Table of Contents

Troubleshooting

Summary of Contents for RITAL GROUP 115HWR3-TR

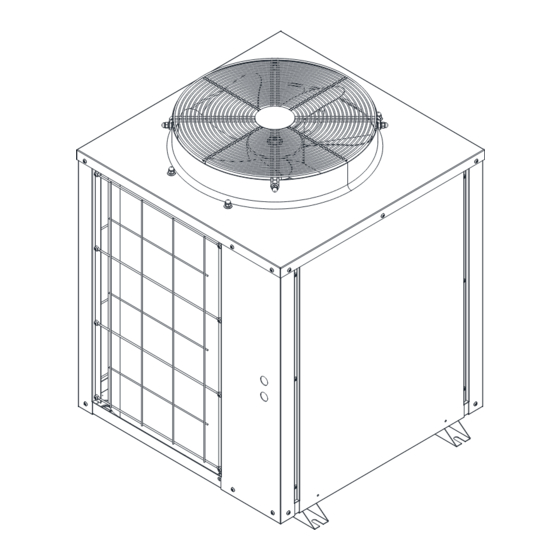

- Page 1 COMMERCIAL AIR SOURCE HEAT PUMP WATER HEATER INSTALLATION MANUAL MPORTANT NOTE: Thank you very much for purchasing our product. Before using your unit, please read this manual carefully and keep it for future reference.

-

Page 3: Table Of Contents

CONTENTS 1. FOREWORD ............................2 2. PRODUCT PARAMETERS ......................... 3 3. INSTALLATION .............................4 3.1 Unit installation ..........................4 a. Open water tank: ........................5 b. Pressurized water tank: ....................... 5 3.2 Installation diagram ........................6 3.3 Circuit Connection ......................... 7 4. TRIAL OPERATION ..........................9 4.1 Check before trial operation ...................... -

Page 4: Foreword

1. FOREWORD Please read this manual carefully before installation and use. This manual provides the necessary information for correct installation, regulation, operation, and maintenance. In production, the unit strictly follows the design standards to ensure that the unit can ... -

Page 5: Product Parameters

2. PRODUCT PARAMETERS Table-1 115HWR3 115HWR3 178HWR3 357HW 520HWR Model: RI T-TR T-TR R3T-TR 3T-TR Hot Water Capacity(kW) 11.4 11.4 17.8 35.7 Power Input(kW) 2.57 2.57 4.45 8.73 11.65 Hot Water Volume(L/h) 1120 Operation Range(℃) -15~43 Rater Outlet Water Temp.(℃) Max.Outlet Water Temp(℃)... -

Page 6: Installation

3. INSTALLATION 3.1 Unit installation Installation location (1) Enough space for installation and maintenance. (2) No blockage at the air inlet and outlet. The unit is installed in a well-ventilated place, which can bear the weight of the unit and can be installed horizontally without increasing the mechanical sound and vibration. -

Page 7: Open Water Tank

Notice A place where there are mineral oils such as cutting oil. Places such as the seaside where the water has a lot of salt in the air. Corrosive gases such as sulfur gas, acidity, or alkalinity exist in hot spring areas. Where the supply voltage fluctuates seriously and there is a strong electromagnetic wave. -

Page 8: Installation Diagram

3.2 Installation diagram... -

Page 9: Circuit Connection

3.3 Circuit Connection Notice! Installation must be done by qualified professionals in accordance with the wiring diagram on the unit. Installation shall be in accordance with the national wiring code. Before installation, confirm if the local voltage agrees with the voltage of the nameplate and if the load capacity of the power socket is agree with the requirement of the input power of the heat pump unit. - Page 10 where the light shines directly. The water quality of the unit must conform to the national standard of domestic water; otherwise, the company will not take any responsibility for machine damage. Wiring diagram Notice: For a detailed electrical control wiring diagram, please check the complete wiring diagram of the unit.

-

Page 11: Trial Operation

4. TRIAL OPERATION 4.1 Check before trial operation A trial operation must be carried out after the installation. Please confirm the following items before the trial run, and tick √ in the box after confirmation. Power supply is agree with the rated Correct installation ... -

Page 12: Instruction Of Control Function

5. INSTRUCTION OF CONTROL FUNCTION 5.1 Controller panel Function Operation method If there is no operation for 30 seconds, the key will be Key lock automatically locked; press and hold for 3 seconds to unlock; function when locked, the lock pattern will be displayed in the upper left corner. - Page 13 In the main interface, in the unlocked state, press the key and then use the key to select [Status Query] to view the unit Status inquiry parameters. Press to view the parameters of various types of unit modules, and then press the key to query the system status parameters.

