Table of Contents

Advertisement

U.S.A.

: Kubota Tractor Corporation

1000 Kubota Drive, Grapevine, Texas 76051, U.S.A.

Telephone : (1)-817-756-1171

Canada

: Kubota Canada Ltd.

1155 Kubota Drive, Pickerinɡ, Ontario L1X 0H4, Canada

Telephone : (1)-905-294-6535

France

: Kubota Europe S.A.S.

19-25, Rue Jules Vercruysse, Z.I., BP88 95101 Arɡenteuil Cedex, France

Telephone : (33)-1-3426-3434

Italy

: Kubota Europe S.A.S. - Filiale Italiana

SP14 Nuova Rivoltana, 2/A, 20090 Seɡrate (MI), Italy

Telephone : (39)02-51650377

Germany

: Kubota Baumaschinen GmbH

Steinhauser Straße 100, 66482 Zweibrucken Rheinlandpfalz, Germany

Telephone : (49)-6332-4870

U.K.

: Kubota (U.K.) Ltd.

Dormer Road, Thame, Oxfordshire, OX9 3UN, U.K.

Telephone : (44)-1844-214500

Australia

: KUBOTA AUSTRALIA PTY LTD.

25-29 Permas Way, Truɡanina, VIC 3029, Australia

Telephone : (61)-3-9394-4400

Malaysia

: KUBOTA MALAYSIA SDN. BHD.

Lot 766, Jalan Subanɡ 4, off Persiaran Subanɡ Sunɡai Penaɡa Industrial Park,

47500 Subanɡ Jaya

Telephone : (60)-3-7890-3533

Philippines : KUBOTA PHILIPPINES, INC.

232 Quirino Hiɡhway, Baesa, Quezon City 1106, Philippines

Telephone : (63)2-422-3500

Taiwan

: SHIN TAIWAN KUBOTA CO., LTD.

No.16 Fenɡpinɡ 2nd Road, Daliao District, Kaohsiunɡ City 831, Taiwan

Telephone : (886)7-702-2333

Thailand

: SIAM KUBOTA CORPORATION CO., LTD.

101/19-24 Moo 20, Navanakorn Industrial Estate, Tambon Khlonɡnuenɡ, Amphur Khlonɡluanɡ,

Pathumthani 12120, THAILAND

Telephone : (66)2-909-0300

Japan

: KUBOTA Corporation

Farm & Industrial Machinery International Operations Headquarters

2-47, Shikitsuhiɡashi 1-chome, Naniwa-ku, Osaka, Japan 556-8601

Printed in Japan

S

V

L

7

5

English (Australia)

3

Code No.

V0532-5811-2

©

2023 Kubota Corporation

OPERATOR'S MANUAL

KUBOTA

CTL

MODEL

SVL75-3

READ AND SAVE THIS MANUAL

Compact

Track

Loader

1DALF00382A01

Advertisement

Table of Contents

Summary of Contents for Kubota SVL75-3

- Page 1 1000 Kubota Drive, Grapevine, Texas 76051, U.S.A. Compact Telephone : (1)-817-756-1171 Canada : Kubota Canada Ltd. Track 1155 Kubota Drive, Pickerinɡ, Ontario L1X 0H4, Canada Telephone : (1)-905-294-6535 France : Kubota Europe S.A.S. Loader 19-25, Rue Jules Vercruysse, Z.I., BP88 95101 Arɡenteuil Cedex, France...

- Page 2 Occupational Safety and Health Administration Pressure Limiter Positive Crankcase Ventilation ROPS Roll-Over Protective Structure Revolutions Per Minute Revolutions Per Second Society of Automotive Engineers, USA Suction Control Valve Slow Moving Vehicle SVL75-3 English (Australia) BB. K. 2 - 3. 2. K...

- Page 3 UNIVERSAL SYMBOLS As a guide to the operation of your machine, various universal symbols have been utilized on the instruments and controls. The symbols are shown below with an indication of their meaning. Forward Caution Return switch Backward Engine, Electrical Preheat Acknowledge Turn Right Engine Lubricating Oil Pressure...

- Page 4 FOREWORD Thank you for the purchase of a Kubota product. Before using this product, read this manual carefully and use the product correctly. After reading, keep the manual in a safe and easy-to-access place for future reference. Note that product specifications are subject to change without prior notice.

- Page 5 Owner The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by Kubota Corporation is under license. Company names, product names and service names described in this manual are the trademarks or registered trademarks of their respective owners.

-

Page 7: Table Of Contents

8. Unit setting..............................52 9. Setting the display brightness........................52 10. Setting the work light turn-off delay function.................... 53 11. Setting the machine lockout........................54 11.1 How to use the machine lockout function ..................55 12. Setting the reversing fan.......................... 56 SVL75-3... - Page 8 19. Reversing fan switch ..........................102 20. Emergency engine stop button ......................103 21. Electrical outlet and USB outlet ......................104 PEDAL AND LEVERS ......................105 CONTROL PEDALS AND LEVERS ......................... 105 SAFETY FEATURES .......................106 HOW TO USE THE EMERGENCY EXIT......................106 SVL75-3...

- Page 9 ADVANCED MULTIFUNCTION VALVE (AMV) ....................129 QUICK-HITCH..........................130 HOW TO USE THE HYDRAULIC QUICK-HITCH .................... 130 RADIO ............................133 BLUETOOTH MICROPHONE .......................... 133 IMPACT OF BLUETOOTH..........................133 MACHINE PRECAUTION ......................135 IMPORTANT INFORMATION ON MACHINE OPERATION ................135 1. Caution while traveling ..........................135 SVL75-3...

- Page 10 EVERY 250 SERVICE HOURS ........................166 1. Changing the engine oil ........................... 166 2. Replacing the engine oil filter cartridge ....................167 3. Checking the radiator hoses and the clamps ..................167 4. Checking the fuel line and the intake air line ................... 168 SVL75-3...

- Page 11 12. Replacing the EGR differential pressure sensor rubber piping (Front and back) ........180 13. Replacing the EGR cooler hose ......................180 SERVICING AS REQUIRED..........................180 1. Checking the amount of refrigerant gas ....................180 2. Draining the water separator in case warning against water of the fuel filter .......... 180 SVL75-3...

- Page 12 OPERATING THE MACHINE AFTER STORING FOR A LONG PERIOD OF TIME........205 1. Periodic replacement of important component parts ................205 RECOMMENDED OILS ......................207 RECOMMENDED OILS, GREASES, AND FUELS ..................207 BIODIESEL FUEL (BDF) ..........................209 APPENDICES ..........................210 MAIN DIMENSIONS OF THE MACHINE......................210 SOFTWARE INFORMATION ....................212 INDEX............................213 SVL75-3...

-

Page 13: Safe Operation

• Do not allow passengers to ride on any part of the regulations. Never approach a machine or load that machine at any time. The operator must remain in is contacting a power source such as power lines. the seat of the machine during operation. SVL75-3... - Page 14 2. Precautions of ROPS and FOPS • Always thoroughly check the surrounding area for • For your safety, KUBOTA installs a ROPS (roll- any possible conditions that could create a over-protective-structure) and a FOPS (falling- dangerous situation.

- Page 15 (such as polycarbonate become unbalanced and rollover. door), depending upon application. KUBOTA Use caution when moving the machine on an recommends the use of a polycarbonate door incline.

- Page 16 • Lower the attachment on the loading bed and • Be alert and shut your machine down if children release the pressure from the hydraulic system. enter the work area. SVL75-3...

- Page 17 • To avoid fire, do not heat the hydraulic components • Do not open the radiator cap before the radiator (tanks, pipes, hoses, and cylinders) before they has cooled down sufficiently. have been drained and washed. SVL75-3...

