Table of Contents

Advertisement

Quick Links

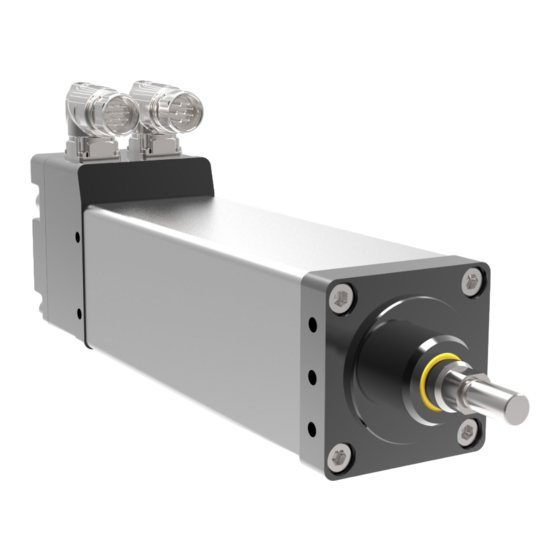

GTX SERIES actuators

Installation & Service Instructions

Rev. J | PN75557 | 12/19/23

Integrated Motor Actuator

This document does not contain any export-controlled technical data.

Information furnished by Exlar Corporation is believed to be accurate and reliable. However, no responsibility is assumed by Exlar Corporation for

its use. Exlar reserves the right to change the design and operation of the equipment described herein and any associated motion products that

may appear in this document. Information in this document pertaining to equipment not furnished by Exlar should be confirmed by that equipment

manufacturer. Exlar assumes no responsibility for changes to information by other manufacturers or errors in that information or the description of that

information. Information in this document is subject to change without notice.

Advertisement

Table of Contents

Summary of Contents for Curtiss-Wright EXLAR GTX Series

- Page 1 GTX SERIES actuators Installation & Service Instructions Rev. J | PN75557 | 12/19/23 Integrated Motor Actuator This document does not contain any export-controlled technical data. Information furnished by Exlar Corporation is believed to be accurate and reliable. However, no responsibility is assumed by Exlar Corporation for its use.

-

Page 2: Table Of Contents

6.3 REPLACEMENT FACEPLATE ASSEMBLY KIT ..................16 7.0 TROUBLESHOOTING ......................16 8.0 PRODUCT RETURNS .......................17 9.0 CERTIFICATIONS ......................17 9.1 IMPORTER REQUIREMENTS ........................18 9.2 DISTRIBUTOR REQUIREMENTS ......................19 10.0 WARRANTY INFORMATION ..................20 2 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 3: Introduction

1.0 INTRODUCTION 1.1 GENERAL PRODUCT DESCRIPTION GTX Series actuators feature a robust planetary roller screw mechanism integrated into the rotor of a brushless servomotor. This unique design combines the high speed and high load capacity of the roller screw with the high torque-to-volume ratio of the brushless servomotor. -

Page 4: Safety Considerations

Indicates a potentially hazardous situation which could result in property damage or minor to moderate injury. IMPORTANT! Identifies statements that provide important information to help ensure safe and trouble-free installation and operation. 4 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 5: System Configuration

2.0 SYSTEM CONFIGURATION 2.1 GTX SERIES ACTUATOR GTX Series actuators provide a robust solution for long-life, continuous-duty applications even when environmental contaminants are an issue. In most rotary-to-linear devices, critical mechanisms are exposed to the environment and must be frequently inspected, cleaned and lubricated. In contrast, GTX Series actuators are designed with all converting components mounted within sealed motor housings. -

Page 6: Splined Rod Options

*** Male/Female and Metric/Imperial Options Figure 2 – Mounting configurations GTX Series actuators mounting configurations: • Rear clevis • Front flange • Tapped face • Side mount. 6 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... - Page 7 GTX060: 5 mm Hex Torque 4.6 Nm (3.4 ft-lbs) GTX080: 6 mm Hex Torque 12.2 Nm (9 ft-lbs) GTX100: 8 mm Hex Torque 23 Nm (17 ft-lbs) NOTE Figure 3 – Rear clevis mount ( : Dimension drawings can be found in the GTX Series Actuator catalog or on the Exlar website.) GTX060: 5 mm Hex 18 mm Long...

