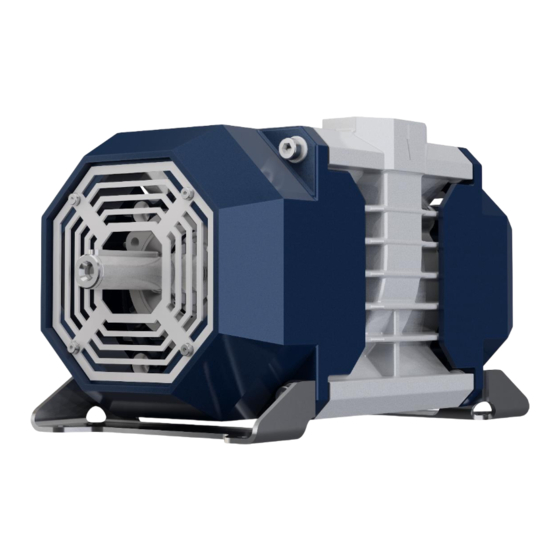

CVS RKL 160 Mounting Instructions

Multi-cell compressor

Hide thumbs

Also See for RKL 160:

- Operating instructions manual (28 pages) ,

- Operating instructions manual (32 pages)

Table of Contents

Advertisement

Quick Links

Contents

Mounting instructions

Multi-cell compressor

RKL 160

Doc-ID: 5006 / MA / EN

Release: Rev. 03 / 28/03/2023

Prior to installing the RKL 160 and putting it into operation you must have read and understood these

instructions. These instructions are only valid together with the operating instructions, they do not

replace them!

Advertisement

Table of Contents

Summary of Contents for CVS RKL 160

- Page 1 Doc-ID: 5006 / MA / EN Release: Rev. 03 / 28/03/2023 Prior to installing the RKL 160 and putting it into operation you must have read and understood these instructions. These instructions are only valid together with the operating instructions, they do not...

- Page 2 Translation of the Original Assembly Instructions © CVS engineering GmbH Großmattstraße 14 79618 Rheinfelden / Germany Phone: +49 (0)7623 71741-0 Customer service: +49 (0)7623 71741-0 E-Mail: info@cvs-eng.de Internet: www.cvs-eng.de...

-

Page 3: Table Of Contents

Safety ................. 15 Setup example ............16 Necessary work ............17 Changing the sense of rotation of the RKL 160 ..17 Attachment and installation space ......17 Suction and pressure flanges ........19 Suction and pressure lines ......... 19 Safety equipment ............ - Page 4 Mounting instructions Multi-cell compressor RKL 160 Contents 6.8.4 Protection against contact ..........21 6.8.5 Display and monitoring equipment ......21 Cooling ...............22 6.10 Drive ................22 6.10.1 V belt drive ..............23 6.10.2 Articulated shaft drive ..........23 6.10.3 Drive via flexible coupling and hydraulic motor ..24 Start-up ..................25...

-

Page 5: General

It is a product component and must be kept in direct proximity of the RKL 160, well accessible to the personnel at all times. All safety instructions of the operating instructions must additionally be... -

Page 6: Pictogram Explanation

Mounting instructions Multi-cell compressor RKL 160 General 1.2 Pictogram explanation Warning notes Warning notes are characterised by pictograms in these mounting instructions. The warning notes are marked by signal words expressing the extent of the hazard. It is absolutely essential to observe the notes and to proceed with caution in order to prevent accidents as well as bodily injuries and property damage. -

Page 7: Limitation Of Liability

Mounting instructions Multi-cell compressor RKL 160 General 1.3 Limitation of Liability See operating instructions "RKL 160" for information about limitation of liability. 1.4 Copyright protection See operating instructions "RKL 160" for information about limitation of liability. 1.5 Spare parts Information regarding the copyright protection can be found in the operating instructions "RKL 160". -

Page 8: Safety

The RKL 160 is intended exclusively for the compression of filtered air. 2.2 Acceptance and monitoring The RKL 160 itself is not subject to any acceptance and monitoring obligation. 2.3 Operator's responsibility See operating instructions "RKL 160" for information about the responsibility of the operating company. -

Page 9: Technical Data

Mounting instructions Multi-cell compressor RKL 160 Technical data Technical data 3.1 Dimensions Fig. 1: Dimensions RKL 160... -

Page 10: Technical Data

Maximum final overpressure at the pressure flange [bar] 1) Consult CVS for suction temperature and/or altitudes outside the permissible working range. 2) Intake pressure at the suction flange = 1 bar, suction and ambient temperature = 20 °C Tab. 2: Permissible working range... -

Page 11: Design

Mounting instructions Multi-cell compressor RKL 160 Design Design 4.1 Design Fig. 2: Design Suction flange – air entry DN 40 Shaft protection grid counter-side Pressure flange – air exit DN 32 Fixing feet Attachment thread for flanges Rating plate Drive shaft... -

Page 12: Function

See chapter 6.10, page 22. 4.3 Sense of rotation The RKL 160 has a continuous drive shaft. It can be driven from either side. The sense of rotation therefore may be chosen either clockwise or counter-clockwise (see page 17). The standard sense... -

