Table of Contents

Advertisement

Quick Links

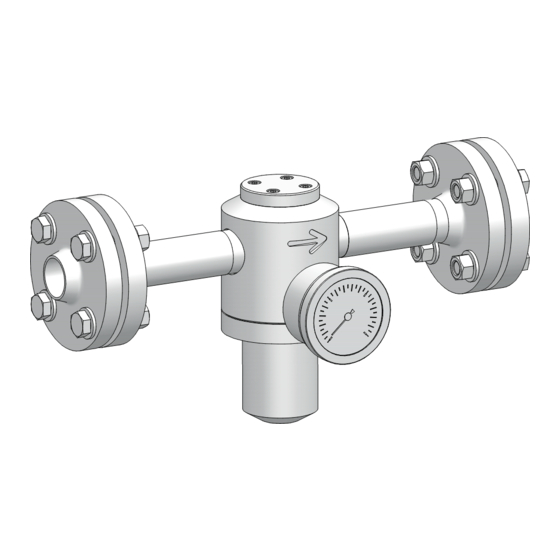

Hauptansicht Druckreduzierventil C 7110 mit Manometer

Original operating instructions

© Lutz-Jesco GmbH 2023

Hauptansicht Druckreduzierventil C 7110 mit Flansch

23100200_4

Read the operating manual!

The user is responsible for installation and operation related mistakes!

Pressure reducing valve

23100201_5

Operating instructions

BA-20701-02-V01

C 7110

Advertisement

Table of Contents

Summary of Contents for Lutz-Jesco C 7110

- Page 1 Pressure reducing valve Hauptansicht Druckreduzierventil C 7110 mit Flansch C 7110 23100201_5 Operating instructions Hauptansicht Druckreduzierventil C 7110 mit Manometer 23100200_4 Read the operating manual! The user is responsible for installation and operation related mistakes! Original operating instructions BA-20701-02-V01 © Lutz-Jesco GmbH 2023...

-

Page 3: Table Of Contents

1 Notes for the Reader ............4 11 Troubleshooting ...............20 1.1 General non-discrimination ............12 Exploded view C 7110 pressure reducing valve ....21 1.2 Explanation of the signal words ..........1.3 Explanation of the warning signs ..........13 Notes to EU conformity ............22 1.4 Identification of warnings ............ -

Page 4: Notes For The Reader

Pressure reducing valve C 7110 Operating instructions 1 Notes for the Reader 1.3 Explanation of the warning signs This operating manual contains information and behaviour rules for the safe and designated operation of the device. Warning signs represent the type and source of a danger:... -

Page 5: Safety

Pressure reducing valve C 7110 Operating instructions 2 Safety 2.1 General warnings PLEASE NOTE The following warnings are intended to help you eliminate the dangers Damage to the plant due to the formation of hydrochloric that can arise while handling the device. Risk prevention measures al- acid! ways apply regardless of any specific action. -

Page 6: Working In A Safety-Conscious Manner

Pressure reducing valve C 7110 Operating instructions 2.4 Working in a safety-conscious manner 2.6 Personnel qualification Besides the safety instructions specified in this operating manual, further Any personnel who work on the device must have appropriate special safety rules apply and must be followed: knowledge and skills. -

Page 7: Intended Use

If people operate the device who are not adequately qualified to carry out their respective activities. No original spare parts or accessories of Lutz-Jesco GmbH are used. Unauthorised changes are made to the device. The user uses different dosing media than those indicated in the or- der. -

Page 8: Product Description

Operating instructions Optional accessories: Pressure gauge Pipe clips 4.2 Design and function Fig. 1: Cross section C 7110 Description Fig. 2: Installation example C 7110 pressure reducing valve Cone Description Diaphragm chamber Diaphragms Pressurized manifold Spring Pressure reducing valve C 7110... -

Page 9: Rating Plate

Lutz-Jesco GmbH 30900 Wedemark Am Bostelberge 19 Germany Pressure Reducing Valve C7110 P/N: S/N: Made in Germany *102A12345678* Fig. 4: Rating plate C 7110 Gaseous Description 50 [°C] Fig. 3: Vapour pressure curve for chlorine Product name Item Alteration Effect... -

Page 10: Technical Data

Pressure reducing valve C 7110 Operating instructions 5 Technical data Specification and Unit Value Chlorine gas flow rate kg/h Nominal pressure PN16 Set output pressure Measuring range 0 – 16 Size Ø63 Optional pressure gauge Accuracy ±2.5 % of scale value Contact load rating 50 V / 0.5 A / 10 W... -

Page 11: Dimensions

Pressure reducing valve C 7110 Operating instructions 6 Dimensions All dimensions in mm Ø89 ~103 Ø57 Fig. 5: Dimensional drawing C 7110 with female thread ~335 Ø89 ~103 Ø57 Fig. 6: Dimensioned drawing C 7110 with flange Dimensions © Lutz-Jesco GmbH 2023 BA-20701-02-V01 Subject to technical changes. -