-

Page 14: Interface Overview

5.2 Interface overview Key switching Five keys: ON/OFF, Function, Up , Down, Enter. Note: In the branch interface (except the countdown interface and the main interface), if the keypad is not utilized for 1-minute, then the system will automatically return to the main interface. -

Page 15: Interface Introduction

5.3 Interface introduction 5.3.1 Overview Interface submenus: a) Main Screen, b) Countdown, c) Status, d) Parameter (User Password:123) Setting, e) Password, f) Fault History. Interface switching Stand by >1 Parameter setting User parameter 1 <enter> <enter> ——— ——— >2 Password change User parameter 2 ———→... -

Page 16: Main Interface

5.3.3 Main interface 【2】 【3】 ↑ ↑ Standby Lock Standby automatically within one Refrigeration minute 12:20 Refrigeration Inquiry ↓ 【1】 ↓ 【4】 Description: 【1】Current operation mode of the unit. 【2】The current control temperature of the unit. 【3】Indicates the status of the unit and the timing status of the unit. 【4】Indicates fault inquiry of the unit. -

Page 17: Timing Set

【3】Indicates to press <Enter> key to reset fault. Display indicates to return to the main interface if there is no fault at present. If there is any fault, it continues to display the current fault. 【4】Indicate there is no fault after pressing <Enter> key. Then it returns to the main interface. - Page 18 【5】Indicates to select 01 group timing. Press <Up> or <Down> to switch among use of timing, primary timing and setting from 01 group to 10# group. After entering the selected timing item, press <Enter> key to change the set timing On/Off, Hour and Minute, Week (1, 2···7;...

-

Page 19: Status Inquiry

5.3.6 Status inquiry After entering the status inquiry interface, press <Enter> key to switch module status inquiry. 【3】 【4】 ↑ ↑ >1 Timing setting System Sysanalog Sysanalog <enter> <up> <up> ———→ ———→ ———→ >2 Status inquiry output: quantity : ▲ quantity : ▲... -

Page 20: Version Inquiry

four 4-way valve Crank Crackshaft heater Low Out Discharge water valve CompM.EEV OD% ST Main EEV opening CompA.EEV OD% ST Assistance EEV opening CompCurrent Compressor current CompSuction tmp Suction temperature °℃ CompEvap. in Temperature after EEV °℃ CompCoil tmp Coil temperature °℃... -

Page 21: Historical Fault Inquiry

<Up> to continue the inquiry. 【2】 Indicates the version and function code corresponding to control. Press <Down> to continue the inquiry. 【3】 Indicates to press <Function> key to return to menu of previous level. 5.3.8 Historical fault Inquiry After entering the Advanced function, press <Down> or <Up> to select inquiry of historical fault. -

Page 22: Module Control Wiring Diagram And Address Table

number 1…16 The number of modules that can be controlled by the unit (the total number of units, including the master and slave), the corresponding address (SR1) is set to 0...F, and 0# is the main module. 5.4.2 Module control wiring diagram and address table Address Table: Module Main... - Page 23 disconnected, the unit will shut down automatically. In module control, the linkage switch only needs to be connected to the main module, but not to the subordinate module. The linkage connection mode is as follows: ...

-

Page 24: Repairing And Maintenance

6. REPAIRING AND MAINTENANCE Trial running Note before trial running The water heater should be bypassed while the pipes are being cleaned. Only after the pipes have been verified clean should the bypass line be closed, and the isolation valves to the water heaters opened. The static water pressure should be a minimum of 15-psig and the water flow should be balanced to match the rated flow of the unit. -

Page 25: Trouble Shooting

Trouble shooting 2.1. Control protection function list 1) Cut-out protection 2) Low water flow 3) Phase sequence protection 4) Low suction pressure protection 5) Compressor overcurrent protection 6) Compressor overload protection 7) Excessive exhaust pressure protection 8) Excessive exhaust temperature protection 9) Frost protection 2.2. -

Page 26: Trouble Shooting

2.3. Trouble shooting Faults Possible cause Trouble shooting There is air in the system or Remove the gas from the nozzle other non-condensable gas and vacuum the condenser fins condenser fin dirty or debris again if necessary. blocked. Insufficient condensing air Repair the condensing fan and Excessive exhaust volume or failure of... - Page 27 Refrigerant leakage or filling is Check for leakage or fill with not enough. sufficient refrigerant. Insufficient air volume. Check fan steering. Low suction Eliminate the cause of air short pressure (Heating) Air short circuit. circuit. Failure of four-way valve or sensor, Insufficient defrost operation.

-

Page 28: Maintenance

The fastening screw on the There is noise Tighten all parts. panel is loose. The overcurrent relay will jump and the safety will burn Replace the damaged components. out. The control circuit is not on. Check the wiring of control system. High pressure protection or See front suction and exhaust low pressure protection. - Page 29 In the case of the use of cleaning agents, the concentration of cleaning agents, cleaning time and temperature are adjusted according to the dirt deposition. After pickling and cleaning, the waste liquid shall be neutralized. Contact the relevant company for waste of liquid treatment.

- Page 30 be circulated and the unit can be started for charging. If necessary, the low-voltage control switch can be temporarily short-circuited. Replenish the refrigerant. Make the frozen water cycle, and start the unit. If necessary, the low voltage control switch short. Slowly fill the system with refrigerant and check the suction and exhaust pressure.

- Page 32 Website: www.rital.com.tr Whatsapp: +90 530 936 74 97 Address: Baglarcesme mah. dogan araslı Bulv no:165 demirpark avm kat:2 ofis:35 Esenyurt İstanbul...

Need help?

Do you have a question about the 115HWR3-TR and is the answer not in the manual?

Questions and answers