Subscribe to Our Youtube Channel

Summary of Contents for Toro LC154FS

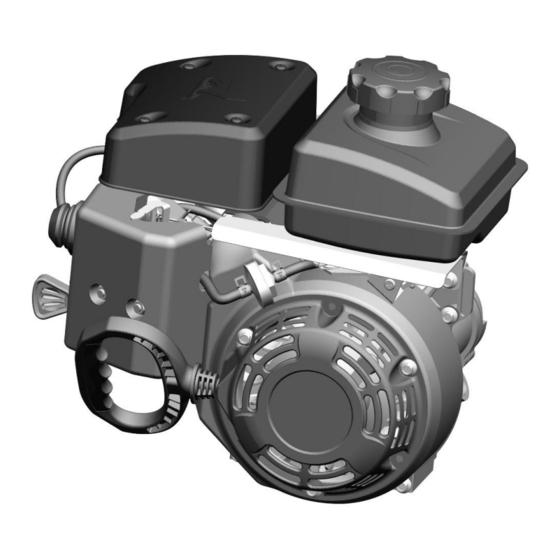

- Page 1 RESIDENTIAL PRODUCTS SINGLE STAGE SNOW ENGINE SERVICE MANUAL LC154FS / LC154FDS (87cc)

- Page 2 An electronic version of this service manual is available on the Toro Dealer Portal. We are hopeful that you will find this manual a valuable addition to your service shop. If you have any questions or comments regarding this...

- Page 3 Chapter 1 – General Service Information Chapter 2 - Engine Service / Maintenance Chapter 3 - Engine Disassembly and Service Chapter 4 - Electrical...

- Page 4 NOTES:...

-

Page 5: Table Of Contents

Chapter 1 – General Service Information Safety Service Rules Engine Model / Serial Number Location Engine Fastener Torque Specification General Specifications Engine Specifications Troubleshooting... -

Page 6: Safety

This manual is intended as a service and repair manual only. The safety instructions provided herein are for troubleshooting, service, and repair of the Toro engine. The Toro operator’s manual contains safety information and operating tips for safe operating practices. -

Page 7: Service Rules

Service Rules 1. Only use genuine Toro parts and lubrication products. 2. Always install new gaskets, O-rings and seals when assembling engine. 3. Always torque fasteners to specification and in sequence. 4. Always lubricate friction components with clean engine oil or engine assembly lube when assembling engine. -

Page 8: Engine Fastener Torque Specification

Engine Fastener Torque Specifications Torque Item Specification Oil Drain Plug 17 ft-lbs (23 Nm) Connecting Rod Bolts 8.5 ft-lbs (12 Nm) Cylinder Head Bolt 25 ft-lbs (34 Nm) Crankcase Cover Bolts 8.5 ft-lbs (12 Nm) Valve Lash Lock Nut 11 ft-lbs (15 Nm) Rocker Arm Studs 22 ft-lbs (30 Nm) Valve Cover Bolts... -

Page 9: General Specifications

General Specifications MODEL LC154FS (Recoil Start) LC154FDS (Electric Start) Engine Type OHV Single Cylinder, Four Stroke, Forced Air Cooling Displacement (cc) Bore x Stroke (mm) 54 x 38 Compression Ratio 8.0:1 Oil Capacity 12 oz. (0.35 l) Engine Operating RPM... -

Page 10: Troubleshooting

Troubleshooting Hard Starting / Poor Running - Incorrect Fuel (Level, Age, Octane, Ethanol Content) - Fuel System Contamination and / or Debris in Carburetor - Incorrect Oil Level - Spark Plug (Incorrect Gap, Fouled, Loose or Faulty) - Air Intake System Leaks - Ignition Coil to Flywheel Gap Incorrect - Weak / No Spark - Choke Function... - Page 11 Chapter 2 - Engine Service / Maintenance Engine Oil Change Procedure Spark Plug Service Valve Clearance Inspection and Adjustment Engine Governor – Zero Point Setting Engine RPM Adjustment Fuel Filter Replacement...

