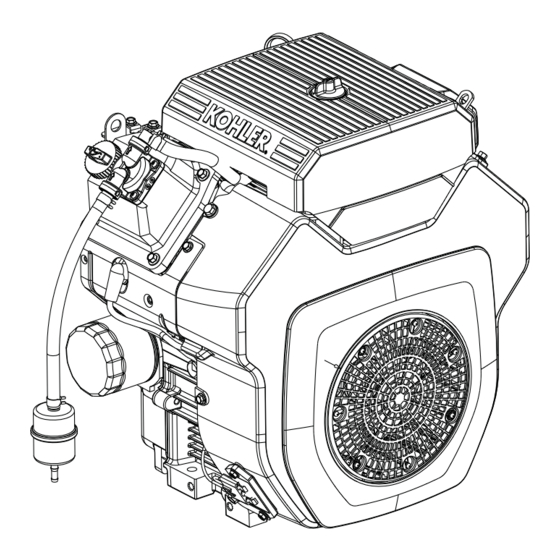

Kohler Command PRO CH620-CH740 Owner's Manual

Hide thumbs

Also See for Command PRO CH620-CH740:

- Owner's manual (8 pages) ,

- Owner's manual (24 pages) ,

- User manual

Table of Contents

Advertisement

CH23, CH620-CH740, CH750

CV23, CV620-CV740, CV750

Owner's Manual

IMPORTANT:

Read all safety precautions and instructions carefully before

operating equipment. Refer to operating instruction of

equipment that this engine powers.

Ensure engine is stopped and level before performing any

maintenance or service.

Warranty coverage as outlined in the warranty card and on

KohlerEngines.com. Please review carefully as it provides you

specifi c rights and obligations.

To maintain compliance with applicable emission regulations,

exhaust system backpressure may not exceed limits which can

be found on KohlerEngines.com. Search by Model No., select

Read More, then select Specs tab.

Record engine information to reference when ordering parts or obtaining warranty coverage.

Engine Model

Specifi cation

Serial Number

Purchase Date

24 590 43 Rev. --

KohlerEngines.com

EN

ESS

FRC

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Kohler Command PRO CH620-CH740

- Page 1 CH23, CH620-CH740, CH750 CV23, CV620-CV740, CV750 Owner's Manual IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating instruction of equipment that this engine powers. Ensure engine is stopped and level before performing any maintenance or service. Warranty coverage as outlined in the warranty card and on KohlerEngines.com.

- Page 2 Safety Precautions WARNING: A hazard that could result in death, serious injury, or substantial property damage. CAUTION: A hazard that could result in minor personal injury or property damage. NOTE: is used to notify people of important installation, operation, or maintenance information. WARNING WARNING WARNING...

- Page 3 Dipstick Oil Fill Fuel Filter Oil Filter Dust Ejector Oil Cooler Oil Drain Plug Debris Screen Valve Heavy-Duty Air End Cap Element Inner Element Cleaner Air Cleaner Inlet Screen Retaining Clip Ejector Area Housing Air Cleaner Air Cleaner Rubber Seal Wing Nut Knob Cover...

- Page 4 4000 ft. (1219 meters) or above, a high altitude authorized dealer. carburetor kit is required. To obtain high altitude carburetor kit information or to fi nd a Kohler 1. Place throttle control midway between slow authorized dealer, visit KohlerEngines.com or and fast positions.

- Page 5 Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment or individual; however, warranty repairs must be performed by a Kohler authorized dealer found at KohlerEngines.com or 1-800-544-2444 (U.S. and Canada). Maintenance Schedule Weekly ●...

- Page 6 Fuel Line correct leaks. Recheck oil level. Low permeation fuel line must be installed on 9. Dispose of used oil and fi lter in accordance carbureted Kohler Co. engines to maintain EPA with local ordinances. and CARB regulatory compliance. Oil Sentry (if equipped) ™...

