Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Yale GDP16-20AF

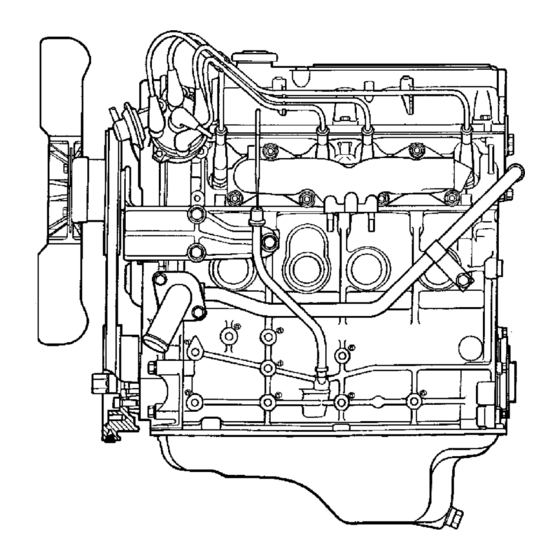

- Page 1 Maintenance 0$='$ (1*,1( FE AND F2 GP/GLP/GDP16-20AF/BF (GP/GLP/GDP030-040AF/BF) [A810]; GC/GLC030-040AF [B809]; GLP/GDP16-20AF (GP/GLP/GDP030-040AF) [B810]; GP/GLP/GDP2.00-3.00RF/TF (GP/GLP/GDP040-060RG/TG/ZG) [A875]; GC/GLC040-065TF/RF [E187] PART NO. 524158742 600 YRM 496...

- Page 2 • Use the correct tools for the job. • Keep the tools clean and in good condition. • Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. • Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts.

-

Page 3: Table Of Contents

Thermostat ..............................Replace............................... Fan Assembly..............................Remove and Disassemble .......................... Assemble and Install........................... Water Pump ..............................Remove and Disassemble .......................... Assemble and Install........................... Distributor Repair..............................Remove ................................Install................................Flywheel and Ring Gear Repair .......................... Remove ................................©2002 Yale Materials Handling Corp. - Page 4 Valve Mechanism ............................Camshaft................................. Crankshaft............................... Connecting Rods............................. Cylinder Block ..............................Pistons ................................Oil Pump ................................. Torque Specifications ............................Troubleshooting ..............................This section is for the following models: GP/GLP/GDP16-20AF/BF (GP/GLP/GDP030-040AF/BF) [A810]; GC/GLC030-040AF [B809]; GLP/GDP16-20AF (GP/GLP/GDP030-040AF) [B810]; GP/GLP/GDP2.00-3.00RF/TF (GP/GLP/GDP040-060RG/TG/ZG) [A875]; GC/GLC040-065TF/RF [E187]...

-

Page 5: General

The removal and installation procedures for the engine (GP/GLP/GDP030-040AF), see the section Frame 100 are not included in this section. For model units YRM 545. For model units GP/GLP/GDP2.0-3.0RF/TF GP/GLP/GDP16-20AF/BF (GP/GLP/BDP030-040AF/ (GP/GLP/GDP040-060RG/TG/ZG) and GC/GLC040- BF), GC/GLC030-040AF, GLP/GDP16-20AF 065TF/RF, see the section Frame 100 YRM 505. -

Page 6: Cylinder Head, Camshaft, And Valve Mechanism Repair

Cylinder Head, Camshaft, and Valve Mechanism Repair 600 YRM 496 Cylinder Head, Camshaft, and Valve Mechanism Repair REMOVE 8. Use chalk to mark direction of timing belt rotation. See Figure 2. Remove timing belt. 1. Disconnect connections at battery. 2. Drain cooling system. 3. -

Page 7: Clean

600 YRM 496 Cylinder Head, Camshaft, and Valve Mechanism Repair 1. FRONT HOUSING 3. OIL SEAL Figure 6. Cylinder Head Removal Sequence 2. GASKET 16. Use valve spring compressor to remove valve re- Figure 4. Front Housing tainers, springs, and valves from head. See Fig- ure 7. -

Page 8: Inspect And Repair

Cylinder Head, Camshaft, and Valve Mechanism Repair 600 YRM 496 INSPECT AND REPAIR Camshaft 1. Check camshaft for cracks or damage. Cylinder Head 2. Use dial indicator on end of camshaft to check Use straight edge and thickness gauge to check bottom movement of camshaft in cylinder head. -

Page 9: Valve Guides

600 YRM 496 Cylinder Head, Camshaft, and Valve Mechanism Repair b. Put plastic gauge material between each camshaft journal and cap. Do not allow camshaft to rotate. c. Tighten capscrews for caps to 18 to 27 N•m (13 to 20 lbf ft). See Figure 12. Correct clearance for journals No. -

Page 10: Valve Seats

Cylinder Head, Camshaft, and Valve Mechanism Repair 600 YRM 496 Valves 1. Inspect stem of each valve for wear. Use microme- ter to measure outside diameter of stem. See Fig- ure 15. Minimum dimension for intake valve is 7.980 mm (0.3142 in.). -

Page 11: Valve Springs

600 YRM 496 Cylinder Head, Camshaft, and Valve Mechanism Repair Valve Springs 1. Check valve springs for damage. 2. Measure free length of outer valve springs. See Figure 16. Minimum length of intake spring is 44.3 mm (1.74 in.). Minimum length of exhaust spring is 50.8 mm (2.00 in.). - Page 12 Cylinder Head, Camshaft, and Valve Mechanism Repair 600 YRM 496 9. Install capscrew and washer for camshaft pulley. See Figure 22. Keep pulley from turning and tighten capscrew to 48 to 66 N•m (35 to 49 lbf ft). A. NO. 1 AND NO. 3 ARE THE SAME B.