Page 12: Installation

Pressure reducing valve C 7110 Operating instructions 7 Installation ü The flange seals must be clean, undamaged and dry. DANGER ü Bolts, nuts and washers are clean and undamaged. ü The distance between the pipe flanges equals the length of the pres- Danger to life from chlorine poisoning! sure reducing valve. -

Page 13: Completing The Installation

Pressure reducing valve C 7110 Operating instructions 7.3 Completing the installation 7.2.2 Assembly using a threaded connection Check that all the connections are leak proof after completing installation. Organic sealing materials must not be used for assembling the fittings and pipes. For this purpose, only Teflon tape or special-... - Page 14 Pressure reducing valve C 7110 Operating instructions ü A nitrogen cylinder with a pressure reducer (0 – 25 bar) has been connected. PLEASE NOTE Perform the following working steps: Damage to the plant by the ammonia solution 1. Slowly raise the system pressure at the nitrogen cylinder's pressure If the ammonia solution comes into contact with the plant, this leads to reducer to 10 bar.

-

Page 15: Operation

Pressure reducing valve C 7110 Operating instructions 8 Operation The pressure-reducing valve does not require any special operation. The device has been factory-set to a fixed positive pressure of 1.5 bar. 8.1 Shutting down in an emergency DANGER Danger to life from chlorine poisoning! Chlorine is poisonous. -

Page 16: Shutdown

Pressure reducing valve C 7110 Operating instructions 9 Shutdown 9.1 Short-term shutdown Perform the following working steps: 1. Close the chlorine gas container valves. 2. Use the ejector to suck off the remaining chlorine. 3. If present, connect the service valve between the dosing device and the injector. -

Page 17: Maintenance

Operating instructions 10 Maintenance Products by Lutz-Jesco are manufactured to the highest quality stand- The state of the diaphragm (8) must be checked, especially its elasticity ards and have a long service life. However, some parts are subject to op- and the degree of deformation on the mounting edge. -

Page 18: Preparing The Device For Maintenance

23100200_1 Pressure reducing valve C 7110 Operating instructions In some cases, regional regulations may require shorter main- tenance intervals. Maintenance intervals depend only on how frequently the equipment is used. Chemical wear of rubber parts, for example, begins with the initial medium contact and continues irrespective of the usage. -

Page 19: Cleaning The Pressure Gauge

Pressure reducing valve C 7110 Operating instructions 10.4 Cleaning the pressure gauge 3. Check the diaphragm (see section 10.1). To change the diaphragm, insert a screwdriver through the groove of the diaphragm mount (7) and open the screw connection with an open-end spanner. - Page 20 Pressure reducing valve C 7110 Operating instructions 11 Troubleshooting See below for information about how to rectify faults on the device or the system. If you cannot eliminate the fault, please consult with the manufacturer on further measures or return the device for repair.

- Page 21 Cylinder head screw Cylinder head screw End cap Guide Pressure gauge or contact pressure gauge Plugs Stop screw Tab. 12: Exploded view C 7110 pressure reducing valve * contained in maintenance kit Maintenance kits Part Content Maintenance kit (for annual ser- Diaphragms...

- Page 22 Pressure reducing valve C 7110 Operating instructions 13 Notes to EU conformity The device falls under the purview of the pressure equipment directive 2014/68/EU. The values stated below do not exceed the limit values. Therefore, it is designed and manufactured in accordance with valid good engineering practice This pressure device may not carry a CE marking and an EU declaration of conformity will not be issued.

- Page 23 Pressure reducing valve C 7110 Operating instructions 14 Declaration of no objection Declaration of no objection Please fill out a separate form for each appliance! We forward the following device for repairs: Device and device type: ..............Part-no.:................... Order No.:..................

- Page 24 Pressure reducing valve C 7110 Operating instructions 15 Warranty claim Warranty claim Please copy and send it back with the unit! If the device breaks down within the period of warranty, please return it in a cleaned condition with the complete warranty claim.

- Page 25 Pressure reducing valve C 7110 Operating instructions 16 Index Accessories ..................8 Rating plate ..................9 Chlorine .....................5 Safety ....................5 Scope of delivery ................8 Short-term shut-down ..............16 Shut-down ..................16 Design ....................8 Shutting down in an emergency ............15 Dimensioned drawings ..............11 Signal words Dimensions ..................11...

- Page 28 Hauptansicht Druckreduzierventil C 7110 mit Flansch 23100201_5 Hauptansicht Druckreduzierventil C 7110 mit Manometer 23100200_4 Lutz-Jesco GmbH Am Bostelberge 19 D-30900 Wedemark Phone: +49 5130 5802-0 info@lutz-jesco.com www.lutz-jesco.com Operating instructions Pressure reducing valve C 7110...

Need help?

Do you have a question about the C 7110 and is the answer not in the manual?

Questions and answers