Table of Contents

Advertisement

Quick Links

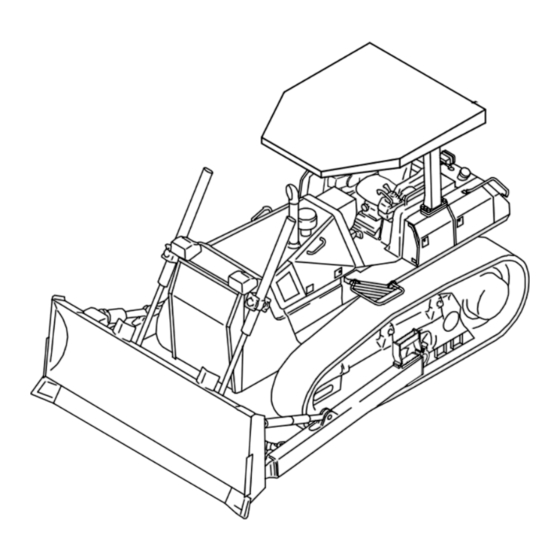

BULLDOZER

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this machine.

This manual should be kept near the machine for

reference and periodically reviewed by all personnel who

will come into contact with it.

Komatsu has Operation & Maintenance Manuals

written in some other languages. If a foreign language

manual is necessary, contact your local distributor for

availability.

D65EX

D65PX

D65WX

SERIAL NUMBERS

WARNING

NOTICE

TEN00276-02

-15E0

-15E0

-15E0

D65EX- 71069

D65PX- 71069

and up

D65WX-69105

Advertisement

Chapters

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Komatsu ecot 3

- Page 1 This manual should be kept near the machine for reference and periodically reviewed by all personnel who will come into contact with it. NOTICE Komatsu has Operation & Maintenance Manuals written in some other languages. If a foreign language manual is necessary, contact your local distributor for availability.

- Page 2 1 - 1...

-

Page 3: Before Reading This Manual

If this manual is lost or damaged, contact your distributor immediately to arrange for its replacement. For details regarding the machine serial No. you will need to provide your Komatsu distributor, see "TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR (PAGE 1-9)". - Page 4 Continuing improvements in the design of this machine may lead to additional changes that are not reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information concerning your machine or with questions regarding information contained in this manual.

-

Page 5: Important Safety Information

FOREWORD IMPORTANT SAFETY INFORMATION IMPORTANT SAFETY INFORMATION To enable you to use the machine safely, and to prevent injury to operators, service personnel or bystanders, the precautions and warnings included in this manual and the safety signs attached to the machine must always be followed. -

Page 6: Intended Use

FOREWORD INTENDED USE INTENDED USE USE OF MACHINE This Komatsu machine is designed to be used mainly for the following work: Dozing Smoothing Cutting into hard or frozen ground or ditching Felling trees, removing stumps See the section "WORK POSSIBLE USING BULLDOZER (PAGE 3-106)" for further details. -

Page 7: Visibility From Operator's Seat

FOREWORD INTENDED USE VISIBILITY FROM OPERATOR'S SEAT The visibility standards (ISO 5006) for this machine require a view shown in the diagram below. PROXIMITY VISIBILITY The figure bellows shows a front visibility from the machine at a spot 1.0 m away from the side and 1.5 m above the ground. -

Page 8: Location Of Plates, Table To Enter Serial No. And Distributor

LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR When ordering replacement parts, please inform your Komatsu distributor of the following. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE This is at the front bottom right of the operator's seat. -

Page 9: Additional Epa Nameplate

FOREWORD LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ADDITIONAL EPA NAMEPLATE The additional EPA nameplate is located on top of the engine head cover on the left side of the machine. EPA: Environmental Protection Agency, U.S.A. SERVICE METER POSITION The service meter is provided at the lower part of the monitor panel. - Page 10 FOREWORD LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR Machine serial No. Engine serial No. Product identification number (PIN) Distributor name Address Service Personnel Phone/Fax 1 - 9...

-

Page 11: Table Of Contents

FOREWORD CONTENTS CONTENTS FOREWORD BEFORE READING THIS MANUAL IMPORTANT SAFETY INFORMATION INTENDED USE USE OF MACHINE GENERAL VIEW AND DIRECTIONS OF MACHINE VISIBILITY FROM OPERATOR'S SEAT LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE ENGINE SERIAL NO. - Page 12 FOREWORD CONTENTS CAP WITH LOCK 3- 49 DOOR - OPEN LOCK 3- 51 SASH GLASS INTERMEDIATE LOCK 3- 51 DOOR POCKET 3- 52 OPENING AND CLOSING ENGINE SIDE COVER 3- 52 ASHTRAY 3- 53 CUP HOLDER 3- 53 TOOL BOX 3- 53 SHOVEL HOLDER 3- 54...

- Page 13 RECOMMENDED FUEL, COOLANT, AND LUBRICANT 4- 12 USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE 4- 13 RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL 4- 14 STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS 4- 15 TORQUE LIST...

- Page 14 FOREWORD CONTENTS HANDLING MACHINES EQUIPPED WITH KOMTRAX 6- 27 BASIC PRECAUTIONS 6- 27 INDEX 1 - 13...

- Page 16 2 - 1...

-

Page 17: Safety

SAFETY SAFETY SAFETY SAFETY LABELS POSITIONS OF SAFETY PICTOGRAMS SAFETY LABELS GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE 2- 10 PRECAUTIONS BEFORE STARTING OPERATION 2- 10 ENSURING SAFE OPERATION 2- 10 UNDERSTANDING THE MACHINE 2- 10 PREPARATIONS FOR SAFE OPERATION 2- 10 PRECAUTIONS REGARDING SAFETY-RELATED EQUIPMENT 2- 10... - Page 18 SAFETY SAFETY PRECAUTIONS FOR OPERATION 2- 16 PRECAUTIONS FOR JOBSITE 2- 16 INVESTIGATE AND CONFIRM JOBSITE CONDITIONS 2- 16 WORKING ON LOOSE GROUND 2- 16 DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES 2- 17 ENSURE GOOD VISIBILITY 2- 17 CHECKING SIGNS AND SIGNALMAN'S SIGNALS 2- 17 BEWARE OF ASBESTOS DUST 2- 18...

- Page 19 SAFETY SAFETY PRECAUTIONS FOR MAINTENANCE 2- 27 PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE 2- 27 DISPLAY WARNING TAG DURING INSPECTION AND MAINTENANCE 2- 27 KEEP WORKPLACE CLEAN AND TIDY 2- 27 SELECT SUITABLE PLACE FOR INSPECTION AND MAINTENANCE 2- 27 ONLY AUTHORIZED PERSONNEL 2- 27 APPOINT LEADER WHEN WORKING WITH OTHERS...

-

Page 20: Safety Labels

When cleaning the labels, do not use organic solvents or gasoline. They may cause the labels to peel off. If the labels are damaged, lost, or cannot be read properly, contact your Komatsu distributor immediately regarding their replacement. For details concerning the part numbers for the labels, see this manual or the actual label. -

Page 21: Safety Labels

SAFETY SAFETY LABELS SAFETY LABELS (1) Caution before operating or maintaining machine (09651-03001) (2) Caution before moving in reverse (09802-13000) (3) Caution for leaving operator's seat (09654-33001) 2 - 6... - Page 22 SAFETY SAFETY SAFETY LABELS SAFETY LABELS (4) Caution for high-temperature coolant (09668-03001) (5) Caution for high-temperature oil (09653-03001) (6) Caution for accumulator (09659-53000) (7) Caution for adjusting track tension (09657-03003) The safety label is attached to the back side of the cover of the track adjustment window.

- Page 23 SAFETY SAFETY SAFETY LABELS SAFETY LABELS (8) Caution for battery cable (09808-03000) (9) Caution for engine running (09667-03001) (10) Caution for approach when machine moving (09812-13000) (11) Jump start prohibited (09842-A0481) 2 - 8...

- Page 24 SAFETY SAFETY SAFETY LABELS SAFETY LABELS (12) Precautions when handling battery (13) Caution for ROPS (09620-B2000) (14) Caution for FOPS (09620-C2000) 2 - 9...

