Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AIRONN AIR-AU Series

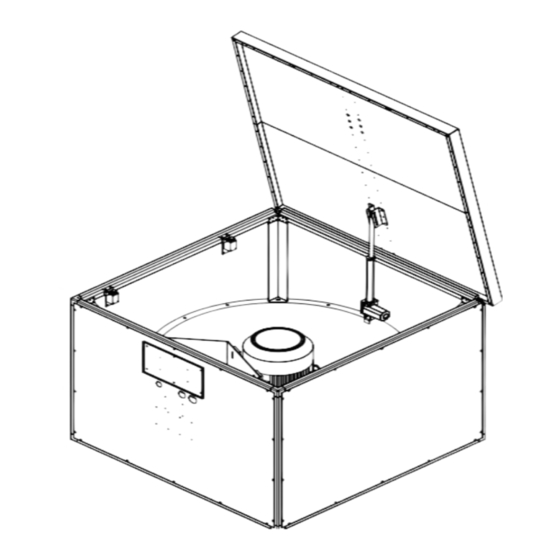

- Page 1 USER MANUAL LOBBY TYPE AXIAL FAN SERIES AIR-AU SERIES FOR ROOFS...

-

Page 2: Table Of Contents

GUARANTEE TERMS ..................6 SPECIAL WARRANTY CONDITIONS ............... 8 USER RESPONSIBILITIES AND WARRANTY ........... 9 PRODUCT KNOWLEDGE ................10 PRODUCT DESCRIPTION .................10 AIRONN AIR-AU SERIES FAN LABEL ............12 AREA OF USE ..................13 PACKAGING CONTENT ................13 ABOUT THE MACHINE GENERAL NOTES ..........14 ABBREVIATIONS ..................15 OVERALL DIMENSIONS ................16... - Page 3 ASSEMBLY INSTRUCTIONS .................29 AXIAL HOUSING ROOF TYPE FAN INSTALLATION ........29 ELECTRIC CONNECTION INSTRUCTIONS ............31 ELECTRIC CONNECTION DIAGRAM ............34 PRODUCT USE ....................35 MANUAL USE ..................35 AUTOMATION WITH USE ..............35 MAINTENANCE INFORMATION ..............36 PERIODIC MAINTENANCE DONE ............36 POSSIBLE FAULTS AND REMEDY ............38 WARRANTY CERTIFICATE ................40...

-

Page 4: Figures List

LIST OF FIGURES PAGE NO FIGURE DESCRIPTION Shape - 1 Axial Swing Roof Type Fresh Air Fan Series Axial Backplane Roof Type Fresh Air Fan Series Tag Shape - 2 Example Axial Backplane Roof Type Fresh Air Fan Series General... -

Page 5: Company Information

COMPANY INFO AIRONN HAVALANDIRMA VE KLİMA SİSTEMLERİ SAN. DIŞ TİC. LTD. ŞTİ HEAD OFFICE : ÇAMLIK MAH. SENOL GÜNEŞ BULVARI NO: 28/A ÜMRANİYE/İSTANBUL FACTORY : KARATEPE MAH. CUMHURIYET CAD. MERA SOK. N0:13 KARTEPE/KOCAELİ TEL / FAX : +90 216 594 5696 / +90 216 594 5717 www.aironn.com.tr... -

Page 6: Guarantee And Service

2. Follow the instructions in the user manual while using your product. This warranty given by AIRONN Ventilation does not cover the elimination of malfunctions caused by using the product other than the instructions specified in the user manual. In addition, the following situations are not covered by the warranty. -

Page 7: Guarantee Terms

All parts on the product are guaranteed under the assurance of AIRONN Ventilation. covered. In case of a possible malfunction of the product, the repair cannot exceed 20 working days and the repair period is added to the warranty period. - Page 8 In case of malfunction 6 (six) times within the period and in case of not being able to benefit from the goods caused by these malfunctions, Exceeding the specified maximum time for repair in case of, It is determined that the repair of the malfunction is not...

