Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AIRONN AIR-J-U Series

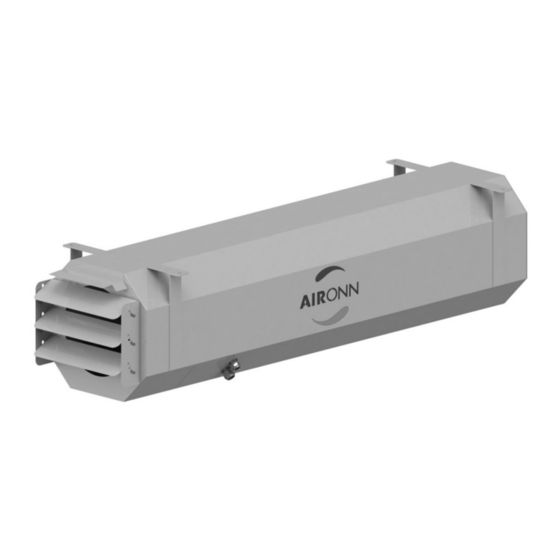

- Page 1 USER MANUAL AXIAL AIR-J-U SERIES UNIDIRECTIONAL JET FAN...

-

Page 2: Table Of Contents

SPECIAL WARRANTY TERMS................. 8 USER'S RESPONSIBILITIES AND WARRANTY ..........9 PRODUCT INFORMATION ................10 PRODUCT DESCRIPTION ................. 10 AİRONN AIR-J-U SERIES FAN LABEL ............11 AREA OF USE ..................12 PACKAGE CONTENTS ................12 GENERAL NOTES ABOUT THE MACHINE ..........13 ABBREVIATIONS .................. - Page 3 ASSEMBLY INSTRUCTIONS ................. 28 ELECTRICAL CONNECTION INSTRUCTIONS ..........30 ELECTRICAL CONNECTION DIAGRAM ............ 33 PRODUCT USE .................... 34 1-MANUAL OPERATION ................. 34 2-AUTOMATED USE ................34 CARE INFORMATION .................. 35 PERIODIC MAINTENANCE............... 35 POSSIBLE MALFUNCTIONS AND ELIMINATION ........37 WARRANTY CERTIFICATE ................

-

Page 4: List Of Figures

LIST OF FIGURES PAGE NO FIGURE DESCRIPTION Figure - 1 Axial Unidirectional Jet Fan Series Figure - 2 Axial Unidirectional Jet Fan Series Label Sample Axial Unidirectional Jet Fan Series Overall Figure - 3 Dimensions Figure - 4 Warning labels on the machine... -

Page 5: Company Information

COMPANY INFORMATION AIRONN HAVALANDIRMA VE KLİMA SİSTEMLERİ SAN. DIŞ TİC. LTD. ŞTİ CENTRAL : TATLISU MAH. ŞENOL GÜNEŞ BULVARI MİRA TOWER OFFICE KAT: 3 D: 16 ŞERİFALİ/ATAŞEHİR/İSTANBUL : KARATEPE MAH. CUMHURİYET CAD. MERA SOK. N0:13 FACTORY KARTEPE/KOCAELİ TEL / FAX : +90 216 594 5696 / +90 216 594 5717 www.aironn.com.tr... -

Page 6: Warranty And Service

Certificate approved by your Authorized Dealer. 2. Follow the instructions in the user manual when using your product. This warranty given by AIRONN Ventilaiton does not cover the elimination of malfunctions caused by the use of the product outside the instructions specified in the user manual. The following conditions are also excluded from the warranty: 1. -

Page 7: Warranty Terms

All parts on the product are under warranty under the assurance of AIRONN Ventilation. In the event of a malfunction, the repair of the product cannot exceed 20 working days and the repair period is added to the warranty period. - Page 8 6 (six) times within the warranty period specified by the manufacturer or importer, and in case of failure to benefit from the goods caused by these failures, If the maximum time specified for repair is exceeded, ...