-

Page 25: General Precautions Common To Operation And Maintenance

SAFETY GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE Mistakes in operation, inspection, or maintenance may result in serious personal injury or death. Before carrying out operation, inspection, or maintenance, always read this manual and the safety labels on the machine carefully and obey the warnings. -

Page 26: Keep Machine Clean

SAFETY GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE KEEP MACHINE CLEAN If you get on or off the machine or carry out inspection and maintenance when the machine is dirty with mud or oil, there is a hazard that you will slip and fall. Wipe off any mud or oil from the machine. Always keep the machine clean. -

Page 27: Fire Prevention

SAFETY GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE FIRE PREVENTION ACTION IF FIRE OCCURS Turn the start switch OFF to stop the engine. Use the handrails and steps to get off the machine. Do not jump off the machine. There is the danger of falling and suffering serious injury. PRECAUTIONS TO PREVENT FIRE Fire caused by fuel, oil, antifreeze, or window washer fluid Do not bring any flame or fire close to flammable substances... -

Page 28: Precautions When Getting On Or Off Machine

SAFETY GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE Explosion caused by lighting equipment When checking fuel, oil, battery electrolyte, or coolant, always use lighting with anti-explosion specifications. When taking the electrical power for the lighting from the machine itself, follow the instructions in this manual. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE USE HANDRAILS AND STEPS WHEN GETTING ON OR OFF MACHINE To prevent personal injury caused by slipping or falling off the machine, always do as follows. -

Page 29: Do Not Get Caught In Work Equipment

SAFETY GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE NO PEOPLE ON ATTACHMENTS Never let anyone ride on the work equipment or other attachments. There is a hazard of falling and suffering serious personal injury or death. PRECAUTIONS WHEN STANDING UP FROM OPERATOR'S SEAT When standing up from the operator's seat to adjust the operator's seat, always lower the work equipment completely to the ground, set work equipment lock lever (1) and parking brake lever (2) to the... -

Page 30: Precautions Related To Protective Structures

If the protective structure is damaged or deformed by falling objects or by rolling over, its strength will be reduced and it will not be able to fulfill its function properly. In such cases, always contact your Komatsu distributor for advice on the method of repair. -

Page 31: Precautions For Operation

SAFETY PRECAUTIONS FOR OPERATION PRECAUTIONS FOR OPERATION PRECAUTIONS FOR JOBSITE INVESTIGATE AND CONFIRM JOBSITE CONDITIONS On the jobsite, there are various hidden dangers that may lead to personal injury or death. Before starting operations, always check the following to confirm that there is no danger on the jobsite. When carrying out operations near combustible materials such as thatched roofs, dry leaves or dry grass, there is a hazard of fire, so be careful when operating. -

Page 32: Do Not Go Close To High-Voltage Cables

SAFETY PRECAUTIONS FOR OPERATION DO NOT GO CLOSE TO HIGH-VOLTAGE CABLES Do not travel or operate the machine near electric cables. There is a hazard of electric shock, which may cause serious personal injury or death. On jobsites where the machine may go close to electric cables, always do as follows. -

Page 33: Beware Of Asbestos Dust

Do not allow other persons to approach during the operation. Always observe the rules and regulations for the work site and environmental standards. This machine does not use asbestos, but there is a danger that imitation parts may contain asbestos, so always use genuine Komatsu parts. 2 - 18... -

Page 34: Starting Engine

SAFETY PRECAUTIONS FOR OPERATION STARTING ENGINE USE WARNING TAGS If there is any "DANGER! Do NOT operate!" warning tag displayed, it means that someone is carrying out inspection and maintenance of the machine. If the warning sign is ignored and the machine is operated, there is danger that the person carrying out inspection or maintenance may be caught in the rotating parts or moving parts and suffer serious personal injury or death. -

Page 35: Precautions When Starting

SAFETY PRECAUTIONS FOR OPERATION PRECAUTIONS WHEN STARTING Start and operate the machine only while seated. When starting the engine, sound the horn as a warning. Do not allow anyone apart from the operator to ride on the machine. Do not attempt to start the engine by short-circuiting the engine starting circuit. This may cause fire, serious personal injury or death. -

Page 36: Operation

SAFETY PRECAUTIONS FOR OPERATION OPERATION CHECKS BEFORE OPERATION If the checks before starting are not carried out properly, the machine will be unable to display its full performance, and there is also danger that it may lead to serious personal injury or death. When carrying out the checks, move the machine to a wide area where there are no obstructions, and pay careful attention to the surrounding area. -

Page 37: Precautions When Traveling

SAFETY PRECAUTIONS FOR OPERATION PRECAUTIONS WHEN TRAVELING Never turn the starting switch key to the OFF position when the machine is traveling. If the engine stops when the machine is traveling, it may become impossible to operate the steering, and this may cause serious personal injury or death. -

Page 38: Traveling On Slopes

SAFETY PRECAUTIONS FOR OPERATION TRAVELING ON SLOPES To prevent the machine from tipping over or slipping to the side, always do as follows. Keep the work equipment approx. 20 to 30 cm (8 to 12 in) above the ground. In case of emergency, lower the work equipment to the ground immediately to help stop the machine. -

Page 39: Traveling On Snow-Covered Or Frozen Surfaces

SAFETY PRECAUTIONS FOR OPERATION TRAVELING ON SNOW-COVERED OR FROZEN SURFACES Snow-covered or frozen surfaces are slippery, so be extremely careful when traveling or operating the machine, and do not operate the levers suddenly. Even a slight slope may cause the machine to slip, so be particularly careful when working on slopes. -

Page 40: Transportation

The machine can be divided into parts for transportation, so when transporting the machine, please contact your Komatsu distributor to have the work carried out. LOADING AND UNLOADING When loading or unloading the machine, mistaken operation may bring the hazard of the machine tipping over or falling, so particular care is necessary. -

Page 41: Towing

SAFETY PRECAUTIONS FOR OPERATION TOWING PRECAUTIONS WHEN TOWING Always use the correct towing equipment and towing method. Any mistake in the selection of the wire rope or towing bar or in the method of towing a disabled machine may lead to serious personal injury or death. For details of the procedure for towing, see the "METHOD OF TOWING MACHINE (PAGE 3-130)"... -

Page 42: Precautions For Maintenance

SAFETY PRECAUTIONS FOR MAINTENANCE PRECAUTIONS FOR MAINTENANCE PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE DISPLAY WARNING TAG DURING INSPECTION AND MAINTENANCE Always display the "DANGER! Do NOT operate" warning tag during the inspection and maintenance. If there is any "DANGER! Do NOT operate!" warning tag displayed, it means that someone is carrying out inspection and maintenance of the machine. -

Page 43: Stop Engine Before Carrying Out Inspection And Maintenance

SAFETY PRECAUTIONS FOR MAINTENANCE STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE Lower the work equipment completely to the ground and stop the engine before performing any inspection and maintenance. Turn the starting switch to the ON position, operate the work equipment control lever to the RAISE and LOWER position 2 or 3 times repeatedly to release the remaining pressure in the hydraulic circuit, then set parking brake lever (1) and work... -

Page 44: Two Workers For Maintenance When Engine Is Running

SAFETY PRECAUTIONS FOR MAINTENANCE TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING To prevent personal injury, do not carry out maintenance with the engine running. If maintenance must be carried out with the engine running, carry out the operation with at least two workers and do as follows. One worker must always sit in the operator's seat and be ready to stop the engine at any time. -

Page 45: Precautions When Working Under Machine Or Work Equipment

SAFETY PRECAUTIONS FOR MAINTENANCE PRECAUTIONS WHEN WORKING UNDER MACHINE OR WORK EQUIPMENT Make sure the hoists or jacks you use are in good repair and strong enough to handle the weight of the component. Never use jacks at places where the machine is damaged, bent, or twisted. -

Page 46: Precautions For Inspection And Maintenance

SAFETY PRECAUTIONS FOR MAINTENANCE PRECAUTIONS FOR INSPECTION AND MAINTENANCE PRECAUTIONS WHEN WELDING Welding operations must always be carried out by a qualified welder and in a place equipped with proper equipment. There is a hazard of gas, fire, or electrocution when carrying out welding, so never allow any unqualified personnel to carry out welding. -

Page 47: Precautions When Using Hammer

SAFETY PRECAUTIONS FOR MAINTENANCE Danger of sparks There is hazard that sparks will be generated, so always observe the following. Do not let tools or other metal objects make any contact between the battery cables. Do not leave tools lying around near the battery. -

Page 48: Precautions With High-Pressure Oil

If the hose or piping mounts are loose or oil or fuel is found to be leaking from the mount, stop operations and tighten to the specified torque. If any damaged or deformed hoses or piping are found, please consult your Komatsu distributor. Replace the hose if any of the following problems are found. -

Page 49: Operation

If it is disassembled by mistake, the spring may shoot out and cause serious personal injury or death. It is necessary to disassemble the recoil spring assembly, always ask your Komatsu distributor to carry out the operation. -

Page 50: Precautions With Compressed Air

SAFETY PRECAUTIONS FOR MAINTENANCE PRECAUTIONS WITH COMPRESSED AIR When carrying out cleaning with compressed air, there is a hazard of serious personal injury caused by flying dust or particles. When using compressed air to clean the filter element or radiator, wear safety glasses, anti-dust mask, gloves, and other protective equipment. - Page 52 3 - 1...

-

Page 53: General View

OPERATION GENERAL VIEW GENERAL VIEW GENERAL VIEW OF MACHINE Machine equipped with ROPS cab Machine equipped with ROPS canopy Blade Sprocket Tilt cylinder Track frame Lift cylinder Frame (10) Idler ROPS guard (11) ROPS canopy Track shoe 3 - 2... -

Page 54: General View Of Controls And Gauges

OPERATION GENERAL VIEW GENERAL VIEW OF CONTROLS AND GAUGES Machine equipped with cab Parking brake lever (12) Fan rotation selector switch Work equipment lock lever (13) Starting switch Cigarette lighter (14) Information switch Fuel control dial (15) Buzzer cancel switch Steering, forward-reverse, gear shift lever (16) Brake pedal... - Page 55 OPERATION GENERAL VIEW Machine equipped with ROPS canopy Parking brake lever (10) Fan rotation selector switch Work equipment lock lever (11) Information switch Fuel control dial (12) Buzzer cancel switch Steering, forward-reverse, gear shift lever (13) Starting switch Auto shift down switch (14) Brake pedal Preset mode switch...

- Page 56 OPERATION GENERAL VIEW MONITOR PANEL Engine coolant temperature gauge (10) Warning lamp Power train oil temperature gauge (11) Power train oil temperature caution lamp Display panel A (Speed range, Engine speed) (12) Fan operation confirmation lamp Hydraulic oil temperature gauge (13) Engine coolant temperature caution lamp Fuel level gauge...

