Summary of Contents for Kobelt 5020-M Series

- Page 1 5020-M Series Disk Brakes Manually Applied Version Owner’s Operation, Installation & Maintenance Manual Kobelt Manufacturing Co. Ltd.

- Page 2 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. NOTES RECORD DATA BEFORE INSTALLATION FOR FUTURE REFERENCE Model #: Serial #: Date of Purchase: Date of Installation: rev B mnl5020-M.docx 2 of 27...

-

Page 3: Table Of Contents

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. ABLE OF ONTENTS Introduction ......................4 Contact ........................4 Safety .......................... 4 Product Description ....................7 Technical Data ......................7 Installation ......................10 Preparation ....................... 10 Brake Discs........................ 10 Caliper Brakes ......................12 Commissioning .................... -

Page 4: Introduction

Kobelt reserves the right, without notice, to change the design, or construction, of any products and to discontinue or limit distribution of any products. Kobelt also reserves the right to change, or update, without notice, any technical information contained within this document. - Page 5 • Do not carry out any modifications to the product. • Only use authentic Kobelt spare parts. • Observe all local regulations, directives and laws during the installation of this product. • All installation, commissioning, and maintenance work must only be conducted by qualified personnel.

- Page 6 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. 1.2.3 Product Hazards Equipment Starts Automatically: Brake systems frequently are controlled remotely and may activate suddenly causing bodily harm. Ensure all power sources are locked out prior to performing work. Pinch Points: Brakes contain numerous pinch points which can cause serious injury.

-

Page 7: Product Description

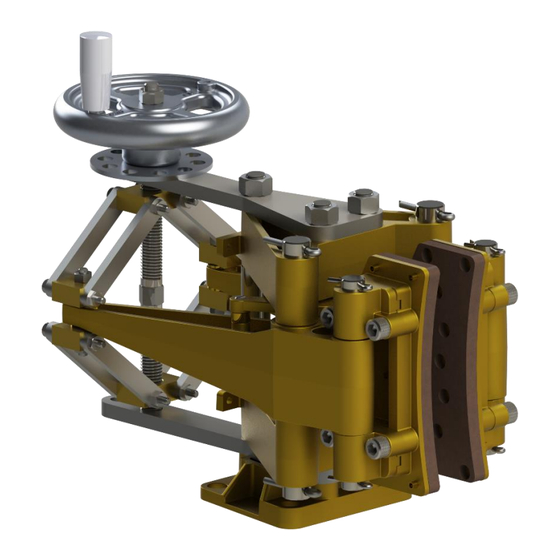

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. RODUCT ESCRIPTION The diagram below shows a typical Kobelt caliper brake with all the major components identified. Figure 1: Caliper Brake Nomenclature ECHNICAL BRAKE SPECIFICATIONS 0 …4550 lbs Normal Force [20.2 KN] F …+120 C …+49... - Page 8 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. 5020-M BRAKING TORQUE 4500 4000 3500 3000 2500 2000 1500 1000 Disc OD (in) 1) Values in this chart are theoretical and for reference only. They are based on properly bedded and burnished linings acting on a rotor at 20 C and manufactured to required specifications.

- Page 9 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. ODEL rev B mnl5020-M.docx 9 of 27...

-

Page 10: Installation

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. NSTALLATION REPARATION The foundation plate to support the brake caliper must be designed to withstand the maximum braking forces generated by the brake caliper. The foundation must also be flat to ISO tolerance grade IT8 and square to the brake disc. See Appendix A for key installation dimensions. - Page 11 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. The disc mounting bolts used must be of a suitable size and grade to safely resist the brake torque plus the stresses induced from thermal expansion of the disc. For high temperature disc applications, the holes for the mounting bolts must be machined oversized to allow the disc to expand during operation.