- Page 13 600 YRM 496 Cylinder Head, Camshaft, and Valve Mechanism Repair 10. Align timing marks for crankshaft pulley. See Fig- ure 23. Install crankshaft pulley, tapered ring, and capscrew. Tighten capscrew to 160 to 170 N•m (118 to 125 lbf ft). 1.

-

Page 14: Crankshaft And Main Bearings Repair

Crankshaft and Main Bearings Repair 600 YRM 496 Crankshaft and Main Bearings Repair REMOVE 8. Put identification marks on bearing caps. Loosen capscrews for main bearing caps in steps. Then 1. Remove bracket for cooling fan. remove capscrews, caps, and crankshaft. 2. -

Page 15: Install

600 YRM 496 Crankshaft and Main Bearings Repair 1. PLASTIC GAUGE 2. SCALE MATERIAL Figure 28. Main Bearings Clearance Check INSTALL 1. Clean areas of cylinder block around main bear- ings. Carefully install bottom half of new main bear- ings if necessary. Lubricate bearings with clean en- gine oil. -

Page 16: Pistons And Connecting Rods Repair

Pistons and Connecting Rods Repair 600 YRM 496 8. Install oil strainer. Tighten M6 capscrews to 8 to 12 N•m (6 to 9 lbf ft). Tighten M8 capscrews to 16 to 23 N•m (12 to 17 lbf ft). 9. Install gasket and oil pan. Tighten capscrews to 7 to 12 N•m (5 to 9 lbf ft). -

Page 17: Connecting Rods And Bearings

600 YRM 496 Pistons and Connecting Rods Repair end clearance of each piston ring. See Figure 31. 2. Clean rod bearings and crankshaft journals. To Correct dimensions are as follows: check bearings for wear, measure clearance be- Top Piston Ring - 0.20 to 0.35 mm (0.008 to tween rod bearings and journals. - Page 18 Pistons and Connecting Rods Repair 600 YRM 496 1. F MARK 2. OIL PORT Figure 33. Connecting Rod and Piston 3. Install piston rings on pistons. During installation, writing on each piston ring must be toward top of piston. Check that rings rotate freely. Then put ends of rings in positions shown in Figure 34.

-

Page 19: Cylinder Block Repair

600 YRM 496 Oil Pump Repair Cylinder Block Repair 1. After cylinder block is cleaned, check its surface for distortion. See Figure 36. If amount of distortion is greater than 0.15 mm (0.0059 in.), grind surface of cylinder block. Max- imum amount of correction permitted is 0.20 mm (0.008 in.). -

Page 20: Clean

Oil Pump Repair 600 YRM 496 INSPECT 1. Check front cover (pump housing) and pump cover for wear or damage. Check plunger spring for dam- age. 2. Measure parts of oil pump. See Figure 40. a. Measure clearance between gears and cres- cent. -

Page 21: Install

600 YRM 496 Cooling System Repair 1. CLEARANCE BETWEEN CRESCENT AND 3. SIDE CLEARANCE OF GEARS IN HOUSING INNER GEAR 4. CLEARANCE BETWEEN HOUSING AND OUTER 2. CLEARANCE BETWEEN CRESCENT AND GEAR GEARS Figure 40. Oil Pump Measurement INSTALL 1. Install O-ring on oil pump housing. Use grease to hold O-ring in position. -

Page 22: Fan Assembly

Cooling System Repair 600 YRM 496 1. FAN 5. SHAFT 2. PULLEY 6. SUPPORT 1. CYLINDER BLOCK 3. THERMOSTAT 3. HUB BRACKET 2. GASKET 4. HOUSING 4. SNAP RING 7. BRACKET Figure 42. Thermostat Figure 43. Fan Assembly 3. Test operation of thermostat. See Cooling System Assemble and Install 700 YRM 626. -

Page 23: Assemble And Install

600 YRM 496 Cooling System Repair 2. Loosen alternator and remove fan belt. 2. Use press to install shaft and bearing in pump body. Make sure shaft turns smoothly. 3. Remove capscrews for the fan. Remove fan and pulley from the hub. 3. -