- Page 7 1. Clean area around element. Remove wing service, and replacement parts for engine. nut, element cover, and paper element with To fi nd a Kohler authorized dealer visit precleaner. KohlerEngines.com or call 1-800-544-2444 (U.S. and Canada).

-

Page 8: Troubleshooting

CH750, and CV750 is EM for U.S. EPA, California, and Europe. Any and all horsepower (hp) references by Kohler are Certifi ed Power Ratings and per SAE J1940 & J1995 hp standards. Details on Certifi ed Power Ratings can be found at KohlerEngines.com. - Page 9 CH18-CH25, CH620-CH730, CH740, CH750 Service Manual IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating instruction of equipment that this engine powers. Ensure engine is stopped and level before performing any maintenance or service. Safety Maintenance Specifi...

-

Page 10: Safety Precautions

Safety SAFETY PRECAUTIONS WARNING: A hazard that could result in death, serious injury, or substantial property damage. CAUTION: A hazard that could result in minor personal injury or property damage. NOTE: is used to notify people of important installation, operation, or maintenance information. CAUTION WARNING WARNING... -

Page 11: Maintenance Instructions

Have a Kohler authorized dealer perform this service. REPAIRS/SERVICE PARTS Kohler genuine service parts can be purchased from Kohler authorized dealers. To fi nd a local Kohler authorized dealer visit KohlerEngines.com or call 1-800-544-2444 (U.S. and Canada). 24 690 06 Rev. K... -

Page 12: Oil Recommendations

Maintenance OIL RECOMMENDATIONS STORAGE We recommend use of Kohler oils for best performance. If engine will be out of service for 2 months or more Other high-quality detergent oils (including synthetic) follow procedure below. of API (American Petroleum Institute) service class SJ 1. -

Page 13: Specifications

Specifi cations Engine Dimensions with Low-Profi le Air Cleaner Dimensions in millimeters. Inch equivalents shown in [ ]. 24 690 06 Rev. K KohlerEngines.com... - Page 14 Specifi cations Engine Dimensions with Heavy-Duty Air Cleaner Dimensions in millimeters. Inch equivalents shown in [ ]. 135.00 424.61 130.00 285.90 304.48 [5.315] [16.717] [5.118] [11.256] [11.987] 50.85 AIR FILTER RAIN 272.17 AIR FILTER COVER 93.33 [2.002] CAP REMOVAL ASSEMBLY REMOVAL [3.674] [10.715] 414.17...

-

Page 15: Engine Identification Numbers

Lubricate threads with engine oil prior to assembly. Any and all horsepower (hp) references by Kohler are Certifi ed Power Ratings and per SAE J1940 & J1995 hp standards. Details on Certifi ed Power Ratings can be found at KohlerEngines.com. - Page 16 Specifi cations TORQUE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Connecting Rod Cap Fastener (torque in increments) 8 mm straight shank 22.7 N·m (200 in. lb.) 8 mm step-down 14.7 N·m (130 in. lb.) 6 mm straight shank 11.3 N·m (100 in.

-

Page 17: Clearance Specifications

Specifi cations TORQUE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Speed Control Bracket Fastener 10.7 N·m (95 in. lb.) into new holes 7.3 N·m (65 in. lb.) into used holes Starter Assembly Thru Bolt Inertia Drive 4.5-5.7 N·m (40-50 in. - Page 18 Specifi cations CLEARANCE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Crankcase Governor Cross Shaft Bore I.D. 6 mm Shaft 6.025/6.050 mm (0.2372/0.2382 in.) Max. Wear Limit 6.063 mm (0.2387 in.) 8 mm Shaft 8.025/8.075 mm (0.3159/0.3179 in.) Max.

- Page 19 Specifi cations CLEARANCE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Governor Governor Cross Shaft-to-Crankcase Running Clearance 6 mm Shaft 0.013/0.075 mm (0.0005/0.0030 in.) 8 mm Shaft 0.025/0.126 mm (0.0009/0.0049 in.) Cross Shaft O.D. 6 mm Shaft 5.975/6.012 mm (0.2352/0.2367 in.) Max.

