Toro 72028 Operator's Manual

Riding mower with 60in turbo force rear discharge mower

Hide thumbs

Also See for 72028:

- Operator's manual (300 pages) ,

- Setup instructions (8 pages) ,

- Operator's manual (76 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Toro 72028

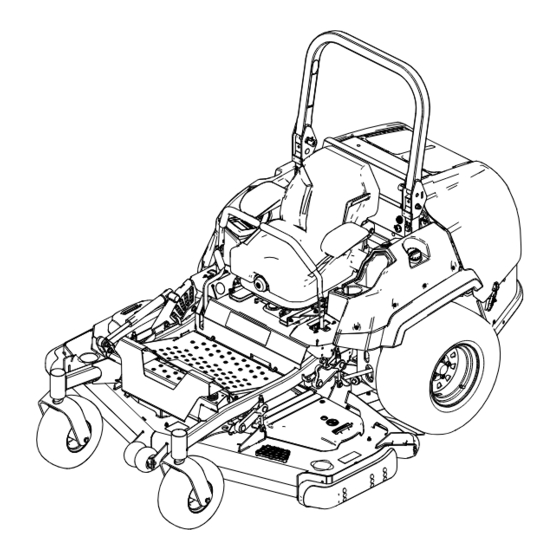

- Page 1 Form No. 3441-790 Rev C Z Master ® Professional 7500-D Series Riding Mower With 60in TURBO FORCE ® Rear Discharge Mower Model No. 72028—Serial No. 407110000 and Up Model No. 72065—Serial No. 400000000 and Up *3441-790* Register at www.Toro.com. Original Instructions (EN)

- Page 2 Authorized Service requirements, the actual engine torque on this class Dealer or Toro Customer Service and have the model of mower will be significantly lower. Please refer to and serial numbers of your product ready.

-

Page 3: Table Of Contents

Contents The safety-alert symbol (Figure 2) appears both in this manual and on the machine to identify important safety messages that you must follow to avoid Safety ............... 5 accidents. This symbol will appear with the word General Safety ........... 5 Danger, Warning, or Caution. - Page 4 Draining the Fuel Filter/Water Separator ... 43 Replacing the Water Separator ......43 Checking the Fuel Lines and Connections..........43 Electrical System Maintenance ......44 Electrical System Safety ........44 Servicing the Battery......... 44 Servicing the Fuses .......... 45 Drive System Maintenance ........46 Checking the Seat Belt ........

-

Page 5: Safety

Safety This machine has been designed in accordance with ANSI standard B71.4-2017. General Safety This product is capable of amputating hands and feet and of throwing objects. Always follow all safety instructions to avoid serious personal injury or death. • Read and understand the contents of this Operator’s Manual before starting the engine. -

Page 6: Slope Indicator

Slope Indicator g011841 Figure 3 You may copy this page for personal use. 1. The maximum slope you can operate the machine on is 15 degrees. Use the slope chart to determine the degree of slope of hills before operating. Do not operate this machine on a slope greater than 15 degrees. Fold along the appropriate line to match the recommended slope. -

Page 7: Safety And Instructional Decals

Safety and Instructional Decals Safety decals and instructions are easily visible to the operator and are located near any area of potential danger. Replace any decal that is damaged or missing. decalbatterysymbols Battery Symbols Some or all of these symbols are on your battery. 1. - Page 8 decal112-9028 112-9028 1. Warning—stay away from moving parts; keep all guards and shields in place. decal116-5988 116-5988 1. Parking brake—engaged 2. Parking brake—disengaged decal107-3069 107-3069 1. Warning–there is no rollover protection when the roll bar is down. 2. To avoid injury or death from a rollover accident, keep the roll bar in the raised and locked position and wear the seat belt.

- Page 9 decal126-8383 126-8383 Note: This machine complies with the industry standard stability test in the static lateral and longitudinal tests with the maximum recommended slope indicated on the decal. Review the instructions for operating the machine on slopes in the Operator’s Manual as well as the conditions in which you would operate the machine to determine whether you can operate the machine in the conditions on that day and at that site.

- Page 10 decal126-9278 126-9278 1. Engine—Off 4. Push the bottom of the button to lower the deck. 2. Engine—On 5. Push the top of the button to raise the deck. 3. Engine—Start decal126-9279 126-9279 1. Read the instructions before servicing or performing 7.

- Page 11 decal135-0328 135-0328 1. Torque the wheel lug nuts 2. Read and understand to 129 N∙m (95 ft-lb). the Operator's Manual before performing any decal126-9280 126-9280 maintenance; check the torque after the first 100 For Models with 152 cm (60-inch) or 183 cm (72-inch) hours, then every 500 Decks with Rear Discharge hours, thereafter.

