Subscribe to Our Youtube Channel

Summary of Contents for Kracht VC 0.025-16

- Page 1 D.0025420002 Operating instructions (Translation) Gear type flow meter VC 0.025 - 16 English 17 • 14/06/2023...

-

Page 2: Table Of Contents

Table of content Kracht GmbH Table of content 1 General ............................1.1 About the documentation..........................1.2 Manufacturer address ............................ 1.3 Other applicable documents ........................1.4 Symbols................................2 Safety............................2.1 Intended use ..............................2.2 Personal qualification ............................. 2.3 Basic safety instructions .......................... - Page 3 Kracht GmbH Table of content 6.3 Electrical connection............................31 6.3.1 Preamplifier (S, H, K)........................31 6.3.2 IO-Link............................... 33 7 Commissioning ........................... 40 7.1 Safety instructions for start-up........................40 7.2 Preparation ................................. 40 7.3 Additional commissioning..........................41 8 Removal............................42 8.1 Safety instructions for disassembly......................42 8.2 Dismantling ................................

-

Page 4: General

1 | General Kracht GmbH 1 General 1.1 About the documentation These operating instructions describe the installation, operation and maintenance of the follow- ing product: Gear type flow meters VC 0.025 -16 These operating instructions are an integral part of the product and must be kept in the imme- diate vicinity of the product and accessible to the personnel at all time. -

Page 5: Symbols

Kracht GmbH General | 1 1.4 Symbols DANGER Identification of an immediate hazard, which can lead to death or severe bodily injury if not avoided. WARNING Identification of a potential medium risk hazard, which can lead to death or severe bodily injury if not avoided. -

Page 6: Safety

2 | Safety Kracht GmbH 2 Safety 2.1 Intended use 1. The product has been designed for operation with fluids. Dry operation is not permitted. 2. The product may only be operated when completely filled. 3. The fluid must be compatible with the materials used in the product. Chemical expertise is required for that. -

Page 7: Basic Safety Instructions

Kracht GmbH Safety | 2 2.3 Basic safety instructions NOTICE Basic safety instructions Non-compliance can lead to hazards for people and the unit. a) Follow existing regulations for accident prevention and safety at work as well as the internal regulations of the operating company. - Page 8 2 | Safety Kracht GmbH DANGER Rotating parts Risk to life due to entanglement or winding of parts of the body, hair or clothing items. a) Take measures to prevent accidental touching of rotating parts. WARNING Rotating parts Risk of injury caused by ejected parts a) Enclose rotating parts so that in the event of fracture or malfunction, there is no risk caused by ejected parts.

-

Page 9: Device Description

Kracht GmbH Device description | 3 3 Device description 3.1 Functional principle The measuring unit is driven by the flow of fluid based on the principle of a gear motor. The gears run without contact in the measuring chamber. The bearing elements are low friction ball bearings or plain bearings. -

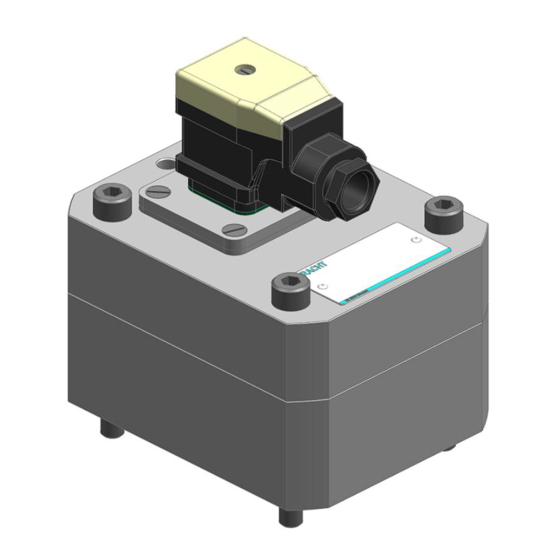

Page 10: Basic Design

3 | Device description Kracht GmbH 3.2 Basic design Gear type flow meters Cover Housing A-magnetic divider Measuring unit Sensor Bearing journal Equipment plug/socket Bearing O-ring 88025420002-17... -

