Table of Contents

Advertisement

Quick Links

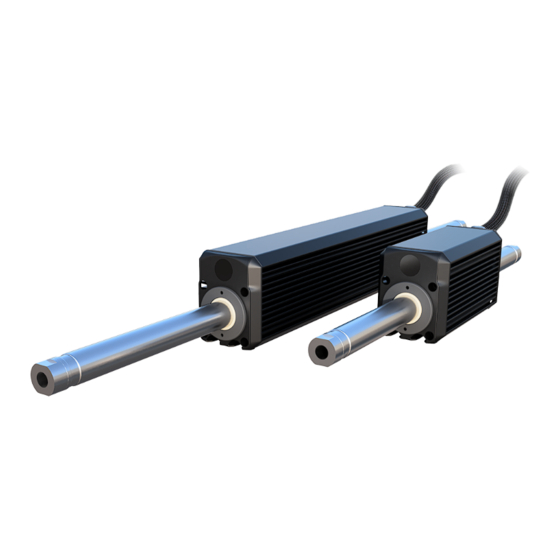

ORCA™ SERIES MOTOR

RM220115

ORCA™ SERIES MOTOR

Reference Manual 220115

This document applies to the following Orca Series linear motor firmware:

● 6.1.7

For more recent firmware versions, please download the latest version of this reference manual at

https://irisdynamics.com/downloads

©2023 Iris Dynamics Ltd.

Go to

irisdynamics.com/support

to create a support ticket

pg. 1

Iris Dynamics Ltd.

Victoria, British Columbia

T +1 (888) 995-7050

irisdynamics.com

Advertisement

Table of Contents

Summary of Contents for IRIS ORCA RM220115

- Page 1 This document applies to the following Orca Series linear motor firmware: ● 6.1.7 For more recent firmware versions, please download the latest version of this reference manual at https://irisdynamics.com/downloads ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg.

-

Page 2: Table Of Contents

Force / Haptics Page........................18 Application Notes:..........................19 Modbus / OAI Page........................21 Modbus Server Status........................21 Orca Analog Interface........................22 IrisControls Logging........................22 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 2 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com... - Page 3 Communication Timeout........................34 Errors.................................. 35 Active and Latched Error Registers.....................35 Configuration Errors...........................35 Force Clipping............................. 35 Temperature Exceeded........................36 Force Exceeded..........................36 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 3 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 4 Figure 12: IrisControls Kinematic Panel Figure 13: IrisControls Force Page Figure 14: IrisControls Modbus Panel Figure 15: IrisControls Orca Analog Interface Panel Figure 16: Changing logging period through console ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 4 Iris Dynamics Ltd.

-

Page 5: Revision History

May, 2023 rm, ab, Update GUI, add Haptics section, change section order Aug, 2023 kh, sj Expand on control register ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 5 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com... -

Page 6: Introduction

RM220115 NTRODUCTION This document describes the functions and operation of Orca™ Series linear motors having integrated drivers and an integrated sensor suite. Figure 1: Block Diagram ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 6 Iris Dynamics Ltd. -

Page 7: Powering The Motor

Suitable power sources for Orca Series motors are AC-to-DC converters, batteries of various chemistry, capacitor banks, or other sources of DC voltages. Engineering support from Iris Dynamics on the selection of a suitable power source is available. -

Page 8: Communication Interfaces

Full Modbus RTU Duplex* * See UG230323 – Orca Series Modbus over Half-Duplex RS485 for information on setting up a half-duplex connection on this port. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 8 Iris Dynamics Ltd. -

Page 9: Methods Of Motor Control

Orca data cable to a hardware button. See the autonomous looping sequence application note section for details on setting up this option. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 9 Iris Dynamics Ltd. -

Page 10: Modes Of Operation

In Kinematic Mode, the motions can be triggered by MODBUS messages, or by hardware edge detection. If hardware triggering is enabled, the Orca will boot up in Kinematic Mode, but MODBUS communication will be disabled. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 11: Getting Started With Iriscontrols

Connect the RJ45 communication cable from the Orca Series motor to the single port side of the RJ45 splitter. Connect the RJ45 connector end of the RS485 cable to the splitter input labeled 1. Finally, connect the USB end of the RS485 cable to the Windows PC running IrisControls. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 12: Connecting To Iriscontrols

