Table of Contents

Advertisement

Quick Links

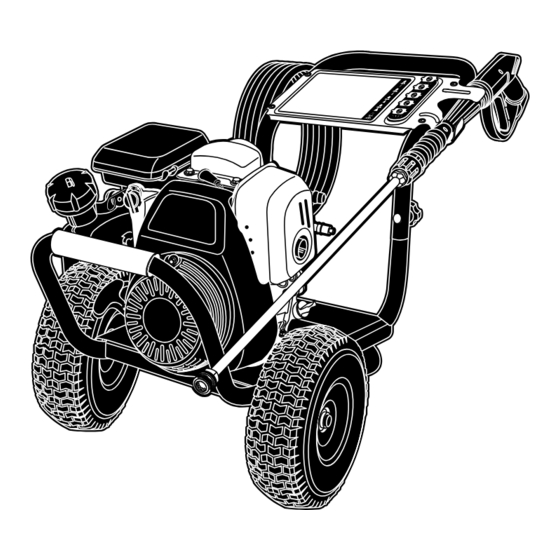

PRESSURE WASHER

USE AND CARE MANUAL

READ THIS MANUAL CAREFULLY BEFORE OPERATION

Failure to follow the instructions and safety precautions in this manual can result

in property damage, serious injury and/or death.

SAVE THIS MANUAL FOR FUTURE REFERENCE

NOTE: Photographs and line drawings used in this manual are for

reference only and may not represent your specific model.

Part Number 7116703 / ENGLISH

For BD2923 and BD3325 models

REV 1 - 10/12/2021

Advertisement

Table of Contents

Summary of Contents for Black Diamond Equipment BD2923

- Page 1 PRESSURE WASHER USE AND CARE MANUAL For BD2923 and BD3325 models READ THIS MANUAL CAREFULLY BEFORE OPERATION Failure to follow the instructions and safety precautions in this manual can result in property damage, serious injury and/or death. SAVE THIS MANUAL FOR FUTURE REFERENCE NOTE: Photographs and line drawings used in this manual are for reference only and may not represent your specific model.

- Page 2 NOTES THIS PAGE WAS INTENTIONALLY LEFT BLANK Page II Part Number 7116703 / ENGLISH REV 1 - 10/12/2021...

- Page 3 SAVE THIS MANUAL FOR FUTURE USE Keep this manual for future reference. This manual should be considered a permanent part of the product and stay with it. This manual should be available to anyone operating the product(s) it covers. This manual should remain with the product(s) it covers if sold to a new owner.

-

Page 4: Table Of Contents

TABLE OF CONTENTS SAFETY INSTRUCTIONS ..............4 READ THIS MANUAL BEFORE OPERATING .............4 ADDITIONAL INSTRUCTIONS ..................4 HAZARD ALERT SYMBOLS ..................4 DISCLAIMERS ................5 UNPACKING ...................6 ASSEMBLY ..................6 Install knob-style handle ....................6 Install button-style handle.....................6 Assemble the spray gun ....................7 Organize Accessories....................7 COMPONENT LOCATION ..............8 CONNECTING HOSES ..............10 PURGING AIR FROM THE PUMP .......... - Page 5 STARTING THE ENGINE .............20 Starting the Engine .....................20 SHUTTING OFF ENGINE .............21 OPERATION TIPS ................22 Terms ..........................22 Preparation .........................22 Pressure Washing ......................22 TROUBLE SHOOTING ..............23 MAINTENANCE ................24 Maintenance .......................24 Cleaning the Pressure Washer ..................24 Connections .......................24 Nozzle Cleaning ......................25 Water Inlet Filter ......................25 Pump Maintenance ....................26 Engine Maintenance....................26 STORAGE AND TRANSPORTATION ..........26...

