Table of Contents

Advertisement

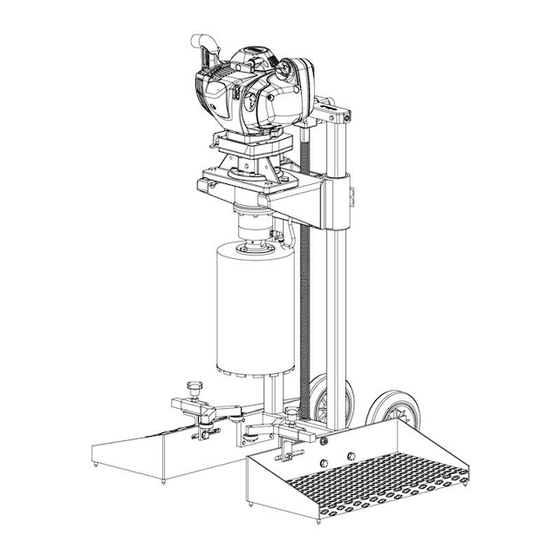

KB200 with FS560

Translation of the original operating instruction and spare parts list

ZN der Bedienungsanleitung:

Erstellt am:

Erstellt von:

Datei:

®

GÖLZ

GmbH

Dommersbach 51

D-53940 Hellenthal

Telefon: +49 (0) 2482 12 200 / Telefax: +49 (0) 2482 12 222

E-Mail: info@goelz.de / Internet: www.goelz.de

with STIHL

5006599-02

05 / 2014

Sabrina Linden

K:\KDV\5006xxx\5006599-Bedienungsanleitung\

5006599-01-Bedienungsanleitung-E.doc

Drill rig

KB 200

®

Petrol-Engine

FS 560

- 1-

®

5006599-02

BA-E

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for GÖLZ KB200

- Page 1 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Drill rig KB 200 ® with STIHL Petrol-Engine FS 560 ZN der Bedienungsanleitung: 5006599-02 Erstellt am: 05 / 2014 Erstellt von: Sabrina Linden Datei: K:\KDV\5006xxx\5006599-Bedienungsanleitung\ 5006599-01-Bedienungsanleitung-E.doc ®...

- Page 2 ® KB200 with FS560 Translation of the original operating instruction and spare parts list All rights reserved according to DIN ISO 16016. No part of this document (instruction manual and spare parts list) may be reproduced, adapted, transmitted, transcribed, stored on a data medium or be translated into another language without prior written approval of ®...

- Page 3 ® KB200 with FS560 Translation of the original operating instruction and spare parts list EC-DECLARATION OF CONFORMITY Manufacturer ® GÖLZ GmbH Dommersbach 51, D-53940 Hellenthal Tel.: +49 (0) 2482 12 200 / Fax: +49 (0) 2482 12 222 Declare hereby certifies on its sole responsibility that the following product:...

-

Page 4: Table Of Contents

® KB200 with FS560 Translation of the original operating instruction and spare parts list Contents Preface ............................ 7 General description ........................ 7 Technical data and accessory ..................8 Technical data of the machine ....................8 1.1.1 KB200 ............................8 ®... - Page 5 ® KB200 with FS560 Translation of the original operating instruction and spare parts list 4.4.1 Assembling a drill motor with gear box ..................24 4.4.2 Changing a drill motor with gear box ................... 24 Water supply ........................25 4.5.1 With water tank-pressurzied type ....................25 4.5.2...

- Page 6 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Getriebeträger ........................55 Planetary gear ........................56 Drive motor ........................57 Tool acceptance ......................... 59 Motor ..........................61 9.6.1 Motor - Crankcase, Cylinder ......................61 9.6.2 Motor - Rewind starter .........................