-

Page 12: Caliper Brakes

Lower the brake down and tighten the mounting bolts to the recommended preload. 3.3.2 Instrumentation Kobelt caliper disc brakes may be equipped with a release indicating proximity switch (part number 6001-3711). The connection to the switch must be made with a 3 pin – M8 cable. -

Page 13: Commissioning

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. OMMISSIONING The running clearance between the pads and disc is factory set and not adjustable. As a check prior to putting the brakes into service, ensure that the airgap between the brake pads and disc when the brakes are released is at least 0.01”... -

Page 14: Torque Test

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. Reference section 5.2 for instructions on manually operating the brake. Disc temperature must not exceed 700°F (371°C) or permanent degradation of the lining may occur. Burnishing is best achieved by applying the maximum torque and minimum speed that the drive can tolerate. -

Page 15: Operation

5.1.1 Disc Temperature The Kobelt brake lining achieves maximum friction at 300°F. Over 300°F the brake begins to fade or experience diminishing friction. The maximum operating temperature of the brake linings is 700°F [371°C]. Temperatures in excess of this limit will permanently damage the linings and require replacement. -

Page 16: Manual Operation

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. ANUAL PERATION To apply the brake, turn the handwheel clockwise until the pads contact the disc. Then, using a torque wrench acting on the torque setting nut and the chart below as a reference, set the desired brake torque by applying the correct amount or torque to the handwheel.. -

Page 17: Maintenance

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. AINTENANCE REVENTATIVE AINTENANCE • Monthly (12 times per year) Measure air gap Determine pad life • Annually (1 time per year) Lubricate pivot pins Inspect brake disc Torque Test • Every 5 years... -

Page 18: Service

ERVICE 6.3.1 Lubrication All Kobelt calipers, during assembly, are pre-greased on the shoe pin and saddle pin with a Lithium based NLGI 2 grease. These pins must be re-greased no less than once annually. 6.3.2 Brake Linings The linings must be replaced before the rivets make contact with the disc. - Page 19 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. Remove bottom cotter pins from pins ‘E’. Remove pins ‘E’ by pulling upwards. Remove shoes by sliding radially forward to clear the ends of the levers. When re-installing the shoes into the caliper assembly, be sure to re-engage the balancing links “A”...

-

Page 20: Recommended Spare Parts

ECOMMENDED PARE ARTS The spare parts kept on hand will depend on the severity of the service. As a minimum Kobelt recommends keeping the following parts for each brake in service: One Lined set of brake shoes One set of brake pads with rivets When purchasing replacement parts refer to Appendix B: Parts List at the back of this manual for Kobelt component Part Numbers. -

Page 21: Troubleshooting

If you encounter problems with the operation of your product, please refer to the trouble- shooting suggestions before contacting Kobelt for assistance. If the steps below do not resolve your issue, please reach out either Kobelt directly or our Dealers in your area. Table 7: Common Solutions... -

Page 22: Warranty

If any part is found to be defective, Kobelt will replace said part FOB the Kobelt factory provided that any such defective part is returned by the Buyer with freight and applicable forwarding charges prepaid by the Buyer. -

Page 23: Appendix A: Technical Drawings

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. A: T PPENDIX ECHNICAL RAWINGS rev B mnl5020-M.docx 23 of 27... -

Page 24: Appendix B: Parts List Drawings

5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. 10 A B: P PPENDIX ARTS RAWINGS rev B mnl5020-M.docx 24 of 27... - Page 25 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. ITEM QTY. PART NUMBER DESCRIPTION 5020- LS SHOE ASSEMBLY, 3/8IN K5 5020- M- SUB HANDWHEEL SUB- ASSEMBLY 5020- 0040 BASE 5020- M 5020- 0041 TURNBUCKLE ROD 5020- M 9899- 0046- 01 HAND WHEEL 5IN ALUMINUM MODIFIED...

- Page 26 5020-M Owner's Manual Kobelt Manufacturing Co. Ltd. rev B mnl5020-M.docx 26 of 27 Heiko Epkens Digitally signed by Heiko Epkens Date: 2020.07.08 17:29:42 -07'00'...

- Page 27 Kobelt Manufacturing Co. Ltd. 8238 129th Street Surrey, British Columbia, Canada, V3W 0A6 Sales Tel: +1-604-572-3935 Fax: +1-604-590-8313 Email: sales@kobelt.com Website: www.kobelt.com Made in Canada / Printed in Canada...

Need help?

Do you have a question about the 5020-M Series and is the answer not in the manual?

Questions and answers