Page 11: Type Key

Kracht GmbH Device description | 3 3.3 Type key Ordering example Explanation of type key 1. Product name 2. Nominal ( Rated volume) 0.025; 0.04; 0.1; 0.2; 0.4; 1; 3; 5; 12; 16 3. Bearing Ball bearing Ball bearing (Increased clearance) -

Page 12: Special Numbers

3 | Device description Kracht GmbH Explanation of type key 11. Electrical connection Aluminium (Al) - terminal box Hirschmann plug (Standard) (M12x1) ext. electronics decoupeable Hirschmann plug Without (M12x1/-4 pole) Aluminium (Al) - terminal box Encoder 512 lmp/U (M12x1/-4 pole) - Page 13 Kracht GmbH Device description | 3 Special number Description Special number 220 Modified PIN assignment For booster systems 88025420002-17...

-

Page 14: Technical Data

4 | Technical data Kracht GmbH 4 Technical data 4.1 General General information Design Gear motor Housing connection Plate structure / Pipe thread Mounting position Flow direction … 2.500.000 mm²/s Viscosity ν … 5.000 mm²/s (Special number 224) Operating pressure Operating pressure [} 21]... -

Page 15: Nominal Sizes

Kracht GmbH Technical data | 4 4.2 Nominal sizes Nominal Measuring range [l/min] Bearing Ball bear- Ball bearing Hybrid - Ball Carbide - Ball Bronze - Ball bearing bearing bearing (Increased clear- ance) 0.025 0.008 - 2 0.008 – 2 0.02 –... - Page 16 4 | Technical data Kracht GmbH Nominal Special number Type of connection P (Plate structure) With connection plate Without connection (Pipe connec- plate tion) MVC .. R. C. G 1/2 G 1/2 MVC .. R. D. G 3/4 MVC .. R. C.

-

Page 17: Flow Resistance ∆P

Kracht GmbH Technical data | 4 4.4 Flow resistance ∆p 4.4.1 Ball bearing version VC 0.025 VC 0.04 VC 0.1 VC 0.2 88025420002-17... - Page 18 4 | Technical data Kracht GmbH VC 0.4 VC 1 VC 3 VC 5 88025420002-17...

-

Page 19: Plain Bearing Version

Kracht GmbH Technical data | 4 VC 12 VC 16 4.4.2 Plain bearing version VC 0.025 VC 0.1 88025420002-17... - Page 20 4 | Technical data Kracht GmbH VC 0.2 VC 0.4 VC 1 VC 3 88025420002-17...

-

Page 21: Operating Pressure

Kracht GmbH Technical data | 4 VC 5 4.5 Operating pressure Nominal Special number Maximum allow- Sound pressure level able pressure [bar] [dBA] 0.025 0.04 ≤ 60 ≤ 70 ≤ 72 ≤ 80 ν= 34 mm²/s; p= 5-15 bar 88025420002-17... -

Page 22: Permissible Temperature Range

4 | Technical data Kracht GmbH 4.6 Permissible temperature range Fluid temperature ϑ [°C] ϑ [°C] m min m max EPDM Sealing material FFKM FVMQ Carbide - Plain bearings Bronze - Plain bearings Bearing Ball bearing Ball bearing ( Increased clearance) -

Page 23: Material Data

Kracht GmbH Technical data | 4 4.7 Material data Nominal Special num- Materials Seal Housing / Measuring Bearing Cover unit 0.025 Ball bearing: 0.04 Roller bearings steel EN-GJS-400-15 - - - - - - EPDM Stainless steel Stainless steel - - - (1.4404) -

Page 24: Dimensions

4 | Technical data Kracht GmbH Nominal Connection plate Added weight [kg] 0.025 MVC ... B04 - - - MVC ... B05 0.04 MVC ... C05 - - - MVC ... B11 MVC ... C08 MVC ... C09 - - - MVC ... -