- Page 18 – Always stay clear of moving parts. Clothing, dismantling of the spring of the track tensioner is hands, or other parts of the body can become necessary, contact your KUBOTA dealer. caught in moving parts of the machine and • Always attach a [DO NOT OPERATE] tag cause personal injury or death.

- Page 19 – Always make sure that the engine is off and – Clean out all accumulated flammable debris cool before removing the fuel cap to refuel the such as leaves, straw, pine needles, branches, tank. Avoid getting fuel on any hot components. bark, small wood chips, and any other SVL75-3...

- Page 20 Oil or other fluids could be solvents, filters, batteries, and any other released when caps or filters are removed before potentially harmful and hazardous material or substance. SVL75-3...

- Page 21 • To avoid sparks from an accidental short circuit, always disconnect the ground cable (-) of the battery first and reconnect it last. SVL75-3...

- Page 22 SAFE OPERATION SAFETY LABELS SVL75-3...

- Page 23 SAFE OPERATION SVL75-3...

- Page 24 SAFE OPERATION SVL75-3...

- Page 25 SAFE OPERATION SVL75-3...

- Page 26 SAFE OPERATION SVL75-3...

- Page 27 SAFE OPERATION SVL75-3...

- Page 28 SAFE OPERATION SVL75-3...

- Page 29 SAFE OPERATION SVL75-3...

- Page 30 • Clean safety labels with soap and water, dry with a soft cloth. • Replace damaged or missing safety labels with new safety labels from your KUBOTA dealer. • If a component with safety label(s) affixed is replaced with new part, make sure that new safety label(s) is (are) attached in the same location(s) as the replaced component.

-

Page 31: Service Of The Machine

SERVICE OF THE MACHINE SERVICE OF THE MACHINE DEALER SERVICE Your Kubota dealer is always ready to help you with problems with your machine and make sure that you get the most value from it. After having carefully read these instructions, you will realize that you can perform much of the routine maintenance by yourself. -

Page 32: Procedure For Scrapping The Machine

Operator's Manual even it is within the warranty period. The product(s) described in this operator's manual are designed and manufactured only for the country in which they are initially wholesaled by KUBOTA or one of its affiliated companies. Neither KUBOTA... -

Page 33: Technical Data

95 L NOTE : • Specifications are based on the machine with KUBOTA standard bucket. (Bucket weight: 216.5 kg, Bucket size: 1727 mm (68 in.) No teeth, side cutter nor bolt-on cutting edge) • Specifications are based on the machine with KUBOTA standard rubber track. (Track width: 320 mm (12.6 in.)) •... -

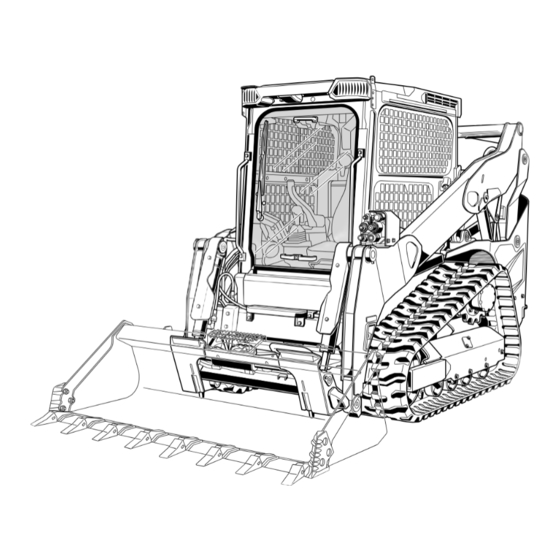

Page 34: Machine Parts

DESCRIPTION OF MACHINE PARTS MACHINE PARTS DESCRIPTION OF MACHINE PARTS (1) Bucket (4) Front working light (7) Drive motor (2) Tilt cylinder (5) Cab (8) Rubber track (3) Armrest (6) AUX supply port [A] High-Flow model (9) Lift arm stopper SVL75-3... - Page 35 MACHINE PARTS (10) Fuel tank cap (11) Rear idler (13) Front idler (15) Rear working light (12) Track roller (14) Lift arm cylinder (16) Lift arm SVL75-3...

-

Page 36: Instrument Panel And Switch

(15) User name ing indicator [A] Home screen generation indicator / engine (16) Condition of Bluetooth con- (21) Blank [B] Rearview camera screen rev up indicator nection (22) AUX operation indicator (8) Blank (17) Memo (handover) (23) Hour meter SVL75-3... -

Page 37: Handling The Touch Panel

81, and Switching to the memo screen on page 92.) (1) Item (A) Touch or tap Slide 1. Touch the slider bar on the touch panel. 2. While holding down your finger on the slider, move to the required setting value. SVL75-3... - Page 38 Indicator and memo (handover) are highlighted (1) Return button When the swipe icon is displayed, the indicator and memo notification are highlighted. Back to home screen Touch the home button to return to the home screen or the rearview camera screen. SVL75-3...

-

Page 39: Handling The Jog Dial

(2) Jog dial switch (B) Press NOTE : • Pressing the jog dial when the starter switch is in the “OFF” mode will launch the touch panel in the fuel notification mode. (See Fill level monitor when refuelling on page 34) SVL75-3... -

Page 40: Low Fuel Warning Indicator

(1) Jog dial switch (1) Cap 4. Low fuel warning indicator If the fuel in the tank goes below the prescribed level, the low-fuel-warning-indicator will blink. If the low-fuel-warning-indicator should blink during operation of the machine, refuel as soon as possible. SVL75-3... -

Page 41: Coolant Temperature Gauge

If the coolant-temperature-gauge is near [H], take the 3. To stop refueling halfway (before filling up), press following steps. the jog dial switch. 1. Discontinue the job. 2. Reduce the engine rpm to idle and keep it at idle for 5 minutes. SVL75-3... -

Page 42: Hydraulic Oil Temperature Gauge

The hour meter indicates the total operating hours of the machine. How the hour meter works • The hour meter advances one hour after an hour of operation of the machine regardless of the engine rpm. (1) Battery voltmeter SVL75-3... -

Page 43: Glow Plug Indicator

While in the self leveling mode, the mark on the (See Parking brake switch on page 96) instrument panel stays on. (1) Parking brake warning indi- (1) Self leveling switch (2) Upper indicator cator SVL75-3... -

Page 44: Master Warning Indicator

• If the master warning indicator lights up continuously after performing, consult your The battery-charge-warning-indicator lights up if the local Kubota dealer immediately. charging system fails with the engine running. When start switch mode is “ACCESSORY,” the battery- NOTE : charge-warning-indicator lights up. -

Page 45: Diesel-Particulate-Filter (Dpf) Regeneration Indicator

In such case, appears, Engine RPM” “Engine output is limited” stop the engine and consult your local KUBOTA dealer rev up the engine until the engine-rev-up-indicator and immediately. the message go out, the DPF regeneration will (See LIST OF SCREEN on page 189) automatically start. -

Page 46: Machine Setting

(1) Home switch (2) Menu icon 2. Rotate the jog dial to select the icon [Vital] and press the jog dial switch. For touch operation, touch the icon [Vital]. The vital screen appears. Vital screen shows the following items. SVL75-3... - Page 47 DPF muf- fler. Sorting the items of the vital screen 1. Rotate the jog dial to select the item sort button and press the jog dial switch. For touch operation, touch the item sort button. SVL75-3...