-

Page 57: Explanation Of Components

OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS The following is an explanation of devices needed for operating the machine. To perform suitable operations correctly and safely, it is important to completely understand methods of operating the equipment, and the meanings of the displays. FRONT PANEL Emergency caution items Lamp... - Page 58 Stop the engine, then turn the starting switch to the ON position and check that the lamps light up for approx. 2 seconds. If they do not light up, please ask your Komatsu distributor to carry out inspection. The monitor check cannot be carried out until at least 5 seconds has passed after the engine was stopped.

- Page 59 OPERATION EXPLANATION OF COMPONENTS EMERGENCY CAUTION ITEMS CAUTION If any of the caution lamps begins to flash, stop the engine or reduce the engine speed to low idle immediately and check the trouble spot for necessary actions. These items must be monitored when the engine is running. If there is any problem, the caution lamp for the location of the problem and warning lamp (A) flash, and the alarm buzzer sounds intermittently.

- Page 60 OPERATION EXPLANATION OF COMPONENTS ENGINE COOLANT TEMPERATURE CAUTION LAMP This lamp (2) indicates a rise in the coolant temperature. When the monitor lamp flashes, run the engine at low idle speed until green range of the engine coolant temperature gauge lights. POWER TRAIN OIL TEMPERATURE CAUTION LAMP Lamp (3) warns operator that the torque converter outlet port oil temperature has risen.

- Page 61 OPERATION EXPLANATION OF COMPONENTS CAUTION ITEMS CAUTION If these caution lamps flash, check and repair the appropriate location as soon as possible. These are items which need to be observed when the engine is running. If any problem occurs, the item needing immediate repair is displayed.

- Page 62 OPERATION EXPLANATION OF COMPONENTS MAINTENANCE CAUTION LAMP This lamp (2) lights up for approx. 30 seconds after the starting switch is turned to the ON position if the filter or oil replacement interval has been reached. After replacing the indicated filter or oil displayed on display panel B (multi-information), reset the interval.

- Page 63 OPERATION EXPLANATION OF COMPONENTS METER GROUP Engine coolant temperature gauge Display panel A Power train oil temperature gauge (Speed range display, Engine speed) Hydraulic oil temperature gauge Display panel B (multi-information) Fuel leve gauge Cooling fan reverse rotation pilot lamp Engine pre-heating pilot lamp ENGINE COOLANT TEMPERATURE GAUGE NOTICE...

- Page 64 OPERATION EXPLANATION OF COMPONENTS POWER TRAIN OIL TEMPERATURE GAUGE NOTICE If the power train oil temperature gauge often enters red range (C), shift down one speed range to reduce the load on the power train when operating. Gauge (2) indicates the torque converter outlet oil temperature. If the temperature is normal during operation, green range (B) will light.

- Page 65 OPERATION EXPLANATION OF COMPONENTS ENGINE PRE-HEATING PILOT LAMP This lamp (5) indicates that the engine is being preheated with an electric heater in cold weather. When the engine starting switch is turned to the ON position, the engine controller detects the engine coolant temperature and automatically starts to preheat the engine at low temperature.

- Page 66 OPERATION EXPLANATION OF COMPONENTS DISPLAY PANEL B (multi-information) The top and bottom lines in display panel B (multi-information) display information related to the condition of the machine. The content of the display is divided into "OPERATING MODE" and "MAINTENANCE MODE". Use the buzzer cancel switch to switch between the operating mode and maintenance mode.

- Page 67 OPERATION OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS Maintenance mode This displays various types of information related to maintenance of the machine. For details, see "METHOD OF USING MAINTENANCE MODE (PAGE 3-24)". COOLING FAN REVERSE ROTATION PILOT LAMP After the starting switch is turned to the ON position and the fan rotation selector switch is turned to the CLN position, this lamp (8) lights up.

- Page 68 OPERATION EXPLANATION OF COMPONENTS LAMPS Warning lamp Fan operation confirmation lamp WARNING LAMP (Red) NOTICE If alarm buzzer sounds, stop work immediately and perform inspection and maintenance of the appropriate point. This lamp (1) flashes when the caution lamp flashes and when an action code is displayed on display panel B (multi-information).

- Page 69 OPERATION EXPLANATION OF COMPONENTS FAN OPERATION CONFIRMATION LAMP (Orange) If the starting switch is at the ON position when this lamp (2) is out, and the engine is started, the fan will rotate in the normal direction. If the fan rotation selector switch is turned to the CLN position when the engine is running, this lamp (2) will flash for 3 seconds to show that the direction of rotation of the fan has not changed.

-

Page 70: Switches

OPERATION EXPLANATION OF COMPONENTS SWITCHES Machine equipped with cab Machine equipped with ROPS canopy Starting switch Rear lamp switch Auto shift down switch Fan rotation selector switch Preset mode switch Information switch Head lamp switch Buzzer cancel switch 3 - 19... - Page 71 OPERATION EXPLANATION OF COMPONENTS STARTING SWITCH This switch (1) is used to start or stop the engine. (A): OFF position At this position, the starting switch key can be inserted and removed. When the switch is turned to this position, all the electric circuits are turned off and the engine stops.

- Page 72 OPERATION EXPLANATION OF COMPONENTS HEAD LAMP SWITCH This switch (4) lights up when the front lamp, and panel lamp light (OFF) position: Lights out (ON) position: Lights on REAR LAMP SWITCH This switch (5) lights up the rear lamps. (OFF) position: Lights out (ON) position: Lights on 3 - 21...

- Page 73 OPERATION EXPLANATION OF COMPONENTS FAN ROTATION SELECTOR SWITCH This switch (6) is used to switch the direction of rotation of the cooling fan. When it is released from the CLE position, it will automatically return to the position. position : Normal rotation Use this switch normally with the fan operation confirmation lamp in the OFF condition.

- Page 74 OPERATION EXPLANATION OF COMPONENTS INFORMATION SWITCH This switch (7) is used to operate display panel B (multi-information). When the switch is released, it returns automatically to the center position. When display panel B (multi-information) is in the operation mode turn the switch to < or > to switch the display to service meter or engine speed.

- Page 75 OPERATION EXPLANATION OF COMPONENTS METHOD OF USING MAINTENANCE MODE To switch from the operation mode to the maintenance mode, turn the buzzer cancel switch to the position and hold it there for at least 2.5 seconds. The screen will switch to the maintenance mode.

- Page 76 OPERATION EXPLANATION OF COMPONENTS METHOD OF SELECTING EACH MODE 3 - 25...

- Page 77 This function is only a guideline. If dirty oil or filters are found during daily maintenance, replace them immediately. If the controllers or monitor panel are replaced, the timer for this function will not work properly. Contact your Komatsu distributor for replacement.

- Page 78 OPERATION OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS When the oil or filter has been replaced, select the applicable item, then operate the buzzer cancel switch to A question asking if the replacement history is to be updated is displayed. Use the information switches (<, >) to select YES, then turn the buzzer cancel switch to .

- Page 79 OPERATION EXPLANATION OF COMPONENTS METHOD OF USING PM CLINIC AUXILIARY MODE CAUTION When moving the work equipment or setting the transmission to the travel position for carrying out measurements, check carefully that the situation is safe. In the PM Clinic auxiliary mode, the engine RPM and battery voltage are shown in display B (multi-information). Display panel B (Malti-information) displays the item on the top line (1) and the measured value on the bottom line (2).

- Page 80 When any disconnection or short circuit in any sensor is detected, the location and fault code are displayed by a 6-digit code on display panel B (multi-information). When contacting your Komatsu distributor, inform your distributor of the code at the same time.

- Page 81 OPERATION EXPLANATION OF COMPONENTS METHOD OF USING USER ADJUST MODE The adjust mode has functions of changing the intensity of the panel backlight and the contrast of LCD panel. They are shown in display B. 1. Adjusting backlighting of liquid crystal display 1) The diagram on the right is the mode for adjusting the brightness of the backlighting of the liquid crystal panel.

- Page 82 OPERATION EXPLANATION OF COMPONENTS 2. Adjusting backlighting of display panel B (multi-information) 1) The diagram on the right is the mode for adjusting the brightness of the backlighting of the display panel B (multi-information). On the screen, operate the buzzer cancel switch to switch to the screen for adjusting the brightness.

- Page 83 OPERATION EXPLANATION OF COMPONENTS 3. Adjusting contrast of liquid crystal display panel B (multi-information) 1) The diagram on the right is the mode for adjusting the contrast liquid crystal display panel (multi-information). On this screen, operate the buzzer cancel switch to to switch to the screen to adjust the contrast.

- Page 84 OPERATION EXPLANATION OF COMPONENTS SWITCHES Machine equipped with cab Machine equipped with ROPS canopy Fuel control dial Wiper switch Horn switch Cigarette lighter Room lamp switch Accessory socket 3 - 33...

- Page 85 OPERATION EXPLANATION OF COMPONENTS FUEL CONTROL DIAL Dial (1) is used to control the engine speed and output. (a) Low idling position: Turn fully to the left (b) High idling position: Turn fully to the right HORN SWITCH The horn sounds when the button (2) at the rear of the blade control lever at the right side of the operator's seat is pressed.

