Subscribe to Our Youtube Channel

Summary of Contents for Gambro AK 98

- Page 1 AK 98™ Dialysis Machine Service Manual Program version 1.xx Order number: MHCEN12630-07/15...

- Page 2 © 2015 Gambro Lundia AB. All rights reserved. Trademarks Gambro, AK 98, BiCart, CleanCart, Diascan, SoftPac, U 9000, Polyflux, Revaclear and Evodial are trademarks belonging to the Gambro Group. Dialox is a trademark belonging to Air Liquide Group. HASTELLOY is a trademark owned by Haynes International Inc.

-

Page 3: Table Of Contents

Responsibility and disclaimer..................Maintenance......................... Competence of an authorised service technician............ Repair ........................... Technical support ......................1.10 Connection of AK 98 dialysis machine to other electrical equipment ....1.11 Waste disposal......................1.12 Symbols........................AK 98™ Installation guide ....................Before installation ....................... - Page 4 2.2.18 Step 18 - Potential equalization connector .............. 2.2.19 Step 19 - Power supply ................... 2.2.20 Step 19 - Power supply, instructions for home installation ........2.2.21 Step 20 - Placement of warning labels ..............Initial start-up procedure .................... Presets for Chemical Disinfection with WRO unit............

- Page 5 3.3.3.4 Conductivity control ..................... 3.3.3.4.1 Mixing ......................3.3.3.4.2 Conductivity Control System, bicarbonate............3.3.3.4.3 Composition supervision ................. 3.3.3.5 Degassing/flow pump system................3.3.3.5.1 Degassing circuit ..................... 3.3.3.5.2 Preset of the degassing pressure..............3.3.3.5.3 Degassing Pressure Control System............... 3.3.3.5.4 Adjustable dialysis fluid flow ................

- Page 6 4.1.9 Profiling........................4.1.10 Diascan™ (option)....................4.1.11 Disinfection and cleaning – chemical disinfection ..........4.1.12 Disinfection and cleaning - heat disinfection ............4.1.13 Auto heat disinfection .................... 4.1.14 Heat disinfection program including WRO 300 H ..........4.1.15 Disinfection and cleaning – rinse/drain..............

- Page 7 5.2.1.3 Installed features ....................5.2.1.4 Logging......................5.2.2 Logging........................5.2.2.1 Fluid unit ......................5.2.2.2 To display logging parameters................Preset mode ....................... 5.3.1 Preset mode overview ................... 5.3.1.1 Presets ......................5.3.1.2 Preset parameter list ..................5.3.1.3 Presets variables ....................5.3.2 Manual preset......................5.3.2.1 To do a manual preset ..................

- Page 8 Fluid module pumps ..................5.4.4.4.4 UF sensor values................... 5.4.4.4.5 To perform a UF taration................5.4.4.4.6 Valves ......................Update AK 98™ system firmware ................Replacements ........................Actions after component replacement ..............6.1.1 Replacement matrix....................6.1.2 Actions to be done - description ................

- Page 9 7.3.7 Variable flow calibration..................7.3.8 Conductivity transducer calibration................ 7.3.8.1 About conductivity transducer calibration ............7.3.8.2 To calibrate conductivity transducer ..............7.3.9 Dialysis pressure transducer calibration..............7.3.10 Degassing pressure transducer calibration ............7.3.11 HPG pressure transducer calibration ..............7.3.12 Pressure regulator calibration, PR 1..............

- Page 10 Limit values for patient leakage current (PLT) ........... Record of Electrical Safety Inspection ..............9.5.1 Machine type and identification ................9.5.2 PET for AK 98™ dialysis machine................. 9.5.3 ELT - Earth Leakage Current Test ................. 9.5.4 PLT - Patient Leakage Current Test ..............

- Page 11 12.1.4 Purpose with this chapter ..................12.1.5 Operation during functional check ................. 12.2 POST - Power On Self Test ..................12.3 Test philosophy ......................12.4 Functional check overview..................12.5 Common tests......................12.5.1 Sub-tests ....................... 12.5.2 Common tests / Light indicator test ...............

- Page 12 12.7.5 Blood leak detector test ..................12.7.6 Conductivity test ....................12.7.6.1 Sub-tests ......................12.7.6.2 Low conductivity test ..................12.7.6.3 High conductivity test..................12.7.7 Degassing pressure test..................12.7.7.1 Test objectives and conditions................12.7.7.2 Test description....................12.7.8 AIVA test ........................ 12.7.9 DIVA/TAVA/EVVA closing test................

-

Page 13: General Information

Maintenance......................... Competence of an authorised service technician............ Repair ........................... Technical support ......................1.10 Connection of AK 98 dialysis machine to other electrical equipment ....1.11 Waste disposal......................1.12 Symbols........................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - General information... -

Page 14: About This Manual

It is a guide for how to identify and repair faults that may occur. All available spare parts to be used for the AK 98 dialysis machine are found in the illustrated spare parts list. -

Page 15: Responsibility And Disclaimer

AK 98 Spare parts list access to and understanding of the AK 98 operator's manual and the AK 98 service manual In general, this policy implies that training will be carried out by Gambro Lundia AB, while local markets are responsible for their own service organisation. -

Page 16: Repair

Only an authorized service technician is allowed to connect the AK 98 dialysis machine to other electrical equipment and thus forming an IT-network in the meaning of IEC 60601-1. Connection of the AK 98 dialysis machine to such an IT-network that includes other equipment could result in previously unidentified risks to patients, operators or third parties. - Page 17 Equipotential connector The AK 98 dialysis machine is protected against solid foreign objects ≥12.5 mm Ø and vertically falling water drops. Type B, applied part NIBP type BF applied part The product does not contain latex. The symbol frame and text are white.

- Page 18 Warning. Do not lean the AK 98 dialysis machine more than 5° from the horizontal plane. The symbol colour is black on a yellow background. Do not lean or push the AK 98 dialysis machine. Risk for overbalance. The symbol colours are red, white, and black.

- Page 19 Management System. The CE conformity mark is only valid for the AK 98 dialysis machine. Disposables and any accessories specified for use with the AK 98 dialysis machine are marked with CE conformity marks in their own right. CSA marking...

- Page 20 This page is intentionally left blank. This page is intentionally left blank.

-

Page 21: Ak 98™ Installation Guide

WRO 300 H communication ..................2.6.4 Supervision of the disinfectant conductivity............. 2.6.5 Communication cables .................... Service reporting - dialysis machine installation ............. Installation checklist ....................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 22: Before Installation

2.1.1 Qualification requirements The initial installation and start-up procedure of the AK 98 dialysis machine may only be performed by the Gambro Technical Service organization or a person authorised by Gambro fulfilling the specified qualifications in AK 98 dialysis machine - service manual, chapter 1 - Competence of an authorised service technician. -

Page 23: Step 2 - Inspection Of Delivered Equipment

Gambro Service representative. Remove the protective plastic from the screen and overlay on hard keys. Check the equipment for any damage. If the equipment is in any way damaged, proper operation cannot be guaranteed. Contact your local Gambro Service representative. NOTE! In case of damage to the machine, inspect the packaging material. -

Page 24: Step 4 - Additional Package Box

(including all available language versions). NOTE! A printed version of the AK 98 operator's manual may be ordered from your local Gambro Service representative. The order number for each translation of the operator's manual is available in the booklet inside the CD-ROM cover. -

Page 25: Step 6 - Dialyzer Connector Set, Blue

Figure 2-4. Dialyzer connector set, blue 2.2.7 Step 7 - Transportation handle Procedure Install the transportation handle according to Figure 2-5 “Transportation handle” on page 24. Tighten the screws. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 26: Step 8 - Pick-Up Tube Holder