-

Page 7: Preface

® KB200 with FS560 Translation of the original operating instruction and spare parts list Preface This operating manual is designed to familiarize the user with petrol drill motor, hereinafter referred to as the machine, and to use its intended applications. -

Page 8: Technical Data And Accessory

® KB200 with FS560 Translation of the original operating instruction and spare parts list Technical data and accessory Technical data of the machine 1.1.1 KB200 Type KB 200 Stroke 630 - 25.8 mm - in. Feed Manual Angle drilling Weight 33 - 72.7... -

Page 9: Provided Accessory

® KB200 with FS560 Translation of the original operating instruction and spare parts list Mixing ratio ® with STIHL 1:50 two-stroke engine oil 1:50 = 1 part oil + 50 parts petrol with other branded two-stroke engine 1:25 = 1 part oil + 25 parts petrol... -

Page 10: Description

-System-Technology ensure highest operational safety and economic efficiency. The KB200 with FS560 is used as a core drilling machine for drilling up to Ø 280 mm for test core drilling in the concrete road construction and asphalt road construction as well as for drilling of bollard and post-setting, underfloor heating, crash barrier construction and fence construction. - Page 11 Due to its compact design, the unit is easy to transport. The motors can be easily and quickly removed for transport. By means of the attached transport rollers the KB200 with FS560 can be transported by one person. The operator's station is on the base plates of the machine.

-

Page 12: Basic Safety Instructions

® KB200 with FS560 Translation of the original operating instruction and spare parts list Basic safety instructions In this manual the following terms and symbols are used for particular important information: Note / Important: Contains important information which stands out from the other text! -

Page 13: Organisational Measures

® KB200 with FS560 Translation of the original operating instruction and spare parts list Organisational measures This operating manual must always be at hand at the place of use of the machine and must be accessible to the person operating the machine! -

Page 14: Selection And Qualification Of Person

® KB200 with FS560 Translation of the original operating instruction and spare parts list Selection and qualification of person Only permitted personnel is allowed to work on and with the machine! The legal minimum age is to be observed! Only assign trained and instructed personnel! Clearly define the responsibilites of the personnel with regard to ®... -

Page 15: Special Work Related To The Maintenance And Repair Of The Machine

® KB200 with FS560 Translation of the original operating instruction and spare parts list Important: Wet drilling is to be accomplished while working! This prevents the appearance of particulate matter and increases the life-time of the diamond tool! During work... -

Page 16: Information About Special Risks With Electrical Energy

® KB200 with FS560 Translation of the original operating instruction and spare parts list Information about special risks with electrical energy Observe the relevant national regulations or standards. Electrical connections must always be kept free from dirt and moisture. Use only original fuses with the specified rating! Switch off the machine immediately, if trouble occurs in the... -

Page 17: Illumination

Before transport the drill bit must be removed! The machine is not suitable for crane transport - it has got no load handling points! By means of the attached transport rollers the KB200 can be transported by one person. 3.13 Store Store the machine in a dry, high or locked place, out of the reach of children or unauthorized persons. - Page 18 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Note: store not mounted drill bits in a dry, high or locked place, out of the reach of children or unauthorized persons! Drill bits with a small diameter are only to be stored in a horizontal position, drill bits with a large diameter only in a vertical position.

-

Page 19: Bringing Into Service

® KB200 with FS560 Translation of the original operating instruction and spare parts list Bringing into service Attention: Do not yet turn the engine on! The following work is to be done with the drill motor being stopped! Export checking Remove the transport packaging and place the unit vertically on a horizontal, flat and stable surface. -

Page 20: Petrol Drill Motor Fs560

® KB200 with FS560 Translation of the original operating instruction and spare parts list Petrol drill motor FS560 The meanings of the pictrograms attached to the machine: Fuel tank Fuel mixture of gasoline and engine oil Operate manual fuel pump... - Page 21 ® KB200 with FS560 Translation of the original operating instruction and spare parts list STIHL 1:50 two-stroke engine oil: 1:50, 1 part oil + 50 parts petrol, with other branded two-stroke engine oils classification TC: 1:25, 1 part oil + 25 parts petrol.

-

Page 22: Air Filter

® KB200 with FS560 Translation of the original operating instruction and spare parts list Filling up with fuel Take care not to spill fuel while fueling and do not overfill the tank! Cosing screw-type tank cap Place the cap in the opening. -

Page 23: Spark Plug

® KB200 with FS560 Translation of the original operating instruction and spare parts list It is advisable to use the optional ”cover plate kit“. The cover plate kit contains the following parts for converting the machine: • Pos. 4: cover plate partially blanks off the slots in the starter housing. -

Page 24: Fixing The Machine

® KB200 with FS560 Translation of the original operating instruction and spare parts list Fixing the machine The machine does not need any fixing options such as dowel fixing or vacuum fixing. The operator stands on the base plates and must, under no circumstances, leave them during operation. The weight of the operator ensures the position of the machine. -