- Page 86 OPERATION EXPLANATION OF COMPONENTS WIPER SWITCH This (4) activates the wipers. The wiper switches are as follows: (A): Left door (LH) (B): Front window (FF) (C): Right door (RH) (D): Rear window (RR) (E): Wiper intermittent operation switch (INT) This is also used as the window washer switch. The switch is operated as follows.

- Page 87 OPERATION OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS Wiper intermittent operation switch When this switch is turned to the ON position (J) to start the wiper moving, the wiper works once in every four seconds. REMARK When the wiper intermittent operation switch is ON position (J), if the wiper switch for each window is turned ON position (J), the wiper will move intermittently.

-

Page 88: Control Levers And Pedals

OPERATION EXPLANATION OF COMPONENTS CONTROL LEVERS AND PEDALS Work equipment lock lever Brake pedal Parking brake lever Decelerator pedal Steering, forward-reverse, gear shift lever Blade control lever WORK EQUIPMENT LOCK LEVER WARNING When leaving the operator's compartment, set the work equipment lock lever securely to the LOCK position. If the work equipment lock lever is not at the LOCK position and the control levers are touched by mistake, it may lead to serious personal injury. - Page 89 OPERATION EXPLANATION OF COMPONENTS PARKING BRAKE LEVER WARNING When parking the machine, always set the parking brake lever in the LOCK position. If the parking brake lever is operated, the brake is applied, even when the machine is traveling. The machine will suddenly stop, so this is dangerous. For this reason, do not operate the parking brake lever when the machine is moving, except in emergencies.

- Page 90 OPERATION OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS Gear shifting When UP switch (U) or DOWN switch (D) is pushed, the transmission speed will change. UP switch (U): Each time the switch is pressed, the transmission will up shift one speed. DOWN switch (D): Each time the switch is pressed, the transmission will down shift one speed.

- Page 91 OPERATION EXPLANATION OF COMPONENTS BRAKE PEDAL WARNING Do not place your foot on this pedal unnecessarily. Depress the pedal (4) to apply the right and left brakes. DECELERATOR PEDAL WARNING Do not place your foot on this pedal unnecessarily. When passing over the top of a hill or when a load is dumped over a cliff, the load is suddenly reduced, so there is danger that the travel speed will also increase suddenly.

- Page 92 OPERATION EXPLANATION OF COMPONENTS BLADE CONTROL LEVER POWER TILTDOZER This lever (6) is used to lift or tilt the blade. Lifting control (A) RAISE: Blade goes up (B) HOLD: Blade is stopped and held in this position. (C) LOWER: Blade goes down (D) FLOAT: Blade will move freely according to external force.

- Page 93 OPERATION EXPLANATION OF COMPONENTS POWERTILT POWER PITCHDOZER This lever (6) is used to lift or tilt and pitch the blade. Lifting control (A) RAISE: Blade goes up (B) HOLD: Blade is stopped and held in this position. (C) LOWER: Blade goes down (D) FLOAT: Blade will move freely according to external force.

- Page 94 OPERATION OPERATION EXPLANATION OF COMPONENTS EXPLANATION OF COMPONENTS Pitch control After moving the lever to the neutral position without fail, tilt the blade while pressing any of the switches (M) in the center of the knob. Then the angle of the blade edge changes. (B) Hold: The blade stops and holds a stationary posture.

- Page 95 OPERATION EXPLANATION OF COMPONENTS ANGLE DOZER This lever (6) is used to lift or tilt the blade. Lifting control (A) RAISE: Blade goes up (B) HOLD: Blade is stopped and held in this position. (C) LOWER: Blade goes down (D) FLOAT: Blade will move freely according to external force. REMARK If the lever is in the FLOAT position, even when it is released, it does not return to the HOLD position, so return it by hand.

-

Page 96: Circuit Breaker

OPERATION EXPLANATION OF COMPONENTS CIRCUIT BREAKER NOTICE When resetting the circuit breaker, always turn off the power first (turn the starting switch OFF). If the reset button for the circuit breaker comes out immediately when it is pushed in, it is necessary to carry out an inspection of the electrical circuit. -

Page 97: Fuse

OPERATION EXPLANATION OF COMPONENTS FUSE NOTICE Before replacing a fuse, be sure to turn starting switch to the OFF position. The fuses protect the electrical equipment and wiring from burning out. If the fuse becomes corroded, or white powder can be seen, or the fuse is loose in the fuse holder, replace the fuse. Replace the fuse with another of the same capacity. - Page 98 OPERATION EXPLANATION OF COMPONENTS FUSE CAPACITY AND CIRCUIT NAME Fuse box (A) Fuse Circuit capacity Spare power source Horn, Ribbon heater, Air suspension seat Front lamp, Rear lamp Transmission, Steering controller Engine controller Fuse box (B) Fuse Circuit capacity Backup alarm Continuous power source Truck power source Engine power source...

-

Page 99: Fusible Link

OPERATION EXPLANATION OF COMPONENTS FUSIBLE LINK If any of the electrical equipment in the operator's cab does not work, a fusible link built in the wiring harness is suspected of disconnection. In that case, check the link and replace it with a new one, if necessary. REMARK A fusible link refers to the large-sized fuse wiring installed in the high current flow portion of the circuit to protect electrical components and wiring from burning, in the same way as an ordinary fuse. -

Page 100: Cap With Lock

OPERATION EXPLANATION OF COMPONENTS CAP WITH LOCK Lock-type caps are available for the hydraulic tank oil filler cap and fuel tank filler cap. For details of the locations of the caps with locks, see "LOCKING (PAGE 3-114)". Use the starting switch key to open and close the locks on the caps. METHOD OF OPENING AND CLOSING HYDRAULIC CAP OPENING THE CAP 1. - Page 101 OPERATION EXPLANATION OF COMPONENTS METHOD OF OPENING AND CLOSING FUEL CAP OPENING THE CAP 1. Insert the key. Make sure that you have inserted the key fully (1) before turning it. If the key is turned when only partially inserted, it may break. (L) : Lock position (F) : Open position (A) : working angle of key 180°...

-

Page 102: Door - Open Lock

OPERATION EXPLANATION OF COMPONENTS DOOR - OPEN LOCK (Machine equipped with cab) Use this when your want to keep the door held open. 1. Push the door against the door catch (1). The door will be held by the door catch. 2. -

Page 103: Door Pocket

OPERATION EXPLANATION OF COMPONENTS DOOR POCKET (Machine equipped with cab) This is inside the left and right doors. Use it for storing the Operation and Maintenance Manual or other things. Do not put heavy tools or other heavy objects in it. If the pocket is dirty, turn 4 clips (1), then remove the pocket and rinse it. -

Page 104: Ashtray

OPERATION EXPLANATION OF COMPONENTS ASHTRAY This is on the left side of the operator's seat. Always make sure that you extinguish the cigarette before closing the lid. CUP HOLDER (If equipped) This is the place to put cans or cups. If drinks are put in places other than the cup holder, the can or cup will fall over and make the surrounding area or equipment dirty. -

Page 105: Shovel Holder

OPERATION EXPLANATION OF COMPONENTS SHOVEL HOLDER (If equipped) This can be used for storing a shovel with a rounded blade. Method of installing 1. Position the shovel with stopper(1) and holder(2). 2. Tighten the adjustment nut (3) so the shovel does not move. 3 - 54... -

Page 106: Car Stereo, Handling

OPERATION EXPLANATION OF COMPONENTS CAR STEREO, HANDLING (Machine equipped with cab) (If equipped) EXPLANATION OF COMPONENTS Power switch/volume Cassette door Auto-store/preset scan button Fast forward, rewind buttons Bass control knob (10) Preset buttons Treble control knob (11) Metal tape button Loudness button (12) Manual tuning buttons... - Page 107 OPERATION EXPLANATION OF COMPONENTS POWER SWITCH/VOLUME Turn this knob (1) to the right until it clicks to turn the power on. Turn it further to increase the volume. AUTO-STORE/PRESET SCAN BUTTON Use this button (2) to actuate the preset scan and auto-store functions.

- Page 108 OPERATION EXPLANATION OF COMPONENTS TREBLE CONTROL KNOB Turn this button (4) to the left to reduce the low tones; turn it to the right to emphasize the high tones. Direction (a): High tone reduced Direction (b): High tone emphasized LOUDNESS BUTTON This button (5) is used when playing at low volume.

- Page 109 OPERATION EXPLANATION OF COMPONENTS TAPE EJECT BUTTON This button (7) is used to stop the tape and to eject the cassette. When this button is pressed, the tape is ejected and the radio plays. CASSETTE DOOR Set the cassette with the exposed portion of the tape on the right side and insert it through the cassette door (8).

- Page 110 OPERATION EXPLANATION OF COMPONENTS METAL TAPE BUTTON (used also for preset button No. 5) This button (11) is used when playing a metal or chrome tape. This button is also used for preset button No. 5. When it is pressed, "MTL"...

- Page 111 OPERATION EXPLANATION OF COMPONENTS METHOD OF OPERATION METHOD OF SETTING PRESET BUTTONS It is possible to preset 6 MW (AM) stations and 12 FM stations (FM1: 6 stations, FM2: 6 stations). REMARK If you are playing the cassette, press the tape eject button to stop the tape. METHOD OF AUTO PRESET 1.