- Page 12 1. Rotating driveline hazard/entanglement hazard; belt—stay away from moving parts; keep all guards and shields in place. decal135-1432 135-1432 decal135-2837 135-2837 1. Read the Operator’s Manual for more information; Use red Toro wet-clutch transmission fluid; do not use green hydraulic fluid.

-

Page 13: Product Overview

Product Overview g227303 Figure 4 1. Height-of-cut pin 7. Motion-control lever 2. Parking-brake lever 8. Fuel-tank cap 3. Monitor/controls 9. Anti-scalp roller 4. Roll bar 10. Skid 5. Engine screen 11. Caster wheel 6. Audible alarm and power point 12. Mower deck... -

Page 14: Controls

Controls Become familiar with all the controls before you start the engine and operate the machine. Control Panel g228164 Figure 6 g225792 Horizon Display Monitor Figure 5 1. Horizon display monitor 3. Key switch 1. Screen 3. Buttons 2. LED status light 2. - Page 15 Blade-Control Switch (Power • A fast chirp sound indicates critical errors. Takeoff) • A slow chirping sound indicates less critical errors, such as required maintenance or service intervals. The blade-control switch (PTO) engages and Note: During startup, the alarm sounds briefly to disengages power to the mower blades (Figure verify functionality.

-

Page 16: Specifications

To ensure optimum performance and continued safety certification of the machine, use only genuine Toro replacement parts and accessories. Replacement parts and accessories made by other manufacturers could be dangerous, and such use could void the... -

Page 17: Before Operation

Fuel Safety Operation • Fuel is extremely flammable and highly explosive. A fire or explosion from fuel can burn you and Note: Determine the left and right sides of the others and can damage property. machine from the normal operating position. –... -

Page 18: Adding Fuel

Adding Fuel Fill the fuel tank to the bottom of the filler neck (Figure Note: Do not fill the fuel tank completely full. Recommended Fuel The empty space in the tank allows the fuel to expand. The engine runs on clean, fresh diesel fuel with a minimum cetane rating of 40. -

Page 19: Using The Rollover Protection System (Rops)

Using the Rollover Protection System (ROPS) WARNING To avoid injury or death from rollover, keep the roll bar in the fully raised, locked position and use the seat belt. Ensure that the seat is secured to the machine. WARNING There is no rollover protection when the roll g225804 Figure 8 bar is in the down position. -

Page 20: Using The Safety-Interlock System

Using the Safety-Interlock operate as described below, have an Authorized Service Dealer repair the safety system immediately. System Sit on the seat, engage the parking brake, and move the blade-control switch (PTO) to the O position. Try starting the engine; the engine WARNING should not start. -

Page 21: Unlatching The Seat

Unlatching the Seat During Operation To unlatch the seat, push the seat latch forward During Operation Safety (Figure 12). General Safety • The owner/operator can prevent and is responsible for accidents that may cause personal injury or property damage. • Use your full attention while operating the machine. - Page 22 Avoid discharging Authorized Service Dealer to inspect the ROPS. material against a wall or obstruction because the • Use only Toro approved accessories and material may ricochet back toward you. attachments for the ROPS. •...

- Page 23 – Evaluate the site conditions of the day to determine if the slope is safe for machine operation. Use common sense and good judgment when performing this evaluation. Changes in the terrain, such as moisture, can quickly affect the operation of the machine on a slope.

-

Page 24: Operating The Parking Brake

Operating the Parking Operating the Mower Brake Blade-Control Switch (PTO) Always engage the parking brake when you stop the The blade-control switch (PTO) starts and stops the machine or leave it unattended. mower blades and any powered attachments. Engaging the Parking Brake Engaging the Blade-Control Switch (PTO) Park the machine on a level surface. -

Page 25: Starting The Engine

Starting the Engine Shutting Off the Engine Important: Do not engage the starter for more CAUTION than 5 seconds at a time. If the engine fails to start, wait 15 seconds between attempts. Failure Children or bystanders may be injured if they to follow these instructions can burn out the move or attempt to operate the machine while starter motor. -

Page 26: Using The Motion-Control Levers

Using the Motion-Control Driving the Machine Levers The drive wheels turn independently, powered by hydraulic motors on each axle. You can turn 1 side in reverse while you turn the other forward, causing the machine to spin rather than turn. This greatly improves the machine maneuverability but may require some time for you to adapt to how it moves. -