-

Page 48: Periodic Check

• If you touch the periodic check indicator on the (1) Home switch (2) Menu icon home screen, the list of periodic check items 2. Rotate the jog dial to select the icon [Maint.] and appears. press the jog dial switch. SVL75-3... -

Page 49: How To Read The List Of The Periodic Check Items

If 20 or more hours have passed since the maintenance time, the length of the red bar will not change. Because the maintenance time has passed, perform servicing as listed immediately. SVL75-3... -

Page 50: Service Hour Meter

• Perform the job indicated by ◎ at the first operation. • The factory default setting is shown in the maintenance table. • The message is displayed in hours of the hour meter by adding the intervals after resetting the inspection time in the list of periodic check items. SVL75-3... -

Page 51: Changing The Maintenance Interval

3. Select the button with jog dial and press the jog dial switch, or touch the button to change the maintenance interval. Button Function Decrease the maintenance interval. Increase the maintenance interval. [Restore de- Return the maintenance interval to the factory fault] default settings. SVL75-3... -

Page 52: Checking Error Messages

NOTE : • It is possible to view records from the last three months (up to 90 days ago). (1) Home switch (2) Menu icon SVL75-3... - Page 53 – When the machine and the user's mobile phone are not connected via Bluetooth. (See Setting the dealer phone number on page 76) (1) List of error messages Example of detailed message (1) Phone call button SVL75-3...

-

Page 54: Setting The Clock

For touch operation, touch [Date and Time]. 5. Setting the clock NOTE : • This setting is available only when logged in with the owner account. 1. Press the home switch or touch the menu icon to make the menu bar appear on the display. SVL75-3... - Page 55 For touch operation, touch [+] or [-] to increase or decrease the numerical value. NOTE : • When the return switch is pressed on the clock setting screen, the clock is not readjusted and returns to the previous menu screen. SVL75-3...

-

Page 56: Reordering Year/Month/Day And Selecting Am/Pm Or 24-Hour

[Date Display Format], and press the jog dial switch. For touch operation, touch [Date Display Format] or [Time Display Format]. (1) Icon 3. Rotate the jog dial to select [Date and Time], and press the jog dial switch. For touch operation, touch [Date and Time]. SVL75-3... -

Page 57: Setting The Display Language

For touch operation, touch the desired language. (1) Home switch (2) Menu icon 2. Rotate the jog dial to select the icon [Settings], and press the jog dial switch. For touch operation, touch the icon [Settings]. The list of settings appears on the display. SVL75-3... -

Page 58: Unit Setting

9. Setting the display brightness The display brightness can be set to one of 100 levels. It is possible to register separate brightness settings for when the working light is on and when the working light is off. (1) Icon SVL75-3... -

Page 59: Setting The Work Light Turn-Off Delay Function

(1) Home switch (2) Menu icon and press the jog dial switch. 5. Rotate the jog dial to the right or left to increase or decrease the display brightness, and press the jog dial switch to confirm the adjustment. SVL75-3... -

Page 60: Setting The Machine Lockout

6. Rotate the jog dial to the right or left to select the desired setting, and press the jog dial switch to confirm the selection. For touch operation, touch the button, [-], or [+] to select the desired setting. SVL75-3... -

Page 61: How To Use The Machine Lockout Function

6. Rotate the jog dial to the right or left to select the desired setting, and press the jog dial switch to confirm the selection. For touch operation, touch the button, [-], or [+] to select the desired setting. SVL75-3... -

Page 62: Setting The Reversing Fan

(2) Menu icon 2. Rotate the jog dial to select the icon [Settings], and press the jog dial switch. For touch operation, touch the icon [Settings]. 5. Rotate the jog dial to select [Interval (min)], and press the jog dial switch. SVL75-3... -

Page 63: Setting The Track Response

13. Setting the track response and press the jog dial switch. For touch operation, touch the desired response. 1. Press the home switch or touch the menu icon to make the menu bar appear on the display. (1) Home switch (2) Menu icon SVL75-3... -

Page 64: Setting The Rearview Camera

1. Press the home switch or touch the menu icon to make the menu bar appear on the display. Setting for switching to the rearview camera screen 1. Rotate the jog dial to [Camera Setting], and press the jog dial switch. For touch operation, touch [Camera Setting]. SVL75-3... - Page 65 4. Rotate the jog dial to select the icon [✔], and press the jog dial switch to save the new setting. For touch operation, touch the icon [✔]. NOTE : • To retain the previous setting, press the return switch. SVL75-3...

-

Page 66: Setting The Rearview Camera Image Position

1. Press the home switch or touch the menu icon to make the menu bar appear on the display. 2. Rotate the jog dial to select the item you wish to adjust, and press the jog dial switch. (1) Home switch (2) Menu icon SVL75-3... -

Page 67: Setting The Restriction Of The Touch Operation During The Hydraulic System Locked

5. Rotate the jog dial to the right or left to select the desired setting, and press the jog dial switch to confirm the selection. For touch operation, touch the button to select the desired setting. SVL75-3... -

Page 68: Auto Shift Adjustment

[✔]. NOTE : • To retain the previous setting, press the return switch. For touch operation, touch the return button. (1) Home switch (2) Menu icon 17. Auto shift adjustment WARNING To avoid personal injury or death: SVL75-3... - Page 69 Adjustment]. 4. Enter the owner password. 5. Perform the following operations following the instructions on the screen. a. Start the engine. b. Rotate the engine speed control dial to the leftmost (minimum) position, and release the accelerator pedal. SVL75-3...

-

Page 70: Setting The User Name

• The icon on the screen rotates while the machine is being adjusted. At this time, the engine speed increases and enters high idle (1) Home switch (2) Menu icon state in approximately 20 seconds. • Operate the left control (traveling) lever straight backward. left control SVL75-3... - Page 71 4. Enter the owner password. For touch operation, touch [User Name]. NOTE : • If you log in with an account other than the owner account, the [User Settings] screen will be displayed. See step 7 onwards. SVL75-3...

-

Page 72: Setting The User Password

11. Rotate the jog dial to select the icon [✔], and press make the menu bar appear on the display. the jog dial switch to save the new settings. For touch operation, touch the icon [✔]. (1) Home switch (2) Menu icon SVL75-3... - Page 73 For touch operation, touch the numbers you want to enter. 5. Rotate the jog dial to select [User List], and press the jog dial switch. SVL75-3...

-

Page 74: Setting Function Restrictions For Each User

20. Setting function restrictions for each user NOTE : • This setting is available only when logged in with the owner account. 1. Press the home switch or touch the menu icon to make the menu bar appear on the display. SVL75-3... - Page 75 7. Rotate the jog dial to select [User Settings], and NOTE : press the jog dial switch. • To retain the previous setting, press the For touch operation, touch [User Settings]. return switch. For touch operation, touch the return button. SVL75-3...

-

Page 76: Adding The User Account

5. Rotate the jog dial to select [Add User], and press the jog dial switch. For touch operation, touch [Add User]. (1) Icon 3. Rotate the jog dial to select [User Management], and press the jog dial switch. For touch operation, scroll the display, and touch [User Management]. SVL75-3... -

Page 77: Deleting The User Account

(See Setting function restrictions for each user on page 68) 9. Rotate the jog dial to select the icon [✔], and press the jog dial switch to save the new settings. For touch operation, touch the icon [✔]. (1) Icon SVL75-3... -

Page 78: Deleting All User Account

• This setting is available only when logged in For touch operation, touch the user account you with the owner account. wish to delete. • Deleting a user account also deletes the user's log record. (See Log record on page 45) SVL75-3... -

Page 79: Setting The Travel Alarm

Travel alarm is a sounding function that expands the back-up alarm, which normally sounds only when backing up, to sound for traveling operation in all 4. Enter the owner password. directions. To switch the travel alarm to on and off, take the following steps. SVL75-3... -

Page 80: Setting The Dealer Name

For touch operation, touch [Travel Alarm]. (1) Home switch (2) Menu icon 4. Rotate the jog dial to select [Function], and press the jog dial switch to select the desired setting. For touch operation, touch the button to select the desired setting. SVL75-3... - Page 81 4. Rotate the jog dial to select the dealer you wish to change the name, and press the jog dial switch. For touch operation, touch the dealer you wish to change the name. NOTE : • The dealer name before registration is blank. SVL75-3...