- Page 112 OPERATION EXPLANATION OF COMPONENTS LISTENING TO RADIO 1. Turn the starting switch ON, then turn power switch (1) ON. 2. Use band selector button (2) to select MW (AM), FM1 or FM2. 3. Select the station with the preset buttons (3). REMARK In case you do not promptly remember the number assigned to a certain preset station, press auto-store/preset scan button (4) for...

- Page 113 If the sound cannot be heard, nothing is displayed, or any other problem occurs, turn off the power switch and ask your Komatsu distributor to make repairs without delay. Stow the antenna when traveling in places with low overhead clearance.

-

Page 114: Air Conditioner, Handling

OPERATION EXPLANATION OF COMPONENTS AIR CONDITIONER, HANDLING (Machine equipped with cab) (If equipped) By taking fresh air into the cab through a filter, it is possible to raise the pressure inside the cab. This makes it possible to provide a pleasant working environment even on dusty jobsites. GENERAL LOCATIONS AND FUNCTION OF CONTROL PANEL Fan switch Temperature control switch... - Page 115 OPERATION EXPLANATION OF COMPONENTS AIR CONDITIONER SWITCH This switch (2) is used to start or stop the cooling or dehumidifying function. When the fan switch is turned ON and the air conditioner switch is pressed, the indicator lamp above the switch lights up. When the switch is pressed again, the switch is turned OFF and the indicator lamp goes out.

- Page 116 OPERATION EXPLANATION OF COMPONENTS TEMPERATURE CONTROL SWITCH This switch (4) can be used to adjust the temperature steplessly between low temperature and high temperature. The temperature level indicator lamps (A) light up to display the temperature of the air coming from the vents. The more blue lamps on, the lower the temperature is.

- Page 117 OPERATION EXPLANATION OF COMPONENTS METHOD OF OPERATION Switch Air conditioner Temperature FRESH/RECIRC Fan switch switch control switch selector switch Condition of use Rapid All blue RECIRC Cooling More than half Normal HI - LO FRESH are blue Dehumidifying, More than half HI - LO FRESH heating...

- Page 118 OPERATION EXPLANATION OF COMPONENTS PRECAUTIONS WHEN USING PRECAUTIONS WHEN USING THE COOLING If you smoke when using the air conditioner in the RECIRC mode, your eyes may start to itch or burn. Ventilate the cab ever so often to remove the smoke. When using the air conditioner for a long period of time, carry out ventilation process at least once every hour.

- Page 119 OPERATION EXPLANATION OF COMPONENTS CLEANING AIR FILTER If the air filter for the FRESH or RECIRC air intake becomes clogged, the cooling or heating capacity will drop. To prevent this, clean the air filter with compressed air once a week. For details of the cleaning method, see "WHEN REQUIRED (PAGE 4-20)".

-

Page 120: Operation

Check carefully, and if any abnormality is found, repair it or contact your Komatsu distributor. Do not get on or off the machine from the rear. Using this position is dangerous because it is easy to slip and you cannot be seen from the operator's compartment. - Page 121 OPERATION OPERATION 8. Check for problems in gauges and monitor Check that there is no problem in the gauges and monitor in the operator's cab. If any problem is found, replace the parts. Clean off any dirt on the surface. 9.

- Page 122 OPERATION OPERATION CHECK BEFORE STARTING Always check the items in this section before starting the engine each day. CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL WARNING Parts and oil are at high temperature immediately after the engine is stopped and may cause serious burns. Wait for the oil temperature to go down before performing this operation.

- Page 123 OPERATION OPERATION 8. If the oil level is correct, tighten the oil filler cap securely and close the engine side cover. REMARK If the machine is at an angle, reposition it to level before checking. When checking the oil level after the engine has been operated, allow the engine to cool for 15 minutes before checking.

- Page 124 OPERATION OPERATION CHECK, DRAIN WATER SEPARATOR The water separator serves to separate moisture mixed in the fuel. 1. Open up the engine side cover on the left side of the machine. The water separator is in one piece with fuel pre-filter (1) and located in the lower part.

- Page 125 OPERATION OPERATION CHECK COOLANT LEVEL, ADD COOLANT WARNING Do not open the radiator cap unless necessary. When checking the coolant, always wait for the engine to cool down and check the sub tank. Immediately after the engine is stopped, the coolant is at a high temperature and the radiator is under high internal pressure. If the cap is removed to check the coolant level in this condition, there is a hazard of burns.

- Page 126 If the circuit breakers are activated and the fuses are blown frequently or there is a trace of short-circuiting in the wirings, check the cause immediately and either correct it by yourself or call your Komatsu distributor for the repair.

- Page 127 70 to 90 mm (2.8 to 3.5 in). 3. When this value exceeds 91 mm (3.6 in), or the brake fails to work, please contact your Komatsu distributor for adjustment. CHECKING WITH MACHINE MONITOR 1. Turn starting switch (1) to the ON position (B).

- Page 128 OPERATION OPERATION CHECK FUEL LEVEL, ADD FUEL WARNING When adding fuel, never spill the fuel or let it overflow. It will cause fire. If any fuel has spilled, wipe it up completely. If fuel has spilled over soil or sand, remove that soil or sand. Fuel is highly flammable and dangerous.

- Page 129 Check that the head lamp, rear lamp, additional working lamp (if equipped), and instrument lamp light up normally and they are free from stain and damage. If the lamps do not light, check for a broken bulb or disconected wire, contact your Komatsu distributor for repairs. 1. Turn starting switch to the ON position (B).

- Page 130 OPERATION CHECK OF OPERATION OF BACKUP ALARM Check that the backup alarm sounds normally. If it does not, a defect or broken wire is suspected, ask your Komatsu distributor for possible repairs. 1. Turn starting switch to the ON position (B).

- Page 131 OPERATION OPERATION ADJUSTMENT ADJUST OPERATOR'S SEAT WARNING When adjusting the position of the operator's seat, always set the work equipment lock lever to the LOCK position to prevent any accidental contact with the control levers. Always adjust the operator's seat before starting each operation or when the operators change shift. When adjusting the seat, put your back against the backrest and adjust to a position where the brake pedal can be fully depressed.

- Page 132 OPERATION OPERATION (E) Seat height adjustment Pull up levers (4) and (5) alternately to adjust the angle of the seat. Then, release the levers to lock the seat. (Height adjustment distance: 5 stages, 60 mm (2.4 in)) FASTENING AND REMOVING SEAT BELT (If equipped) WARNING Before fastening the seat belt, check that there is no problem in the securing brackets or belt.

- Page 133 OPERATION OPERATION ADJUST MIRROR (If equipped) Loosen nut (1) of the mirror and adjust the mirror to a position where it gives the best view from the operator's seat. In particular, be sure to adjust the mirror so that people at the rear left or right of the machine can be seen clearly.

- Page 134 OPERATION OPERATION ADJUST ARMREST The height of the armrests on the right and left sides of the operator's seat can be adjusted according to the following procedure. After adjusting the operator's seat, adjust the armrest height properly. ADJUST ARMREST (RIGHT) Arm rest (1) can be adjusted in three stages;...

- Page 135 OPERATION OPERATION OPERATION AND CHECK BEFORE STARTING ENGINE WARNING When starting the engine, check that the parking brake lever and work equipment lock lever are placed securely at the LOCK position. If the work equipment control lever is touched by accident when the engine is started, the work equipment may move unexpectedly and cause serious injury or damage.

- Page 136 OPERATION OPERATION OPERATION OPERATION 3. Check that the blade is lowered to the ground and that blade control lever (3) is in the HOLD position (B). 4. Check that the work equipment lock lever (4) is LOCK position (L). 3 - 85...

-

Page 137: Starting Engine

OPERATION OPERATION STARTING ENGINE NORMAL STARTING WARNING Sit down in the operator's seat before starting the engine. Do not attempt to start the engine by short-circuiting the engine starting circuit. Such an act may cause serious bodily injury or fire. Check that there are no persons or obstacles in the surrounding area, then sound the horn and start the engine. - Page 138 OPERATION OPERATION OPERATION OPERATION 3. When the engine starts, release the key in starting switch (2). The key will return automatically to the ON position (B). STARTING IN COLD WEATHER WARNING Start the engine only after sitting down in the operator's seat. Do not attempt to start the engine by short-circuiting the engine starting circuit.

- Page 139 OPERATION OPERATION OPERATION OPERATION 2. Insert the key into starting switch (2) and turn the key to the ON position (B). 3. Check that engine pre-heating pilot lamp (3) on the monitor panel lights up. 4. Maintain the key in the on position until the pre-heating pilot lamp (3) goes off.

- Page 140 OPERATION OPERATION REMARK Regardless of the ambient temperature, if the key in starting switch (2) is turned from OFF position to left, preheating pilot lamp (3) will light up and preheating will start. (Preheating continues while the starting switch is held at the left.) For the details of the preheating time, see the table in Step 5.

-

Page 141: Operations And Checks After Starting Engine

BREAKING IN THE NEW MACHINE NOTICE Your Komatsu machine has been thoroughly adjusted and tested before shipment from the factory. However, operating the machine under full load before breaking the machine in can adversely affect the performance and shorten the machine life. - Page 142 (B). (A): White range (B): Green range (C): Red range 3. Check for abnormal exhaust gas color, noise, or vibration. If any problem is found, contact your Komatsu distributor. STARTING IN COLD WEATHER (Ambient temperature below 10°C (50°F)) NOTICE When the hydraulic oil is at low temperature, do not carry out operations or move the levers suddenly.