-

Page 12: Engine Oil Change Procedure

Engine Oil Change Procedure 1. Run engine to warm engine oil. 2. Remove the ignition key. NOTE: Ensure fuel system contains no fuel to prevent leak when engine is tipped. 3. Position oil drain pan under oil drain plug. 4. Remove the oil fill / check cap. 5. -

Page 13: Spark Plug Service

Spark Plug Service NOTE: Spark plugs of the wrong size or incorrect heat range can cause severe engine damage. High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems 1. Disconnect the spark plug boot and thoroughly clean the spark plug area. 2. -

Page 14: Valve Clearance Inspection And Adjustment

Valve Clearance Inspection and Adjustment NOTE: Valve clearance inspection and adjustment must be done with the engine cold 1. Rotate Engine to TDC (top-dead-center) of the compression stroke. 2. Remove the valve cover. Be sure both valves are completely closed and the decompression arm is not holding the valve open. -

Page 15: Engine Governor - Zero Point Setting

Engine Governor – Zero Point Setting 1. Remove the (3) fuel tank mounting fasteners to gain access to the governor asm. Fuel tank removal is not necessary. 2. Loosen but do not remove the governor pinch nut (A). 3. Move the governor arm (B) towards the carburetor to fully open the throttle valve. Firmly hold the governor arm in this position. -

Page 16: Fuel Filter Replacement

Fuel Filter and Hose Replacement - Fuel is Extremely Flammable - Use Extreme Caution When Servicing Fuel System 1. Properly drain the fuel tank into an approved container. NOTE: Ensure fuel system contains no fuel to prevent leak when the fuel filter is replaced. 2. - Page 17 Chapter 3 - Engine Disassembly and Service Engine Service – Upper End 14-24 Muffler / Heat Shield Exploded View Fuel Tank Mounting Heater Box Exploded View Carburetor / Governor Mounting Carburetor Exploded View Recoil Asm. Exploded View Starter / Flywheel / Coil Exploded View Cylinder Head Exploded View and Service Information Cylinder Head / Valves Exploded View and Service Information Valve Seat Width Inspection / Cylinder Head Warp Inspection...

-

Page 18: Engine Service - Upper End

Engine Service – Upper End Muffler / Heat Shield Exploded View Self Tapping Screws Muffler Shield Muffler Gasket 27 ft-lbs (30 Nm) -

Page 19: Fuel Tank Mounting

Fuel Tank Mounting - Fuel is Extremely Flammable - Use Extreme Caution When Servicing Fuel System Fuel Tank Fuel Tank Mounting Hardware 7 ft-lbs (10 Nm) Shield Fuel Tank Mounting Hardware 7 ft-lbs (10 Nm) Fuel Filter Fuel Tank Fitting... -

Page 20: Heater Box Exploded View

Heater Box Exploded View 7 ft-lbs (10 Nm) 18 in-lbs (2 Nm) Key Switch Primer Asm. Switch Carburetor Note: Verify primer hose is not kinked or pinched upon heater box installation. -

Page 21: Carburetor / Governor Mounting

Carburetor / Governor Mounting Exploded View Governor Arm 7 ft-lbs (10 Nm) Governor Spring Carburetor Asm. Clip Spacer Gasket... -

Page 22: Carburetor Exploded View

Carburetor Exploded View O-ring Throttle Shaft Choke Lever Stop Screw Carburetor Body Choke Plate Plate Main Jet Needle Asm. Gasket Float Float Bowl Gasket 7 ft-lbs (10 Nm) -

Page 23: Recoil Asm. Exploded View

Recoil Asm. Exploded View Shroud and Recoil Asm. 7 ft-lbs (10 Nm) 7 ft-lbs (10 Nm) Recoil Set Screw Spring Clip Asm. Guide Ratchet Spring... -