If the RP 98 remote panel is to be used, attach the pick-up tube holder using the rear position to the right or the left. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 27: Step 9 - Ultrafilter (Option)

NOTE! The ultrafilter (UFD) is not included at delivery of the AK 98 dialysis machine. NOTE! Make sure that the ultrafilter is handled in an aseptic way according to the corresponding package insert. -

Page 28: Step 11 - Top Tray

Figure 2-8. Dialyzer holder 2.2.11 Step 11 - Top tray Procedure Place the top tray on the AK 98 dialysis machine according to Figure 2-9 “Top tray” on page 26. Figure 2-9. Top tray NOTE! To avoid leakage into the machine, the top tray shall always be placed on the top of the machine, except during technical service. -

Page 29: Step 13 - Infusion Stand

You can swing the fluid bag holder between a position over the tray and to the left of the dialysis machine. A mechanical stop limits the holder movement. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 30: Step 14 - Remote Panel, Rp 98 (Option)

(moving) the machine to avoid overbalance. The fluid bags may be placed on the top tray. NOTE! The AK 98 dialysis machine is prepared for installation of the RP 98 remote panel, either on the left or the right side of the machine. 2.2.14.2... -

Page 31: Installation Process - Rp 98

Mount the fastening parts on the holder arm according to Figure 2-15 “Fastening parts” on page 30. Fasten the cap nut onto the threaded rod, but do not tighten the expander. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... - Page 32 Figure 2-16. RP 98 cable connection Fasten the cover (1) with two screws (2), 100378406, according to Figure 2-17 “Fasten the cover” on page 31. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx...

- Page 33 Figure 2-17. Fasten the cover Fasten the plate (3) and the RP 98 arm (4) to the AK 98 dialysis machine with the attached screws, 100388425, (5) according to Figure 2-18 “Installation process - RP 98” on page 32. (Allen key).

-

Page 34: Step 15 - Water Supply

Use hose clamp 100334015. Figure 2-19. Connection of the water supply NOTE! Other connections may also be used for connection of the AK 98 dialysis machine to the distribution loop, e.g. PEX spiral tubes with quick connectors. HCEN12630 Revision 07.2015 AK 98™... -

Page 35: Step 16 - Drain

An air gap to atmospheric pressure shall always be arranged at the tube outlet. NOTE! The drain tube shall not exceed 10 metres in length. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 36: Step 17 - Suction Tube For Chemical Intake

Treatment location The user must make sure that the location where the AK 98 dialysis machine is installed, including the patient environment, is suitable for dialysis treatment. The location shall be maintained at a hygienic standard suitable for dialysis treatment and kept free from pets and pests. -

Page 37: Step 19 - Power Supply

Procedure If a potential equalization connector is to be installed, follow local installation procedures. The AK 98 dialysis machine is in compliance with certain requirements concerning patient leakage current from the dialysis fluid in accordance with international standards and regulations. - Page 38 Connect the machine to a grounded power socket. WARNING! The mains power cable from the AK 98 dialysis machine (cable length is 3.5 metres) shall be connected to a socket with protected earth (PE) to avoid risk of electrical shock.

-

Page 39: Step 19 - Power Supply, Instructions For Home Installation

WARNING! The following tasks must be carried out by a qualified electrician: ● The electrical installation of the AK 98 dialysis machine including correct protective earth connection. ● Connection and verification that the protective earth terminal is connected to the external protective earthing system. -

Page 40: Step 20 - Placement Of Warning Labels

Attach the “do not lean” warning labels according to Figure 2-28 “Placement of “do not lean” warning labels” on page 38. Figure 2-28. Placement of “do not lean” warning labels HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide Program version 1.xx... -

Page 41: Initial Start-Up Procedure

Press the On/Off button. Preset the machine according to the local clinic requirement. See section "Preset mode" in chapter 5 in the AK 98 service manual. To verify full functionality - let the AK 98 dialysis machine pass the functional check. NOTE! Each time the AK 98 dialysis machine is started, an automatic functional check is carried out. -

Page 42: Presets For Chemical Disinfection With Wro Unit

8 in the AK 98 service manual. WARNING! After completing the installation process, the composition of the dialysis fluid shall be confirmed in laboratory tests before the AK 98 dialysis machine is ready for use. Presets for Chemical Disinfection with WRO unit Table 2-3. -

Page 43: Requirements And Presets For Performing Integrated Heat Disinfection

Set to Yes Overnight disinfection allowed. 2.6.3 WRO 300 H communication Communication between the AK 98 dialysis machine and WRO 300 H: 1-17 WRO 300 H Installed Set to not installed (Needed for both WRO 300 and WRO 300 H) HCEN12630 Revision 07.2015... -

Page 44: Supervision Of The Disinfectant Conductivity

2.6.4 Supervision of the disinfectant conductivity If supervision of the disinfectant conductivity is desired for the AK 98 dialysis machine: 6-0-0-6 Chemical disinfection ALT 1: Conductivity check limits (min. = 0.0, max. = 50.0), mS/cm 2.6.5 Communication cables Communication cables for the AK 98 dialysis machine: Parallel communication (only remote start/stop, yellow): K21186003 (2.9 m) Serial... -

Page 45: Installation Checklist

Date Signature This record is to be signed and filed by the Service Engineer responsible for the initial installation and start-up procedure of this AK 98 dialysis machine. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - AK 98™ Installation guide... - Page 46 This page is intentionally left blank. This page is intentionally left blank.

- Page 47 UF control taration ................... 3.3.3.6.9 The UF Supervision System................3.3.3.6.10 UF protective taration ..................3.3.3.6.11 Diascan - Conductivity cell C (option) ............® 3.3.3.6.12 Blood leak detection ..................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

- Page 48 ....................3.4.3.2 Blood flow description..................3.4.3.3 BPM - blood pressure module (option)..............3.4.3.4 Single needle treatment..................3.4.4 BM component description ..................Power supply ......................Operator's panel ......................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 49: Introduction

Introduction 3.1.1 General information The AK 98 dialysis machine is designed to be used as a single patient machine to perform haemodialysis treatments upon prescription by a physician. Patient counselling and teaching of treatment techniques are directly under the supervision and discretion of the physician. -

Page 50: Power Supply

The buttons are language-independent. The information in the display can be set to different languages. Detailed information about the functionality of the operator's panel is available in the AK 98 operator's manual. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 51 This page is intentionally left blank. This page is intentionally left blank.

-

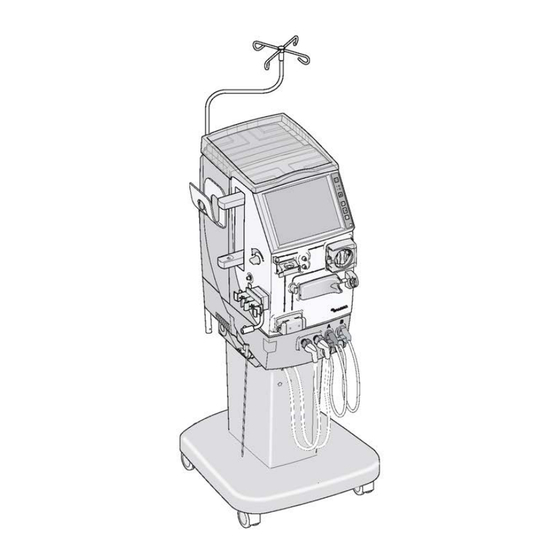

Page 52: Product Description

Product description 3.2.1 Blood unit - exterior parts Figure 3-1. Blood unit - exterior parts HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 53 Blood line guides connector Level adjustment knob Blood pump BPM cuff holder (option) Heparin pump Top tray Priming detector Infusion stand Arterial blood line clamp Venous blood line clamp HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 54: Blood Unit - Interior Parts