- Page 143 REMARK If the power train oil temperature is not raised sufficiently, it will take longer to accelerate to the maximum speed. 6. Check for abnormal exhaust gas color, noise, or vibration. If any problem is found, contact your Komatsu distributor.

-

Page 144: Stopping Engine

OPERATION OPERATION STOPPING ENGINE NOTICE If the engine is stopped without allowing it to cool down, there is danger that the service life of various parts of the engine will be reduced. Except in emergencies, never stop the engine suddenly. If the engine overheats, do not stop it suddenly. -

Page 145: Machine Operation

OPERATION OPERATION MACHINE OPERATION MOVING MACHINE WARNING When moving the machine, check that the area around the machine is safe, and sound the horn before moving. Do not allow anyone to enter the area around the machine. There is a blind spot at the rear of the machine, so be particularly careful when traveling in reverse. - Page 146 Check that the backup alarm buzzer (rear side warning buzzer) properly sounds, when steering - forward / reverse shifting - gearshift lever (6) is operated to the REVERSE (R) position. If it does not, call on your Komatsu distributor for repairs.

- Page 147 OPERATION OPERATION STOPPING MACHINE WARNING Avoid stopping suddenly. Give yourself ample room when stopping. 1. Depress brake pedal (1) to stop the machine. NOTICE If the brake pedal is depressed when the engine speed or machine travel speed is high, the brake disc may produce a slipping sound. When depressing the brake pedal, usually depress decelerator pedal (2) to reduce the engine speed and machine travel speed.

-

Page 148: Shifting Gears

OPERATION OPERATION SHIFTING GEARS The machine does not have to be stopped to shift gears. 1. Move steering, forward-reverse, gear shift lever (1) to the desired gear position to shift gears. GEARSHIFTING OPERATION When UP switch (U) or DOWN switch (D) is pushed, the transmission speed will change. - Page 149 OPERATION OPERATION GEARSHIFTING OPERATION USING PRESET MODE FUNCTION If the preset mode function is used, the speed ranges used when the machine travels in forward and reverse can be preset as desired. 1. Set steering, forward-reverse, gear shift lever (1) to the NEUTRAL position (N).

- Page 150 OPERATION OPERATION REMARK Even when the preset mode function is being actuated, it is possible to select the speed range by operating the UP switch or DOWN switch when the machine is traveling forward or in reverse. However, the preset mode remains set as it is. If the steering, forward-reverse, gear shift lever is returned to the NEUTRAL position and then operated again to the FORWARD or REVERSE position, the set speed range is selected.

-

Page 151: Shifting Between Forward And Reverse

Check that the backup alarm buzzer (rear side warning buzzer) properly sounds, when the steering - forward / reverse shifting - gearshift lever is operated to the REVERSE (R) position. If it does not, call on your Komatsu distributor for repairs. 3 - 100... - Page 152 OPERATION OPERATION OPERATION OPERATION 4. Release decelerator pedal (1) and raise the engine speed. REMARK If the forward- reverse control lever is shifted when the machine is traveling downhill, a directional change may automatically take place via 1st gear for safety. For example, when the forward- reverse control lever is shifted from F2 to R2, the directional change may take place in the sequence of F2 to R1 to R2.

-

Page 153: Steering Machine

OPERATION OPERATION STEERING MACHINE WARNING Avoid as much as possible turning the machine on a slope. The machine will tend to slip sideways. Particular care should be taken on soft or clay soil. Never make a pivot turn at high speed. NORMAL TURNING WARNING When performing a counterrotation turn, the feeling of operation when your head is facing the rear is different from the feeling if... - Page 154 OPERATION OPERATION WHEN MAKING PIVOT TURN TO LEFT WHILE TRAVELING NOTICE When carrying out a counterrotation turn, if the load is not equal on the left and right sides, the machine may carry out a pivot turn, so check the ground conditions and be careful not to hit any obstacles.

-

Page 155: Precautions For Operation

OPERATION OPERATION PRECAUTIONS FOR OPERATION PAY ATTENTION TO GAUGES When the red range lights on the power train oil temperature gauge while operating, reduce the load and wait for the temperature to decrease. PERMISSIBLE WATER DEPTH When operating in water, always keep the bottom of carrier rollers (1) above the surface of the water. - Page 156 OPERATION OPERATION METHOD OF USING BRAKES The following actions cause premature damage to the brakes, so avoid such operations. Using emergency brake at full speed Using brake with engine running at full speed in first gear (F1, R1) (Machine stall condition) REMARK Always depress the decelerator pedal to lower the engine speed before actuating the brakes.

-

Page 157: Work Possible Using Bulldozer

OPERATION OPERATION WORK POSSIBLE USING BULLDOZER In addition to the following, it is possible to further increase the range of applications by using various attachments. DOZING A bulldozer digs and transports dirt in a forward direction. Slope excavation can always be most effectively carried out by proceeding from the top downward. - Page 158 OPERATION OPERATION CUTTING INTO HARD OR FROZEN GROUND OR DITCHING For digging and ditch excavation of hard or frozen ground, tilt the blade. Even hard ground can be dug effectively by a tilted or angled blade. FELLING TREES, REMOVING STUMPS NOTICE Do not uproot trees or stumps or fell trees by angling or tilting the blade.

-

Page 159: Adjusting Posture Of Work Equipment

OPERATION OPERATION ADJUSTING POSTURE OF WORK EQUIPMENT ADJUST ANGLE OF BLADE EDGE WARNING It is dangerous if the work equipment moves by mistake when adjusting angle of the blade edge. Set the work equipment in a stable condition, then stop the engine and lock the work equipment securely with the work equipment lock lever. Blade cutting edge angle (A) can be adjusted to meet soil conditions. - Page 160 OPERATION OPERATION ADJUSTING SHIMS IN ASSEMBLING WORK EQUIPMENT When assembling the work equipment, if the adjustment of the play is not carried out properly, excessive bending stress will be generated at all parts, and this will lead to cracks or breakage. Adjust the play of parts (1) to (4) to the correct value.

- Page 161 OPERATION OPERATION ADJUST AMOUNT OF TILT ANGLE DOZER WARNING When adjusting the amount of tilt, it is dangerous if the work equipment is moved by mistake. Set the work equipment in a safe condition, then stop the engine and lock the work equipment securely with the work equipment lock lever. NOTICE An amount of tilt (A) can be increased to a maximum of 400 mm (15.8 in).

- Page 162 OPERATION OPERATION METHOD OF ANGLING BLADE Angledozers only When dozing toward one side only, operate with angled blade. WARNING When adjusting the amount of angling, it is dangerous if the work equipment is moved by mistake. Set the work equipment in a safe condition, then stop the engine and lock the work equipment securely with the work equipment lock lever.

-

Page 163: Parking Machine

OPERATION OPERATION PARKING MACHINE WARNING When stopping the machine, select flat hard ground and avoid dangerous places. If it is unavoidably necessary to park the machine on a slope, place the parking brake lever in the LOCK position and insert blocks underneath the track shoes. -

Page 164: Check After Finishing Work

OPERATION OPERATION OPERATION OPERATION 4. Set work equipment lock lever (3) in the LOCK position (L). CHECK AFTER FINISHING WORK BEFORE STOPPING ENGINE Use the meters and caution lamps to check the engine coolant temperature, engine oil pressure, fuel, and power train oil temperature. -

Page 165: Locking

OPERATION OPERATION LOCKING To prevent vandalism, there are locks in the following places. Places that can be locked with the starting switch key. Top cover at front of chassis (1) Right and left engine side covers (2) Battery inspection cover (3) Inspection cover for fuel tank drain valve(4) Cab door opener (5) (Machine equipped with cab) Fuel tank filler cap (6) -

Page 166: Tips For Longer Undercarriage Life

OPERATION METHOD Select the track shoe that best suits the type of soil to be encountered in service. Please consult your Komatsu distributor when selecting track shoes. Do not allow shoe slipping to occur during operation. If shoe slipping occurs, reduce load on the blade until slipping stops. - Page 167 Frequent inspection and prompt repair will reduce repair costs. The following items for inspection will serve as a guide to maintenance service of each undercarriage part. Perform periodical inspection and contact the Komatsu distributor in your area when machine has approached repairable limits and reversing limits.

- Page 168 OPERATION OPERATION MEASURING HEIGHT OF GROUSER (D65EX,D65WX) After taking up slack in track shoes, measure height at center of shoe as shown below. Standard height (h): 65 mm (2.6 in) Repair limits: 25 mm (1.0 in) MEASURING OUTSIDE DIAMETER OF TRACK ROLLER 1.

-

Page 169: Transportation

If it is necessary to remove the cab for transportation, there is danger that the seal may be damaged when removing or installing the cab, so please contact your Komatsu distributor. When installing the cab, please contact your Komatsu distributor, too. -

Page 170: Precautions When Removing Work Equipment

OPERATION TRANSPORTATION PRECAUTIONS WHEN REMOVING WORK EQUIPMENT If there is any pressure remaining in the tilt piping after the work equipment has been removed, it may be difficult to remove the quick coupler of the tilt hose, so remove the work equipment as follows. 1. -

Page 171: Loading, Unloading Work

OPERATION TRANSPORTATION LOADING, UNLOADING WORK WARNING Since loading and unloading of the machine is dangerous, be extremely careful. When loading or unloading the machine, operate it slowly with the engine speed low and the transmission in the 1st gear. Use ramps having sufficient width, length, thickness, and strength. Install them securely and set their angle to 15° or less. If the ramps are deflected appreciably, reinforce them with blocks. - Page 172 OPERATION TRANSPORTATION SECURING MACHINE NOTICE Be sure to lower the car radio antenna to the stow position (if the machine is equipped with a cab). Load the machine onto a trailer as follows: 1. Lower the work equipment slowly. (When transporting with work equipment installed) 2.