Page 27: Using The Side Discharge

Using the Side Discharge Machines with Side Discharge Only The mower has a hinged grass deflector that disperses clippings to the side and down toward the turf. DANGER Without a grass deflector, discharge cover, or a complete grass-catcher assembly mounted in place, you and others are exposed to blade contact and thrown debris. -

Page 28: Adjusting The Height Of Cut

Adjusting the Height of Cut Adjusting the Anti-Scalp Rollers Adjust the height of cut from 25 to 140 mm (1 to 5-1/2 inches) in 6 mm (1/4 inch) increments by moving the For maximum deck flotation, install the rollers 1 hole clevis pin into different hole locations. - Page 29 g227782 Figure 27 g227783 Figure 29 Side Discharge Machines Rear Discharge Machines 1. Bolt 4. Spacer 1. Bolt 3. Anti-scalp roller 2. Bushing 5. Flange nut 2. Bushing 4. Flange nut 3. Anti-scalp roller For side discharge machines, torque the flange nut to 68 to 75 N∙m (50 to 55 ft-lb).

-

Page 30: Adjusting The Skids

Adjusting the Skids For Models with Rear Discharge Mount the skids in the lower position when operating at heights of cut greater than 51 mm (2 inches) and in a higher position when operating at heights of cut lower than 51 mm (2 inches). Adjust the skids as shown in Figure g035646... -

Page 31: Positioning The Flow Baffle

Positioning the Flow Baffle Position B Use this position when bagging. Always align it with For Machines with Side Discharge the blower opening. The following figures are recommendations only. Adjustments vary by grass type, moisture content, and the height of the grass. Note: If the engine power draws down and the mower ground speed is the same, open the baffle. -

Page 32: Operating With The Overheat Sensor

g295812 Figure 33 Operating with the Overheat Sensor The PTO disengages, an alarm sounds, and a bar graph displays the engine temperature when it reaches an overheat condition. The PTO does not engage until the engine has cooled and you manually shut off the PTO and engage it. -

Page 33: Operating Tips

It is best to cut only about a third of the grass blade. genuine Toro replacement blade. Cutting more than that is not recommended unless grass is sparse, or it is late fall when grass grows more slowly. -

Page 34: After Operation

Transporting the Machine After Operation Use a heavy-duty trailer or truck to transport the machine. Use a full-width ramp. Ensure that the trailer After Operation Safety or truck has all the necessary brakes, lighting, and marking as required by law. Please carefully read all the safety instructions. - Page 35 If using a trailer, connect it to the towing vehicle and connect the safety chains. If applicable, connect the trailer brakes and lights. Lower the ramp, ensuring that the angle between the ramp and the ground does not exceed 15 degrees (Figure 35).

-

Page 36: Maintenance

• Check the alternator-belt tension. Every 100 hours • Change the engine oil and filter if not using Toro Premium Engine Oil, but any oil Every 200 hours meeting API classification CJ-4 or higher or as stated in Engine-Oil Specifications. - Page 37 • Grease the caster pivots (more often in dirty or dusty conditions). • Service the air cleaner (More frequently in extremely dusty or dirty conditions). • Change the engine oil and filter if using Toro Premium Engine Oil (API classification CK-4 or higher) (more often in dirty or dusty conditions).

-

Page 38: Lubrication

Lubrication Greasing the Machine Service Interval: Every 400 hours/Yearly (whichever comes first)—Grease the deck-idler pivots. Yearly—Grease the deck drive PTO. Grease more frequently when operating conditions are extremely dusty or sandy. Grease Type: No. 2 lithium or molybdenum grease Park the machine on a level surface, disengage the blade-control switch, and engage the parking Lubricating the Drive brake. -

Page 39: Greasing The Caster Pivots

Greasing the Caster Pivots Remove a spacer nut from the axle assembly in the caster wheel. Service Interval: Every 400 hours/Yearly (whichever Note: Thread-locking compound has been comes first) (more often in dirty or applied to lock the spacer nuts to the axle. dusty conditions). -

Page 40: Engine Maintenance

Engine Maintenance Servicing the Air Cleaner Note: If the foam gasket in the cover is damaged, replace it. Engine Safety Important: Avoid using high-pressure air, which • Keep your hands, feet, face, clothing, and other could force dirt through the filter into the intake body parts away from the muffler and other hot tract. -

Page 41: Servicing The Engine Oil

After the first 200 hours—Change the engine oil and filter. Every 200 hours—Change the engine oil and filter if not using Toro Premium Engine Oil, but any oil meeting API classification CJ-4 or higher or as stated in Engine-Oil Specifications. -