If the motor does not connect, toggle the connect button off and press the gear icon in the top right of the IrisControls window and select a baudrate of 460800 from the dropdown menu, and press apply. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 13: Navigating The Gui

GUI within the page content area. The default page upon connection is the home page, shown below. Several other indicators, such as power draw and mode of operation will remain visible on the GUI regardless of the page selection. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 14: Home Page

Figure 11. This page displays the firmware version, hardware version, firmware build date and the motor serial number. There are no interactive elements specific to this page. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 15: Position / Kinematics Page

PID controller. The left y-axis is position, and the right y-axis is force. The green “Target” line will show the active commanded position. (Modbus or Kinematic Controller). ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 16: Tuning Panel

Zero position does not persist through motor power cycles. Kinematic Page Button This button will switch the interface to the kinematic panel. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 17: Kinematic Panel

!!WARNING!! This will disable the Modbus interface upon the next power cycle of the motor. This is because the Modbus interface inputs can be used as hardware triggering inputs. Save Configuration Button Saves the global settings and motion ID configurations to permanent memory. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 18: Application Note

Once the motor is power cycled, the Home Motion will be triggered, and each motion will be performed sequentially as defined by the ‘Next ID’ parameter. Delays between motions can be added as required. Figure 13: Autonomous kinematic looping sequence configuration ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 19: Force / Haptics Page

Toggling it again will return the motor to Sleep Mode (1). Save Configuration Button Clicking this button will save the haptic effects currently displayed on the GUI to the long-term memory on the motor. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 20: Application Notes

Frequency to 1 dHz will have the waveform repeat every 10 seconds (which is the total time ‘high’ and ‘low’). Setting the Duty to 10 will give 1 second high and 9 seconds low. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support... - Page 21 Set up a ‘Spring’ effect with a large dead zone and high Gain to create virtual hard stops. Then use a ‘Constant’ effect to the desired force. This will allow for the demonstration of high forces within a range of the shaft without pushing against hard stops. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg.

-

Page 22: Modbus / Oai Page

Connection information is shown below the last received message, on the right-hand side of the page. Information shown includes current baudrate, rate of successful messages and connection status. Modbus Options Default Modbus behaviour can be configured. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 22 Iris Dynamics Ltd. -

Page 23: Orca Analog Interface

“Orca_[serial number]_data_log.txt” in the logs folder of your IrisControls installation directory. The frequency of data logging can be changed by typing “log [time ms]” into the IrisControls console. Figure 18: Changing logging period through console ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 24: Orca Registers

Save the parameter section of registers to flash save parameters memory. RESERVED Save the stator calibration section of registers to flash stator cal save memory. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 24 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com... -

Page 25: Ctrl_Reg_3

Set the motor settings in the user options section of defaults registers to their default values. modbus user options Set the modbus settings in the user options section of ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 25 Iris Dynamics Ltd. - Page 26 The user options section of registers share motor settings and Modbus settings in the same block of flash memory. Therefore they are saved together with 1 bit in CTRL_REG_2, but can have their defaults restored separately. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg.

-

Page 27: Sensors

The power sensor reflects the rate at which the stator will be increasing in temperature. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 28: Temperature Sensors

The coil temperature can be obtained by reading the COIL_TEMP register. This value represents the temperature of the windings and is a calculated estimate based on thermocouple reading and power draw. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 29: Controllers

In precise systems where small errors are unacceptable, Integral gain should be added after Proportional gain to remove steady state errors. The proportional gain register value is scaled up by a factor of 64 for increased resolution. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 30: Integral Action

The proportional gain register value is scaled up by a factor of 2 for increased resolution. Saturation Level Units: millinewtons This setting limits the maximum force the position controller will generate in either direction. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 31: Kinematic Controller

50 ms 0b11 100 ms If the TRIG_PERIOD field is changed, the kinematic configuration must be saved, and the motor must be restarted to take effect. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 31 Iris Dynamics Ltd. -

Page 32: Configuring A Motion

01 = min. jerk The Type field is interpreted as a 2-bit binary number indicating motion type. The Chain bit is 1 when the chain feature is enabled and 0 when it is disabled. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 33: Haptic Controller