- Page 173 OPERATION TRANSPORTATION UNLOADING WORK 1. Load and unload on firm level ground only. Maintain a safe distance from the edge of a road. 2. Apply the trailer brakes securely and put blocks (1) under the tires to hold the trailer in position.Set gap (3) between ramps (2) to match the distance between the left and right tracks, and keep angle (4) to a maximum of 15°.

-

Page 174: Lifting Machine

This method of lifting applies to the standard specification machine. The method of lifting differs according to the attachments and options installed. For details of the procedure for machines that are not the standard specification, please consult your Komatsu distributor. For weight, see "SPECIFICATIONS (PAGE 5-2)". - Page 175 OPERATION TRANSPORTATION For machine equipped with ripper Fit the wire ropes at the center to both left and the right pivot shafts (2). Hang the rear wire rope to ripper beam (3). When lifting the machine, stop it on a level place, then observe the following procedure. 1.

-

Page 176: Traveling On Roads

OPERATION TRANSPORTATION TRAVELING ON ROADS When traveling on paved roads, use flat shoes to protect their surface. Even when travelling a short distance, always place boards to protect the road surface. REMARK Note that the asphalt road becomes soft in summer. 3 - 125... -

Page 177: Cold Weather Operation

Antifreeze is flammable. Do not bring any flame close. Do not smoke when handling antifreeze. NOTICE Please use Komatsu genuine supercoolant (AF-NAC) for the coolant. As a basic rule, we do not recommend the use of any coolant other than Komatsu genuine supercoolant. -

Page 178: After Completion Of Work

OPERATION COLD WEATHER OPERATION BATTERY WARNING The battery generates flammable gas. Do not bring fire or sparks near the battery. Battery electrolyte is dangerous. If it gets in your eyes or on your skin, wash it off with a large amount of water and consult a doctor. -

Page 179: Long-Term Storage

Place all control levers in the neutral position, set the work equipment lock lever and parking brake lever in the LOCK position, and set the fuel control dial to the low idling position. To prevent rust, fill with Komatsu genuine supercoolant (AF-NAC) to give a density of at least 30% for the engine coolant. -

Page 180: Troubleshooting

OPERATION TROUBLESHOOTING TROUBLESHOOTING AFTER RUNNING OUT OF FUEL When starting the engine again after running out of fuel, fill with fuel, then bleed the air from the fuel system before starting the engine. PROCEDURE FOR BLEEDING AIR 1. Insert the key into the engine starting switch and turn the key to ON position (B). -

Page 181: Method Of Towing Machine

To move the machine in this case, the oil pressure in the brake circuit must be heightened to the specified level with a special device. Ask your Komatsu distributor. Moving a machine by towing is only used to move it to a place where it is possible to carry out inspection and maintenance. -

Page 182: If Battery Is Discharged

OPERATION TROUBLESHOOTING IF BATTERY IS DISCHARGED WARNING It is dangerous to charge a battery when mounted on a machine. Make sure that it is dismounted before charging. When checking or handling the battery, stop the engine and turn the starting switch key to the OFF position. The battery generates hydrogen gas, so there is a hazard of explosion. - Page 183 OPERATION TROUBLESHOOTING PRECAUTIONS FOR BATTERY CHARGING If the battery is charged improperly, it may explode. Accordingly, charge it according to "IF BATTERY IS DISCHARGED (PAGE 3-131)" and the instruction manual attached to the charger, and observe the following items. Set the voltage of the charger to match the voltage of the battery to be charged.

- Page 184 OPERATION TROUBLESHOOTING STARTING ENGINE WITH BOOSTER CABLE When starting the engine with a booster cable, do as follows. PRECAUTIONS WHEN CONNECTING AND DISCONNECTING BOOSTER CABLE WARNING When connecting the cables, never contact the positive (+) and negative (-) terminals. When starting the engine with a booster cable, wear safety glasses and rubber gloves.

- Page 185 OPERATION TROUBLESHOOTING STARTING ENGINE WARNING Always check that the work equipment lock lever is set to the LOCK position, regardless of whether the machine is working normally or has failed. Check also that all the control levers are in the HOLD or NEUTRAL position. 1.

-

Page 186: Other Trouble

TROUBLESHOOTING OTHER TROUBLE ELECTRICAL SYSTEM ( ): Always contact your Komatsu distributor when dealing with these items. In cases of problems or causes which are not listed below, contact your Komatsu distributor for repairs. Problem Main cause Remedy Lamp does not glow brightly... - Page 187 Note: If a problem display appears on display panel B, check the fault code. For details, see "METHOD OF USING FAULT CODE DISPLAY MODE (PAGE 3-29)". When contacting your Komatsu distributor, please give the fault code also. 3 - 136...

- Page 188 OPERATION TROUBLESHOOTING CHASSIS ( ): Always contact your Komatsu distributor when dealing with these items. In cases of problems or causes which are not listed below, contact your Komatsu distributor for repairs. Problem Main causes Remedy Improper tightening of oil pipe,...

- Page 189 OPERATION TROUBLESHOOTING Problem Main causes Remedy Track is too loose Adjust track tension. For details, Track comes off see WHEN REQUIRED Track is too loose or too tight Adjust track tension. For details, Sprocket develops abnormal wear see WHEN REQUIRED Initial improper adjustment of ( Adjust) Machine does not travel in straight...

- Page 190 OPERATION TROUBLESHOOTING ENGINE ( ): Always contact your Komatsu distributor when dealing with these items. In cases of problems or causes which are not listed below, contact your Komatsu distributor for repairs. Problem Main causes Remedy Engine oil pan oil level is low...

- Page 191 Damage inside muffler ( Replace muffler) Excessive valve clearance ( Adjust valve clearance) Monitor displays error code Alarm buzzer sounds Engine horsepower lowered Please contact your Komatsu distributor suddenly (Engine is running in duration mode) 3 - 140...

- Page 192 4 - 1...

-

Page 193: Maintenance

Use Komatsu genuine parts specified in the Parts Book as replacement parts. KOMATSU GENUINE OILS: For lubrication of the machine, use the Komatsu genuine lubricants. Moreover use oil of the specified viscosity according to the ambient temperature. ALWAYS USE CLEAN WASHER FLUID: Use automobile window washer fluid, and be careful not to let any dirt get into it. - Page 194 MAINTENANCE GUIDE TO MAINTENANCE DUSTY WORKSITES: When working at dusty worksites, do as follows: Inspect the dust indicator frequently to see if the air cleaner is dirty or clogged. Clean the radiator core frequently to avoid clogging. Clean and replace the fuel filter frequently. Clean electrical components, especially the starting motor and alternator, to avoid accumulation of dust.

- Page 195 MAINTENANCE GUIDE TO MAINTENANCE PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES: When removing parts at locations where there are O-rings or gasket seals, clean the mounting surface, and replace with new parts. When doing this, be careful not to forget to assemble the O-rings and gaskets. When installing the hoses, do not twist them or bend them sharply.

-

Page 196: Outline Of Service

Komatsu distributor. When using commercially available oil, it may be necessary to reduce the oil change interval. We recommend that you use the Komatsu oil clinic to carry out a detailed checks of the characteristics of the oil. 4 - 5... - Page 197 2 years or 4000 hours. As a basic rule, we do not recommend the use of any coolant other than Komatsu genuine supercoolant (AF-NAC). If you use another coolant, it may cause serious problems, such as corrosion of the engine and aluminum parts of the cooling system.

- Page 198 Be particularly careful to wipe off the old grease in places where sand or dirt sticking in the grease would cause wear of the rotating parts. CARRYING OUT KOWA (Komatsu Oil Wear Analysis) KOWA is a maintenance service that makes it possible to prevent machine failures and downtime. With KOWA, the oil is periodically sampled and analyzed.

-

Page 199: Relating To Electric System

Service relating to the electric system is checking fan belt tension, checking damage or wear to the fan belt and checking battery fluid level. Never install any electric components other than those specified by Komatsu. External electro-magnetic interference may cause malfunction of the control system controller, before installing a radio receiver or other wireless equipment, contact your Komatsu distributor. -

Page 200: Handling Hydraulic System

MAINTENANCE OUTLINE OF SERVICE HANDLING HYDRAULIC SYSTEM During operations and after completion of operations, the hydraulic equipment is at a high temperature. During operations, it is also under high pressure, so when carrying out inspection and maintenance of hydraulic related equipment, be careful of the following points. -

Page 201: Wear Parts List

When replacing parts, always use Komatsu genuine parts. As a result of our continuous efforts to improve product quality, the part number may change, so inform your Komatsu distributor of the machine serial number and check for the latest part number when ordering parts. WEAR PARTS LIST The parts in parentheses are to be replaced at the same time. - Page 202 MAINTENANCE MAINTENANCE WEAR PARTS LIST WEAR PARTS LIST Weight Replacement Item Part No. Part Name Q'ty (kg(lb)) frequency 130-70-41130 Cutting edge (right) 37.5 130-920-2180 Cutting edge (left) 34.0 (02090-11270) (Bolt) (17) D65EX (02290-11219) (Nut) (17) Semi-U blade 175-71-22272 End bit (left) 39.0 (tilt dozer) 175-71-22282...

