Summary of Contents for Aspen FP00097

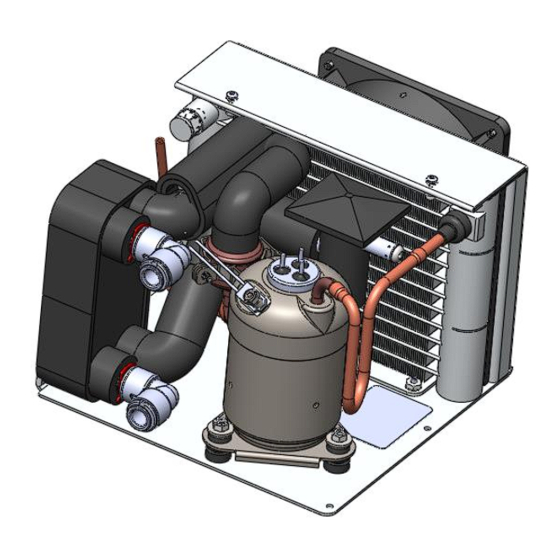

- Page 1 24 St. Martin Dr. Marlborough, MA 01752 Installation and Operation Instructions Liquid Chiller Module FP00097 Installations Notes Date of Purchase Date of Installation Installer Model Number Serial Number...

-

Page 2: Table Of Contents

Maintenance ..............................8 Customer Service ............................8 Commercial Product Warranty ......................... 8 Warranty Repairs ............................9 Technical Support ............................. 9 Aspen Contact Information ........................9 APPENDIX ..............................9 OM00016 Rev C, FP00097 Operation Manual – March 5, 2023 Page 2 of 9... -

Page 3: System Information

The LCM also contains Polyalkylene Glycol (PAG) oil, which is used by the compressor. Contact Aspen for the MSDS for either of these internal fluids. Precautions relating to the personnel hazards regarding contact with this substance should be outlined in training and technical manuals. -

Page 4: General Operation

24 VDC power supply (0.8 A draw). The provided fan generates 190 cfm (without restriction). Aspen Systems does NOT recommend using the available voltage output on the compressor drive board to operate the fan. Please connect the fan directly to a 24 VDC supply. - Page 5 Airflow direction Figure 2: LCM Dimensional Drawing - Note all dimensions are in inches OM00016 Rev C, FP00097 Operation Manual – March 5, 2023 Page 5 of 9...

-

Page 6: Power Supply

VDC – 27.0 VDC. The LCM may draw up to 17.0 A of current during normal operation (compressor and fan combined). Aspen recommends at least 12 AWG wire for the power supply to the compressor drive board with an in-line 15 A fuse (see Appendix page 3). The LCM fan requires a separate 24 VDC power as well. -

Page 7: Performance

Figure 3 – FP00097 Drive Board Jumper Configuration (Circled in Red) The default FP00097drive-board default jumper configuration is shown in the image above. More information about jumper settings and the drive board functionality is located in the appendix. Performance The performance curve below (Figure 4) defines the performance of the LCM. The data shown below is derived using 2 L/min water flow and a 30% glycol solution. -

Page 8: Maintenance

Aspen at buyer’s expense, transportation charges prepaid. Aspen’s sole obligation under its warranty shall be, at its option, to repair, replace or refund the price of any product thereof which is proved to violate such warranty. In no event, whether based on contract,... -

Page 9: Warranty Repairs

Aspen Systems, LLC. Depending on the circumstances of the problem, it may be deemed necessary to return the products to Aspen Systems. for repair. In order to return the product for repair, please contact Aspen Systems via email, telephone, or through the Aspen Systems’ website (see Contact... - Page 10 Universal Low Noise Sinusoidal BLDC Drive Operating Instructions Aspen’s Universal Low Noise Sinusoidal BLDC Drive can be operated in 2 distinct modes. This allows it the ability to seamlessly replace all existing Aspen drives, as well as offer significant compressor noise reduction, lower compressor operational speeds and several different input types for speed control.

- Page 11 Drive Mode Jumper Jumper Mode 2 Universal Quiet Sinusoidal Not Installed Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com Feb, 2023 Rev. D...

- Page 12 Aspen’s Universal Sinusoidal Low Noise Drive is available in 12, 24 and 48 volts. The use of adequate wire gage and an inline fuse for short circuit protection is required for safe reliable operation. The table below shows the recommended wire gage and input fuse size for each of the Aspen drives.

- Page 13 1. Condenser Fan Output (TB7 & TB8) An output has been provided for running condenser fan(s) from the Aspen drive. The voltage of this output will be equivalent to the DC input voltage provided to the board. The power to the condenser fan is enabled 10 seconds after the drive starts the compressor.

- Page 14 Jumper settings for these options can be found at the end of this section. Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323...

- Page 15 This tab should be used when a secondary power supply is being used to supply power for speed control and the user wants the secondary supply to be isolated from the power supply being used to power the Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323...

- Page 16 Additional Board Functions 1. Compressor Start Delay – The Aspen drive has the ability to delay the compressor start in situations where starting may be difficult due to an unbalanced system. The logic behind the delay is based on a minimum off time for the compressor and can be enabled by installing jumpers per the table at the end of this section.

- Page 17 5. Lock Rotor Protection - The Aspen drive has the ability to detect if the compressor is not running due to a lock rotor condition. After the drive has made several unsuccessful attempts to start the...

- Page 18 1501048 1501018 48 Volt 8 Amp The ramping speed of the compressor will also be reduced to further enhance sound reduction. Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com Feb, 2023 Rev.

- Page 19 1501050 2.8 & 5.6cc T & H Series 48 Volt 10 Amp 1501052 3.8cc & 7.6cc T & H Series 48 Volt 10 Amp Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com...

- Page 20 24v compressors and 8 amps for 48v 10 or 15 amps for 24v compressors and to 8 amps compressors. for 48v compressors. Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com...

- Page 21 Mounting Diagram Compressor Wiring – The Aspen Universal Quiet Sinusoidal drive is supplied with a cable to attach the drive to the compressor. All other wiring is to be supplied by the end user. It is important to wire the compressor to the drive with the colors coded in the order per the picture below.

- Page 22 Universal Low Noise Sinusoidal BLDC Drive Typical Compressor Wiring Wiring with user supplied speed input voltage Typical Wiring Diagram Wiring with user supplied 20k potentiometer Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com...

- Page 23 / pressure. 2. Liquid refrigerant being Limiting 2. Verify superheat to be between returned to the compressor. recommended 8-12 deg. F. Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com Feb, 2023 Rev. D...

- Page 24 4 Flashes Repeating Board overheated 8 Flashes Repeating Compressor overheated 16 Flashes Repeating Compressor multiple stall over time 32 Flashes Repeating Aspen Compressor, LLC 24 St. Martin Drive, Marlborough, MA 01752 508-281-5322 508-281-5323 web: email: www.aspencompressor.com info@aspencompressor.com Feb, 2023 Rev. D...

Need help?

Do you have a question about the FP00097 and is the answer not in the manual?

Questions and answers