Page 24: Starter / Flywheel / Coil Exploded View

Starter / Flywheel / Coil Exploded View Blower Shroud Electric Start Starter Asm. Blower Shroud Recoil Start 7 ft-lbs (10 Nm) Flywheel Ignition Coil Asm. Side Plate 7 ft-lbs (10 Nm) Flywheel Nut 50 ft-lbs (70 Nm) Starter Removal 1. Remove recoil and shroud asm. 2. -

Page 25: Cylinder Head Exploded View And Service Information

Cylinder Head Exploded View and Service Information Spark Plug Gasket 22 ft-lbs (30 Nm) Gasket Cylinder Head 7 ft-lbs (10 Nm) Breather Tube Cylinder Head Bolt Torque Sequence: 1. Initially Torque the (4) Cylinder Head Bolts in a Crisscross Pattern to 10 ft-lbs (14 Nm). 2. -

Page 26: Cylinder Head / Valves Exploded View And Service Information

Cylinder Head / Valves Exploded View and Service Information Valve Spring Exhaust Valve Push Rod 7 ft-lbs (10 Nm) Intake Valve Guide Plate Retainer Valve Lash Lock Nut 11 ft-lbs (15 Nm) -

Page 27: Valve Seat Width Inspection / Cylinder Head Warp Inspection

Valve Seat Width Inspection Remove carbon deposits from the combustion chamber. Inspect the valve seats for pitting or other damage. Standard Service Limit 0.0315 - 0.0394” 0.0787” (0.8-1.0 mm) (2.0 mm) Cylinder Head Warp Inspection - Remove carbon deposits from the combustion chamber. -

Page 28: Valve Seat Reconditioning

Valve Seat Reconditioning 1. Thoroughly clean the combustion chamber and valve seats to remove carbon deposits. 2. Apply a light coat of Prussian Blue or erasable felt-tipped marker ink to the valve faces. 3. Properly install valves, springs and keepers. Manually open the valves, then and snap them closed against their seats several times. -

Page 29: Engine Service - Lower End

Engine Service – Lower End Crankcase Exploded View and Service Information 8.5 ft-lbs (12 Nm) Seal Bearing Gasket Governor Crankshaft Shaft Governor Bearing Crankcase Cover Camshaft 8.5 ft-lbs (12 Nm) Connecting Rod Oil Splash Spoon Point Down to Match Piston Arrow Piston Asm. -

Page 30: Governor Exploded View

Governor Exploded View Clip Weight Slider Governor Gear Washer Washer Governor Shaft Clip Shaft... -

Page 31: Piston / Connecting Rod Exploded View And Service Information

Piston / Connecting Rod Exploded View and Service Information Second Ring / Gap Piston Rotation Arrow Install Piston Ring Markings “UP” Oil Rings Top Ring / Gap Stagger Scraper Rings 150°~ 210° from the Oil Ring Connecting Rod Piston Pin Piston Pin Clip Oil Splash Spoon Point Down to... -

Page 32: Valve Timing

Valve Timing Crankshaft Timing Marks Camshaft... - Page 33 Chapter 4 – Electrical System Information Ignition Coil Gap Adjustment Ignition Coil Resistance Inspection Spark Testing...

- Page 34 Ignition Coil Gap Adjustment High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems Install the ignition coil and lightly tighten the ignition coil mounting bolts. Rotate engine so ignition coil is aligned with the magnet portion of the flywheel. Insert the feeler gauge between the flywheel and coil.

- Page 35 Ignition Coil Resistance Inspection Primary Coil Place Ohm meter leads between the harness connection lead and the exposed metal coil leg. 1.0-1.6 Ω A - Primary Coil Resistance Secondary Coil Place Ohm meter leads between exposed metal coil leg and the spark plug terminal connection. 15 KΩ...

- Page 36 RESIDENTIAL PRODUCTS Form Number: 492-9233...

Need help?

Do you have a question about the LC154FS and is the answer not in the manual?

Questions and answers