-

Page 9: Special Warranty Conditions

SPECIAL WARRANTY CONDITIONS 1. Our company is responsible for the damage that may occur during the transportation and installation of the customer. is not. 2. Failures that may occur during the warranty period are only repaired by our company's service personnel or service personnel who have received the necessary training and are authorized by us. -

Page 10: User Responsibilities And Warranty

USER RESPONSIBILITIES AND WARRANTY AIRONN is in no way responsible for the following except those included in this user manual. cannot be held. All kinds of laws and norms do not allow. from uses Inappropriate and unsuitable of the area and structure where the machine will be used. -

Page 11: Product Knowledge

PRODUCT INFORMATION PRODUCT DESCRIPTION Aironn Lobby Type Roof Fresh Air Fan series fans max. It is suitable for operation at 55 °C. Backstage Axial Roof Type Fresh Air fans, which are offered in the diameter range of 400 mm – 1250 mm, prevent heat transfer under normal conditions thanks to their motorized retractable cover and 50 mm thermal insulation. - Page 12 Fan Body The body of the fans is made of high quality sheet metal and coated with corrosion-resistant hot-dip galvanization. Fan flanges are manufactured by bending from the body and thus the fans are self-flange. It is produced as a long body as standard.

-

Page 13: Aironn Air-Au Series Fan Label

AIRONN AIR-AU SERIES FAN LABEL Figure – 2: Axial Lobby Type Roof Fresh Air Fan Series Label Example AIR – AU-SERIES Page 12... -

Page 14: Area Of Use

AREA OF USE AIR-AU Series Axial Lobby Type Roof Type Fresh Air Fans; It is used for pressurization in systems such as stairs and elevator shafts, and for fresh air supply in systems such as parking lots, hospitals, warehouses. -

Page 15: About The Machine General Notes

If the instructions in the user manual are not followed will occur no danger damage or any situation AIRONN VENTILATION AND AIR CONDITIONING SYSTEMS Ltd.' It cannot constitute a good binding reason . Giving all kinds of training and information to the user personnel in accordance with the employer CE norms has to. -

Page 16: Abbreviations

ABBREVIATIONS AIR – XX / XXX – XX – XX / XX – X – XX Motor Frequency (Hz) Motor Pole Number (P) Engine Power (kW) Propeller Blade Angle(⁰) Number of Blades Fan Diameter (mm) Fan Type AU – Axial Fan AIR –... -

Page 17: Overall Dimensions

OVERALL DIMENSIONS Figure – 3: Axial Lobby Type Roof Fresh Air Fan Series General Dimensions AIR – AU-SERIES Page 16... -

Page 18: General Security Instructions

GENERAL SAFETY INSTRUCTIONS **In this section, the safety instructions that must be followed during the transportation, installation, use, maintenance and scrapping of the machine are given. WARNING LABELS ON THE MACHINE Electric Yes Caution Spinning Machine Warning Hand Jamming... -

Page 19: Handling And Transport During

DURING HANDLING AND SHIPPING In order for your product not to suffer any damage during transportation; While packaging the product, care was taken to ensure that it was suitable for normal transportation conditions. Always in its original package to avoid possible damage or damage. must be moved. - Page 20 If there is any damage during transportation, take photos of the damaged products and take a record, and immediately report to the Aironn Logistics Department representative and the shipping company . please report. The product should not be lifted by holding the electrical cables or the junction box.

- Page 21 Follow the instructions below during handling and shipping; 1- Make sure that the packaging of the products is done correctly and securely before putting them on the transport vehicle. should 2- Before lifting or transporting the fan or its accessories, determine the following: Please: ...

- Page 22 PLACING ANY MATERIAL, TOOLS OR LOAD ON THE PRODUCTS IS PROHIBITED! ** AIRONN cannot be held responsible for any negative situation that may arise during the transportation of the product. AIR – AU-SERIS...

-

Page 23: During Installation And Placement

DURING INSTALLATION AND PLACEMENT Follow the safety instructions below during installation and placement; The products should be transported safely to the place where they will be used in the enterprise with suitable vehicles. The products are placed on the floor slowly and in the correct position. -

Page 24: Operation During

DURING THE OPERATION The machine described in the user manual has been manufactured according to the appropriate principles, taking into account the applicable law. The machine is equipped with necessary technical solutions and devices to prevent any risk of accident. -

Page 25: Care During

DURING MAINTENANCE During the periodical maintenance of the machine, signs with the warning statement 'machine is in maintenance' should be placed on the machine and in the area where the maintenance is performed. Maintenance operations should only be carried out by trained and competent personnel. - Page 26 THE ELECTRICAL CONNECTION OF THE MACHINE MUST BE DISCONNECTED COMPLETELY BEFORE STARTING THE MAINTENANCE PROCESS! MAINTENANCE OR REPAIR SHOULD NEVER BE DONE WHILE THE MACHINE IS WORKING! ** While some parts of the machine are routinely checked and maintained, the machine may need to be in working condition. In this case, if the engineer, maintenance person or technician leaves the machine, the machine must be shut down.