Page 25: Transport And Storage

Kracht GmbH Transport and storage | 5 5 Transport and storage 5.1 General a) After receiving the delivery, check the product for transport damage. b) If transport damage is found, the manufacturer and the transport company must be notified immediately. The product must then be replaced or repaired. -

Page 26: Storage Conditions

5 | Transport and storage Kracht GmbH Products with EPDM seals are not mineral oil resistant and their function is not tested. The in- ternal parts are not preserved. If the product is not put into operation immediately, all surfaces exposed to corrosion must be protected by suitable preservation measures. -

Page 27: Installation

Kracht GmbH Installation | 6 6 Installation 6.1 Safety instructions for installation DANGER Hazardous fluids Danger to life when handling hazardous fluids a) Comply with the safety data sheets and regulations on handling the hazardous fluids. b) Collect and dispose of hazardous fluids so that no hazard is created for persons or the en- vironment. - Page 28 6 | Installation Kracht GmbH WARNING Exposed gears Gearwheels can trap and crush fingers and hands. a) Do not engage gearwheels. WARNING Failure of pressure bearing parts due to overload Risk of injury from flying parts. Risk of injury due to splashing fluids.

-

Page 29: Mechanical Installation

Kracht GmbH Installation | 6 6.2 Mechanical installation 6.2.1 Preparation a) Check the product for transport damage and contamination. b) Remove any preservative present. c) Clean all lines. ð Only use cleaning agents that are compatible with the materials used. - Page 30 6 | Installation Kracht GmbH a) Position the housing on the connection plate. ð Make sure that the seal fits correctly. ð The contact surface must be free from dirt, paint residues, etc. b) Tighten the fastening screws to the specified torque.

-

Page 31: Pipe Connection

Kracht GmbH Installation | 6 6.2.3 pipe connection a) Clean all lines. ð Do not use cleaning wool. ð Pickle and rinse welded pipes. b) Remove existing protective plugs. c) Install the lines. ð Comply with the manufacturer's instructions. ð Do not use any sealing materials such as hemp, Teflon tape or putty. - Page 32 6 | Installation Kracht GmbH ATTENTION Damage by overvoltage Excessive voltage can cause damage and dysfunction to the product. a) Use the product only with the correct voltage. b) Please consult the manufacturer in cases of doubt. ATTENTION The power supply line must match the used preamplifier.

-

Page 33: Io-Link

Kracht GmbH Installation | 6 6.3.2 IO-Link 6.3.2.1 General IO-Link overview Name VC IO-Link Vendor ID 0x0524 Device ID 0x000001 Vendor name KRACHT GmbH Communication parameters IO-Link connection plug V1.1 Bit rate COM3 Minimum cycle time 500 μs Standard I/O mode (SIO) supported... - Page 34 6 | Installation Kracht GmbH 6.3.2.1.1 Terminal layout The terminal assignment for channel 1 and channel 2 influences the direction of rotation dis- played by the measuring element. IO-Link Mode SIO-Mode Blue 0 Volt Brown White Channel 1 Black Channel 2...

- Page 35 Kracht GmbH Installation | 6 6.3.2.2 IO-Link mode process data 6.3.2.2.1 Input process data PD input (input process data): total length 32 bit Can be set via the variable: output unit (index 64) Name Description Data Length Value range Unit type Selected by "output...

- Page 36 6 | Installation Kracht GmbH 6.3.2.2.2 Output process data PD output (output process data): total length 1 bit Can be set via the variable: output unit (index 64) Name Description Data type Length Value Unit range "Reset activ- ated" resets the...

- Page 37 Kracht GmbH Installation | 6 88025420002-17...

- Page 38 6 | Installation Kracht GmbH 88025420002-17...

- Page 39 Kracht GmbH Installation | 6 6.3.2.3.1 Calibration of the tooth volume (Index 80) If necessary, the Vgz factor can be calibrated. Such a calibration may be necessary due to deviating viscosity, temperature or other external in- fluences and is taken into account in the measurement as follows:...