Page 25: Water Supply

® KB200 with FS560 Translation of the original operating instruction and spare parts list Loosen the four M10x45 screws, SW17, between the gear box and the gear carrier. Remove the four screws as well as the eight washers and the four nuts. -

Page 26: Public Water Mains

® KB200 with FS560 Translation of the original operating instruction and spare parts list The maximum pressure is 6 bar (87 PSI). If the pressure is not released at max., pressure automatically, the valve has to be replaced immediately. Any sort of damage on the tank (bottle) cracks or bumps, the bottle must be changed and taken out of operation. -

Page 27: With 3-Hole Flange

® KB200 with FS560 Translation of the original operating instruction and spare parts list 4.6.2 With 3-hole flange Important: The connection flanges must be clean! Fit the 3-hole flange to the gear box. Fit the flange to the gearshaft in such a way that the serration meshes and screw the two set screws in the flange into the gearshaft. -

Page 28: Operation

® KB200 with FS560 Translation of the original operating instruction and spare parts list Operation Attention: Make the site free of parts that might obstruct the operation! Make sure, the drill bit is well mounted! Make sure, only authorized personnel is in the working area! - Page 29 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Function of stop switch and ignition system The stop switch is normally in the run position: Ignition is on in this position - the engine is ready to start and may be started.

-

Page 30: Operating Instructions Engine

® KB200 with FS560 Translation of the original operating instruction and spare parts list At very low outside temperatures • Set the engine to winter operation if necessary. • If the machine is very cold (frost on machine), allow the engine to warm up in the start ▲ position after starting until normal operating temperature is reached. -

Page 31: Stop Drilling

® KB200 with FS560 Translation of the original operating instruction and spare parts list Attention: Transport the unit only when the engine is stopped! This applies also to a short change of location! Attention: Wear appropriate individual protective equipment! Care for safety clearance regarding third persons and take the operator's station on the base plates at the machine! First provide the water supply as described in the chapter "water supply". -

Page 32: Maintenance And Care

® KB200 with FS560 Translation of the original operating instruction and spare parts list Maintenance and care Attention: All maintenance, repair and care work is only to be done with the motor being stopped! ® Spare parts must comply with the technical requirements specified by the manufacturer. Spare parts from GÖLZ can be relied to do so! Observe the following indications: In accordance to the given cycles, the subsequently described maintenance work has to be enforced. -

Page 33: Cleaning The Air Filter

® KB200 with FS560 Translation of the original operating instruction and spare parts list • Remove the filter cover (Pos. 2). • Clean away loose dirt from around the filter (Pos. 3) and inside the filter cover. The air filter (Pos. 3) is a pleated paper filter element. -

Page 34: Replacing The Starter Rope And Rewind Spring

® KB200 with FS560 Translation of the original operating instruction and spare parts list Possible causes are: • too much oil in fuel mix, • dirty air filter, • unfavourable running conditions. Attention: If the spark plug comes with a detachable adapter nut (Pos. 1) screw the... - Page 35 ® KB200 with FS560 Translation of the original operating instruction and spare parts list • Allow tensioning wrench to rotate slowly and thus release spring tension. The rope winds itself around the tensioning wrench in this process until the spring is no longer under tension.

- Page 36 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Replacing the rewind spring Attention: The bits of the spring may still be under tension and could fly apart when you remove the rope rotor and spring housing. To reduce the risk of injury, wear face protection and work gloves! •...

-

Page 37: Fuel Pickup Body In Tank

® KB200 with FS560 Translation of the original operating instruction and spare parts list • Release the tensioning wrench and rope slowly so that it winds onto the rotor. • Remove the tensioning wrench. The starter grip must locate firmly in the guide bushing. If the grip droops to one side: add one more turn on the rope rotor to increase spring tension. - Page 38 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Visual inspection (condition, leaks) Complete machine clean Replace any damaged parts Control handle Check operation Visual inspection Air filter, paper filter replace Visual inspection Air filter, synthetic...

- Page 39 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Visual inspection Tool replace Check tightness Decoke after first 139 hours of operation, then Exhaust port every 150 hours of operation Safety labels replace Only if there is a noticeable loss of engine power...