3.2.2 Blood unit - interior parts Figure 3-2. Blood unit - interior parts HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 55 Tubings to/from BiCart cartridge Fluid unit flow path) holder BPM (blood pressure module), option Heparin pump Clamp unit Blood pump BPTT (blood pressure transducer Operator's panel test) Front I/O board HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 56: Fluid Unit - Exterior Front Parts

3.2.3 Fluid unit - exterior front parts Figure 3-3. Fluid unit - exterior front parts HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 57 Pick-up tube holder Blue: concentrate connector with BiCart cartridge holder white tube marking Red: concentrate connector Machine outlet dialysis fluid tube from the machine to the dialyzer (blue) HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 58: Fluid Unit - Exterior Rear Parts

3.2.4 Fluid unit - exterior rear parts Figure 3-4. Fluid unit - exterior rear parts HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 59 Mains connection Over temperature protection Fuses (230 V AC 10AT, 115 V AC Outlet tube (Drain) 15AT) Inlet water tube Blood leak detector Disinfectant inlet tube Main switch HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 60: Fluid Unit - Interior Parts 1

3.2.5 Fluid unit - interior parts 1 Figure 3-5. Fluid unit - interior parts 1 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 61 Pressure regulator, PR2 Feeding pump A Heater Flow pump Flow switch Pressure transducer, degassing pressure Concentrate filter Pressostate, INPS Mixing chamber A Degassing chamber Mixing chamber B Expansion chamber HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 62: Fluid Unit - Interior Parts 2

3.2.6 Fluid unit - interior parts 2 Figure 3-6. Fluid unit - interior parts 2 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 63 Blood leak detector Pressure transducer, HPG (high Pressostate, SAGS pressure guard) Temperature transducer, Heater Suction pump (outlet) Deaerating chamber UFS channel 1 Temperature transducer, Cond. cell P HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 64: Fluid Unit - Interior Parts 3

3.2.7 Fluid unit - interior parts 3 Figure 3-7. Fluid unit - interior parts 3 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 65 Heat exchangers Back-up battery FIVA (option for Ultrafilter) Ultrafilter holder (option) Pressure regulator, PR 1 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 66: Fluid Unit - Valves

3.2.8 Fluid unit - valves Figure 3-8. Fluid unit - valves HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 67: Fluid Unit Description

Degassing/flow pump system ● Fluid output - UF control system The description of the AK 98 fluid unit is based on the fluid unit flow path on the next page. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description... -

Page 68: Fluid Unit - Flow Path

3.3.2 Fluid unit - flow path Figure 3-9. See chapter 11: "Fluid unit - flow path" HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 69: Fluid Unit - Flow Path Description

REVA – Recirculation Valve – is used during disinfection and rinsing (water is circulating). HBVA – Heat exchanger Bypass Valve is used to help cool down the AK 98 dialysis machine faster after a heat disinfection program. Water is heated as it passes through the heating element in the heater. The flow switch in the inlet is used for overheat protection (no flow = heater off). -

Page 70: The Temperature Control And Protective System

The temperature drop from conductivity cell B to the dialyzer should be estimated by measuring the (stabilized) temperature in the fluid tubes with a Gambro reference instrument and comparing it to the conductivity cell B temperature reading in GXL. The default value for the estimated temperature drop is 0.2ºC. - Page 71 The heater element is driven by an OPTO relay in series with the Mechanical relay, which is controlled by both the Control System and the Protective System. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 72: Disinfectant Inlet

CHVA and CBVA. These valves are controlled separately. CHVA is controlled by the protective system and CBVA is controlled by the control system. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 73: Conductivity Control

NOTE! Refer to the AK 98 operator's manual for detailed information about disinfection of the machine. 3.3.3.4 Conductivity control 3.3.3.4.1 Mixing The heated water passes through the concentrate pick-up tube connectors. If a concentrate connector is pulled out, the connector will seal and there will be a suction from the respective feeding pump to the tube’s stick. - Page 74 60 seconds, if it doesn’t an attention appears. Otherwise, the FLVA is closed, the B-concentrate pump is stopped, and the machine waits for the B-conductivity to drop below 2.0 mS/cm. Priming is completed. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 75: Conductivity Control System, Bicarbonate

±10% for the A-pump, and ±20% for the B-pump by default. If these limits are exceeded there will be a pump speed alarm or attention. Refer to the AK 98 operator's manual for more information. The relative pump speed – the deviation between the actual and calculated speed, in percent, can be logged, of course, and should ideally be zero. -

Page 76: Degassing/Flow Pump System

(default 15%) between the two pumps. Refer to the operator's manual for the AK 98 dialysis machine for more information. The value that triggers the alarm or attention can be logged as FI_PumpSpeedRatio. The value may vary between 850 and 1150 (default). The limits can be preset as a % (default 15%) pump speed deviation. -

Page 77: Preset Of The Degassing Pressure

The default preset value is -610 mmHg, but can be preset to other values (-300 to -700 mmHg in 5 mmHg steps) in case the AK 98 dialysis machine is operated at other altitudes than sea level. -

Page 78: Degassing Pressure Control System

(-300 to -700 mmHg in 5 mmHg steps) in case the AK 98 dialysis machine is operated at other altitudes than sea level. See the relation between pressure and altitude in Table 3-2 “Degassing pressure as function of... -

Page 79: Adjustable Dialysis Fluid Flow

3.3.3.5.4 Adjustable dialysis fluid flow The fluid flow in the AK 98 dialysis machine can be adjusted between 300 mL/min to 700 mL/min in 20 mL/min steps. The control is done with an adjustable valve (DRVA) driven by a stepper motor with an aspheric axis connected in parallel with a 200 mL/min restrictor. -

Page 80: Fluid Output - Uf Control System

P venous = +120 mmHg, P dialysis = -300 mmHg TMP = +120 -(-300) = +420 mmHg TMP is only shown as information. The UF protective system is used as supervision of the UF control system. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 81: Flow Calculation - Uf Protective System

The fluid level in the chamber is monitored by a ring-shaped floater, containing a magnet which activates a reed relay if the level drops below approx. 15 mm. The HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 82: Uf Control

UF cell self-calibration. It will be described later in this document. 3.3.3.6.6 UF control The UF rate is controlled by the Suction pump. The AK 98 dialysis machine has one “machine” treatment mode only: “Volume control”. In this mode the operator is required to set two parameters: ●... -

Page 83: The Uf Control System

The process is called taration or self-calibration. It works as follows: The self-calibration is divided in following three phases: Prepare Taration phase Zero Flow phase Differential Flow phase HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 84 ZEVA now closes. The Taration Valve (TAVA) is closed and BYVA opens. The channels are now placed in series, which means that the flow in channel 2 is the same as the flow in channel 1. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 85: The Uf Supervision System

The protective subsystem calculates its UF volume by integrating the UF rate over time. The protective subsystem supervises the calculated UF volume against the expected UF volume, which also is calculated from the treatment parameters. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 86: 3.3.3.6.10 Uf Protective Taration

Due to the location of the UF measurment cells for the UF protective measurement there is no zero flow phase, instead the differential flow phase is prolonged. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 87: Diascan ® - Conductivity Cell C (Option)

5-7 minutes and then measure the conductivity before and after the dialyzer, the ability of the dialyzer to transport sodium can be calculated. Depending on HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 88: 3.3.3.6.12 Blood Leak Detection

3.3.3.6.12 Blood leak detection Blood leakage is detected by a detector situated between channel 2 (or the optional conductivity cell C, if it is installed) and the Suction pump. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 89: Fm Component Description