-

Page 6: Safety Instructions

SAFETY INSTRUCTIONS READ THIS MANUAL BEFORE OPERATING This manual contains important safety information and instructions. Do not operate this product until you have read, and completely understand all safety, operation, and maintenance instructions listed in this manual. Failure to follow the information contained in this manual will result in property damage, injury, and/or death. -

Page 7: Disclaimers

CALIFORNIA PROPOSITION 65 WARNING This product and the engine exhaust can expose you to chemicals which are known to the state of California to cause cancer, birth defects, or other reproductive harm. For more information on California Proposition 65, go to www.P65Warnings.ca.gov. POLYCYCLIC AROMATIC HYDROCARBON WARNING The air filter element and air box assembly may contain polycyclic aromatic hydrocarbons (PAHs). -

Page 8: Unpacking

UNPACKING Follow the steps outlined in this section to unpack and assemble your pressure washer. If you have any questions regarding the unpacking or assembly of your pressure washer, please have your model number and serial number ready, then contact customer support at 1-877-258-6182. -

Page 9: Assemble The Spray Gun

Assemble the spray gun Thread the lance into the spray gun. Organize accessories Place the spray gun and lance assembly into the holder on the dashboard. Push the nozzles into the rubber grommets on the dashboard. Note: the dashboard label indicates correct nozzle placement. -

Page 10: Component Location

COMPONENT LOCATION High-pressure hose Hose hanger Thermal relief valve Pump Fuel fill cap Fuel tank High-pressure pump output Low-pressure pump input Handle retaining knobs and bolts Page 8 Part Number 7116703 / ENGLISH REV 1 - 10/12/2021... - Page 11 10. Engine choke 11. Nozzle holder 12. Spray gun 13. Spray gun holder 14. Oil fill cap / dipstick 15. Oil drain plug 16. Spray wand quick connector 17. Engine starter recoil 18. Engine ignition switch Page 9 Part Number 7116703 / ENGLISH REV 1 - 10/12/2021...

-

Page 12: Connecting Hoses

CONNECTING HOSES Before connecting a water supply hose, be sure the water supply is capable of providing an uninterrupted source of clean, cold water at a minimum rate of 5 gallons per minute (GPM) and 20 pounds per square inch (PSI) of pressure. Once a proper water supply is secured, follow the instructions below to connect both the water supply and high-pressure hoses to the pressure washer. -

Page 13: Purging Air From The Pump

PURGING AIR FROM THE PUMP PUMP PURGING Running a pressure washer pump without water will severely damage the pump seals and other internal components. To avoid this hazard, make sure your water supply is uninterrupted and at least 5 GPM at 20 PSI, and always purge the air your pressure washer pump before starting the engine. -

Page 14: Nozzles

NOZZLES Nozzle Selection The nozzles supplied with the pressure washer have specific spray patterns designed to clean different surfaces. Using the incorrect nozzle can damage surfaces. Refer to the table below to select the correct nozzle before using the pressure washer. NOTE: The selection of nozzles included may vary with pressure washer models. -

Page 15: Using Chemicals

USING CHEMICALS VOLATILE LIQUIDS Pressure washing with volatile, flammable, or corrosive liquids could cause pressure washer damage, fire, or explosion resulting in severe injury and/or death. To avoid these hazards, use only approved soaps and chemicals, do not attempt to pressure wash with volatile, flammable, or corrosive liquids, and NEVER use bleach. -

Page 16: Operating Checklist

OPERATING CHECKLIST Location Place the pressure washer on a level surface outside in a well-ventilated area before operating. Keep all flammable materials at least five feet away from all sides of the product. ● Never use pressure washer inside a house, garage, or any other kind of enclosure even if doors and windows are open. -

Page 17: High Altitude Operation

High Altitude Operation This engine will have proper engine performance and emission control when it is operated at or below an altitude of 5000 feet (1524 meters). This engine requires a high-altitude carburetor kit to ensure proper engine performance and emission control when operated at altitudes above 5000 feet (1524 meters). -

Page 18: Checking The Engine Oil

INJECTION INJURY The high pressures created by a pressure washer can cause fluid injection injuries, severe lacerations, amputations, and / or death. To avoid these hazards, always aim the spray gun and lance in a safe direction when using the pressure washer and never attempt to touch a leak in a high-pressure hose or fitting. - Page 19 FILL ENGINE BEFORE USE The engine is shipped from the factory without oil. Running the engine without oil will result in severe engine damage and void the warranty. To avoid causing engine damage and voiding the warranty, fill the engine with the recommended oil type before starting. USE CORRECT ENGINE OIL Oil is a major factor in the performance and service life of any engine.

