designs are shown below: • Single-acting • Double-acting • Single-acting with two air pistons 0000000194 - 004 - EN...

- Page 18 Product description • Double-acting with two air pistons • Single-acting with three air pistons • Double-acting with one high-pressure piston 0000000194 - 004 - EN...

-

Page 19: Intended Use

Product description Intended use Within their technical limits, high-pressure pumps are used to deliver and pres- surise adequate types of fluids. The compressed air-driven high-pressure pump is intended to be installed into a system. It must only be operated if all residual risks have been assessed as part of the risk assessment of the system. -

Page 20: Technical Specifications

Product description Control air port “X” Port for control air. The high-pressure pump will only operate if the control air connection is pressurised. The pressure of the control air must always be larger or equal to the drive pressure to ensure flawless function. The same require- ments regarding compressed air quality apply to the control air as to the drive air. - Page 21 Depending on the degree of purity of the demineralised water and the require- ments for the cleanliness of the pump, various options are possible here. In many cases, special pump materials can be used. Let Maximator advise you on the se- lection of a suitable pump.

- Page 22 Maximum particle size µm a. Maximator high-pressure pumps generally do not need a compressed air oiler as they are treated with special grease during installation. However, after the first time an oiler is used, the drive fluid should always be oiled, as the oil washes out the special grease. The oil in the oiler must be in accordance with DIN 51524 - ISO VG 32.

-

Page 23: Dimensions And Weight

Certain high-pressure pump de- signs can be suitable for other drive fluids. If you are unsure regarding the use of a special fluid, please don't hesitate to contact Maximator. 3.6.2 Dimensions and weight The dimensions and weight of the high-pressure pump are indicated on the gen- eral drawing. -

Page 24: Service Life

Product description Based on the following assumptions, a rough estimate of the amount of leakage can be made from the determined strokes at standstill pressure n – The strokes n determined at standstill pressure and closed pressure port P result solely from external leakage via the high-pressure seal. –... -

Page 25: Transport, Packaging And Storage

Transport, packaging and storage Transport, packaging and storage Dimensions and weight The dimensions and weight of the high-pressure pump are indicated on the gen- eral drawing. Delivery Scope of delivery Designation Quantity High-pressure pump Installation and operating manual including Decla- ration of Incorporation and EU Declaration of Con- formity General drawing... - Page 26 Transport, packaging and storage Maintenance during storage Even under the aforementioned storage conditions, the high-pressure pump can- not be stored indefinitely. – If in storage for longer than 3 months: Inspect the packaging and the high- pressure pump for damage on a regular basis. –...

-

Page 27: Installation

► The high-pressure pumps are designed to be self-priming. Operation with primary pressure is only possible upon consultation with Maximator. The product is enclosed in dust-protection packaging. Do not remove this pack- aging until shortly before installation. Dispose of this packaging in an environ- mentally friendly manner. -

Page 28: Installation Of Connecting Lines

Installation The preferred installation position is vertical. Lifting points The pumps of the GPD, GPD-2 and DPD series can be at- tached with 2 belt straps. Tab. 5-1 Lifting points Installation of connecting lines WARNING Risk of injury posed by improper installation of the connecting lines! Improper installation of the high-pressure pump may lead to accidents resulting in severe or fatal injuries. -

Page 29: Connecting The Drive Air

Improper installation of the high-pressure pump may lead to accidents resulting in severe or fatal injuries. ► The high-pressure pumps are designed to be self-priming. Operation with primary pressure is only possible upon consultation with Maximator. 0000000194 - 004 - EN... - Page 30 Installation WARNING Risk of injury posed by improper installation of the connecting lines! Improper installation of the high-pressure pump may lead to accidents resulting in severe or fatal injuries. ► Connecting lines must be hermetically sealed long-term. ► Check connecting lines for leaks. ►...

