Summary of Contents for Kobelt 5040-SA

- Page 1 5040-SA CALIPER BRAKE SPRING / AIR VERSION Owner’s Operation, Installation & Maintenance Manual KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B)

-

Page 2: Table Of Contents

Maintenance ....................... 15 Preventative Maintenance ..................15 Inspection ........................15 5.2.1 Pad Wear ........................ 15 5.2.2 Seals ........................16 5.2.3 Actuator Test ......................16 5.2.4 Pin Wear ......................... 16 5.2.5 Brake Disc ....................... 16 KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) - Page 3 5.3.2 Stroke Adjustment ....................19 5.3.3 Spring Actuators...................... 19 5.3.4 Brake Linings ......................20 Recommended Spares....................20 Warranty ........................21 Appendix A: Technical Drawings ................... 22 Appendix B: Parts List Drawings ................... 23 KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B)

-

Page 4: Introduction

• Do not carry out any modifications to the product. • Only use authentic Kobelt spare parts. • Observe all local regulations, directives and laws during the installation of this product. • All installation, commissioning and maintenance work must only be conducted by qualified personnel. -

Page 5: Hazards

Ensure all power sources are locked out prior to performing work. HIGH PRESSURE FLUIDS Kobelt lever brakes use high pressure hydraulics or air. Ensure all pressure is exhausted and the pressure source locked out prior to performing work. HOT SURFACES Disc brakes are capable of making the surfaces of the brake disc dangerously hot when burnishing or during braking events. -

Page 6: Product Description

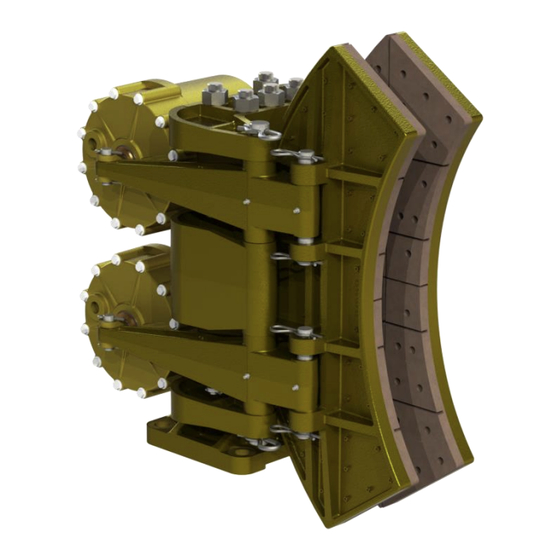

The diagram below shows a typical Kobelt caliper brake with all the major components identified. All of the Kobelt caliper brakes can be fitted with either air applied, hydraulic applied, spring applied with air released or spring applied with hydraulic released actuators depending on the required service. -

Page 7: Installation

The disc mounting bolts used must be of a suitable size and grade to safely resist the brake torque plus the stresses induced from thermal expansion of the disc. For high temperature disc KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) - Page 8 For cases where a disc guard or some protective cover is required for a ventilated disc ensure that the guard does not compromise the performance. An improperly designed cover or shield KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B)

-

Page 9: Caliper Brakes

The piping to the brakes must be adequately sized to ensure rapid response times in all weather conditions. The piping must be selected to safely withstand the pressures required to operate the brakes. Secure the piping against vibration with pipe clamps per the schedule in the table below. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 10: Instrumentation

2.3.3 Instrumentation Kobelt caliper disc brakes may be equipped with sensors and switches. The connection to the instruments must be made by cable or flexible conduit. Follow the governing electrical code for wiring practices. Use only hardware approved for the zone that the brake is installed in. -

Page 11: Commissioning

3.1 F LUSHING Kobelt spring applied, air released disc brakes may be used in low pressure hydraulic applications. Before subjecting the brake system to full hydraulic pressure the brake lines must be flushed to an ISO 4406 cleanliness rating of 19/17/14. -

Page 12: Torque Test

Before putting equipment into service, confirm that full rated braking torque has been achieved through load testing or a torque test against the drive motors. If full brake torque has not been achieved, continue burnishing. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 13: Operation

In applications where the brakes cycle infrequently with significant changes in ambient temperature it may be necessary to provide a thermal relief to protect the actuators from over pressurization due to thermal expansion. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 14: Control

4.2 S ERVICE IMITS 4.2.1 Disc Temperature The Kobelt brake lining achieves maximum friction at 300 F. Over 300 F the brake begins to fade or experience diminishing friction. The maximum operating temperature of the brake linings is 700 F [371 C]. -

Page 15: Maintenance

The maximum allowable pad life has been reached when the brake pad has worn down to 3/16” [4.8 mm] thick. The lining must be replaced before the shoe lining bolts or rivets start making contact with the brake disc. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 16: Seals

2.2 are no longer met the disc must be removed and resurfaced or replaced. Follow the minimum thickness allowances in the table below as a guideline for when a disc must be replaced. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 17: Nde Structural Components

AMS 2175, Class 4, grade D. 2. Tie Rods: Inspect the thread roots using the wet magnetic particle method per ASTM A275. No linear indications are permitted. KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) - Page 18 KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B)

-

Page 19: Service

This is to prevent premature seal wear and reduce seal friction. All Kobelt calipers, during assembly, are pre-greased on the shoe pin and saddle pin with a Lithium based NLGI 2 grease. These pins must be re-greased no less than once annually. -

Page 20: Brake Linings

4. Tighten screws ‘B’ ECOMMENDED PARES The spare parts kept on hand will depend on the severity of the service. As a minimum Kobelt recommends keeping the following parts for each brake in service: 1. One Lined set of brake shoes 2. -

Page 21: Warranty

If any part is found to be defective, Kobelt will replace said part FOB the Kobelt factory provided that any such defective part is returned by the Buyer with freight and applicable forwarding charges prepaid by the Buyer. -

Page 22: Appendix A: Technical Drawings

A: T PPENDIX ECHNICAL RAWINGS KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) -

Page 23: Appendix B: Parts List Drawings

B: P PPENDIX ARTS RAWINGS KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) - Page 24 KOBELT MANUFACTURING CO. LTD MNL-5040-SA.docx (rev B) Digitally signed by Heiko Heiko Epkens Epkens Date: 2022.01.11 10:03:23 -08'00'...

Need help?

Do you have a question about the 5040-SA and is the answer not in the manual?

Questions and answers