Advertisement

Quick Links

5330 East 25

th

Street

Indianapolis, Indiana 46218

Phone (317) 261-1212

Fax (317) 261-1208

Thermostatic Water Controllers will not work satisfactorily if improperly installed.

Read these instructions carefully before installing and follow directions as outlined.

General Description

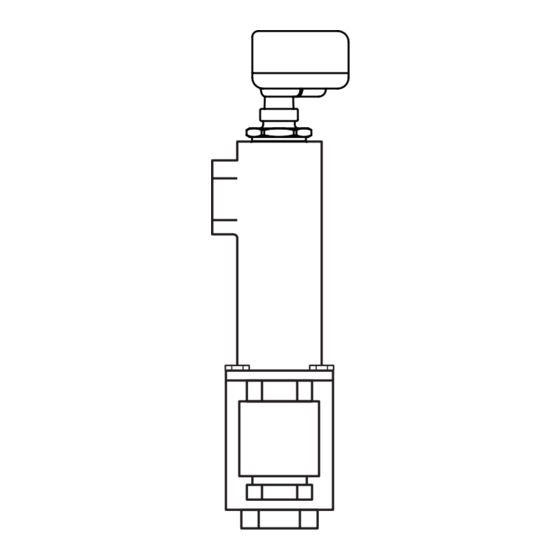

The Model 804 water temperature controller is care-

fully assembled and tested at the factory to mix hot

and cold water to any desired temperature within

range. The temperature of the hot water should be

at least 20°F higher than the maximum valve setting.

The major safety features are:

1. Failure of cold water supply causes the hot water

ports to reduce hot water flow.

2. Failure of hot water supply causes the cold water

ports to reduce cold water flow.

3. Failure of the thermostat allows both ports to

reduce flow of hot and cold water.

At each inlet of the controller is a union end stop and

check valve with removable strainer. Stop and check

valves are to prevent water from bypassing between

hot and cold water supply lines. These valves should

be fully open when in operation.

Maximum Inlet Conditions

Pressure: 125 psi

Temperature: 200°F

Maintenance

The controller should be checked periodically and,

if needed, cleaned as outlined in "INSPECTING and

CLEANING VALVE." To test for proper setting and

operation - proceed as follows:

1. Turn on full hot and cold water supply to the

valve. The mixing valve should deliver water

Model 804 SEA Deluxe

NOTICE!

ASSE 1017 Approved

CAPACITIES – MODEL 804

Pressure Drop PSI

Valve Number

804-GPM

804-LPM

at the outlet temperature stamped on the label.

Standard setting is 110°F. If the outlet temperature

is different than that shown on the label, readjust

valve according to "TEMPERATURE ADJUST-

MENT" procedure on page 2.

2. If after adjusting the outlet temperature the wa-

ter stays below the set temperature, see "CHECK-

ING COLD WATER SHUT-OFF." If the tem-

perature stays above the set temperature, see

"CHECKING HOT WATER SHUT-OFF."

Caution: When maintaining and adjusting the

mixing valve, all fixtures should be isolated from

use. Lawler Manufacturing Co., Inc. recommends

that you work safely at all times and in a manner

consistent with the OSHA Lock/Tagout standard,

29 CFR 1910.147 and other applicable standards.

WARNING: Opening of the actuator may result in

electrical shock.

Checking Cold Water Shut-Off

Turn on full hot and cold water supply to the valve

and let it run for one minute. Then shut off the hot

water stop and check valve only. Cold water should

flow through the controller momentarily then be re-

duced to a negligible amount.

Failure to do so indicates that:

a. Plunger is sticking and requires cleaning or

replacement.

-1-

Installation &

Maintenance Manual

Certified to

CSA B125.3

5

10

20

30

45

60

Capacity

52

72

100 124 150 174 193

197 273 379 469 568 659 731

M 804 E

U P

C

C

®

80

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Lawler 804 SEA Deluxe

- Page 1 Stop and check use. Lawler Manufacturing Co., Inc. recommends valves are to prevent water from bypassing between that you work safely at all times and in a manner hot and cold water supply lines.

- Page 2 Figure A 1. Place a ″ wooden dowel Checking Cold Water Shut-Off (Cont.) rod into center of thermo- b. Spring #13 has lost its strength and should stat then place in 85° F REFERENCE be replaced. water. Make a reference MARKS mark on the rod as shown Note: Lack of water flow can be normal on the first...

- Page 3 Model 804 Repair Parts See Fig. B Item Description Part No. Actuator — Bonnet Gasket Dome — 805 cut-away Liner O-Ring Liner Plunger Piston Liner Assembly Figure C Valve Spring — Bottom Plug — Pusher O-Ring Bonnet Pusher Thermostat Body Screw (NS) Liner Gasket, Upper See Fig.

- Page 4 GUARANTEE We guarantee the Lawler Mixing Valve to be free from held responsible, however, for any labor incidental def ects in workmanship and material, and for a pe-...

Need help?

Do you have a question about the 804 SEA Deluxe and is the answer not in the manual?

Questions and answers