-

Page 82: Setting The Dealer Phone Number

9. Rotate the jog dial to select the icon [ ], and (1) Phone number press the jog dial switch. For touch operation, touch the icon [ 26. Setting the dealer phone number NOTE : • This setting is available only when logged in with the owner account. SVL75-3... - Page 83 For touch operation, touch [Phone Number]. jog dial switch. For touch operation, scroll the display, and touch [Dealer]. 4. Rotate the jog dial to select the dealer you wish to change the phone number, and press the jog dial switch. SVL75-3...

- Page 84 For touch operation, touch the numbers you want to enter. 9. Rotate the jog dial to select the icon [ ], and (1) Phone number press the jog dial switch. For touch operation, touch the icon [ SVL75-3...

-

Page 85: Calling The Dealer

3. Rotate the jog dial to select [Dealer], and press the jog dial switch. For touch operation, scroll the display, and touch [Dealer]. 4. Rotate the jog dial to select the phone number you want to call, and press the jog dial switch. SVL75-3... -

Page 86: Rearview Camera Mode

• Drive slowly and carefully until you become Replace damaged missing camera familiar with the wide-angle image from the immediately with new one. CMOS camera displayed on the LCD panel. SVL75-3... -

Page 87: Audio Mode

1. On the home screen, swipe the display to the right to make the audio screen appear on the display. (1) Icon How to change from the audio pop-up NOTE : • The audio pop-up appears only when the audio power is on. SVL75-3... -

Page 88: Switch Audio Power On/Off

[C] Bluetooth selected [D] Weather band selected 2. Rotate the jog dial to select the icon [More...], and press the jog dial switch to make the audio screen appear on the display. For touch operation, touch the icon [More...]. SVL75-3... -

Page 89: Operation Of Am Mode

1. Rotate the jog dial, select the auto seek down button or auto seek up button, press the jog dial switch to search for frequencies that are available for reception. For touch operation, touch the auto seek down button or auto seek up button SVL75-3... - Page 90 2. Rotate the jog dial and select the required channel, press the jog dial switch to confirm the selected channel. For touch operation, scroll to the left or right and touch the required channel. (1) Channel area (2) Channel SVL75-3...

-

Page 91: Operation Of Fm Mode

2. Rotate the jog dial and select the required channel, press the jog dial switch to confirm the selected channel. (1) Channel area (2) Channel For touch operation, scroll to the left or right and touch the required channel. SVL75-3... -

Page 92: Bluetooth Mode Operation

Bluetooth device selection screen. NOTE : For touch operation, touch the Bluetooth connection • If you cannot connect to a Bluetooth device, settings button. restart Bluetooth device connecting again. SVL75-3... - Page 93 6. Rotate the jog dial to select the icon [✔], and press the jog dial switch to save the new settings. For NOTE : touch operation, touch the icon [✔]. • The text displayed after "-" (hyphen) in the Bluetooth device name of the Machine is a SVL75-3...

-

Page 94: Operation Of The Weather Band Mode

1. Rotate the jog dial to select the auto seek down button or auto seek up button and press the jog dial switch to search for frequencies that are available for reception. For touch operation, touch the auto seek down button or auto seek up button SVL75-3... -

Page 95: Call Control For Bluetooth-Connected Cell Phone

Ending a call 1. While the Talking pop-up is displayed, rotate the jog (1) Channel area (2) Channel dial to select the end button, and press the jog dial switch to end the call. For touch operation, touch the end button. SVL75-3... -

Page 96: Adjustment Of Audio Volume

For touch operations, touch the volume increase or volume decrease buttons, or slide the button on the volume adjustment slider left or right to adjust to the required volume. (A) Outgoing call pop-up SVL75-3... - Page 97 For touch operations, touch the volume increase or volume decrease buttons, or slide the button on the volume adjustment slider left or right to adjust to the required volume. SVL75-3...

-

Page 98: Switching Audio Source

1. Touch the memo screen icon on the home screen. (1) Home switch (2) Menu icon 2. Rotate the jog dial to select the icon [Settings], and press the jog dial switch. For touch operation, touch the icon [Settings]. (1) Memo screen icon SVL75-3... -

Page 99: How To Enter A Memo

3. Rotate the jog dial left or right to select the characters you want to enter, and press the jog dial switch to enter the memo. For touch operation, touch the characters you want to enter. SVL75-3... - Page 100 For touch operation, touch the icon [✔]. NOTE : • The user name of the user entering the memo is displayed on the memo display screen. (A) Memo display screen (B) Name of user who entered the memo SVL75-3...

-

Page 101: Switches, Electrical Outlet, And Usb Outlet

(6) AUX electrical control switch (13) Return switch (22) AUX port switch (29) Reversing fan switch (7) AUX port variable switch (14) Jog dial (23) Wiper switch (30) Electrical outlet (8) AUX hold switch (left) (15) Jog dial switch (31) USB outlet SVL75-3... -

Page 102: Start Switch

0.5 seconds or more. When the hydraulic system has been locked, the travel system gets locked too, and the brakes are applied. • The status of the parking brake is memorized, and even if the start switch is turned “OFF” SVL75-3... -

Page 103: Hydraulic Unlock Switch

2. When pressing the travel-speed-switch again, the buzzer beeps once, the travel speed changes from high to low speed, and the symbol appears. IMPORTANT : • The travel speed automatically changes into first speed (low speed) when drive resistance increases while traveling in second SVL75-3... -

Page 104: Working Light Switch

2. When pressing the inhibit-DPF-regeneration-switch • Press a second time and the rear working light once again, the automatic mode returns from turns on. Both the upper indicator and the lower disable. indicator light up. SVL75-3... -

Page 105: Float Switch

• Move up the lift arm (pulling the right-control-lever This switch is used to enable the AUX port and also to backward). enable the High-Flow mode. CAUTION [High-Flow model only] To avoid personal injury: • Be careful high-flow- incompatible attachment High-Flow SVL75-3... -

Page 106: Aux Port Variable Switch

12. AUX port variable switch With the AUX port unlocked, the flow rate of the hydraulic oil varies depending on the tilt angle of the AUX-port-variable-switch. • Right-hand control The flow rate of the hydraulic oil through the right- hand port (male) varies. SVL75-3... -

Page 107: Aux Electrical Control Switch (Option)

AUX-electrical-mode-change-function will turn switch back to the lock position. off. The AUX-electrical-mode-change-indicator and the light on the AUX-electrical-mode-change-switch will go off. (1) Hydraulic quick-hitch switch (A) Unlock (2) Guard (B) Lock (C) Slide SVL75-3... -

Page 108: Self Leveling Switch

This machine is only equipped with the beacon light switch (It contains a coupler for connecting and is located in the speaker cover at the back right of the cab). The machine is not equipped with the beacon main part. Please install the part if required. SVL75-3... -

Page 109: Emergency Engine Stop Button

2. The switch will return to automatic operation when released. (1) Start switch (2) Emergency engine stop but- NOTE : • If the emergency engine stop button is activated, a message will appear on the display as shown in the following figure. SVL75-3... -

Page 110: Electrical Outlet And Usb Outlet

21. Electrical outlet and USB outlet Max power of electrical outlet is less than 120 W. If you need another auxiliary electric, contact your Kubota dealer for details. Max output current of USB outlet is less than 2 A. (1) Electrical outlet... -

Page 111: Pedal And Levers

CONTROL PEDALS AND LEVERS PEDAL AND LEVERS PEDAL AND LEVERS CONTROL PEDALS AND LEVERS (1) Left control (traveling) lever (3) Armrest (2) Right control (front operating) (4) Seat lever (5) Accelerator pedal SVL75-3... -

Page 112: Safety Features

HOW TO USE AND CHECK THE 2. If clear, engage hydraulics and start to reverse. FUNCTION OF THE ARMREST Alarms should sound. If not, check by your KUBOTA dealer. 1. Sit in the operator's seat. 2. Fasten the seat belt. SVL75-3... -

Page 113: How To Use The Forced Lift Arms Lowering Device

3. Push the lever to make sure that the lift arms descend. 4. Release the lever to make sure that the lift arms stop descending. 5. Place the rubber cap back to its original position. (1) Rubber cap (A) Push (2) Lever SVL75-3... -

Page 114: Exhaust Aftertreatment Device

DPF, the engine may automatically stop. DPF regeneration system The catalyst-containing-DPF-device has the following On the Kubota CTL, the ECU prompts the DPF- two functions. regeneration cycle. When starting the engine, auto- • Reducing certain emissions, like hydrocarbon (HC) regeneration-mode is set by default. - Page 115 • The DPF regeneration usually takes about the following times. DPF regeneration time 15 minutes to 20 minutes The DPF regeneration time depends, however, on the outside air temperature, exhaust gas temperature and filter PM level. • Do not interrupt the DPF regeneration cycle unnecessarily. SVL75-3...