-

Page 40: Troubleshooting

® KB200 with FS560 Translation of the original operating instruction and spare parts list Troubleshooting Cause Remedy Blunt drill bit Hard bonded segment! Use segments one class softer bonded Attach a drill bit with less segments or reduce the rpm Segment too big surface an increase the feed compression. - Page 41 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Cause Remedy Drill bit is stuck Apply wrench and rotate drill bit in both directions Loose material (cut steel or aggregate is blocking the while drill bit is under tension. Disconnect drill bit...

-

Page 42: Spare Parts List

® KB200 with FS560 Translation of the original operating instruction and spare parts list Spare parts list Using the spare parts list The spare parts list is not a mounting or dismounting instruction. The only purpose of the spare parts list is to easily and quickly find spare parts which can be ordered with distribution agencies, see chapter 8.1.3... -

Page 43: Distribution Agencies

® KB200 with FS560 Translation of the original operating instruction and spare parts list So bekommen Sie schnell und Pour obtenir rapidement les Always indicate richtig Ihr Ersatzteil pièces de rechange indiquer • Maschinentyp gemäß • machine type according to •... -

Page 44: Wearing Parts

® KB200 with FS560 Translation of the original operating instruction and spare parts list Wearing parts Wearing parts for construction devices mentioned in the operating manual such as drilling and sawing machines. Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device. The wearing time cannot be uniformly defined, and differs according to the intensity of use. -

Page 45: Exploded View And Spare Parts List

® KB200 with FS560 Translation of the original operating instruction and spare parts list Exploded view and spare parts list - 45- 5006599-02 BA-E... - Page 46 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 202 2000 KB 200 mit FS 560 KB 200 with FS 560 KB 200 avec FS 560...

-

Page 47: Drill Rig Assy

® KB200 with FS560 Translation of the original operating instruction and spare parts list Drill rig assy. 9.1.1 Drill rig - 47- 5006599-02 BA-E... - Page 48 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 202 1031 Bohrständer kpl. Drill rig assy. Foreuse carotteuse compl. 0295 002 0043 Rohrführung Column Guide en fer carré...

- Page 49 ® KB200 with FS560 Translation of the original operating instruction and spare parts list - 49- 5006599-02 BA-E...

- Page 50 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 899 0051 Typenschild Type plate Plaque d’identification 0295 010 0014 Abgasschlauch Exhaust hose Tuyau d’évacuation des gaz 0295 010 0531 Schlauch kpl.

-

Page 51: Carriage

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.1.2 Carriage Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 000 0048 Pos. 1-7 Bohrschlitten kpl. Carriage assy. Chariot compl. 0295 000 0093 Bohrschlitten Carriage... -

Page 52: Crankcase

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.1.3 Crankcase Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 000 0092 Pos. 1-4 Brücke kpl. Crankcase assy. Pond de commande compl. 0295 000 0046 Brückengehäuse... -

Page 53: Roller Support

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.1.4 Roller support Pos Artikelnummer Menge Norm Info Bezeichnung Description Désignation Support de roulettes 0295 000 0111 Rollenhalter kpl. Roller support assy. complète Rollanhalter Roller support... -

Page 54: Clamping Tube

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.1.5 Clamping tube Pos Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 000 0114 Klemmrohr kpl. Clamping tube assy. Tube de serrage complète 0295 200 5000... -

Page 55: Getriebeträger

® KB200 with FS560 Translation of the original operating instruction and spare parts list Getriebeträger Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation 0295 300 0049 Getriebeträger Gear box carrier Support engrenage DIN EN 0286 570 0047 B 10,5 Scheibe... -

Page 56: Planetary Gear

® KB200 with FS560 Translation of the original operating instruction and spare parts list Planetary gear Interstices of Pos. 2 and Pos. 3 fill with waterproof fat. Install Pos. 4 so that the hole of the flushing drill in the groove from Pos. 1 remains free Use Pos. -

Page 57: Drive Motor

® KB200 with FS560 Translation of the original operating instruction and spare parts list Drive motor - 57- 5006599-02 BA-E... - Page 58 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Bezeichnung Description Désignation Pos.1-26 0295 003 0005 Antriebsmotor kpl. Drive motor assy. Moteur commande compl. EUROPA Pos.1-26 0295 003 0003 Antriebsmotor kpl.