230 V/3*580 W. The Heater unit for 230 V contains three windings of each 580 W. The heater unit is controlled with a duty cycle. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 90 Citric acid is produced in the similar way using the disposable CleanCart cartridge. Fluid spillage is prevented by valves. Magnet sensors indicate closed arm position. Flow pumps Gear pumps controlled with a duty cycle. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

- Page 91 The pressure transducers are so called Gauge transducers which means that the pressure transducer uses the atmospheric pressure as reference. The transducers are connected to the main electronic via data buses. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

-

Page 92: Extracorporeal Blood Circuit Description

Arterial pressure transducer Expansion chamber holder Air detector Venous blood line clamp Blood line guide Dialyzer holder Blood line guide Blood pump Arterial blood line clamp Heparin pump HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 93: Treatment Modes And Disposables

Treatment modes and disposables 3.4.2.1 Double needle treatment Figure 3-27. Arterial and venous blood lines setup in HD - double needle mode Arterial blood line Venous blood line HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 94: Single Needle Treatment

3.4.2.2 Single needle treatment Figure 3-28. Arterial and venous blood lines setup in HD - single needle mode HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 95: Blood Flow

For example, if the needle or the arterial blood line is blocked, an alarm will be given (the blood pump is stopped). The HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... - Page 96 The blood pump cannot be run when the pump cover is open. If necessary, the blood can be returned to the patient manually. The blood passes the dialyzer under controlled ultrafiltration. Refer to the AK 98 operator's manual for more information about the treatment conditions and operating instructions.

-

Page 97: Bpm - Blood Pressure Module (Option)

When blood is detected for more than 20 seconds, the control system and the protective system disconnect the priming detector function and keep the AK 98 dialysis machine in blood mode until the end of the treatment, i.e. when Time = 0:00 is confirmed. -

Page 98: Single Needle Treatment

3.4.3.4 Single needle treatment When the AK 98 dialysis machine is used for single needle treatment, the arterial and venous phases are pressure-controlled. Arterial blood is removed from the patient when the arterial line clamp is open, and the venous line clamp is closed. - Page 99 The heparin pump unit consists of the following components: ● Heparin pump. The inner diameter of the syringe can range between 10 to 30 mm ● Stepping motor ● Gear box (1:120) HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx...

- Page 100 Arterial pressure transducer The AK 98 dialysis machine is equipped with a second pressure transducer named Arterial Pressure Transducer. This pressure will be displayed on the arterial bargraph. The transducer is used for the measurement of true arterial pressure. The pressure transducer is mounted on a pressure transducer board, which interfaces directly with the Front I/O board via a board connector.

- Page 101 When blood is detected for more than 20 seconds, the control system and the protective system disconnect the priming detector function and keep the AK 98 dialysis machine in blood mode until the end of the treatment, i.e. when Time = 0:00 is confirmed.

-

Page 102: Power Supply

+24 V is supplied by the AC/DC power supply and fed to an internal DC/DC converter; the converter produces ±12 V. The ±12 V and +24 V supplies are monitored by the A/D converters in the Control System and the Protective System. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description Program version 1.xx... -

Page 103: Operator's Panel

NOTE! For detailed information about the operator’s panel and its operation, refer to Chapter 3 Handling the dialysis machine in the AK 98 operator's manual. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical description... - Page 104 This page is intentionally left blank. This page is intentionally left blank.

-

Page 105: Technical Data And Specifications

Other materials ...................... Environmental data ....................4.6.1 Operation....................... 4.6.2 Transportation and storage ................... 4.6.3 Electromagnetic environment ................4.6.4 Expected service life....................4.6.5 Energy consumption....................Standards ........................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 106: Performance And Specification - Control System

Syringes between 10-30 mL can be used. Syringes shall be compliant to ISO 7886-2 and have a luer lock. Stop time The heparin pump stops before end of treatment 0:00 to 9:59 h HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 107: Blood Pressure

30 - 220 bpm (±3 bpm or ±2 % of reading) Low alarm limit 30 - 220 bpm (40 bpm) High alarm limit 30 - 220 bpm (130 bpm) HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 108: Dialysis Fluid Preparation

, 130 to 150 mmol/L , 20 to 40 mmol/L Measuring range 9 to 16 mS/cm Accuracy 0.2 mS/cm Alarm limits ±5 % of the calculated conductivity set value HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 109: Ultrafiltration Control

0 to 100 L (±6% (±1SD, based on 7 measurements) volume cleared of Kt Dialysis dose Kt/V 0 to 3 Measurement interval 30 or 60 minutes HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 110: Disinfection And Cleaning - Chemical Disinfection

CleanCart cartridge disinfection / heating program alternative. The default settings are as follows: HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 111: Auto Heat Disinfection

(if preset, see WRO 300 H service manual). 4.1.15 Disinfection and cleaning – rinse/drain Total time for disinfection programs is estimated and may vary. Rinse/Drain 10 minutes Drain 4 minutes HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 112: Disinfection And Cleaning - Exterior Cleaning

Increasing: +150 mmHg, ±20 mmHg (INPS) Decreasing: +99 mmHg, ±20 mmHg Safety guard switch Increasing: -59 mmHg, ±7 mmHg (SAGS) Decreasing: -74 mmHg, ±7 mmHg HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 113: Power Supply

500 μA Patient leakage max 100 μA AC current max 10 μA DC All leakage currents specified are without external equipment connected to the AK 98 dialysis machine. 4.1.19 Connection of external equipment External connector To communicate via the external connector 25 pin D-Sub as USB, a virtual COM port driver (VCD) needs to be installed on your PC. -

Page 114: Battery Back-Up

±5 mmHg or ±3 %, whichever is largest within range -500 to 500 mmHg ±10 % within range 500 to 750 mmHg Table 4-21. Extracorporeal blood loss to the environment Detection method Venous pressure supervision HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 115: Air Detection

Alarm will be given for ≥0.3 mL blood, hematocrit 32 %, per minute at 300-700mL/min dialysis fluid flow. Time delay for alarm, maximum 5 seconds (diffusion mode). HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 116: Alarm Sound Pressure

PSU (Polysulphone) PVDF (Polyvinylidene fluoride) PTFE (Polytetrafluoro ethylene) PPE/PS (Polyphenyl ether/Polystyrene) 4.5.2 Metals Stainless steel EN 1.4435 Stainless steel EN 1.4436 Stainless steel EN 1.4539 Titanium HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... -

Page 117: Other Materials

Electromagnetic environment The AK 98 dialysis machine is intended for use in the electromagnetic environment specified below. The customer or the user of the AK 98 dialysis machine should assure that it is used in such an environment. HCEN12630 Revision 07.2015 AK 98™... - Page 118 RF emissions Class B The AK 98 dialysis machine is suitable for use in CISPR 11 all establishments, including domestic establishments and those directly connected to the public low-voltage power supply network that supplies buildings used for domestic purposes.

- Page 119 If the measured field strength in the location in which the AK 98 dialysis machine is used exceeds the applicable RF compliance level above, the AK 98 dialysis machine should be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as reorienting or relocating the AK 98 dialysis machine.

-

Page 120: Expected Service Life

Recommended separation distances between portable and mobile RF communications equipment and the AK 98 dialysis machine The AK 98 dialysis machine is intended for use in an electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the AK 98 dialysis... -

Page 121: Standards

IEC 60601-2-16:2012 Medical electrical equipment - Part 2-16: Particular requirements for basic safety and essential performance of haemodialysis, haemodiafiltration and haemofiltration equipment. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx... - Page 122 SFDA Order no.10 : Order of the State Food and Drug Administration; Administrative Regulations on Medical Device Instructions for Use, Labels and Marking of Packaging 2004-07. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Technical data and specifications Program version 1.xx...