- Page 20 Specifi cations CLEARANCE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Piston, Piston Rings, and Piston Pin (Style A continued) Thrust Face O.D. 76.943/ 79.943/ 82.949/82.967 mm 76.961 mm 79.961 mm (3.2656/3.2664 in.) (3.0292/ (3.1473/ 3.0299 in.) 3.1480 in.) Max.

- Page 21 Specifi cations CLEARANCE SPECIFICATIONS CH18/CH20/ CH22/CH23/ CH25/ CH750 CH22/ CH620/ CH730/ CH620/CH621/ CH640/ CH740 CH640/CH641 CH670/CH680 Valves and Valve Lifters Hydraulic Valve Lifter to Crankcase Running Clearance 0.0241/0.0501 mm (0.0009/0.0020 in.) Intake Valve Stem-to-Valve Guide Running Clearance 0.038/0.076 mm (0.0015/0.0030 in.) Exhaust Valve Stem-to-Valve Guide Running Clearance 0.050/0.088 mm (0.0020/0.0035 in.) Intake Valve Guide I.D.

-

Page 22: General Torque Values

Specifi cations GENERAL TORQUE VALUES English Fastener Torque Recommendations for Standard Applications Bolts, Screws, Nuts and Fasteners Assembled Into Cast Iron or Steel Grade 2 or 5 Fasteners Into Aluminum Size Grade 2 Grade 5 Grade 8 Tightening Torque: N·m (in. lb.) ± 20% 8-32 2.3 (20) 2.8 (25) - Page 23 Shrader Valve Adapter Hose DTI-037 Wire Probe Set (2 pieces regular wire with clip; 1 piece fused wire) DTI-031 Hose Removal Tool, Dual Size/End (also sold as individual Kohler tool) DTI-033 Flywheel Puller SE Tools KLR-82408 For properly removing fl ywheel from engine.

- Page 24 For reaming worn valve guides to accept replacement oversize valves. Can be used in low-speed drill press or with handle below for hand reaming. Reamer Handle Design Technology Inc. For hand reaming using Kohler 25 455 12-S reamer. DTI-K830 AIDS Description Source/Part No.

- Page 25 Tools and Aids FLYWHEEL HOLDING TOOL ROCKER ARM/CRANKSHAFT TOOL A fl ywheel holding tool can be made out of an old junk A spanner wrench to lift rocker arms or turn crankshaft fl ywheel ring gear and used in place of a strap wrench. may be made out of an old junk connecting rod.

-

Page 26: Troubleshooting Guide

Troubleshooting TROUBLESHOOTING GUIDE When troubles occur, be sure to check simple causes which, at fi rst, may seem too obvious to be considered. For example, a starting problem could be caused by an empty fuel tank. Some general common causes of engine troubles are listed below and vary by engine specifi cation. Use these to locate causing factors. - Page 27 Troubleshooting EXTERNAL ENGINE INSPECTION Engine Loses Power NOTE: It is good practice to drain oil at a location away ● Dirty air cleaner element. from workbench. Be sure to allow ample time for ● Engine overheated. complete drainage. ● Excessive engine load. ●...

-

Page 28: Crankcase Vacuum Test

Troubleshooting CRANKCASE VACUUM TEST WARNING WARNING Carbon Monoxide can cause severe nausea, Rotating Parts can cause severe injury. fainting or death. Stay away while engine is in operation. Avoid inhaling exhaust fumes. Engine exhaust gases contain poisonous carbon Keep hands, feet, hair, and clothing away from all monoxide. -

Page 29: Compression Test

Troubleshooting COMPRESSION TEST For Command Twins: A compression test is best performed on a warm engine. Clean any dirt or debris away from base of spark plug(s) before removing them. Be sure choke is off, and throttle is wide open during test. Compression should be at least 160 psi and should not vary more than 15% between cylinders. -