-

Page 59: Tool Acceptance

® KB200 with FS560 Translation of the original operating instruction and spare parts list Tool acceptance Pos Artikelnummer Menge Norm Info Bezeichnung Description Désignation Werkzeugaufnahme Tool acceptance Levé outillage 0295 002 0000 3-Loch-Flansch Flange Bride DIN EN 0285 300 0026... - Page 60 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos Artikelnummer Menge Norm Info Bezeichnung Description Désignation Werkzeugaufnahme Tool acceptance Levé outillage 0295 002 0001 5/4“ UNC Adapter Adapter Adapter DIN EN 0285 300 0026...

-

Page 61: Motor

® KB200 with FS560 Translation of the original operating instruction and spare parts list Motor 9.6.1 Motor - Crankcase, Cylinder - 61- 5006599-02 BA-E... - Page 62 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation Kurbelgehäuse, Zylinder Crankcase, Cylinder Carter, Cylindre 4148 020 2602 Pos. 2-4 Kurbelgehäusehälfte Crankcase Demi-carter de vilebrequin 9503 003 0340...

-

Page 63: Motor - Rewind Starter

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.2 Motor - Rewind starter - 63- 5006599-02 BA-E... - Page 64 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation 4148 190 4000 Pos. 1-13 Anwerfvorrichtung Rewind starter Dispositif de lancement 4148 190 0400 + Pos. 2 Starterdeckel...

-

Page 65: Motor - Muffler, Shroud

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.3 Motor - Muffler, Shroud - 65- 5006599-02 BA-E... - Page 66 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation Schalldämpfer, Haube Muffler, Shroud Silencieux, Capot 4148 140 0601 Schalldämpfer Muffler Silencieux 4148 140 6900 Stutzen mit Gitter...

-

Page 67: Motor - Fuel Tank

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.4 Motor - Fuel tank - 67- 5006599-02 BA-E... - Page 68 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation 4148 350 0401 Pos. 2-15 Kraftstofftank Fuel tank Réservoir d’essence 4147 350 5802 Tankfüllung Tank vent Aération de réservoir 4223 353 9201 Tülle...

-

Page 69: Motor - Spacer Flange, Air Filter, Filter Housing

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.5 Motor - Spacer flange, Air filter, Filter housing - 69- 5006599-02 BA-E... - Page 70 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation Zwischenflansch, Luftfilter, Spacer flange, Air filter, Bride intermédiaire, Filtre à Filtergehäuse Filter housing air, Boiter de filtre 4148 120 2300...

-

Page 71: Motor - Carburetor

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.6 Motor - Carburetor - 71- 5006599-02 BA-E... - Page 72 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation 4148 120 0601 Pos. 1-17 Vergaser HDA-302A Carburetor HDA-302A Carburateur HDA-302A 4116 121 5100 Einlassnadel Inlet needle Pointeau d’admission...

-

Page 73: Motor - Ignition System

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.7 Motor - Ignition system - 73- 5006599-02 BA-E... - Page 74 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation Zündanlage Ignition system Dispositif d’allumage 4148 400 4710 + Pos. 3, 4 Steuergerät Control unit Appareil de commande...

-

Page 75: Motor - Clutch, Clutch Housing

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.8 Motor - Clutch, Clutch housing - 75- 5006599-02 BA-E... - Page 76 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation Kupplung, Embrayage, Carter Clutch, clutch housing Kupplungsgehäuse d’accouplement 4148 160 2000 Pos. 1-5 Kupplung Clutch Embrayage Fliehgewicht Clutch shoe...

-

Page 77: Motor - Handlebar

® KB200 with FS560 Translation of the original operating instruction and spare parts list 9.6.9 Motor - Handlebar - 77- 5006599-02 BA-E... - Page 78 ® KB200 with FS560 Translation of the original operating instruction and spare parts list Pos. Artikelnummer Menge Norm Info Benennung Description Désignation 4148 790 1303 Pos. 7-20 Bedienungsgriff Handlebar Poignée tubulaire 4148 790 0301 Handgriff Handle Poignée 4147 442 1600...

Need help?

Do you have a question about the KB200 and is the answer not in the manual?

Questions and answers