-

Page 116: Air Conditioner

Rear air outlet port (right side) (A) Windshield (C) Chest area (B) Foot area Front air outlet port (right side) (A) Windshield (C) Chest area (A) Windshield (B) Foot area (1) Fresh air inlet AIR CONTROL VENT CAUTION To avoid personal injury: SVL75-3... - Page 117 Front air outlet port (left side) (A) Windshield (D) Closed (C) Chest area Rear air outlet port (right side) (A) Windshield (C) Chest area (B) Foot area (D) Closed (A) Windshield (D) Closed (C) Chest area SVL75-3...

-

Page 118: How To Use The Control Panel

Defrosting or demisting To defrost or demist the windshield, take the following steps. 1. Open the front-air-outlet and direct it to the windshield. 2. Set the blower switch to the [3] position and set the temperature-control-dial [warm] (rightmost) position. SVL75-3... -

Page 119: Operation

The upper indicator lights up. • Press a second time and the wiper activates continuously. The lower indicator lights up. • Press a third time and the wiper stops. Both the upper indicator and the lower indicator go out. SVL75-3... - Page 120 (2) Lock lever Closing the cab door from outside 2. Pull the handles slightly upward and toward 1. Before closing, unlock the cab door in place by yourself to let the cab door slide inward. moving both lock pins to inside. SVL75-3...

-

Page 121: Opening And Closing The Side Cab Window

3. To close the side window, slide it forward or backward until the lock snaps into the window frame. 4. Turn the knob bolt after closing the window. SVL75-3... -

Page 122: Starting The Engine

3. Repeat the following step 2. through step 5.. If not, the system is malfunctioned. Contact your • If the battery is dead and must be connected to local KUBOTA dealer. another battery with jumper cable, use a 12 V battery. Never use any 24 V batteries. -

Page 123: Checking The Machine After Starting The Engine

IMPORTANT : • If any preceding conditions occur, check the machine and consult your local KUBOTA dealer for service of the machine. 3. Adjusting the engine speed (1) Setting value of engine (A) Low idling engine speed... -

Page 124: Stopping The Engine

(same) voltage is permissible. • Do not connect the black jumper cable to the negative (-) terminal of the machine battery. 1. Bring the helping machine with the same battery voltage as near as possible to the machine. SVL75-3... -

Page 125: Operation Of The Machine

• Adjust the seat so that full pedal travel can be achieved with the operator's body against back of the seat. • Make sure that the machine is equipped with a lighting system that is adequate for the job conditions. SVL75-3... -

Page 126: How To Use The Seat Belt

To avoid personal injury or death: • Always use the seat belt with a ROPS and FOPS protection structure. Adjust the operator's seat to the optimal position and buckle it up. • Always fasten the seat belt securely before starting the engine. SVL75-3... -

Page 127: How To Use The Armrest

3. Driving WARNING To avoid personal injury or death: • Before starting the engine, make sure that no one is near the machine. 3.1 Traveling forward and backward To move forward 1. Push the left control (traveling) lever forward. SVL75-3... -

Page 128: Turning The Machine

1. Tilt the left control (traveling) lever forward to the right. 4. Turning the machine CAUTION To avoid personal injury: • Before changing direction of the machine, beware of people in the work area. • Make sure that the bucket or attachment is lowered on the ground. SVL75-3... -

Page 129: How To Use Spin Turn

To lower the lift arms 1. Push the right-control-lever (front-operating-lever) 4.2 How to use spin turn forward. To spin the machine left 1. Tilt the left control (traveling) lever to the left. (1) Left control (traveling) lever (A) Tilt (B) Left SVL75-3... -

Page 130: How To Use The Lift Arm Stopper

2. Remove the front attachment. 3. Stop the engine. 4. Ask the second person to remove the lift-arm- stopper from the storage position. (1) Lift arm stopper (2) Knob bolt 5. Start the engine. 6. Set parking-brake-switch parking position. SVL75-3... -

Page 131: Operating The Bucket

(3) Knob bolt 11. Start the engine. 12. Set the parking brake switch to the parking position. 13. Slowly lower the lift arms against the lift-arm- stopper. Removing 1. Sit in the operator's seat with the seat belt fastened. SVL75-3... - Page 132 NOTE : • To stop the bucket operation, return the right- control-lever (front-operating-lever) neutral position. (1) Right control (front operat- (A) Tilt ing) lever (B) Roll back To dump the bucket 1. Tilt the right-control-lever (front-operating-lever) to the right. SVL75-3...

-

Page 133: Auxiliary Hydraulic

[High-Flow model only] on page 99. (2) Female coupler (small) (3) Male case drain coupler 1. Start the engine. (4) Male coupler (large) (See Starting the engine on page 116 and Start of (5) Female coupler (large) the machine on page 119) SVL75-3... -

Page 134: Operating The Attachment Control Device (Option)

NOTE : (1) 14-pin coupler • The oil flow rate responds to the tilt of the AUX-port-variable-switch. • Press the AUX-hold-switch, and the oil continues to flow at its highest flow rate. To interrupt the oil flow, press AUX-hold-switch again. SVL75-3... -

Page 135: Advanced Multifunction Valve (Amv)

14-pin coupler harness connection chart Ref. no. Pin port Remarks AUX 1st func. AUX 1st func. AUX 2nd func. AUX 2nd func. AUX 3rd func. AUX 3rd func. AUX electrical mode change +12 V NOTE : • AUX 3rd func. is momentary action. SVL75-3... -

Page 136: Quick-Hitch

1. Push the hydraulic quick-hitch switch in the tilt cylinders. unlocked position and hold it to make sure that the quick-hitch levers are up (unlocked position). (1) Quick-hitch 3. Ease the quick-hitch mounting plate into the saddle of the attachment. SVL75-3... - Page 137 – The lock pins of the quick-hitch have to 2. Stop the engine. protrude into and through the pin slots The parking brake automatically engages. of the attachment on both sides. SVL75-3...

- Page 138 (front-operating-lever) dump position until the attachment is pushed away from the quick-hitch. 6. Lower the lift arms so that the quick-hitch mounting plate clears the saddle of the attachment. 7. Back the machine away from the attachment slowly. SVL75-3...

-

Page 139: Radio

Do not remove the – On-site radio stations for moving object sticker. identification used in factory production • Disassembling or modification of this product is lines, etc. (radio stations that require a punishable by law. license) SVL75-3... - Page 140 This may cause the microphone to under the blazing sun, etc., which may cause malfunction. failure. Situations when the hands-free function cannot be used • Hands-free operation is not possible in the following cases: – When outside the calling area SVL75-3...