- Page 123 5.4.3.3.1 Service test types ..................5.4.3.3.2 To do a service test..................5.4.3.3.3 Sensor tests....................5.4.3.3.4 Pump test ...................... 5.4.3.3.5 Fluid path leakage test .................. 5.4.3.4 Service drain...................... HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx...

- Page 124 Variable flow ....................5.4.4.4.3 Fluid module pumps ..................5.4.4.4.4 UF sensor values................... 5.4.4.4.5 To perform a UF taration................5.4.4.4.6 Valves ......................Update AK 98™ system firmware ................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx...

-

Page 125: Service Menu

Only service engineers fulfilling the minimum level of competence, according to AK 98 service manual, Section 1.7 “Competence of an authorised service technician” page 13, are allowed to use Service and Preset mode to repair or maintain AK 98 dialysis machines. NOTE! The access code to Service and Preset mode is available from your local Gambro Service representative. -

Page 126: Main Mode

Logging means to read a value over a period of time. In Logging mode the service engineer can check the condition and the status of the machine hardware and the software. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 127: Logging

Logged values are displayed under the Logging tab in the Information field. 5.2.2 Logging 5.2.2.1 Fluid unit Fluid unit flow path with logging variables. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 128: To Display Logging Parameters

This means, e.g. setting specific start up conditions and parameter limits, and setting up the machine to run on the clinic’s concentrates: concentrate presetting. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 129: Preset Parameter List

● Manual: The AK 98 dialysis machine can be preset directly from the operator's panel. Refer to Section 5.3.2.1 “To do a manual preset” on page 128. ● Import: Preset files can be imported to the machine from a USB flash drive. -

Page 130: Manual Preset

4 - Assisted priming 5 - Rinse back 6 - Disinfection 7 - Single needle 8 - Bicarbonate concentrates 9 - BPM settings 10 - Profiling 11 - Diascan settings HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 131: Language

Insert the USB flash drive. Enter Preset mode, see Section 5.1.3 “Enter service or preset mode” page 123. Select the Import tab. Press Import to load the settings to the machine. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 132: To Edit Preset Files Offline

With the Gambro software AK 98 Preset Editor installed on a PC you can edit preset files offline. Install AK 98 Preset Editor on the PC. Export the preset files from the AK 98 dialysis machine to a USB flash drive and then import them to the PC. -

Page 133: Calibration

Select the Utility tab. Press Chem status and Disinf/Decalc attentions. Press Clear Chem Status. Press Clear Disinf/Decalc attentions. Press Exit to FCH to do a functional check. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 134: Service Tests

Press Start. 5.4.3.3.3 Sensor tests This is a test of the detectors in the AK 98 dialysis machine. The machine will prompt the user to perform a certain action, e.g. to disconnect the “A”-concentrate connector, connect the “A”-concentrate connector. NOTE! Press Skip to cancel the test. -

Page 135: Pump Test

System 5.4.4.2.1 System tasks ● I2C scan – scan and update transducer E PROMs ● Technical error support select – view and erase the error code buffer HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 136: To Scan Transducers Via The Data Bus

The buffer’s content is kept after the machine is switched off, allowing a technician to view it at a later time. NOTE! For more information about the error message refer to the AK 98 dialysis machine - Error Code and Service logging List. NOTE! It is important that the program version on the “Error Codes and Service Logging... -

Page 137: To Erase Technical Errors

“Enter service or preset mode” page 123. Select the Diagnose tab. Press Blood module. Press BPM. Press the test you need to run. Press Confirm to start the test. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 138: Check Of Air Leakage

18 mmHg / 3 minutes, this indicates that there is a possible air leakage in the system. To check for air leakage within the AK 98 dialysis machine, replace the cuff and cuff hose with a closed tube. -

Page 139: Check Of Inflation Speed

Check of pressure transducer By entering this test mode it will be possible to check the actual pressure value for the BPM pressure on the AK 98 dialysis machine display. NOTE! Before entering pressure test mode, connect the Gambro reference instrument, together with a calibration tube set from kit K13983002, to the BPM connector on the AK 98 dialysis machine. -

Page 140: 5.4.4.3.10 Check Of Pressure Transducer Calibration And Measured Pressure

5.4.4.3.12 To start a pump test Procedure Enter Service mode, see Section 5.1.3 “Enter service or preset mode” page 123. Select the Diagnose tab. Press Blood module. Press Pumps. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... -

Page 141: Fluid Module

Press Variable flow. Press Start to initiate the test. Results ● Flow: The average dialysis flow in the AK 98 dialysis machine. ● Calibration steps: The number of steps at entrance to service/functional check according to a previous calibration. ●... -

Page 142: Fluid Module Pumps

5.4.4.4.3 Fluid module pumps 5.4.4.4.3. Pump diagnose In Pumps the AK 98 dialysis machine enters “normal” treatment mode, starts the fluid part, and maintains a flow. It runs with the following set values: ● Temperature 37.0°C ● Conductivity 14 mS/cm ●... -

Page 143: To Perform A Uf Taration

Press Start to change the valve status. Update AK 98™ system firmware Procedure Insert the USB flash drive in the USB port (1) according to Figure 5-1 “USB port” on page 142. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance support Program version 1.xx... - Page 144 The update can fail for several reasons, for example, when the update file is corrupt or missing. Check that the correct file is on the USB stick, then retry the update from the start. Please contact your local Gambro Service representative if the problem persists.

-

Page 145: Replacements

6.1.2 Actions to be done - description ................6.1.3 Fluid unit - flow path ....................Replacement of Batteries ..................6.2.1 Battery ........................6.2.2 Battery and electronic waste handling..............HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Replacements Program version 1.xx... -

Page 146: Actions After Component Replacement

The replacement matrix is only a guideline for service technicians to know which actions to perform after a component has been replaced. NOTE! For technical error handling, (information regarding error codes) refer to the AK 98 Error Codes and Service Logging List. HCEN12630 Revision 07.2015 AK 98™... - Page 147 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Replacements Program version 1.xx...

-

Page 148: Actions To Be Done - Description

7.3.8 “Conductivity transducer calibration” page 165. Calibrate Pressure Transducer Calibrate according to calibration instructions in the AK 98 service manual. See Section 7 “Calibrations” on page 151. Calibrate Blood leak Calibrate according to calibration instructions in the AK 98 service manual. See Section 7.3.6... - Page 149 AK 98 service manual Section 7 “Calibrations” on page 151. Calibrate clock Calibrate according to calibration instructions in the AK 98 service manual. See Section 7 “Calibrations” on page 151. Check fluid flow Start the machine and wait until the green fluid path lights up.

-

Page 150: Fluid Unit - Flow Path

6.1.3 Fluid unit - flow path Figure 6-1. See chapter 11: "Fluid unit - flow path" HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Replacements Program version 1.xx... -

Page 151: Replacement Of Batteries

Waste handling Batteries from the AK 98 dialysis machine shall not be discarded in normal waste, instead separate and proper collection systems shall be used. If improperly disposed, batteries might contaminate the environment and risk the health of people. - Page 152 This page is intentionally left blank. This page is intentionally left blank.

-

Page 153: Calibrations

7.4.4.2 During the verification of the UF control calibration........... 7.4.4.3 When the verification of the UF control calibration is finished ......7.4.4.4 To disconnect the UF calibration box..............HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Calibrations Program version 1.xx... - Page 154 7.4.5 Clock........................7.4.5.1 To set the time ....................7.4.6 Touch Screen......................7.4.6.1 To calibrate the touch screen ................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Calibrations Program version 1.xx...