-

Page 31: Commissioning

Installation Prior to commissioning the high-pressure pump, the system-specific standstill pressure must be calculated. The standstill pressure of the high-pressure pump is calculated for the respective pump type using the following formulas: Pump type and operating conditions Standstill pressure Operation of all pump types without primary pressure of the media Operation of double-acting pump pB = p... -

Page 32: Operation

Operation Operation Prerequisites for operation Follow the manual and general drawing for the product. In addition, the following conditions are required: – The product must be free of damage. – The product must be securely attached. – The product is not exposed to any vibrations. –... -

Page 33: Put The Pumps In A Safe State

Operation Put the pumps in a safe state In a safe state, the high-pressure pump is depressurised on the drive end and the high-pressure side. The steps necessary in order to achieve a safe state depend on the installation position in the system. Refer to the general system documen- tation for the required actions. -

Page 34: Maintenance

The individual mainte- nance activities are described in the following section. Maximator recommends the intervals listed below. These intervals are calculated based on 1,300,000 strokes / year. The required maintenance intervals depend on the system and application. The intervals must be adjusted based on the given conditions of use. -

Page 35: Maintenance Work

Risk of injury due to inappropriate spare parts! Making repairs using inappropriate spare parts can lead to accidents resulting in severe injuries or death. ► Only use spare parts that comply with Maximator specifications. WARNING Risk of sustaining injury posed while handling lubricants! Handling lubricants may lead to accidents resulting in severe or fatal injuries. -

Page 36: System Inspection

Maintenance WARNING Risk of injury due to dangerous system status! Maintenance and inspection activities sometimes require that the high-pressure pumps be operated with modified connection cables or without safety equip- ment. The operation of the high-pressure pump may lead to accidents with seri- ous or fatal injuries. -

Page 37: Leak-Testing The Connections

Maintenance 7.2.2 Leak-testing the connections The following section explains how to check the connections for leaks: Description Qualifications Operating the system Type of mainte- Check nance Interval weekly Prerequisites – The high-pressure pump is easy to access. – All connections are pressurised. –... -

Page 38: Cleaning The Pumps

Maintenance 7.2.4 Cleaning the pumps The following section explains how to clean the high-pressure pump: Description Qualifications Clean the high-pressure pump Type of mainte- Cleaning nance Interval quarterly Prerequisites – The high-pressure pump is easy to access. – The high-pressure pump is depressurised. Tools –... -

Page 39: Leak Detection

Maintenance 7.2.5 Leak detection The following section explains how to inspect for leaks: Description Qualifications Repair and service the high-pressure pump Type of mainte- Check nance Interval semi-annually Prerequisites The high-pressure pump is easy to access. – Safety goggles – Hearing protection Tools –... -

Page 40: Lubricating The Pump

Maintenance 7.2.6 Lubricating the pump The following section explains how to lubricate the pump Description Qualifications Repair and service the high-pressure pump Type of mainte- Maintenance nance Interval Notice on the general drawing Prerequisites – The high-pressure pump is easy to access. –... -

Page 41: Checking Screw Connections At The Pump And Connecting Elements

Maintenance 7.2.7 Checking screw connections at the pump and connecting elements The following section explains how to inspect the screw connections and con- necting elements at the pump: Description Qualifications Repair and service the high-pressure pump Type of mainte- Check nance Interval quarterly... -

Page 42: Spare Parts And Consumables

7.2.5 - Leak test If the high-pressure pump has passed all tests, the repair is complete. Maximator devices can be sent in for repairs to your local Maximator representa- tive. All the necessary details are available on the Maximator website http:// www.maximator.de... -

Page 43: Customer Service

Maintenance Customer service Our customer service is also at your disposal for technical details and repairs: Address Maximator GmbH Ullrichstraße 1-2 99734 Nordhausen Germany Customer service phone +49 3631 9533-5444 Mon. – Thurs.: 06:30 – 16:15 CET Fri.: 06:30 – 14:00 CET... -

Page 44: Troubleshooting

Troubleshooting Troubleshooting The following is a list of typical high-pressure pump faults, their causes, and the appropriate solutions. If you experience any other specific or unexpected faults, please notify us at ser- vice@maximator.de 0000000194 - 004 - EN... -