-

Page 203: Recommended Fuel, Coolant, And Lubricant

RECOMMENDED FUEL, COOLANT, AND LUBRICANT RECOMMENDED FUEL, COOLANT, AND LUBRICANT Komatsu genuine oils are adjusted to maintain the reliability and durability of Komatsu construction equipment and components. In order to keep your machine in the best conditioner for long periods of time, it is essential to follow the instructions in this Operation and Maintenance Manual. -

Page 204: Use Of Fuel, Coolant And Lubricants According To Ambient Temperature

MAINTENANCE RECOMMENDED FUEL, COOLANT, AND LUBRICANT USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE ASTM: American Society of Testing and Material 4 - 13... -

Page 205: Recommended Brands, Recommended Quality For Products Other Than Komatsu Genuine Oil

3) To maintain the anticorrosion properties of Supercoolant (AF-NAC), always keep the density of Supercoolant between 30% and 68%. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL When using commercially available oils other than Komatsu genuine oil, consult your Komatsu distributor. 4 - 14... -

Page 206: Standard Tightening Torques For Bolts And Nuts

Unless otherwise specified, tighten the metric nuts and bolts to the torque shown in the table below. If it is necessary to replace any nut or bolt, always use a Komatsu genuine part of the same size as the part that was replaced. -

Page 207: Periodic Replacement Of Safety Critical Parts

These parts are particularly closely connected to safety and fire prevention, so please contact your Komatsu distributor to have them replaced. Material quality of these parts can change as time passes and they are likely to wear out or deteriorate. However, it is difficult to determine the extent of wear or deterioration at the time of periodic maintenance. - Page 208 MAINTENANCE PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS NO. Safety critical parts for periodic replacement Q'ty Replacement interval Hose (main valve - central drain block) Hose (main control valve - blade tilt relay block) Hose (blade tilt relay block - Tilt cylinder) Hose (main valve - blade tilt relay tube) Hose (Radiator guard upper part - Lift cylinder) Hose (self-reducing pressure valve - fan pump)

-

Page 209: Maintenance Schedule Chart

MAINTENANCE MAINTENANCE SCHEDULE CHART MAINTENANCE SCHEDULE CHART MAINTENANCE SCHEDULE CHART WHEN REQUIRED CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT 4- 20 CLEAN INSIDE OF COOLING SYSTEM 4- 23 CHECK TRACK SHOE TENSION, ADJUST 4- 26 CHECK AND TIGHTEN TRACK SHOE BOLTS 4- 28 REVERSE AND REPLACE END BITS AND CUTTING EDGES 4- 29... - Page 210 MAINTENANCE MAINTENANCE SCHEDULE CHART EVERY 1000 HOURS SERVICE REPLACE FUEL MAIN FILTER CARTRIDGE 4- 66 CHANGE OIL IN POWER TRAIN CASE, CLEAN STRAINERS (POWER TRAIN STRAINER, SCAVENGING PUMP STRAINER) 4- 69 REPLACE HYDRAULIC TANK BREATHER ELEMENT 4- 71 CHECK OIL LEVEL IN DAMPER CASE, ADD OIL 4- 72 CHANGE OIL IN FINAL DRIVE CASE 4- 73...

-

Page 211: Service Procedure

MAINTENANCE SERVICE PROCEDURE SERVICE PROCEDURE WHEN REQUIRED CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT WARNING If inspection, cleaning, or maintenance is carried out with the engine running, dirt will get into the engine and damage it. Always stop the engine before carrying out these operations. When using compressed air, there is danger that dirt may be blown around and cause serious injury. - Page 212 MAINTENANCE MAINTENANCE SERVICE PROCEDURE SERVICE PROCEDURE NOTICE The inner element must not be used again even after cleaning. When replacing the outer element, replace the inner element at the same time. 5. Direct dry compressed air (Max. 0.69 MPa (7 kg/cm , 99.4 PSI)) from the inside of the outer element along its folds.

- Page 213 MAINTENANCE SERVICE PROCEDURE REPLACING ELEMENT 1. Open the left engine side cover. 2. Remove three clips (2), then remove cover (3). 3. Remove outer element (4). Do not remove inner element (5) at this time, however. 4. Clean the interior of the air cleaner body, cover (3) and evacuator valve (6).

-

Page 214: Clean Inside Of Cooling System

2 years or 4000 hours. As a basic rule, we do not recommend the use of any coolant other than Komatsu genuine supercoolant (AF-NAC). If you use another coolant, it may cause serious problems, such as corrosion of the engine and aluminum parts of the cooling system. - Page 215 When changing the coolant or draining the coolant from the radiator before carrying out repairs, ask a specialist company to handle any coolant containing antifreeze, or contact your Komatsu distributor. Antifreeze is toxic, so never pour it into drainage water ditches or drain it onto the ground surface.

- Page 216 MAINTENANCE MAINTENANCE SERVICE PROCEDURE SERVICE PROCEDURE 2. Turn radiator cap (1) slowly until it hits the stopper and by so doing, relieving the internal pressure. 3. Turn radiator cap (1) until it hits the next stopper, while depressing it. Keep turning the radiator cap (1) until it hits the last stopper.

-

Page 217: Check Track Shoe Tension, Adjust

Never loosen any part other than plug (1). Never put your face in the mounting direction of plug (1). If the track tension cannot be loosened with the procedure given here, please contact your Komatsu distributor. WHEN INCREASING TENSION Prepare a grease pump. - Page 218 It is extremely dangerous to release the grease by any method except the procedure given below. If the track tension is not relieved by this procedure, please contact your Komatsu distributor. 1. Loosen plug (1) gradually to release the grease.

-

Page 219: Check And Tighten Track Shoe Bolts

MAINTENANCE SERVICE PROCEDURE CHECK AND TIGHTEN TRACK SHOE BOLTS Track shoes may be broken, if they are used with loosened shoe bolts (1). Hence whenever a loosened bolt is found, be sure to retighten it. METHOD OF TIGHTENING (TRACK SHOE BOLTS) 1. -

Page 220: Reverse And Replace End Bits And Cutting Edges

MAINTENANCE SERVICE PROCEDURE REVERSE AND REPLACE END BITS AND CUTTING EDGES WARNING It is dangerous if the work equipment moves during the turning or replacement operation. Set the work equipment in a stable condition, set the work equipment lock lever to the LOCK position, then stop the engine. Reverse or replace the end bits and cutting edges before it is worn out to the blade end. - Page 221 MAINTENANCE SERVICE PROCEDURE 4. Remove the cutting edge and the end bit and clean the mounting surface. 5. Reverse or replace the cutting edge and the end bit when worn out. 1) Remove nut (1) and bolt (2), then replace or reverse the cutting edge and the end bit.

-

Page 222: Cleaning And Inspection Of Fins Of Radiator, Oil Cooler, Condenser And After-Cooler

MAINTENANCE SERVICE PROCEDURE CLEANING AND INSPECTION OF FINS OF RADIATOR, OIL COOLER, CONDENSER AND AFTER-COOLER If the radiator fins are clogged or dirty, clean and inspect them. CLEANING BY COOLING FAN REVERSE TURN NOTICE When working on jobsites where the fins often become clogged, always do as follows after completing operations. When rotating the cooling fan in the reverse direction, be extremely careful of flying dust. - Page 223 MAINTENANCE SERVICE PROCEDURE 4. Turn engine starting switch key (1) to the ON position to start up the engine. Then the cooling fan begins to rotate in the reverse direction. 5. Run the engine at high idle. Select the time for running the engine at high idle as follows according to the condition of clogging. Normal clogging: 1 to 2 minutes Excessive clogging: 2 to 3 minutes 6.

- Page 224 MAINTENANCE SERVICE PROCEDURE CLEANING OF OIL COOLER FINS AND CONDENSER FINS When the oil cooler fins and condenser fins are clogged or lots of dust is accumulated, clean them with compressed air. 1. Open up right and left side covers (1). 2.

-

Page 225: Clean Hydraulic Tank Breather

MAINTENANCE MAINTENANCE SERVICE PROCEDURE SERVICE PROCEDURE 6. Remove right and left bolts (11) - 2 bolts in total, and loosen bolts (12) - 2 bolts in total - to swing back oil cooler (9) and air conditioner condenser (10). 7. Blow off dirt, dust and dry leaf shreds clogging the oil cooler fins and air conditioner condenser fins with compressed air. -

Page 226: Check, Adjust Air Conditioner

MAINTENANCE SERVICE PROCEDURE CHECK, ADJUST AIR CONDITIONER (Machine equipped with cab) CHECKING TENSION OF COMPRESSOR BELT If the driving belt slackens, it is likely to slip, lowering the cooling efficiency. Depress the mid point between drive pulley (1) and compressor pulley (2) with a thumb (approx. 98 N (10 kg)) every now and then to make sure that deflection amount (A) is approx. -

Page 227: Grease Door Hinge

MAINTENANCE SERVICE PROCEDURE GREASE DOOR HINGE (Machine equipped with cab) If the door makes a squeaking noise when it is opened or closed, spray lubricant in through the split in the hinge bushing. If the bushing is worn, replace the hinge. CHECK DOOR LOCK STRIKER (Machine equipped with cab) If wear (A) of the door of lock striker exceeds 0.5 mm (0.02 in),... -

Page 228: Check Door Latch