Page 13: Transport And Storage

Secure against vibrations Securely fasten the RKL 160 prior to transport (e.g. screw it onto a pallet) Transport and put down the RKL 160 with a fork lift or secure with straps and lift with suitable lifting gear. -

Page 14: Storage

Mounting instructions Multi-cell compressor RKL 160 Transport and storage 5.3 Storage Storage of packages Store packages under the following conditions: Do not store outdoors. Store dry and dust free. Do not expose to aggressive media. Protect against solar irradiation. -

Page 15: Installation And Assembly

Mounting instructions Multi-cell compressor RKL 160 Installation and assembly Installation and assembly 6.1 Safety DANGER! Electrical system Mortal danger due to electric current! There is mortal danger in case of contact with live components. Activated electrically driven components can start to move uncontrolled and cause severest injuries. -

Page 16: Setup Example

Mounting instructions Multi-cell compressor RKL 160 Installation and assembly 6.2 Setup example The figure gives a schematic illustration of the RKL 160 with accessories and drive variants. Fig. 3: Setup with accessories and drive variants RKL 160 Hydraulic motor Manometer installation point... -

Page 17: Necessary Work

4 attachment screws: 4.5 Nm. 6.5 Attachment and installation space Attachment of the feet at the Attachment of the RKL 160 to the vehicle takes place by two feet RKL 160 connected to the RKL 160; connection takes place right to the chassis or the traverses. - Page 18 Accessible for maintenance and repair work (e.g. for replacing the air filter, or for checking the safety and non-return valve). The RKL 160 must not be installed on a closed ground plate. There must be sufficient free space for discharge of cooling air. Fig. 4: Installation position Top: Impermissible installation position, cooling air exit covered.

-

Page 19: Suction And Pressure Flanges

RKL 160. Support the lines, if necessary. Place suction lines rising towards the RKL 160; place pressure line falling away from the RKL 160. Provide a condensate sack with drain outlet at the lowest point. Check for tightness when using aplastic hose on the suction side ... -

Page 20: Safety Valve

6.8.2 Non-return valve The non-return valve prevents the reverse operation of the RKL 160 after it has been switched off when the pressure tank is not relieved. The valve is not suitable for retaining material to be conveyed. ... -

Page 21: Suction Filter

Mounting instructions Multi-cell compressor RKL 160 Installation and assembly 6.8.3 Suction filter Liquids and solids may not be sucked in. Requirements Provide combination filter with integrated cyclone Filter mesh < 5 Micron Filter resistance when it is new < 15 mbar ... -

Page 22: Cooling

Mounting instructions Multi-cell compressor RKL 160 Installation and assembly 6.9 Cooling The RKL 160 is air-cooled. Ensure at installation that no heat accumulation results and that the cooling air can circulate freely. The front cooling air entry openings must not be covered;... -

Page 23: Belt Drive

ATTENTION! V-belt drive only in connection with a layshaft via elastic coupling. Assembly of the V-belt pulley on the shaft of the RKL 160 is not permitted. No radial forces must be introduced into the shaft of the RKL 160. -

Page 24: Drive Via Flexible Coupling And Hydraulic Motor

Observe the design, installation and inspection instructions of the manufacturer. The hydraulic motor is installed to the RKL 160 via an intermediate flange. The power is transmitted via a flexible coupling. Components that match the RKL 160 can be ordered from CVS. -

Page 25: Start-Up

– Pay attention to tidiness and cleanliness in the working area! Loosely stacked or scattered components and tools are accident sources. Please observe all safety instructions as per the operating instructions "RKL 160", Chapter "Occupational safety and special danger". -

Page 26: Start-Up

Check the attachment screws. (see page 18, chapter 6.5.) Start-up Proceed as follows during start-up: Pay attention to permissible inclination of the RKL 160 Open shut-off devices (if available) Start the RKL 160 drive (engage gently). ... -

Page 27: Declaration Of Incorporation

Mounting instructions Multi-cell compressor RKL 160 Declaration of Incorporation Declaration of Incorporation Einbauerklärung im Sinne der Maschinenrichtlinie 2006/42/EG Anhang II 1B - Orginaleinbauerklärung Declaration of Incorporation according to the EC Machinery Directive 2006/42/EC Annex II 1B – Original Declaration of Incorporation... - Page 28 Mounting instructions Multi-cell compressor RKL 160 Declaration of Incorporation Declaration of Incorporation according to The Supply of Machinery (Safety) Regulations 2008 Annex II 1B - Original Declaration of Incorporation Manufacturer: CVS engineering GmbH Großmattstraße 14 D-79618 Rheinfelden Importer: CompVac Ltd.

-

Page 29: Index

Mounting instructions Multi-cell compressor RKL 160 Index Index Requirement ............18 Installation position ..........18 Acceptance ............8 Intended use ............8 Accessories ............16 Intended use ............8 Articulated shaft Requirement ........... 23 Liability ..............7 Articulated shaft drive ......... 23 Lubrication ............12... - Page 30 Mounting instructions Multi-cell compressor RKL 160 Index Technical data..........9, 10 V belt drive ............23 Transport ............13 Warranty ............... 7...

Need help?

Do you have a question about the RKL 160 and is the answer not in the manual?

Questions and answers