Page 30: Air Cleaner

Air Cleaner/Intake AIR CLEANER NOTE: Operating engine with loose or damaged air cleaner components could cause premature These systems are CARB/EPA certifi ed and components wear and failure. Replace all bent or damaged should not be altered or modifi ed in any way. components. -

Page 31: Fuel Pump

fi tting on crankcase or valve cover. Low permeation fuel line must be installed on carbureted Kohler Co. engines to maintain EPA and CARB 4. Attach new fuel pump using screws. Torque screws regulatory compliance. - Page 32 Fuel System CARBURETORS Gasoline is extremely fl ammable and its vapors can WARNING explode if ignited. Store gasoline only in approved Explosive Fuel can cause fi res and severe containers, in well ventilated, unoccupied buildings, away burns. from sparks or fl ames. Spilled fuel could ignite if it comes in contact with hot parts or sparks from ignition.

- Page 33 Fuel System Keihin One-Barrel Carburetor Components Engines in this series are equipped with Keihin fi xed main jet carburetors. CH18-740 engines use a one- barrel carburetor. Most applications use a fuel shut-off solenoid installed in place of fuel bowl retaining screw, and also contain an accelerator pump.

- Page 34 Fuel System Troubleshooting-Carburetor Related Causes Condition Possible Cause Conclusion Engine starts hard, runs rough, or Low idle fuel mixture (some models)/ Adjust low idle speed tab, then adjust stalls at idle speed. speed improperly adjusted. low idle fuel needle. Engine runs rich (indicated by black, Clogged air cleaner.

- Page 35 Fuel System 2. Release governor lever and check that throttle lever Carburetor Circuits is in idle position. Turn governed idle adjustment Float screw to obtain equipment manufacturer’s Fuel level in bowl is maintained by fl oat and fuel inlet recommended idle speed (1500-1800 RPM). Some needle.

- Page 36 1219 meters (4000 ft.). To obtain high altitude kit Disconnect and ground spark plug lead(s) information or to fi nd a Kohler authorized dealer visit before servicing. KohlerEngines.com or call1-800-544-2444 (U.S. and Canada).

- Page 37 Governor System GOVERNOR Engine is equipped with a centrifugal fl yweight mechanical governor. It is designed to hold engine speed constant under changing load conditions. Governor gear/fl yweight mechanism is mounted inside crankcase on closure plate, and is driven off gear on camshaft. Governor Components H Inside Engine Throttle Lever...

-

Page 38: Electronic Governor

Governor System Sensitivity Adjustment GCU Safety Features Governor sensitivity is adjusted by repositioning In event of an engine overspeed condition, GCU will shut governor spring in holes of governor lever. If speed down engine by grounding ignition modules. surging occurs with a change in engine load, governor is set too sensitive. -

Page 39: Check Oil Level

Lubrication System This engine uses a full pressure lubrication system which 4. Reinstall dipstick and tighten securely. delivers oil under pressure to crankshaft, camshaft, CHANGE OIL AND FILTER connecting rod bearing surfaces, and hydraulic valve Change oil while engine is warm. lifters. -

Page 40: Installation

Lubrication System OIL SENTRY (if equipped) ™ This switch is designed to prevent engine from starting in a low oil or no oil condition. Oil Sentry may not shut ™ down a running engine before damage occurs. In some applications this switch may activate a warning signal. Read your equipment manuals for more information. -

Page 41: Spark Plugs

Electrical System SPARK PLUGS Inspection Inspect each spark plug as it is removed from cylinder CAUTION head. Deposits on tip are an indication of general Electrical Shock can cause injury. condition of piston rings, valves, and carburetor. Do not touch wires while engine is running. Normal and fouled plugs are shown in following photos: Normal Spark Plug Component and Details... - Page 42 Electrical System Carbon Fouled ELECTRONIC IGNITION SYSTEMS Ignition System Components Soft, sooty, black deposits indicate incomplete combustion caused by a restricted air cleaner, over rich Kill Switch/ carburetion, weak ignition, or poor compression. Off Position of Air Gap Key Switch Overheated Flywheel Magnet...