Page 24: Distributor Repair

Distributor Repair 600 YRM 496 1. PULLEY 3. WASHER 1. TENSIONER 3. LOCK BOLT 2. SHAFT AND 4. HOUSING 2. SPRING 4. TENSION SIDE BEARING 5. SEAL ASSEMBLY 6. IMPELLER Figure 47. Timing Belt Installation Figure 46. Water Pump Distributor Repair NOTE: This section only has the removal and installa- tion procedures for the distributor. -

Page 25: Flywheel And Ring Gear Repair

600 YRM 496 Flywheel and Ring Gear Repair Flywheel and Ring Gear Repair NOTE: This flywheel and ring gear repair is for GP/GLP/ NOTE: Before ring gear is removed, note position of GDP2.0-3.0RF/TF (GP/GLP/GDP040-060RG/TG/ZG) chamfer on teeth. and GC/GLC040-065TF/RF models. 1. -

Page 26: Flywheel Repair

Flywheel Repair INSTALL NOTE: This flywheel repair GP/GLP/ GDP16-20AF/BF (GP/GLP/GDP030-040AF/BF), 1. If adapter plate for the torque converter housing GC/GLC030-040AF, GLP/GDP16-20AF was removed, install it on engine. See Figure 51. (GP/GLP/GDP030-040AF) models. Tighten capscrews to 43 to 51 N•m (32 to 38 lbf ft). -

Page 27: Valve Adjustment

600 YRM 496 Valve Adjustment Valve Adjustment 1. Rotate crankshaft until No. 1 piston is at TDC on compression stroke (intake and exhaust valves closed). 2. Adjust clearance of intake valves for No. 1 and No. 2 cylinders and exhaust valves for the No. 1 and No. 3 cylinders. -

Page 28: Compression Pressure Check

The correct timing for the GC/GLC040-065TF/RF YRM 524 for the adjustment procedure for engine tim- and GP/GLP/GDP2.0-3.0RF/TF (GP/GLP/GDP040- ing. 060RG/TG/ZG) units is as follows: The correct timing for the GP/GLP/GDP16-20AF/BF • Gasoline Engine = 0 BTDC @ 725 ±25 rpm (white (GP/GLP/GDP030-040AF/BF), GC/GLC030-040AF, mark) -

Page 29: Throttle Linkage Adjustment

(GP/GLP/ GDP030-040AF/BF), GC/GLC030-040AF, For later units, see LPG Fuel System, Aisan GLP/GDP16-20AF (GP/GLP/GDP030-040AF) units, Open-Loop 900 YRM 925 or LPG Fuel System, see Gasoline Fuel System 900 YRM 547 for the Aisan Closed-Loop 900 YRM 948 for the correct correct adjustment procedure. -

Page 30: Cylinder Head

Engine Specifications 600 YRM 496 CYLINDER HEAD – Service Limit FE........44.3 mm (1.744 in.) Height ........91.25 to 92.05 mm Spring Free Length (3.620 to 3.624 in.) - Inner F2 ......47.7 mm (1.878 in.) Distortion Limit..... 0.15 mm (0.006 in.) –... -

Page 31: Crankshaft

600 YRM 496 Engine Specifications CRANKSHAFT PISTONS Diameter ......85.944 to 85.964 mm Distortion FE......less than 0.03 mm (0.0012 in.) (3.3836 to 3.3844 in.) Distortion F2 ......less than 0.04 mm Clearance Between Piston and Bore ....0.036 to 0.075 mm (0.0016 in.) (0.0014 to 0.0030 in.) Main Bearing Journal... -

Page 32: Torque Specifications

Torque Specifications 600 YRM 496 Side Clearance Between Gears and Housing....0.03 to 0.063 mm (0.0012 to 0.0025 in.) – Service Limit ....0.10 mm (0.004 in.) Torque Specifications Camshaft Pulley Lock Bolt Oil Pan 48 to 66 N•m (35 to 49 lbf ft) 7 to 12 N•m (62 to 106 lbf in) Cooling Fan Oil Pump... -

Page 33: Troubleshooting

600 YRM 496 Troubleshooting Troubleshooting PROBLEM POSSIBLE CAUSE PROCEDURE OR ACTION The engine will not start. The fuel tank is empty. Fill fuel tank. The battery is not fully charged. Charge battery. The connections at the battery are Check and tighten battery connections. loose or they have corrosion. - Page 34 Troubleshooting 600 YRM 496 PROBLEM POSSIBLE CAUSE PROCEDURE OR ACTION The engine does not have The valve mechanism does not work Check and repair valve mechanism. enough power. (Cont.) correctly. The piston assemblies are worn or Install new pistons. damaged. The exhaust system has restrictions.

- Page 35 600 YRM 496 Troubleshooting PROBLEM POSSIBLE CAUSE PROCEDURE OR ACTION The engine gets too hot. The cooling system has restrictions. Check radiator and hoses. (Cont.) The belt for the water pump is worn or Check and adjust the belt. not adjusted correctly. The thermostat has damage.

- Page 36 NOTES ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________...

- Page 38 Yale Materials Handling Corp. 1400 Sullivan Dr., Greenville, NC 27834-2011 600 YRM 496 1/02 Printed in U.S.A.