-

Page 8: Mounting Considerations

Should an installed feedback device become misaligned or there is a change in amplifier status, contact the Exlar factory to make arrangements to have the alignment readjusted. 8 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 9: Anti-Rotation Assembly

3.2.3 Anti-rotation Assembly To keep the extending rod from rotating, Exlar offers the Anti-rotation Assembly shown in Figure 6. GTX060: 4 mm Hex Torque 4.6 Nm (3.4 ft-lbs) GTX080: 5 mm Hex Torque 9.5 Nm (7 ft-lbs) GTX100: 8 mm Hex Torque 21.7 Nm (16 ft-lbs) 5 mm Hex GTX060: Torque 4.6 Nm (3.4 ft-lbs) -

Page 10: External Limit Switch

GTX100: 5 mm Hex GTX060: Torque 0.6 Nm (0.5 ft-lbs) GTX080: Torque 0.6 Nm (0.5 ft-lbs) GTX100: Torque 9.5 Nm (7 ft-lbs) Figure 7 – Limit switch mounting 10 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 11: Lubrication

3.3 LUBRICATION GTX Series actuators are shipped from the factory fully greased and ready for installation. Exlar uses Mobil SHC 220, a high- performance grease that performs well under extreme pressure. The unique physical properties of the synthetic-based oil provide outstanding protection against wear, rust, corrosion and high- or low-temperature degradation. Mobil SHC allows for very low starting and running torque values. -

Page 12: Amplifier Pinouts And Connections

BIM-UNT-RP6X Closed, Output Normally 43403 BIM-UNT-AP6X Open, Output Normally 67635 BIM-UNT-RN6X Closed, Output Normally 67634 BIM-UNT-AN6X Open, Output Figure 9 – Logic switch part numbers 12 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 13: Startup

5.0 STARTUP 5.1 CONSIDERATIONS FOR STARTUP 5.1.1 Safety Considerations WARNING! NEVER attempt to connect or disconnect the actuator with power applied. Many amplifiers have voltage present after incoming power is removed. Ensure that the amplifier has discharged all power. CAUTION! Do NOT exceed the maximum input voltage for GTX Series actuators (460 Vac). - Page 14 Figure 34.00 22.00 10.00 4.00 Normalized Continuous Current (Motor) Figure 10 – Duty cycle for peak current operation 14 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23...

-

Page 15: Maintenance Procedures

6.0 MAINTENANCE PROCEDURES 6.1 LUBRICATION GTX Series actuators lubricated with grease require periodic inspection and renewal of the bearing and roller screw grease to maximize actuator life. Maintenance indicators during a physical inspection include: • Contamination of grease with foreign matter •... -

Page 16: Seal Maintenance

Torque 23 Nm (17 ft-lbs) GTX100 PN 75536 and fasteners Figure 12 – Grease renewal reference Figure 13 – Faceplate Assembly Kit 16 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 17: Troubleshooting

7.0 TROUBLESHOOTING GTX Series actuators are engineered for years of trouble-free operation. If problems are encountered while installing or using the actuator, the information in Figure 14 may help solve the problem. Symptom / Trouble Possible Cause / Troubleshooting Procedure No response from actuator. -

Page 18: Certifications

Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/ Page 2 of 2 Page 1 of 2 18 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... -

Page 19: Importer Requirements

NOTE: GTX Series actuators that are intended as components in a third-party machine in which the enclosure and assembly will affect the EMC emissions, are covered by the EMC standard that relates to the final product. Per EU directives implemented on April 20th, 2016, the following procedures must be followed by importers and distributors. 9.1 IMPORTER REQUIREMENTS •... -

Page 20: Warranty Information

Technologies, Inc. has not technically approved, nor does it warrant or support these products. All warranty and support for these products and their application is provided solely by Exlar Corporation. 20 | GTX Installation & Maintenance Instructions Curtiss-Wright | Rev J | PN75557 | 12/19/23... - Page 21 EXLAR Curtiss-Wright 18400 West 77th Street Chanhassen, MN 55317 Phone: 855-620-6200 (US & Canada) Phone: 952-500-6200 Email: CHA_info@curtisswright.com Website: www.exlar.com © 2023 Curtiss-Wright Exlar 18400 W 77th St, Chanhassen, MN 55317 | www.exlar.com...

Need help?

Do you have a question about the EXLAR GTX Series and is the answer not in the manual?

Questions and answers