Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Pentair AURORA 1040 Series

- Page 1 INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL NOTE! To the installer: Please make sure you provide this manual to the owner of the equip ment or to the responsible party who maintains the system. Part # A-03-330 | © 2012 Pentair Ltd. | 11/19/12...

-

Page 2: California Proposition 65 Warning

SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 CALIFORNIA PROPOSITION 65 WARNING: This product and related accessories contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. MODEL 3DV, HARD FLANGED TRIPLE DUTY COMBINATION VALVE "... - Page 3 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 3.0 FLANGE BOLT TIGHTENING: CAUTION 125 psi/150 psi Recommended Bolt Cast Iron Tightening Procedure Safety glasses should be used and the probe should not Valve Size be left inserted into fittings for prolonged periods of time Bolt (overnight, etc), as leakage from the PMP may occur Size...

-

Page 4: Seat Replacement

SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 6.3.4 On the Triple Duty Performance Curve (Fig. 2) locate the maximum force of 45 ft./lbs. This will ensure good metal- differential pressure obtained in Step 6.3.2 and project line to-metal contact and minimum leakage. horizontally across to intercept with Valve Performance Curve. Drop a line vertically down to read the flow rate at 8.4 The valve bonnet may now be removed. There may be a the bottom of the chart. slight leakage. As the metal-to-metal back seating does not provide a drip-tight seal. - Page 5 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 HARD FLANGED TRIPLE DUTY VALVES REPLACEMENT PARTS LIST 2-1/2" 3" 4" 5" 6" Part Item Straight or Straight or Straight or Straight or Straight or Angle Angle Angle Angle Angle Shaft 570202-006 570202-006...

- Page 6 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 MODEL 3DV, GROOVED END 2.0 INSTALLATION: TRIPLE DUTY COMBINATION VALVE 2.1 The valve should be mounted to a spool piece on the discharge side of the pump. Spool piece required is based on a minimum recommended space of 12" for pump sizes 2 x 2 to 6 x 6 and 24"...

-

Page 7: Flow Measurement

SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 5.0 FIELD CONVERSION Flange Adapter Details (Straight to Angle pattern valve): 125 psi/150 psi 250 psi/300 psi 5.1 Open valve at least one complete turn. Ductile Iron Ductile Iron Valve Size Bolt Bolt 5.2 Remove the body bolts from valve body using Allen Key. - Page 8 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 FLOW INDICATOR SCALE: The valve stem with its grooved rings and positioning sleeve indicates the throttled position of the valve. The quarter turn graduations on the sleeve, Inherent Flow with the scribed line on the stem provides for approx. flow measurement.

- Page 9 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 GROOVED END TRIPLE DUTY VALVES REPLACEMENT PARTS LIST 2-1/2" 3" 4" 5" 6" 8" 10" 12" Part Item Straight or Straight or Straight or Straight or Straight or Straight or Straight or Straight or Angle...

- Page 10 SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 MODEL 3DV THREADED – STRAIGHT TRIPLE DUTY COMBINATION VALVE 3.0 MEMORY STOP ADJUSTMENT INSTRUCTION: 1.0 INTRODUCTION: 1.1 The Aurora Model 3DV Triple Duty Combination Valves are designed for installation on the discharge side of centrifugal pumps.

-

Page 11: Standard Operation

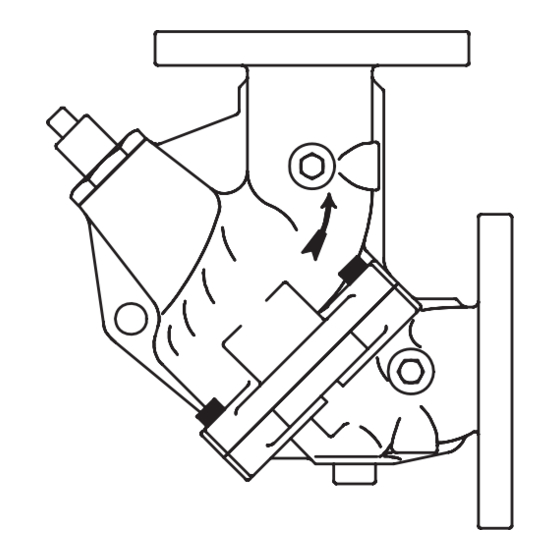

SECTION 2 ITEM 1040 DATED NOVEMBER 2012 SUPERCEDES MAY 2010 5.0 CLAPPER REPLACEMENT PROCEDURE: 7.0 STANDARD OPERATION: 5.1 Position clapper firmly against The principle of operation for the 3DV threaded valve is the seat face. simple. When in the open position, the clapper swings out of the flow. If the flow stops, the spring allows the clapper to 5.2 Pre-load spring and bind using close. -

Page 12: Warranty

WARRANTY Seller warrants equipment (and its component parts) of its own manufacture against defects in materials and workmanship under normal use and service for one (1) year from the date of installation or start-up, or for eighteen (18) months after the date of shipment, whichever occurs first.

Need help?

Do you have a question about the AURORA 1040 Series and is the answer not in the manual?

Questions and answers