-

Page 141: Machine Precaution

• Never scoop or grade areas while the tilt cylinders are fully extended. Extremely heavy loads apply excessive traction force to the bucket cylinders and can cause damage. Avoid loads that are too heavy. SVL75-3... -

Page 142: Precautions When Traveling On Inclines

169) • Never allow the main body of the machine to become submerged in water or sand. Contact your KUBOTA Dealer or Service Outlet if the main body of the machine is exposed to water. 4. Precautions when traveling on... -

Page 143: Prohibited Actions For The Machine

• Never move, transport material, or operate the machine in the following places: mud, broken stone, jagged or unstable base rock, iron beams, iron scrapes, iron sheets, and so on. Navigating, turning, and moving the machine over sharp material may damage or break the tracks. SVL75-3... -

Page 144: Lifting

4. Set the armrest to the locked position. • Master links, 2pc. 5. Apply the parking brake switch. • Do not lift loads that exceed the maximum rated Model name SVL75-3 capacity of the hoist and attaching hardware. Model type Closed Cab • Refer... - Page 145 • Locations to apply the pads (1) Hook (A) LH – Cab top (2) Lifting fixture mount (Rear tie (B) RH down point) – Lift arm – Track – Track frames SVL75-3...

- Page 146 • Never put yourself around the machine when it is lifted. • Never lift the machine with person in operator station or on the attachment. Procedure for lifting the machine 1. Lift the machine slowly and vertically. 2. Move the machine slowly into place. SVL75-3...

-

Page 147: Transporting

7. If the bucket or attachment is installed, avoid the bucket or attachment contact with ramps during travel. 8. Once the machine is loaded, lower the bucket or attachment completely. 9. Stop the engine, and set the parking brake. SVL75-3... -

Page 148: Towing An Operable Machine

Therefore it may be necessary to use the alternate front center tie-down for securement of the machine. Use two separate straps or chains as shown in the following figure and secure the attachment with a separate strap or chain. Consult SVL75-3... -

Page 149: Towing An Inoperable Machine

TOWING AN INOPERABLE MACHINE WARNING To avoid personal injury or death: • Towing an inoperable machine will damage the hydraulic drive or track system. Contact your local KUBOTA dealer for towing an inoperable machine. SVL75-3... -

Page 150: Maintenance

– The paint, coating, and plating may peel away. IMPORTANT : • Do not remove the plate (step). Once this plate is removed, the airtightness of the cab will degrade. SVL75-3... - Page 151 MAINTENANCE (1) Plate (step) SVL75-3...

-

Page 152: Maintenance Intervals

○ every 500 hrs draulic tank ◎ Hydraulic oil filter replace ○ ○ ○ ○ ○ every 500 hrs clean ○ ○ ○ ○ ○ every 500 hrs Front window roller replace ○ ○ ○ every 1000 hrs (Continued) SVL75-3... - Page 153 173. Clean and replace the air cleaner element more frequently if used under dusty conditions. When the filter is very dirty from dusty conditions, replace the filter. Consult your local Kubota dealer for this service. SVL75-3...

- Page 154 Air-conditioner pipes and hose replace every 2 years service as re- Refrigerant (gas) check quired Clean and replace the air filter more frequently if used under dusty conditions. When the filter is very dirty from dusty conditions, replace the filter. SVL75-3...

-

Page 155: Opening And Closing Of Components

(1) Lever (A) Turn NOTE : • Before detaching the rear upper covers, remove dirt or debris off the cover top and around the covers. This is to prevent such (2) Rear door deposits from coming into the cooling system. SVL75-3... -

Page 156: Opening The Air-Conditioner Condenser

3 from the hook 2, and remove the rear upper cover 3. 5. While pulling the rear upper cover 4 backward, raise the back side of the rear upper cover 4 and open it. (1) Lever (C) Unlock SVL75-3... -

Page 157: Opening The Fan Motor Cover

1. Clean the cab tilt fulcrums before tilting the cab. 2. Set the armrest to the raised position. (1) Retainer (A) Turn 3. Remove the lock bolts from the front of the (2) Fan motor cover (B) Pull off machine. SVL75-3... - Page 158 • The required force to lift the cab is affected 1. Set the stopper lock to the release position. by the temperature. (1) Stopper lock (A) Release (1) Cab (A) Fig [A] 2. Support release latching (B) Raise mechanism. SVL75-3...

-

Page 159: Discharging Mud From Operator Cab And Main Frame

(1) Floor outlet (2) Bolts (2) Lock bolt Tightening torque 77.5 N⋅m to 90.2 N⋅m DISCHARGING MUD FROM OPERATOR CAB AND MAIN FRAME 1. Discharging mud from the operator cab 1. With removing the bolts, remove the floor outlets. SVL75-3... -

Page 160: Discharging Mud From The Main Frame

WARNING 1. Tilt the cab. To avoid personal injury or death: 2. Open the rear door. SVL75-3... -

Page 161: Checking The Coolant Level

• See Purging of the fuel system on page 180. • To prevent condensation (water) accumulations in the fuel tank, fill the fuel tank full before parking overnight. SVL75-3... -

Page 162: Checking The Engine Oil Level

To check the oil level, follow the following procedure. 1. Draw out the dipstick. 2. Wipe the dipstick clean. 3. Replace the dipstick. 4. Draw the dipstick out again. 5. Check to see that the oil level lies between the two notches. SVL75-3... -

Page 163: Lubrication Points Of The Machine

• Check the rubber hoses for damage and replace them if they are cracked or old. Check if the hose clamps are tight enough. SVL75-3... -

Page 164: Checking And Cleaning The Engine And The Electrical Wiring

4. Then loosen the drain plug and let out water until the float drops down to the bottom. WARNING To avoid personal injury or death: • Always stop the engine before cleaning the wiring, the cables, and the engine. SVL75-3... -

Page 165: Checking The Evacuator Valve

• Before checking or cleaning the DPF muffler, stop the engine and wait long enough until it is cooled down. (1) Evacuator valve NOTE : • If evacuator valve missing damaged, the air cleaner does not function properly. Accordingly, its element's service life will get shorter. SVL75-3... -

Page 166: Checking The Washer Liquid

Half filled of the washer-liquid-tank about 0.8 liter 16. Checking the battery condition DANGER To avoid the possibility of a battery explosion: For refillable type battery, follow following instructions. SVL75-3... -

Page 167: Checking The Air-Conditioner Condenser And The Reverse Fan

• The battery self-discharges while it is stored. Recharge the battery once every three months in hot seasons and once every six months in cold seasons. 17. Checking the air-conditioner condenser and the reverse fan WARNING To avoid personal injury or death: SVL75-3... -

Page 168: Cleaning The Fuel Tank Cap

2. Blow air through the vent holes to remove dust or 3. Reinstall the drain cap. dirt in the vent path. 3. Clean if the tank cap filter becomes dirty. 4. Assemble the fuel tank cap, gasket and tank cap filter. SVL75-3... -

Page 169: Checking The Track Tension

• Once every 250 hours or after every sixth cleaning, whichever comes first, replace the air 2. Lift the track from the ground as shown. cleaner elements. • Do not remove the inner element. If removed, replace it with new one. SVL75-3... -

Page 170: Cleaning The Air Cleaner Element

4. Cleaning the air cleaner element • Do not tap-clean the element. The element may get deformed, which may adversely affect the air cleaner performance. WARNING To avoid personal injury or death: • Wear eye protection. SVL75-3... -

Page 171: Cleaning The Evacuator Valve

• If the machine is used in extremely dusty areas, (1) Fresh air filter (3) Thumbscrew (2) Cover clean the fresh-air-filter more frequently than in the specified maintenance periods. 1. Remove the thumbscrews and cover, and pull out the fresh-air-filter. SVL75-3... -

Page 172: Cleaning The Recirculation Air Filter

Under 205 kPa (2.1 kgf/ cm Carry out all 50 hour servicings at the same time. 1. Changing the engine oil WARNING To avoid personal injury or death: • First stop the engine, and wait long enough for the oil to cool down. SVL75-3... -