-

Page 155: General Information About The Calibrations

7.1.2 The data bus The AK 98 dialysis machine uses a separate data bus – the I2C data bus – to communicate with the transducers. Each transducer board (1) contains an address – information about the board’s physical position on the transducer motherboard... - Page 156 There are nine data buses connected to various components, for example transducers. An overview of the data buses is shown in the figures below. Figure 7-2. Front I/O board HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Calibrations Program version 1.xx...

-

Page 157: Installation Of New Pressure Tranducers

Installation of new pressure tranducers Always perform an I2C data bus scanning when a new transducer has been installed. See Section 5.4.4.2.2 “To scan transducers via the data bus” on page 134 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Calibrations Program version 1.xx... -

Page 158: I2C Data Bus Errors

– a factor, typically between 0.90 – 1.10 which will correct the slope of the line so it matches the ideal. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Calibrations Program version 1.xx... -

Page 159: Calibration Errors

+18 mmHg will generate a poor result. 7.1.8 Calibration errors - Pressure transducers If the AK 98 dialysis machine finds, during the pressure transducer calibration procedure, that a calculated offset or calibration coefficient is outside certain limits, a calibration error appears. These limits are: ●... -

Page 160: Test Equipment

K12755001 connectors Linear transducers 7.3.1 Calibration of linear transducers Procedure Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. Select Calibration. Press Transducers. Press External flow support or Internal flow support. -

Page 161: Venous Pressure Transducer Calibration

Venous pressure transducer calibration Procedure Connect the Gambro reference instrument (together with a calibration tube set) to the venous pressure transducer (blue) on the front of the AK 98 dialysis machine, according to Figure 7-5 “Connect reference instrument.” on page 159. -

Page 162: Arterial Pressure Transducer Calibration

Arterial pressure transducer calibration Procedure Connect the Gambro reference instrument (together with a calibration tube set) to the arterial pressure transducer (red) on the front of the AK 98 dialysis machine, according to Figure 7-6 “Connect reference instrument” on page 161. - Page 163 Figure 7-6. Connect reference instrument Zero set the reference instrument, wait for stable reading. Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. Select Calibration. Press Transducers. Press External flow support.

-

Page 164: Priming Detector Calibration

If the error occurs a second time: Change the transducer and the transducer board. 7.3.4 Priming detector calibration Procedure Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. Select Calibration. -

Page 165: Adjustment Instruction

Procedure Make sure there is no fluid in the AK 98 dialysis machine monitor. If there is fluid in the monitor, press the Disinfection button to drain the machine. Remove the blood leakage detector cover and clean the inside of the blood leakage detector housing. -

Page 166: Variable Flow Calibration

If the calibration is to be aborted without saving the new calibration values: Press Cancel. Drain the AK 98 dialysis machine and remount the standard blood leakage cover. 7.3.7 Variable flow calibration The variable flow calibration has a flow of 500 mL/min. -

Page 167: Conductivity Transducer Calibration

NOTE! Before conductivity calibration, decalcification and cleaning shall be performed. NOTE! To keep the temperature inside the AK 98 dialysis machine, do not remove the blood monitor. NOTE! Make sure the variable flow is calibrated before performing the conductivity cell calibration. -

Page 168: Dialysis Pressure Transducer Calibration

Deactivate Fluid Bypass to let the fluid run through the dialyser tubes. Calibration with concentrate Let the AK 98 dialysis machine stabilize at 14 mS/cm and 37 °C during 15 minutes. Check that the temperature on the reference instrument is approximately 37 °C. - Page 169 “Connect reference instrument” on page 167. Figure 7-8. Connect reference instrument Zero set the reference instrument, wait for stable reading. Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. Press Calibration.

-

Page 170: Degassing Pressure Transducer Calibration

“Connect reference instrument” on page 168. Figure 7-9. Connect reference instrument Zero set the reference instrument, wait for stable reading. Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. HCEN12630 Revision 07.2015 AK 98™... -

Page 171: Hpg Pressure Transducer Calibration

Insert a plug (from the calibration kit) according to Figure 7-10 “Connect reference instrument” on page 170. Connect Gambro reference instrument to the angled silicone connector according to Figure 7-10 “Connect reference instrument” on page 170. HCEN12630 Revision 07.2015 AK 98™... - Page 172 Figure 7-10. Connect reference instrument Zero set the reference instrument, wait for stable reading. Start the AK 98 dialysis machine. Enter Service mode, see Section 5.1.3 “Enter service or preset mode” on page 123. Press Calibration. Press Transducers. Press External flow support.

-

Page 173: Pressure Regulator Calibration, Pr 1

7.3.12 Pressure regulator calibration, PR 1 Procedure Turn off the water supply. Connect Gambro reference instrument just before the INPS pressure switch, according to Figure 7-11 “Connect reference instrument” on page 171. Figure 7-11. Connect reference instrument Close clamp C. -

Page 174: Pressure Regulator Calibration, Pr 2

Close clamp A and B. Turn on the water supply. Start the AK 98 dialysis machine. Perform a functional check and wait until the conductivity and the temperature are stable. The fluid path on the screen shall be green before the calibration begins. -

Page 175: Uf Control Calibration

Select UF Internal calibration for an internal calibration (taration but updating the E PROM instead of RAM). This is done without the external UF calibration equipment connected to the AK 98 dialysis machine. ● Select UF Verify calibration for a verification of the result from the latest calibration. -

Page 176: Prerequisite For The Complete Uf Control Calibration

Prerequisite for the complete UF control calibration ● Perform both a disinfection and a cleaning decalcification to remove both organic and calcium precipitates, according to the operator’s manual for the AK 98 dialysis machine. ● Make sure the variable flow is calibrated before performing the UF control calibration. -

Page 177: Complete Mode

AK 98 dialysis machine is turned on. NOTE! If the machine is equipped with an ultrafilter, let the AK 98 dialysis machine pass functional check (wait for green fluid path) before entering Service mode. NOTE! The UF calibration station should be placed so that the dialyzer connectors are at the same level (height) as the dialyzer connectors on the AK 98. -

Page 178: When The Automatic Uf Control Calibration Is Finished

7.4.2.3 When the automatic UF control calibration is finished After calibration, the AK 98 dialysis machine continues to store the calculated values. When the storage is completed, the verification results are displayed. Table 7-4. The table shows an example with results after completed UF complete calibration. -

Page 179: If The Calibration Is Out Of Limits

7.4.2.5 To disconnect the UF calibration box Procedure Press the AK 98 dialysis machine On/Off button. Turn off the AK 98 dialysis machine with the main switch. Disconnect the UF calibration box from the mains power. 7.4.3 Internal mode 7.4.3.1... -

Page 180: Verify Mode

AK 98 dialysis machine is turned on. NOTE! If the machine is equipped with an ultrafilter, let the AK 98 dialysis machine pass functional check (wait for green fluid path) before entering Service mode. NOTE! The UF calibration station should be placed so that the dialyzer connectors are at the same level (height) as the dialyzer connectors on the AK 98. -

Page 181: When The Verification Of The Uf Control Calibration Is Finished

Isolated UF. 7.4.4.3 When the verification of the UF control calibration is finished When the verification is completed, the AK 98 dialysis machine displays the results: Table 7-5. The table shows an example with results after completed UF Verify calibration. - Page 182 7.4.4.4 To disconnect the UF calibration box Procedure Press the AK 98 dialysis machine On/Off button. Turn off the AK 98 dialysis machine with the main switch. Disconnect the UF calibration box from the mains power. 7.4.5 Clock 7.4.5.1 To set the time Procedure Enter Service mode, see Section 5.1.3...