Page 42: Inspecting The Engine-Valve Clearance

Changing the Engine Oil and Filter If possible, run the engine just before changing the oil because warm oil flows better and carries more contaminants than cold oil. Park the machine on a level surface, disengage the blade-control switch (PTO), and engage the parking brake. -

Page 43: Fuel System Maintenance

Replacing the Water Fuel System Separator Maintenance Service Interval: Every 400 hours—Replace the DANGER fuel-filter canister for the water separator (more often in dirty and In certain conditions, fuel is extremely dusty conditions). flammable and highly explosive. A fire or explosion from fuel can burn you and others and can damage property. -

Page 44: Electrical System Maintenance

Electrical System WARNING Incorrect battery cable routing could damage Maintenance the machine and cables causing sparks. Sparks can cause the battery gasses to explode, resulting in personal injury. Electrical System Safety • Always disconnect the negative (black) • Disconnect the battery before repairing the battery cable before disconnecting the machine. -

Page 45: Servicing The Fuses

Installing the Battery Note: Do not run the machine with the battery disconnected, electrical damage may occur. Note: Position the battery in the tray with the terminal posts opposite from the hydraulic tank. g000960 Figure 49 1. Positive battery post 3. -

Page 46: Drive System Maintenance

Drive System Align the levers in the front-to-rear position by bringing the levers together to the N EUTRAL Maintenance position, and slide them until they are aligned, then tighten the bolts (Figure 52). Checking the Seat Belt Service Interval: Before each use or daily Inspect the seat belt for wear, cuts, and proper operation of the retractor and buckle. -

Page 47: Checking The Tire Pressure

Checking the Tire Pressure Adjusting the Caster-Pivot Bearing Service Interval: Every 50 hours/Monthly (whichever comes first) Service Interval: Every 500 hours/Yearly (whichever Rear tire air pressure specification: 124 kPa (18 comes first) psi). Park the machine on a level surface, disengage Note: the blade-control switch, and engage the parking The caster tires are semi-pneumatic tires and... -

Page 48: Servicing The Gearbox

Checking the Gearbox-Oil Level Every 400 hours Service Interval: Every 50 hours If the oil becomes contaminated, contact your Toro Distributor because the system must be flushed. Use SAE 75W-90 synthetic gear lube. Contaminated oil looks milky or black when compared Park the machine on a level surface and engage to clean oil. -

Page 49: Cooling System Maintenance

Cooling System Maintenance Cooling System Safety • Swallowing engine coolant can cause poisoning; keep out of reach from children and pets. • Discharge of hot, pressurized coolant or touching a hot radiator and surrounding parts can cause severe burns. – Always allow the engine to cool at least 15 minutes before removing the radiator cap. -

Page 50: Changing The Engine Coolant

Note: If debris remains, repeat until clean. Operate engine until the engine thermostat opens and the coolant is circulating through the Lower the hood. radiator core. Start the engine to ensure that the fan functions As air purges from the engine block and the properly. -

Page 51: Brake Maintenance

Brake Maintenance Adjusting the Parking Brake Service Interval: After the first 100 hours Every 400 hours Check to ensure that parking brake is adjusted properly. Follow this procedure also whenever you have removed or replaced a brake component. Park the machine on a level surface, disengage the blade-control switch, and engage the parking brake. -

Page 52: Belt Maintenance

Belt Maintenance Repeat steps through until a visible gap is achieved and the wheel hub rotates freely. Repeat this procedure for the other side. Inspecting the Belts Note: The brake should fully disengage when the brake is in the released position. Service Interval: Every 50 hours Rotate the drive wheel release handle to Replace the belt if it is worn. -

Page 53: Checking The Alternator-Belt Tension

Controls System square hole, install the belt around the idler pulley (Figure 60). Maintenance Install the belt covers. Checking the Adjusting the Alternator-Belt Tension Control-Handle Position Service Interval: Every 100 hours There are 2 height positions for the control levers—high and low. Remove the bolts to adjust the Apply 44 N (10 lb) of force to the alternator belt, height for the operator. -

Page 54: Adjusting The Motion-Control Linkage

Raise the rear of the machine up and support it with jack stands (or equivalent support) just high enough to allow the drive wheels to turn freely. Remove the electrical connection from the seat safety switch, located under the bottom cushion of the seat. -

Page 55: Adjusting The Motion-Control Damper

Catalog or contact an authorized Toro distributor for part numbers.) g008620 Figure 65 Alternate fluids: If the Toro fluid is not available, Right Motion Control Shown Mobil® 424 hydraulic fluid may be used. Note: Toro does not assume responsibility for 1. - Page 56 Remove the hydraulic-tank cap (Figure 66). and filter if using Mobil® 424 hydraulic fluid. Every 800 hours—Change the hydraulic fluid and filter if using Toro Premium Transmission/Hydraulic Tractor Fluid. Disengage the PTO, move the motion-control levers to the N position, and...