Page 173: Replacing The Engine Oil Filter Cartridge

2. Replacing the engine oil filter cartridge 1. Place a container underneath the engine-oil-filter- cartridge to catch the spilled engine oil. 2. Replace the engine-oil-filter-cartridge at the same time as changing the engine oil. a. Remove the engine-oil-filter-cartridge with the filter wrench. SVL75-3... -

Page 174: Checking The Fuel Line And The Intake Air Line

• If the engine is run with a loose alternator belt, the belt could slip and cause insufficient battery charging. Check V-belt tension regularly. • If the alternator belt breaks or jumps off, the indicator light for battery charge will light up. Stop the engine immediately. SVL75-3... -

Page 175: Checking And Adjusting The Air-Conditioner Belt Tension

4. Replace the V-belt if worn out, cracked, or torn. 5.1 Checking and adjusting the air- conditioner belt tension 1. Press the air-conditioner belt down in the middle, with the following force. Pressing force Approx. 98.0 N (10 kgf) (1) Plate SVL75-3... -

Page 176: Replacing The Air Cleaner Element

1. Set the shutoff-valve of the water separator to the (8000 hours or service as required). close position. • Use KUBOTA genuine inner and outer element. 2. Loosen and remove the cup properly and replace • Do not blow air to clean the case inside. It the filter element. -

Page 177: Replacing The Fuel Filter Cartridge

Use prescribed gear oil SAE 90. WARNING To avoid personal injury or death: • Keep fire away. IMPORTANT : • If you do not replace the fuel-filter-cartridge regularly, the cleaning efficiency of the DPF (8000 hours or service as required) will be SVL75-3... -

Page 178: Changing The Return Filter

173. (1) Hydraulic oil filter 7. Cleaning the front window roller (1) Return filter Consult your local KUBOTA dealer for cleaning the front window roller. 5. Replacing the hydraulic breather filter The breather filter for the hydraulic tank is located above the hydraulic tank. -

Page 179: Checking The Air-Conditioner Drain

See RECOMMENDED OILS on page 207 section. Do not mix different oils. 1. Park the machine on a firm, flat, and level surface. 2. Lower the lift arms to the ground, and stop the engine. (1) Drain plug (2) Oil drain hose SVL75-3... -

Page 180: Hydraulic Oil Check With The Hydraulic Hammers

100 Hrs. more every 200 Hrs. 3. Adjusting the engine valve clearance Consult your local KUBOTA dealer for adjusting the engine valve clearance. 4. Replacing the front window roller (1) Return filter 9. Install the tank cover. Consult your local KUBOTA dealer for replacing the 10. -

Page 181: Every 1500 Service Hours

Carry out all 50, 100, 250, and 500 hour servicing at the same time. 1. Checking the injector tip Consult your local KUBOTA dealer for checking the injector tip. 2. Checking the EGR cooler Consult your local KUBOTA dealer for checking the EGR cooler. -

Page 182: Annual Servicing

“DPF requires cleaning soon” filter (DPF) exhaust gas temperature appears on the display. sensor ANNUAL SERVICING Consult your local KUBOTA dealer for checking the DPF exhaust gas temperature sensor. 1. Checking the air-conditioner pipes and hoses 8. Checking the EGR piping for gas... -

Page 183: Checking The Relief Valve

5. Loosen the bolts and slide the under cover on the bottom of the frame. (1) CCV internal pressure switch 11. Checking the relief valve Consult your local KUBOTA dealer for checking the relief valve. BIENNIAL SERVICING (1) Under cover (A) Slide 1. - Page 184 (1) Radiator cap 8. To clean, rinse the radiator with water. 9. Close the drain plug and return the coolant drain hose to its original position as following figure. SVL75-3...

-

Page 185: Replacing The Fuel Hose

Checking the fuel line and the intake air line on page 168. (1) Radiator hose (2) Hose clamps 6. Replacing the coolant rubber piping Consult your local Kubota dealer for replacing the coolant rubber piping. 7. Replacing the air-conditioner pipes and hoses WARNING To avoid personal injury or death: •... -

Page 186: Replacing The Diesel-Particulate-Filter (Dpf) Differential Pressure Sensor Rubber Piping (Front And Back)

2. Air-conditioner belt is loosened. back) If there is nothing unusual with the above points, a shortage of refrigerant is possible. Too short refrigerant Consult your local KUBOTA dealer for the DPF- may cause a poor performance of the air-conditioner. differential-pressure-sensor-rubber-piping (front Consult your local KUBOTA dealer for servicing and back). -

Page 187: Cleaning The Plastic Parts And Synthetic Leather

• Wipe off any remaining moisture or detergent with a soft cloth that has been moistened with water and then thoroughly wrung out. • Cleaning the plastic parts with alkaline, acidic, or organic solvents such as alcohol or benzene can damage them. SVL75-3... -

Page 188: Track

(B) Front turning over. Clearance between outer end of track roller a. Put the machine on the jack stand. 20 mm to 30 mm and track interior surface (A) SVL75-3... - Page 189 2. Additionally follow the following points when adjusting rubber tracks. • Check track tension 50 hours after initial use and readjust if necessary. • Check and adjust thereafter every 50 service hours. IMPORTANT : • Clean the track after every use. SVL75-3...

-

Page 190: Fuse

Beacon 10 A (1) Cover (3) Fuse box (2) Fuse and relay box Wiper/Washer 15 A Arm harness 10 A Attachment - 2 20 A Attachment - 1 Blank Air ride seat 20 A Electric outlet 15 A (Continued) SVL75-3... -

Page 191: Slow Blow Fuse

Alternator 100 A Bolted NOTE : • The fuse of No.22 is not set at the factory. When Engine 30 A Plug-in using the attachments-1, contact your KUBOTA Glow/CAB 60 A Plug-in dealer. Slow blow fuse B Protected circuit Capacity... - Page 192 (1) Slow blow fuse case cap (4) Bolted slow blow fuse (2) Cover (3) Bolt 2.94 N⋅m to 3.92 N⋅m M5 bolt (0.30 kgf⋅m to 0.40 kgf⋅m) Tightening torque 4.90 N⋅m to 5.88 N⋅m M6 bolt (0.50 kgf⋅m to 0.60 kgf⋅m) SVL75-3...

-

Page 193: Troubleshooting

Clogged oil filter • Replace the oil filter. Armrest is in the raised position. • Lower the armrests. Lift arms, bucket, or travel motor can not move. Operator is not in the operator's seat. • Sit in the operator's seat. (Continued) SVL75-3... - Page 194 Track too loose or too tight • Adjust the track accordingly. mark appears in the • Check the error code number of NAVIGATION Electric system Electric system is malfunctioning. SCREENS on page 189 and contact your local dealer. instrument panel. SVL75-3...

-

Page 195: List Of Screen

If an error occurs in the machine, one of the following messages appears on the display. In case of trouble, immediately contact your local Kubota dealer for inspection and repair. To view detailed information, rotate and press the jog dial, or touch the error message (does not apply to numbers 1 through 4). - Page 196 Contact your local dealer. High Flow Solenoid circuit. are still operative. High Flow operation may not work. Short Circuit detected on the The other functions of the machine Contact your local dealer. High Flow Solenoid circuit. are still operative. (Continued) SVL75-3...

- Page 197 Both machine operation and traveling Open circuit detected on main are possible, but machine perform- Contact your local dealer. travel pressure sensor. ance may be reduced. (Continued) SVL75-3...

- Page 198 If the error still appears, con- automatically. tact your local dealer. The engine output is limited. Stop the Engine and check for debris in the cooling pack- Engine Coolant Temperature is age. elevated. If the error still appears, con- tact your local dealer. (Continued) SVL75-3...