- Page 183 Replacing valve membranes ................8.6.3.2 Valve mounting tool K15391C ................8.6.4 Actions to carry out after the parts in the B- and C-kit have been exchanged ......................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 184: General

A yearly maintenance is recommended. The rate of preventive maintenance might be different due to variations of the operating environment. The AK 98 dialysis machine will perform as designed only if it is used and maintained in accordance with Gambro’s instructions. -

Page 185: How To Open The Machine

The purpose of these checklists is to record the work done. 8.1.2 How to open the machine 8.1.2.1 Opening illustration 8.1.2.2 How to remove the rear cover Procedure Remove the two screws (1). HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx... -

Page 186: How To Remove The Blood Monitor (Bm)

* If installed Water inlet tube disinfection Before you begin The water inlet tube between the water supply system and the tube into the AK 98 dialysis machine up to the recirculation valve (REVA) is not automatically disinfected HCEN12630 Revision 07.2015 AK 98™... - Page 187 Disinfectant suction. Prepare a diluted peracetic (Dialox) solution of 2 ml peracetic/50 ml treated water in a chemical resistant container (see Table 8-2 “Peracetic solution table” page 186). HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

- Page 188 Use the syringe of the manual disinfection device to pump appropriate volume (see Table 8-2 “Peracetic solution table” on page 186) of diluted peracetic HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 189: Preventive Maintenance: Base-Kit

Preventive Maintenance: Base-kit 8.4.1 Parts in the Base-kit The Base-kit (K40429001) includes all parts necessary to fulfil the mandatory preventive maintenance procedures for the AK 98 dialysis machine. Table 8-3. Base-kit Denomination Part No. Air filter, AC/DC... -

Page 190: How To Exchange The Parts Included In The Base-Kit

Then perform a heat disinfection program in combination with CleanCart A agent or a Chemical disinfection program with sodium hypochlorite. Refer to the operator’s manual for the AK 98 dialysis machine. Change air filter, K23734002, in the AC/DC power supply. - Page 191 Change o-rings, K63278001, on the A- and B-connectors (male). Change o-rings, 100319060, on the A- and B-connectors (female) Change O-ring, 100319054, in the deaerating chamber. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

- Page 192 Change O-ring, 100319008, in the degassing chamber. Change the O-rings, 100319009, in the dialyzer connectors. (Only for the AK 98 dialysis machine equipped with UFD-kit). Change the O-rings, 100319029, and square-ring, K14920001 in the ultrafilter holder. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual...

- Page 193 Change both o-rings, 100319008, in the BiCart cartridge holder (upper and lower). Change particle filter, K16538A, from the BiCart cartridge holder. Change O-ring, 100319008, in the mixing chamber. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 194: Actions To Carry Out After The Parts In The Base-Kit Have Been Exchanged

Reconnect the cable K64897/K68678 (on RP 98) to the connector P202. Reconnect the cable K67217/K68679 (on RP 98) to the connector P203 on the display card K67455. BPM-test (Only for the AK 98 dialysis machine equipped with BPM) BPM sub-tests ● Air leakage test: measures that the equipment is airtight. - Page 195 It is of course also possible to perform this test without the cuff and cuff hose connected, but then the test will only check for air leakage within the AK 98 dialysis machine. In this case replace the cuff and cuff hose by a tube, which is closed.

- Page 196 BPM reaches its overpressure point. Check that the overpressure point is at 300 mmHg (±20 mmHg). Priming detector calibration Start the AK 98 dialysis machine with the main switch and the On/Off button. Enter Service mode, see Section 5.1.3 “Enter service or preset mode”...

- Page 197 T = wall thickness of the blood tubing Check the range between the blood pump rollers and the path according to Figure “Blood pump - - - = Measuring” on page 196. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

- Page 198 (1). Stop the blood pump rotor by manually grabbing the handle (2). Check that the power to the blood pump motor is switched off within 2 seconds. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

- Page 199 “Calibrations” on page 151 for details). NOTE! To reach atmospheric pressure in the transducer housing, disconnect the corresponding tube, refer to the AK 98 service manual Section 7 “Calibrations” on page 151. Enter Service mode and enable the fluid path leakage test.

- Page 200 Enter Service/Diagnose/System/Technical error support select/Erase technical errors. (Only if error codes 0504 020 xxx error codes were present in the error code buffer.) Perform a full calibration of the UF cell according to the AK 98 service manual Section 7 “Calibrations” on page 151.

- Page 201 Put a piece of paper around the tube connector to avoid leakage inside the monitor. Turn on the inlet water again and start the AK 98 dialysis machine. Make sure that the blood monitor is placed on the fluid monitor.

- Page 202 It is very important to do step 38.12-14 more or less simultaneously i.e. within seconds. Check the residual volume at TIME = 0:00. Approved residual volume: 100 mL +/- 50 mL HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 203: Preventive Maintenance: A-Kit

24 h before this test is to be done. The charge indicator on the power supply is lit when the AK 98 dialysis machine is equipped with back-up batteries. -

Page 204: How To Exchange The Exterior Parts Included In The A-Kit

How to exchange the exterior parts included in the A-kit Procedure Change air filter, K23734002, in the AC/DC power supply. Change air filter, K24358001, in the cover of the AK 98 dialysis machine. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx... - Page 205 K40374001 (red) Add/change the washers, K07316001, for the blood pump rotors. Change the pick-up tubes: ● Pick-up tube, A (white) 100850007 ● Pick-up tube, B (blue) 100850008 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 206: Actions To Carry Out After The Parts In The A-Kit Have Been Exchanged

Actions to carry out after the parts in the A-kit have been exchanged Procedure First perform a heat disinfection program. Refer to the AK 98 operator’s manual. After the heat disinfection; re-tighten the nuts of the dialyzer connector set to the machine. -

Page 207: Preventive Maintenance: B- And C-Kit

Parts in the B- and C-kit The B- and C-kits are designed to be used as a complementary addition to the Base-kit for the preventive maintenance procedures of the AK 98 dialysis machine. The B-kit, K40431001, and the C-kit, K40432001, includes following overhaul parts: HCEN12630 Revision 07.2015... -

Page 208: How To Exchange The Parts Included In The B- And C-Kit

How to exchange the parts included in the B- and C-kit Procedure Change both the venous and arterial pressure monitoring line, including disc filter. Arterial line: K15168001 Venous line for level adjustment: K19459A HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx... - Page 209 Change following complete 2-way valves, K15235A: AIVA, CHVA, ZEVA, DIVA, BYVA, TAVA and EVVA. ● C-kit only! Change the complete 3-way valve, K21139002, for CBVA and FLVA. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Maintenance manual Program version 1.xx...

-

Page 210: Valve Membranes

(Only for the AK 98 dialysis machine equipped with BiCart cartridge holder) Change both the upper and the lower spike kit in the BiCart cartridge holder. Assemble according to machine configuration. ● K23031004 (Upper) ● K21557006 (Lower) 8.6.3 Valve membranes 8.6.3.1... -

Page 211: Actions To Carry Out After The Parts In The B- And C-Kit Have Been Exchanged

Actions to carry out after the parts in the B- and C-kit have been exchanged Procedure First perform a heat disinfection program. Refer to the AK 98 operator’s manual. Enter Service mode and enable the fluid path leakage test. Let the machine pass functional check. - Page 212 This page is intentionally left blank. This page is intentionally left blank.

- Page 213 Machine type and identification ................9.5.2 PET for AK 98™ dialysis machine................. 9.5.3 ELT - Earth Leakage Current Test ................. 9.5.4 PLT - Patient Leakage Current Test ..............HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx...