-

Page 9: Special Warranty Terms

SPECIAL WARRANTY TERMS 1. Our company is not responsible for any damage that may occur during transportation and assembly by the customer. 2. Any malfunctions that may occur during the warranty period shall only be repaired by our service personnel or by service personnel who have received the necessary training and authorized by us. -

Page 10: User's Responsibilities And Warranty

USER'S RESPONSIBILITIES AND WARRANTY AIRONN cannot be held responsible in any way for the following except as included in this user manual. Any use not permitted by laws and norms The area and structure where the machine will be used is inappropriate and unfavorable ... -

Page 11: Product Information

PRODUCT INFORMATION PRODUCT DESCRIPTION Aironn Axial Unidirectional Jet Fan series fans have 300 °C-2 hours and 400 °C-2 hours certificates in accordance with EN 12101-3. The series with 290 mm - 400 mm diameter range has high performance thanks to its airfoil blade structure. -

Page 12: Ai̇ronn Air-J-U Series Fan Label

IP 55 electrical connection box in galvanized steel body is offered as standard. Accessories Maintenance Switch AİRONN AIR-J-U SERIES FAN LABEL JET FAN –UNIDIRECTION TESTED Figure - 2: Axial Unidirectional Jet Fan Series Label Sample A I R - J U S E R İ S İ... -

Page 13: Area Of Use

THIS MANUAL. IT IS STRICTLY FORBIDDEN TO USE THE MACHINE FOR OTHER THAN THESE PURPOSES !!! AIRONN shall not be liable for any damages resulting from the use of the machine for other than its intended purpose. The machine's operating capacity is limited to the channel dimensions on the label. -

Page 14: General Notes About The Machine

No danger, damage or any condition that may occur if the instructions in the user manual are not followed cannot be a binding reason for AIRONN HAVALANDIRMA VE KLİMA SİSTEMLERİ Ltd. The employer is obliged to provide all kinds of training and information to the user personnel in accordance with CE norms. -

Page 15: Abbreviations

ABBREVIATIONS AIR – XX – XXX Fan Diameter (mm) 290, 315, 355, 400 Fan Type JU - Axial Jet Fan A I R - J U S E R İ S İ Page 14... -

Page 16: Overall Dimensions And Technical Specifications

OVERALL DIMENSIONS AND TECHNICAL SPECIFICATIONS ØN 1508 1500 1650 1880 Figure - 3: Axial Unidirectional Jet Fan Series Overall Dimensions A I R - J U S E R İ S İ Page 15... -

Page 17: Table

SINGLE CYCLE Sound Level Motor Thrust Motor Current at 3m Weight Type Speed Power (kW) Drawn (A) Distance (kg) (rpm) (dBA) AIR-J-U-290 0.75 1.57 2790 60 / 45 AIR-J-U-315 0.75 1.57 2790 60 / 45 AIR-J-U-355 3.01 2870 68 / 52 AIR-J-U-400 4.48... -

Page 18: General Safety Instructions

GENERAL SAFETY INSTRUCTIONS **This section contains safety instructions to be followed during transportation, installation, use, maintenance and scrapping of the machine. WARNING LABELS ON THE MACHINE There's an Caution Rotating electricity Machine Warning Danger of the Grounding Standing Under... -

Page 19: During Transportation And Shipping

DURING TRANSPORTATION AND SHIPPING To prevent any damage to your product during transportation; When packing the product, care has been taken to ensure that it is suitable for normal transportation conditions. It should always be transported in its original packaging to avoid possible damage and loss. - Page 20 Check that the product has not been damaged during transportation. If any missing or damaged part(s) are found, the transportation company and Aironn Logistics Department must be informed immediately verbally and in writing. When receiving the devices in the field, check from the delivery note that the parts shipped separately and unassembled from the device are shipped in a separate box.

- Page 21 IT IS FORBIDDEN TO PLACE ANY MATERIAL, TOOL OR LOAD ON THE PRODUCTS! ** AIRONN cannot be held responsible for any adverse situation that may arise during the transportation of the product.

-

Page 22: During Installation And Placement

DURING INSTALLATION AND PLACEMENT Observe the following safety instructions during installation and positioning; Products must be transported to the place where they will be used within the enterprise with appropriate vehicles and in a safe manner. Products should be lowered to the floor slowly and in the correct position. -

Page 23: During Operation

DURING OPERATION The machine described in the operating instructions has been manufactured according to appropriate principles, taking into account the law in force. The machine is equipped with the necessary technical solutions and devices to prevent any risk of accidents. -

Page 24: During Maintenance

DURING MAINTENANCE During the periodic maintenance of the machine, signs with the warning phrase 'the machine is under maintenance' should be placed on the machine and in the area where maintenance is carried out. Maintenance must only be carried out by trained and competent personnel. - Page 25 THE MACHINE MUST BE COMPLETELY DISCONNECTED FROM THE MAINS BEFORE STARTING MAINTENANCE ! DANGER GETTING STUCK NEVER PERFORM MAINTENANCE OR REPAIR WORK WHILE THE MACHINE IS RUNNING! ** During routine inspection and maintenance of some parts of the machine, it may be necessary to keep the machine running. In this case, the machine must be switched off if the engineer, maintenance person or technician leaves the machine.