- Page 199 Please check the Periodic Check The engine can still start, but imme- After replacement, this mes- Screen to see the required main- diately ask your local Kubota dealer sage will disappear once you tenance. for replacement. reset the time of the relevant...

- Page 200 DPF regeneration. Air filter is clogged. It may cause the serious damage on the En- Clean the air filter element. gine. The coolant temperature is too During engine warm up, the engine low. RPM will be limited. (Continued) SVL75-3...

- Page 201 The Engine Output is limited to pre- immediately. vent the Engine Failures. DPF Regeneration is required The Engine Output is limited to pre- immediately and must be per- Contact your local dealer. vent the Engine Failures. formed by your local dealer. (Continued) SVL75-3...

- Page 202 The Coolant Temperature seems whether the Grill or Radiator to be high. is clogged. Continuous operation of revers- Operation of reversing fan is prohibit- Please wait for the regenera- ing fan during DPF regeneration tion to complete. is prohibited. SVL75-3...

-

Page 203: Automatic Diesel Particulate Filter (Dpf) Regeneration

Blinking Unless the auto regeneration starts, (red) consult your local Kubota dealer. DPF must be repaired. To protect the DPF, the engine output is limited. Immediately contact your local Kubota When the hydraulic system is locked, the engine dealer. -

Page 204: Locking And Releasing The Diesel Particulate Filter (Dpf) Regeneration

LOCKING AND RELEASING THE DIESEL PARTICULATE FILTER (DPF) REGENERATION LOCKING AND RELEASING THE DIESEL PARTICULATE FILTER (DPF) REGENERATION 1. Press the inhibit switch (1). The automatic DPF regeneration is locked and the inhibit lamp on the display lights up. (1) Inhibit switch (1) Inhibit lamp SVL75-3... - Page 205 • DPF must be repaired. • To protect the DPF, engine output is limited. Immediately contact your local Kubota • When the hydraulic system is locked, dealer. the engine will stop after 60 seconds (Refer to No. 44 and 68 in Navigation list of in order to protect DPF.

-

Page 206: Engine System Error

1. Engine error list ◎:Sure to happen 〇:May happen Engine performance Problem of failure Provisional measure and correction Accelera- Engine out- Engine tion limited put limited stopped 〇 〇 Engine Speed Sensor System Immediately contact your local dealer. (Continued) SVL75-3... - Page 207 2 Main Relay System Immediately contact your local dealer. 4 Engine Atmospheric Pressure Sen- Immediately contact your local dealer. 〇 sor System 523572 523574 523574 ◎ 523575 Engine EGR Valve System Immediately contact your local dealer. 523576 523577 523578 (Continued) SVL75-3...

- Page 208 Engine Fuel System (Fuel Leak- ◎ ◎ 1239 Immediately contact your local dealer. age) ◎ ◎ 1347 7 Engine Fuel System (SCV) Immediately contact your local dealer. 523539 2 Engine Fuel System (Supply ◎ ◎ Immediately contact your local dealer. Pump) 523540 (Continued) SVL75-3...

- Page 209 Engine Differential Pressure Sen- This error is determined after the engine is 〇 〇 sor System warmed up. 523634 523635 Engine ECU System Immediately contact your local dealer. 〇 523636 ◎ 1 Battery Voltage System Immediately contact your local dealer. SVL75-3...

-

Page 210: Cold Weather

• The antifreeze acts as an anti-corrosive, it is not necessary to add an additive to the water and antifreeze mixture. • See Checking the coolant level on page 155 for radiator fill volumes. • See STARTING THE ENGINE UNDER COLD CONDITIONS on page 117. SVL75-3... -

Page 211: Long Storage

Lower the lift arms on the ground. To ensure safety in operation, inspect and service the machine at regular intervals. For added safety, ask your KUBOTA dealer to replace the following important STORING THE MACHINE FOR A component parts. - Page 212 Intake air line To prevent serious damage to the hydraulic system, use only a KU- BOTA genuine hydraulic hose. IMPORTANT : • When the biennial operating hours are below 4000 hours, change the important component parts every 2 years. SVL75-3...

-

Page 213: Recommended Oils

– See the following table for the suitable API classification engine oil and the fuel. Engine oil classification (API classification) Fuel used Oil class of engines except external DPF Ultra Low Sulfur Fuel [< 0.0015 % (15 ppm)] CJ-4 or CK-4 SVL75-3... - Page 214 • Filters must trap fuel and lubricant sulfate additives (Zn, Pb, Na, K, Ca, Mg, Cu, Ba, P, etc.) as ash during combustion. You must control the fuel carefully to prevent the additives being mixed into fuel such as the fuel tank anti-oxidants, the water remover, the antifreeze, and so on. SVL75-3...

-

Page 215: Biodiesel Fuel (Bdf)

8. The Kubota warranty, as specified in the owner's warranty information guide, only covers defects in product materials and workmanship. Accordingly, any problems that may arise due to the use of poor quality fuels that fail to meet the above requirements, whether biodiesel or mineral oil based, are not covered by the Kubota warranty. Routine handling: 1. -

Page 216: Appendices

APPENDICES MAIN DIMENSIONS OF THE MACHINE APPENDICES MAIN DIMENSIONS OF THE MACHINE Model SVL75-3 Length of track on ground 1436 mm Track gauge 1355 mm Length w/o bucket 2844 mm Length w/bucket on ground 3609 mm Height to top of cab 2078 mm Bucket hinge pin height at max. - Page 217 • Dimensions are based on the machine with Kubota standard bucket. Bucket size 1727 mm No teeth, side cutter nor bolt-on cutting edge • Dimensions are based on the machine with Kubota standard rubber track. Track width 320 mm • Specifications are subject to change without notice.

-

Page 218: Software Information

• If you purchase this product, you may obtain, copy, modify and distribute the applicable source code under the OSS licenses. Disclaimer This product includes “Open Source Software”, which is provided “as is” and Kubota shall not be liable for any damages arising out of this software and its use or the inability to use it. SVL75-3... -

Page 219: Index

112 AUX port switch............99 operating............. 112 AUX port switch [High-Flow model only]..... 99 control pedals............105 AUX port variable switch........... 100 coolant level auxiliary hydraulic control..........127 checking.............. 155 operating............. 127 coolant rubber piping replacing..............179 coolant temperature gauge......... 35 SVL75-3... - Page 220 (front and back) opening .............. 151 replacing..............180 fill level monitor DPF (diesel-particulate-filter) muffler refuelling..............34 checking.............. 159 float switch..............99 DPF (diesel-particulate-filter) regeneration indicator...39 FM mode driving................121 Operation.............. 85 fresh air filter cleaning...............165 front window roller EGR cooler cleaning...............172 checking.............. 175 replacing..............174 SVL75-3...

- Page 221 11 checking.............. 156 maintenance interval hydraulic oil temperature gauge........36 changing..............45 hydraulic quick-hitch..........130 maintenance intervals..........146 hydraulic quick-hitch switch ........101 master warning indicator..........38 hydraulic tank memo suction filter and return filter........173 procedure for entering...........93 hydraulic unlock switch..........97 SVL75-3...

- Page 222 44 washing whole machine........158 side cab window............115 prevention of slippage of rubber tracks..... 137 slow blow fuse............185 prohibited actions............137 replacing..............185 Software information..........212 specification table............27 spin turn..............123 start of the machine........... 119 SVL75-3...

- Page 223 171 travel speed switch use................ 97 travel system setting..............62 traveling..............121 troubleshooting engine and other systems........187 turbocharger checking.............. 175 unit setting..............52 USB outlet............95,104 user account adding..............70 deleting..............71 deleting all............. 72 user name setting..............64 user password setting..............66 SVL75-3...

Need help?

Do you have a question about the SVL75-3 and is the answer not in the manual?

Questions and answers

Where in the manual does it list oil capacities?