-

Page 214: General

IEC 60601-1: Medical electrical equipment - Part 1: General requirements for basic safety and essential performance. IEC 62353: Medical electrical equipment - Recurrent test and test after repair of medical electrical equipment. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... -

Page 215: Visual Inspection

...the mounting plate to the potential equalization connector, measure on one of the screws,..the potential equalization connector..the heparin pump (rear plate)..does not exceed 300 mΩ. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... -

Page 216: Elt/Plt

ELT and PLT values shall be less than the maximum values shown in the tables. 9.4.3 9.4.3.1 Earth Leakage Current Test Procedure Let the machine pass functional check. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... -

Page 217: Limit Values For Earth Leakage Current (Elt)

Let the machine pass functional check. Connect the dialysis fluid tubes to the PLT box. The access point on the PLT box shall be connected to the Safety Tester. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... -

Page 218: Limit Values For Patient Leakage Current (Plt)

A visual inspection of the dialysis machine has □ been performed without any remarks, according to the specified step instruction in Section 9.2 “Visual inspection” on page 213. Remarks: HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... -

Page 219: Pet For Ak 98™ Dialysis Machine

Compare with the measured leakage currents at the last ESI and evaluate if the changes are approved or not for the next operational period of the machine. Write notes here: _____________________________________________________ HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx... - Page 220 Electrical Safety Inspection. If this is the ESI at installation please make comparison with the ”Production Summary” measured values supplied by the manufacturer at delivery of the machine. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical safety inspection Program version 1.xx...

- Page 221 10 Electrical Connections 10.1 Cable connection....................... HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 222 P113 External K66097001 POWER I/O Interface unit Interface unit communicatio EXT COM K64410001 K64410002 CABLE P114 External USB K68301001 USB CABLE Interface unit Interface unit K64410001 K64410002 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 223 UF CELL CABLE P508 Dia Scan K66089001 GENERAL I/O Dia Scan DIASCAN CABLE P509 24V Input power K68297001 POWER CABLE P104 on Power TO GENERAL I/O board HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 224 POWER CABLE P103 on Power TO FRONT I/O I/O board P608 CAN (control K68299001 CAN CABLE P111 on Power and protective) I/O and P511 on General I/O HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 225 Table 10-6. Alarm Light Bar board K63362005 Contact Contact name Cable Cable name Connected to Components number for Self-Care Alarm Light Bar K67216001 ALARM AND P1 on Button BACK LIGHT Board CABLE HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 226 P934 FM I/O K66095001 POWER I/O P110 on Power HEATER I/O board (2-pin CONTROL connector) CABLE P935 AC/DC Mains power from power supply unit K62989 (3-pin connector) HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Electrical Connections Program version 1.xx...

- Page 227 11 Fluid unit - flow path HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Fluid unit - flow path Program version 1.xx...

- Page 228 REVA UF-measuring pump Deairating cell chamber Dialyzer BYVA TAVA FIVA* DIVA SAGS Pure water A concentrate B concentrate Fluid connector Dialysis fluid detection Dialysate ® U 9000 Dialysis *=option fluid filter* HCEN12630 © 2015 Gambro Lundia AB, Rev. 02.2015...

- Page 229 12.6.6 Arterial clamp test....................12.6.7 Air detector test ..................... 12.7 Fluid monitor – functional check ................12.7.1 Sub-tests ....................... 12.7.2 Flow switch and heater relay test ................HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx...

- Page 230 12.7.10.4 UF Supervision evaluation phase 2..............12.7.10.5 UF Supervision function check time out ............12.7.11 Blood leak clean test ..................... 12.8 Automatic restart of the FM functional check ............HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx...

-

Page 231: Functional Check

Functional check will appear in the Machine state indicatior field. 12.1.2 The different parts in functional check The AK 98 dialysis machine functional check begins with a Power On Self Test (POST) that includes tests of CPU and RAM. Refer to Section 12.2 “POST - Power On Self Test”... -

Page 232: Purpose With This Chapter

This chapter does not include a complete description of the Error codes. Therefore the Error Codes and Service Logging List for the AK 98 dialysis machine is needed as a complementary information when troubleshooting the machine. -

Page 233: Post - Power On Self Test

If they are connected to the dialyzer, the fluid will enter the dialyzer at that time. Refer to the AK 98 operator's manual for instructions on how to properly attach the dialysis fluid tubes to the dialyzer. - Page 234 I/O Protective Power I/O Protective Display Control User Interface Protective Figure 12-2. LED groups located on the General I/O. The arrows shows on which side LED1 is located. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx...

- Page 235 0011 Register tests 0100 Register tests 0101 Register tests 0110 Register tests 0111 Register tests 1000 Register tests 1001 Register tests 1010 Register tests 1011 RAM test HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx...

-

Page 236: Test Philosophy

When a signal is received in control system, indicating a test failure, the control system will increment a dedicated error counter. If the counter exceeds a predefined limit, an error code will be generated. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 237: Functional Check Overview

12.4 Functional check overview The functional check of the safety system is divided into following three main sections: ● Common tests ● BM tests ● FM tests HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 238: Common Tests

12.5 Common tests 12.5.1 Sub-tests The common test includes following sub-tests: ● Light indicator test, refer to Section 12.5.2 “Common tests / Light indicator test” page 237 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 239: Common Tests / Light Indicator Test

It should be very close to zero. In the following tests, the reference current is used to compensate the current measurement. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 240: Safety Relay Test Description

0511 088 097 BYVA and DIVA. requests the control system to close BYVA and DIVA. The control system does not acknowledge, then repeat test until error code is generated. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 241: Common Tests / Valve Current Test - Close Failure Test

If current is too high, then 0511 088 101 and the control system closes repeat test until error code is DIVA. generated. 12.5.4.5 Common tests / Valve current test - CHVA HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 242: Common Tests / Valve Current Test - Byva

The protective system opens If current is too low, then 0511 088 104 and the control system closes repeat test until error code is BYVA. generated. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 243: Common Tests / Valve Current Test - Evva / Tava

EVVA repeat test until error code is generated. 12.5.4.8 Common tests / Valve current test - FLVA / DRVA / AIVA / FIVA / CBVA / HBVA HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 244: Common Tests / Speakers Test

If the first speaker is 0510 088 018 quiet, then repeat the test until error code is generated. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 245: Common Tests / Battery Test

● Arterial clamp test, refer to Section 12.6.6 “Arterial clamp test” on page 249 ● Air detector test, refer to Section 12.6.7 “Air detector test” on page 250 HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 246: Blood Pressure Transducer Test

The arterial pressure reading describes the amount of suction needed to achieve the blood pump speed set on the AK 98 dialysis machine and best describes the blood flow from the patient's vascular access into the extracorporeal circuit. -

Page 247: Negative Pressure Test

The relay controlling the pump and the valve is disabled. The pump is started to generate a negative pressure. The pump shall not work and the valve shall not close. The pressure shall not decrease. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 248: Priming Detector Test

Blood in priming detector. Functional check is stopped. When the blockage disappears, then the functional check will continue, i.e. the functional check will be halted until no blood is detected. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 249: Blood Pump Test

Two signals are associated with the blood pump: the Blood Pump Edge signal (rotation guard, Hall effect transducer), and the Blood Pump Tacho signal (encoder): HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... - Page 250 The blood pump tacho value is too low AND the rotation indicator is not detecting movement (second check). Repeat test until error code is generated. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx...

-

Page 251: Venous Clamp Test

The arterial clamp has two shut-off paths. Both the protective system and the control system must agree to open the arterial clamp. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 252: Air Detector Test

I/O Protective Front Receiver amplifier I/O Control Front Start condition for the test is no alarm, i.e. a filled venous drip chamber. The test starts when this is fulfilled. HCEN12630 Revision 07.2015 AK 98™ Dialysis Machine - Functional check Program version 1.xx... -

Page 253: Fluid Monitor - Functional Check