Page 45: Drive Side

Troubleshooting Drive side Fault Cause of fault Solution – The high-pressure pump Friction of the O-rings on Relubricate does not operate at low the spool valve is too – Replace the O-rings air pressure high on the spool valve The high-pressure pump O-rings will swell if the –... -

Page 46: High Pressure Side

Troubleshooting High pressure side Fault Cause of fault Solution – The high-pressure pump Air in the hydraulic sys- Bleed the hydraulic operates without deliv- system ering the fluid, or it oper- – Check connecting ates erratically. It does lines for leaks not reach the calculated –... -

Page 47: Removal And Disposal

Removal and disposal Removal and disposal Prerequisites for removal and disposal Follow the manual and general drawing for the product. In addition, the following conditions must be met: – The product must be in a safe state. – The product must be at ambient temperature. Removal WARNING Risks of sustaining injuries are posed by improper handling of operating fluids! -

Page 48: Disposal

► Dispose of operating fluid residues in an appropriate manner. ► Notify other people (for example: repair department) of hazardous operat- ing fluids. If the service life has expired: Send the product back to Maximator, postage paid, for proper disposal. 0000000194 - 004 - EN... -

Page 49: Use In Explosion-Prone Zones

Use in explosion-prone zones Use in explosion-prone zones 10.1 General information High-pressure pumps bearing an ATEX label and delivered with a declaration of conformity with 2014/34/EU are suitable for use in potentially explosive atmo- spheres. They conform with equipment group II, equipment category 2G, explo- sion group IIB or IIC, structural safety. -

Page 50: Temperature Class

Use in explosion-prone zones 10.2 Temperature class The temperature of the high-pressure pump mainly depends on the temperature of the operating fluid. The following table indicates the relationship of the operating fluid temperature and the temperature class of the high-pressure pump: Max. -

Page 51: Summary Of Ignition Hazards

Use in explosion-prone zones 10.4 Summary of ignition hazards Ignition hazard Cause Protective measure implemented Source of ignition Hot surface Heat generated by the operat- Definition of the temperature class ing fluid and friction Selection of the lubricant Specifications regarding the dry run Definition of maintenance work and inter- vals Definition of the compressed air quality... -

Page 52: Appendix

Appendix Appendix The appendix comprises the following documents: – EU Declaration of Conformity for the high-pressure pumps – Incorporation Declaration for the high-pressure pumps 0000000194 - 004 - EN... - Page 53 Appendix 0000000194 - 004 - EN...

- Page 54 Appendix 0000000194 - 004 - EN...

- Page 55 Appendix Appendix for the Declaration of Incorporation according to 2006/42/EC Appen- dix II, No. 1 B Description of the basic safety and occupational health and safety requirements according to 2006/42/EC Appendix I to be applied and observed. Basic requirement Applicable Met Comment General information 1.1.1...

- Page 56 Appendix Basic requirement Applicable Met Comment 1.3.4 Risks posed by surfaces, edges and corners 1.3.5 Risks posed by multiple ma- chines combined 1.3.6 Risks posed by changed usage conditions 1.3.7 Risks posed by movable parts 1.3.8 Selection of protective equip- ment against risks posed by mov- able parts 1.3.9...

- Page 57 Appendix Basic requirement Applicable Met Comment 01/05/ Risk of being locked into the ma- 2014 chine 01/05/ Risk of slipping, tripping or falling No 2015 01/05/ Lightning strike 2016 Maintenance 1.6.1 Machine maintenance In context of the overall system 1.6.2 Access to the operator stations and access points for mainte- nance...

- Page 58 Appendix 0000000194 - 004 - EN...

- Page 59 Appendix 0000000194 - 004 - EN...

- Page 60 Visit our website at: www.maximator.de Article number: 1999.3178 0000000194 - 004 - EN...

Need help?

Do you have a question about the M Series and is the answer not in the manual?

Questions and answers