-

Page 40: Commissioning

7 | Commissioning Kracht GmbH 7 Commissioning 7.1 Safety instructions for start-up DANGER Hazardous fluids Danger to life when handling hazardous fluids a) Comply with the safety data sheets and regulations on handling the hazardous fluids. b) Collect and dispose of hazardous fluids so that no hazard is created for persons or the en- vironment. -

Page 41: Additional Commissioning

Kracht GmbH Commissioning | 7 7.3 Additional commissioning a) Open existing shut-off elements in front of and behind the product. b) Set pressure relief valves installed in the system to the lowest opening pressure. c) Run the product pressureless or at low pressure for a few minutes. -

Page 42: Removal

8 | Removal Kracht GmbH 8 Removal 8.1 Safety instructions for disassembly DANGER Hazardous fluids Danger to life when handling hazardous fluids a) Comply with the safety data sheets and regulations on handling the hazardous fluids. b) Collect and dispose of hazardous fluids so that no hazard is created for persons or the en- vironment. -

Page 43: Dismantling

Kracht GmbH Removal | 8 CAUTION Hot surfaces Burns of the skin on contact. a) At temperatures ≥48 °C, allow the product to cool first. ATTENTION Blocking of the product due to curing media Curing media can mechanically block the product and make it unusable. -

Page 44: Maintenance

9 | Maintenance Kracht GmbH 9 Maintenance 9.1 Safety instructions for maintenance DANGER Hazardous fluids Danger to life when handling hazardous fluids a) Comply with the safety data sheets and regulations on handling the hazardous fluids. b) Collect and dispose of hazardous fluids so that no hazard is created for persons or the en- vironment. -

Page 45: Maintenance Work

Kracht GmbH Maintenance | 9 9.2 Maintenance work Checking and documentation of the operating data Regular checking and documentation of all operating data helps to detect faults at an early stage. – Perform the maintenance work according to specifications. – Replace defective or worn components. -

Page 46: Maintenance Instructions

9 | Maintenance Kracht GmbH a) Undo the fastening screws. b) Remove the cover from the housing. c) Remove the gears from housing. d) Remove the bearing journals from the housing. e) Clean the product. f) Replace O-ring. g) Insert bearing journal and gears into the housing. -

Page 47: Maintenance Table

Kracht GmbH Maintenance | 9 9.4 Maintenance table 9.4.1 Maintenance table Additional in- formation 9.4.2 Check the rate of flow 9.4.3 Check the operating pressure 9.4.4 Check the media temperature 9.4.5 Check the device temperature 9.4.6 Check the equipotential bonding 9.4.7... -

Page 48: Check The Operating Pressure

9 | Maintenance Kracht GmbH 9.4.3 Check the operating pressure The operating pressure is indicated by the pressure gauges. – If there is no operating pressure, check the individual components of the product. – Comply with the product-specific data sheets/operating instructions. -

Page 49: Visual Check Of The Condition Of Housing Parts

Kracht GmbH Maintenance | 9 9.4.12 Visual check of the condition of housing parts Look for damage to the housing. 9.4.13 Visual check of the condition of the bearings Look for damage to the bearings. Cleaning - deposits in the measuring device [} 45] 9.4.14 Replacing other seals... -

Page 50: Repair

10 | Repair Kracht GmbH 10 Repair 10.1 Safety instructions for repairs DANGER Hazardous fluids Danger to life when handling hazardous fluids a) Comply with the safety data sheets and regulations on handling the hazardous fluids. b) Collect and dispose of hazardous fluids so that no hazard is created for persons or the en- vironment. -

Page 51: General

Kracht GmbH Repair | 10 10.2 General Corrective maintenance includes: 1. Troubleshooting Finding damage, determining and localising the cause of the damage. 2. Damage repair Removing the primary causes and replacing or repairing defective components. Repairs are generally carried out by the manufacturer. -

Page 52: Fault Table

10 | Repair Kracht GmbH 10.3 Fault table If the product does not function properly, the electrical components should be tested first. The measuring instrument must remain in operation for this. Fault Potential causes Possible measures LED display Both LED displays flash -how-...

Need help?

Do you have a question about the VC 0.025-16 and is the answer not in the manual?

Questions and answers