-

Page 57: Mower Deck Maintenance

On multi-bladed machines, take care as rotating Fill each wheel motor with approximately one blade can cause other blades to rotate. 1.4 L (1.5 US qt) of Toro Premium • Transmission/Hydraulic Tractor Fluid. Replace worn or damaged blades and bolts in sets to preserve balance. - Page 58 g006530 Figure 70 1. Cutting edge 3. Wear/slot forming g014973 Figure 72 2. Curved area 4. Crack 1. Blade (in position for measuring) 2. Level surface Checking for Bent Blades 3. Measured distance between blade and the surface (A) Note: The machine must be on a level surface for Rotate the same blade 180 degrees so that the following procedure.

- Page 59 g014973 Figure 74 1. Opposite blade edge (in position for measuring) 2. Level surface 3. Second measured distance between blade and surface (B) If the difference between A and B is greater than 3 mm (1/8 inch), replace the blade with g295816 Figure 75 a new blade;...

-

Page 60: Leveling The Mower Deck

Apply copper-based lubricant or grease to the threads of the blade bolt as needed to prevent seizing. Install the blade bolt finger-tight. Place a wrench on the flat of the spindle shaft g000553 and torque the blade bolt to 75 to 81 N∙m (55 Figure 77 to 60 ft-lb). - Page 61 g009997 Figure 81 1. 76 mm (3 inches) 4. 76 mm (3 inches) 2. Rear blade tip 5. Level surface g231991 Figure 82 3. Front blade tip 1. Deck adjustment 3. Adjustment nut 2. Jam nut Fine-tune the adjustment nut on the front deck lift assembly by turning it (Figure 82).

- Page 62 adjustment bolt by rotating it counterclockwise (Figure 85). Note: Loosen or tighten the single-point adjustment bolt enough to move the height-of-cut plate mounting bolts at least 1/3 the length of the available travel in their slots. This regains some up and down adjustment on each of the 4 deck links.

-

Page 63: Cleaning

Cleaning Cleaning the Engine and Exhaust System Area Service Interval: Before each use or daily—Clean the engine and exhaust system area. Important: Do not use water to clean the engine. Use low-pressure compressed air. See the engine owner's manual. Park the machine on a level surface, disengage the blade-control switch (PTO), and engage the parking brake. -

Page 64: Storage

Storage Check the condition of the blades; refer to Servicing the Cutting Blades (page 57). Prepare the machine for storage when non-use Storage Safety occurs over 30 days. Prepare the machine for storage as follows: • Shut off the engine, remove the key, and wait for all moving parts to stop before you leave the Add a petroleum-based operator’s position. -

Page 65: Troubleshooting

Troubleshooting Problem Possible Cause Corrective Action The starter does not crank. 1. The blade-control switch is engaged. 1. Disengage the blade-control switch. 2. The parking brake is disengaged. 2. Engage the parking brake. 3. The motion-control levers are not in 3. - Page 66 Problem Possible Cause Corrective Action The machine does not drive. 1. The bypass valves are not closed tight. 1. Tighten the bypass valves. 2. The pump belt is worn, loose, or 2. Change the belt. broken. 3. The pump belt is off a pulley. 3.

-

Page 67: Schematics

Schematics SWITCH PTO SWITCH SEAT BRAKE SWITCH NEUTRAL NEUTRAL SWITCH g229105 Electrical Schematic—Machine with Horizon Display Monitor (Rev. A) - Page 68 POWER DISTRIBUTION MODULE TO HARNESS B CONNECTOR 43 g229107 Electrical Schematic—Yanmar Engine 3TNV80FT (Rev. A)

- Page 69 g229106 Electrical Schematic—Yanmar Engine 3TNV88C (Rev. A)

- Page 70 Notes:...

- Page 71 While the exposure from Toro products may be negligible or well within the “no significant risk” range, out of an abundance of caution, Toro has elected to provide the Prop 65 warnings. Moreover, if Toro does not provide these warnings, it could be sued by the State of California or by private parties seeking to enforce Prop 65 and subject to substantial penalties.

Need help?

Do you have a question about the 72028 and is the answer not in the manual?

Questions and answers