-

Page 20: Checking Fuel

Checking Fuel REFUELING Gasoline is highly flammable and gasoline vapors are extremely explosive. Fire and explosions can cause severe burns and/or death. Keep gasoline away from flames, sparks, and other ignition sources. Refuel outdoors in a well-ventilated area with the engine stopped and cool. - Page 21 GASOLINE STORAGE It is important to prevent gum deposits from forming in essential fuel system parts, such as the carburetor, fuel filter, fuel hose or tank during storage. Alcohol-blended fuels (also called gasohol, ethanol, or methanol) attract moisture, which leads to separation and formation of acids during storage.

-

Page 22: Starting The Engine

STARTING THE ENGINE OPERATING CHECKLIST Attempting to start the engine incorrectly or using the pressure washer incorrectly can result in engine and/or pressure washer damage, and may cause serious injury or death. To avoid these hazards, be sure to read, understand, and follow the steps outlined in the OPERATING CHECKLIST section of the owner’s manual before starting the engine, and follow all the guidelines for proper use of the pressure washer. -

Page 23: Shutting Off Engine

Pull recoil slowly until resistance is felt, then pull rapidly to start the engine. RAPID RETRACTION Rapid retraction (also known as kickback) of the engine recoil starter cord will pull your hand and arm towards the engine faster than you can let go of the handle resulting in sprains, broken bones, lacerations, and/or traumatic amputations. -

Page 24: Operation Tips

OPERATION TIPS Terms ● PSI – Stands for pounds per square inch and measures the water pressure or stripping power produced by the pressure washer. The higher the PSI number, the greater the pressure and stripping power produced. ● GPM – Stands for gallons per minute and measures the flow rate of the water. The higher the GPM, the greater the flow or rinsing power produced. -

Page 25: Trouble Shooting

TROUBLE SHOOTING Issue Possible Cause Solution The fuel tank is empty. Add fresh fuel. Aim the spray gun in safe Water pressure in the pump direction and pull trigger to is preventing the engine release water pressure in from turning over. the pump. -

Page 26: Maintenance

MAINTENANCE For safety reasons, the manufacturer recommends all pressure washer service and repairs be performed by an authorized service center. All warranty replacements or repairs must be performed by an authorized distribution or service center. To find an authorized service center near you, make a warranty claim, or get authorized warranty repair, call 1-877-258- 6182. -

Page 27: Nozzle Cleaning

Nozzle Cleaning If a nozzle becomes clogged, the pump may pulsate and spray patterns could change. If the nozzle is not cleaned, excessive pressure may develop possibly damaging the pump, or other accessories. Inspect nozzles before using them and follow the instructions in this section for the proper nozzle cleaning procedure. -

Page 28: Pump Maintenance

Pump Maintenance The pump on this unit is a maintenance free design. The pump was filled with oil at the factory and has no oil drain or fill plugs. If there is a problem with the pump on this pressure washer call 1-877-258-6182. -

Page 29: Storing For More Than Two Months

Storing for More Than Two Months Make sure the engine is completely cool. Remove all the fuel from fuel tank, fuel lines, and carburetor by loosening the drain screw at the bottom of the carburetor, and draining fuel into an appropriate container. Change the engine oil. - Page 30 NOTES THIS PAGE WAS INTENTIONALLY LEFT BLANK Page 28 Part Number 7116703 / ENGLISH REV 1 - 10/12/2021...

- Page 31 NOTES THIS PAGE WAS INTENTIONALLY LEFT BLANK Page 29 Part Number 7116703 / ENGLISH REV 1 - 10/12/2021...

- Page 32 Manufactured by the FNA Group, Inc. 7152 99th Street, Pleasant Prairie, WI 53185. Black Diamond® is a registered trademark of Mid-States Distributing, LLC. Mid States Distributing, LLC. Manufactured for and distributed by Mid-States Distributing, LLC, TX 76137 USA. For product, service, or warranty information, call 1-877-258-6182. Product style and configuration may vary.

Need help?

Do you have a question about the BD2923 and is the answer not in the manual?

Questions and answers