-

Page 27: Scrapped Separation During

DURING SCRAPING All parts of the machine are made from recyclable materials. Thus, all parts can be reused as raw materials. No materials that could harm human health were used in the production of the machine. When the machine has completed its service life, it can be separated down to the smallest component and safely sent to the relevant recycling facilities. -

Page 28: Product Storage

STORAGE OF THE PRODUCT Follow the instructions below when storing the product after receipt. Make sure that the product is protected against all weather conditions by covering it with a tarpaulin. should be. The product should be stored in a closed area without being unpacked until it is time for assembly. - Page 29 General warning; The product is shipped from our factory either wrapped in stretch film on a pallet or in a box. If water enters between the stretch film on the product delivered to the customer or stored in the assembly area, the product faces the risk of corrosion.

-

Page 30: Assembly Instructions

The on-site assembly of the fan and bringing it to its balance must be carried out by qualified personnel only. Incorrect mounting or fan base may cause malfunctions. In these cases, the products are not commissioned by Aironn authorized personnel and the products are excluded from the warranty. ... - Page 31 Assembly; should be made using bolts, nuts and washers. Vibration pads must be properly connected between the connecting feet of the device and the surface to be mounted. The weight of the device must be mounted on the vibration wedge in such a way that it exerts force in the compression direction in any case.

-

Page 32: Electric Connection Instructions

ELECTRICAL CONNECTION INSTRUCTIONS Before electrical wiring is connected, the existing electricity is directly from the source. should be cut. When mounting the apparatus, make sure that the mounting elements have the capacity to carry the weight of the product and that all connections are made correctly. - Page 33 In case of a possible problem, if the thermal circuit opens (when the product does not work), the system is reset from the mains and reactivated. should be taken. Product wiring, as in the electrical wiring diagram should be.

- Page 34 Motor power PN ≤ 3 kW PN > 3 kW Way of Giving 3 ~ 400V 3 ~ 400V Direct Connection Y - Connection (15b) ∆ - Connection (15a) Y / ∆ - Connection Impossible Remove bridges (15c) Table 1: Electrical connection table according to engine power Figure 7: ∆...

-

Page 36: Product Use

USE OF THE PRODUCT Axial backplane roof type fresh air fans have easy-to-use features. These usage features vary according to the wishes of the users. These; 1- Manual use 2- with automation use MANUAL USE With manual use, it is possible to use the product by operating from a switch or fuse. -

Page 37: Maintenance Information

MAINTENANCE INFORMATION PERIODIC MAINTENANCE Simple anomalies may require simple maintenance interventions while the machine is starting to separate. Although these interventions are simple, they can be done by the operator. More complex interventions should be performed by trained caregivers. Other complex interventions are carried out by the manufacturer's technical service. - Page 38 The product must never come into direct contact with water or pressurized water. should not. **AIRONN company does not take responsibility for malfunctions and personnel safety caused by a reason contrary to this booklet. **Electrical maintenance of the machine must be carried out regularly by trained specialist personnel on a daily, weekly, monthly and semi- annual basis.

-

Page 39: Possible Faults And Remedy

POSSIBLE FAULTS AND THEIR REMEDIES MECHANICAL FAULTS ARIZA NEDEN ÇÖZÜM Civata ve somunların torkla sıkılması Civata ve somun gevşemeleri Vibrasyona maruz kalmak kendinden flanşlı civata, somun ve vibrasyon takozu kullanılması Vibrasyon takoz kafalarının kopması, Vibrasyon takozları iki yıl garanti altındadır. - Page 40 ELECTRICAL FAULTS ARIZA NEDEN ÇÖZÜM Düzensiz elektrik, istenilen düzeyde genlik İşletme görevlisinin enerji nakil hattını sağlanamaması. Motor elektrik klemens Voltaj arızası regüle etmesi veya faz dağılımını eşit bağlantılarında gevşeme, pano ve panodan dağıtması sonraki hatlarda düzensizlik Motorun devreye girmemesi Yıldız veya üçgen bağlantılarının olmaması...

-

Page 41: Warranty Certificate

WARRANTY CERTIFICATE MANUFACTURER OR IMPORTER COMPANY AIRONN HAVALANDIRMA VE KLİMA SİSTEMLERİ TITLE SAN. DIŞ TİC. LTD. ŞTİ ÇAMLIK MAH. SENOL GÜNEŞ BULVARI NO: 28/A ADDRESS ÜMRANİYE/İSTANBUL TEL / FAX (0216) 594 5696 / (0216) 594 5717 SIGNATURE AND STAMP OF THE...

Need help?

Do you have a question about the AIR-AU Series and is the answer not in the manual?

Questions and answers