This makes it both more difficult to get the shaft in motion, but also keep the shaft in motion once moved. The force is proportional to the value in the ‘Gain’ field. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 34: Configuring Effects

Amplitude (N) On_GAIN_N Frequency (dHz) On_FREQ_DHZ Oscillator n Duty (x / 65535) On_DUTY Type On_TYPE ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 34 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com... - Page 35 ORCA™ SERIES MOTOR RM220115 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 35 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

-

Page 36: User Configurations

By default, Force Mode and Position Mode will timeout when serial communications fail to send a successful message within a timeout period. This timeout period can be decreased with this user setting, but cannot be increased. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 37: Errors

Force Clipping error is asserted. This error has no effect on operation except to inform the user that linear force output has been compromised. The error self clears as soon as the condition is removed. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 38: Temperature Exceeded

Users can make the communications timeout shorter than the default setting by writing a non-zero value to the USER_COMMS_TIMEOUT register. This register has units of milliseconds (ms). ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. -

Page 39: Appendix : Orca Memory Map

GUI_PERIOD_CMD GUI frames in milliseconds. Software trigger for initiating kinematic KIN_SW_TRIGGER movements over Modbus. 10 - 27 Reserved ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 39 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050... - Page 40 User configurable maximum force output in USER_MAX_FORCE millinewtons. Lower 2 bytes. User configurable maximum force output in USER_MAX_FORCE_H millinewtons. Upper 2 bytes. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 40 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 41 0-65535 to alpha values of 0 to 1. Default Modbus interframe delay in USR_MB_DELAY microseconds. Default value is 2000 us. USR_MB_ADDR Start up Modbus address. Default value is 1 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 41 Iris Dynamics Ltd.

- Page 42 Period between IrisControls GUI GUI_PERIOD communications in milliseconds. 314 - Reserved Active mode the actuator is currently running MODE_OF_OPERATION ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 42 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050...

- Page 43 Lower 2 bytes. Sensed actuator output force in FORCE_H millinewtons. Upper 2 bytes. POWER Sensed actuator output power in watts. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 43 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 44 Firmware minor version. REVISION_NUMBER Firmware revision number. Firmware commit ID lower 2 bytes. COMMIT_ID_LO COMMIT_ID_HI Firmware commit ID upper 2 bytes. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 44 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 45 Return bus communication error. Refer to MB_CNT1 Modbus specification. Return server exception error count. Refer to MB_CNT2 Modbus specification. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 45 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 46 Modbus server address. 486 - Reserved Size of last received Modbus message in MESSAGE_0_SIZE bytes. MESSAGE_0 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 46 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050...

- Page 47 Location of spring center, low 2 bytes S2_CENTER_UM_H Location of spring center, high 2 bytes Coupling type, 0 (Both), 1 (Positive), 2 S2_COUPLING (Negative), ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 47 Iris Dynamics Ltd.

- Page 48 ILOOP_OUT_CH2 4-20 mA output channel 2. ILOOP_IN 4-20 mA input. Reserved ILOOP_CONFIG Configuration for 4-20mA control. ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 48 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050...

- Page 49 Byte 3 - Settling Time High Byte 4 - Auto-Start Delay Byte 5 - bit 0 - Auto start enable, bits 2:1 - type, bits 7:3 Next ID ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg.

- Page 50 KIN_MOTION_11 KIN_MOTION_12 KIN_MOTION_13 KIN_MOTION_14 KIN_MOTION_15 KIN_MOTION_16 KIN_MOTION_17 KIN_MOTION_18 KIN_MOTION_19 KIN_MOTION_20 KIN_MOTION_21 KIN_MOTION_22 KIN_MOTION_23 KIN_MOTION_24 KIN_MOTION_25 ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 50 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

- Page 51 KIN_MOTION_27 KIN_MOTION_28 KIN_MOTION_29 KIN_MOTION_30 KIN_MOTION_31 ID of kinematic motion triggered when KIN_HOME_ID Kinematic mode enabled ©2023 Iris Dynamics Ltd. Go to irisdynamics.com/support to create a support ticket pg. 51 Iris Dynamics Ltd. Victoria, British Columbia T +1 (888) 995-7050 irisdynamics.com...

Need help?

Do you have a question about the ORCA RM220115 and is the answer not in the manual?

Questions and answers