-

Page 26: During Scrapping

DURING SCRAPPING All parts of the machine are made from recyclable materials. All parts can thus be reused as raw material. No materials that may harm human health have been used in the production of the machine. At the end of its service life, the machine can be disassembled down to the smallest component and safely sent to the relevant recycling facilities. -

Page 27: Product Storage

PRODUCT STORAGE Please follow the instructions below when storing the product after receipt; The product should be covered with a tarpaulin to ensure that it is protected against all weather conditions. The product should be kept in a closed area without being unpacked until the installation time. - Page 28 General warning; The product is shipped from our factory wrapped in stretch film on the pallet or in a box. If water enters between the stretch film on the product delivered to the customer or stored at the assembly site, the product faces the danger of corrosion.

-

Page 29: Assembly Instructions

ASSEMBLY INSTRUCTIONS Please pay attention to the following instructions during the installation of the products; Before starting installation, make sure that there is no visible damage to the motor supply cables and that the fan wheel rotates freely. -

Page 30: Figure - 5 Axial Unidirectional Jet Fan Connection Type

CONSTRUCTION CEILING Figure - 5: Axial Unidirectional Jet Fan Connection Form A I R - J U S E R İ S İ Page 29... -

Page 31: Electrical Connection Instructions

ELECTRICAL CONNECTION INSTRUCTIONS Before connecting the electrical cables, the existing power must be disconnected directly at the source. When mounting the apparatus, make sure that the mounting elements are capable of supporting the weight of the product and that all connections are made correctly. - Page 32 The electrical connection information (frequency, voltage, power, etc.) indicated on the product must match the electrical connection information at the place of installation. For safety reasons, make sure that the grounding terminal on the terminal block is connected to the building earth line.

-

Page 33: Figure - 6 ∆ Connection

In the unlikely event of a burnout of the electrical safety device, immediately disconnect the power supply from the mains. Check the entire installation again carefully before operating the product. If you encounter any problems, please contact the authorized persons. -

Page 34: Electrical Connection Diagram

ELECTRICAL CONNECTION DIAGRAM A I R - J U S E R İ S İ Page 33... -

Page 35: Product Use

PRODUCT USE Axial Unidirectional Jet Fans have easy operation features. These usage features vary according to the wishes of the users. These are; 1- Manual operation 2- Automated use 1-MANUAL OPERATION With manual use, it is possible to operate the product by operating it from the pako switch or fuse. -

Page 36: Care Information

CARE INFORMATION PERIODIC MAINTENANCE Simple abnormalities during machine start-up may require simple maintenance interventions. These interventions are simple and can be performed by the operator. More complex interventions should be carried out by trained caregivers. Other complex interventions must be carried out by the manufacturer's technical service. - Page 37 The product must never come into direct contact with water or pressurized water. **AIRONN assumes no responsibility for malfunction and personnel safety due to any reason contrary to this manual. **Electrical maintenance of the machine must be carried out regularly in daily, weekly, monthly and semi-annual periods by trained specialized personnel.

-

Page 38: Possible Malfunctions And Elimination

POSSIBLE MALFUNCTIONS AND ELIMINATION MECHANICAL FAILURES FAILURE REASON SOLUTION Bolt and nut loosening Exposure to vibration Torque tightening of bolts and nuts using self-flanged bolts and nuts and vibration wedges Breakage of the vibration chock vibration wedges Replacing vibration... -

Page 39: Table - 4 Possible Electrical Faults And Their Elimination

ELECTRICAL FAULTS FAILURE REASON SOLUTION Voltage failure Irregular electricity fails to provide the operator regulates phase desired level of amplitude. Loosening of distributes the power transmission line. motor electrical terminal connections and irregularities in the panel and lines after the panel. -

Page 40: Warranty Certificate

WARRANTY CERTIFICATE MANUFACTURER OR IMPORTER COMPANY AIRONN HAVALANDIRMA ve KLİMA SİSTEMLERİ SAN. TITLE ve DIŞ TİC. LTD. STİ. Tatlısu Mah. Şenol Güneş Bulvarı Mira Tower Kat:3 ADDRESS D:16 Şerifali / İstanbul TEL / FAX (0216) 594 5696 / (0216) 594 5717...

Need help?

Do you have a question about the AIR-J-U Series and is the answer not in the manual?

Questions and answers