- Page 43 Electrical System Wiring Diagram-15/20/25 Amp Regulated Battery Charging System with Fixed Timing 24 690 06 Rev. K KohlerEngines.com...

- Page 44 Electrical System Fixed Ignition System This system uses a capacitive discharge (CD) coil. Ignition timing and spark remains constant regardless of engine speed. Timing of spark is controlled by location of fl ywheel magnet group as referenced to engine TDC. A typical fi xed ignition system consists of: ●...

- Page 45 Electrical System Wiring Diagram-15/20/25 Amp Regulated Battery Charging System with Variable Ignition Timing SMART- SPARK ™ 24 690 06 Rev. K KohlerEngines.com...

- Page 46 Electrical System Smart-Spark Advance Ignition System ™ SMART-SPARK equipped engines utilize an electronic capacitive discharge ignition system with electronic spark ™ advance. A typical application consists of following components: ● 1 magnet assembly which is permanently affi xed to fl ywheel. ●...

- Page 47 Electrical System Wiring Diagram-15/20/25 Amp Regulated Battery Charging System with DSAI Ignition and Key Switch 24 690 06 Rev. K KohlerEngines.com...

- Page 48 Electrical System Digital Spark Advance Ignition (DSAI) System This system uses a digital microprocessor which is located in ignition modules. Ignition timing varies depending upon engine speed with this system. There are 2 inductive-style ignition modules that control ignition timing based on engine RPM.

- Page 49 Electrical System Wiring Diagram-3 Amp Unregulated Battery Charging System/70 Watt Lighting Optional Oil Optional Oil Ground-To-Kill Sentry Switch Sentry Switch 12 V. Battery Light Lead (White) ™ ™ (Shutdown) (Indicator Light) Optional Ground Optional Fuse Key Switch Ammeter Blue Solenoid Lights Starter Yellow...

- Page 50 Electrical System Test for Spark NOTE: If 2 testers are available, testing can be performed simultaneously for both cylinders. However, if only 1 tester is available, 2 individual tests must be performed. Side not being tested must have spark plug lead connected or grounded.

- Page 51 Electrical System Test Ignition Modules and Connections (Smart- Ignition Module Resistance Table Spark only) ™ 24 584 03 24 584 15-S NOTE: Resistance values apply only to modules that have been on a running engine. New service 24 584 11 24 584 36-S modules may have higher resistance until they (1 11/16 in.

- Page 52 Electrical System Condition Possible Cause Conclusion Strong, steady spark is now present Problem should be corrected. Go to on both sides. Test SAM step 4. Still a spark problem. Test SAM. Test SAM 1. Trace red power source lead from SAM to harness connection. Separate connector and connect red lead of a DC voltmeter to harness terminal.

-

Page 53: Battery Charging System

Electrical System To test ASAM only using 25 761 21-S tester: ● Yellow tester lead to long yellow module lead. ● Brown tester lead to long brown module lead. NOTE: SAM must be at room temperature when tested. ● Red tester lead to red module lead. Disconnect all SAM leads, isolating it from main ●... - Page 54 Electrical System 15/20/25 Amp Regulated Charging System Stator Stator is mounted on crankcase behind fl ywheel. Follow procedures in Disassembly and Reassembly if stator replacement is necessary. Rectifi er-Regulator NOTE: When installing rectifi er-regulator, take note of terminal markings and install plug(s) accordingly. NOTE: Disconnect all electrical connections attached to rectifi...

- Page 55 Electrical System 15/20/25 Amp Battery Charging Systems NOTE: Always zero ohmmeter on each scale before testing to ensure accurate readings. Voltage tests should be made with engine running at 3600 RPM with no load. Battery must be good and fully charged. When problems occur in keeping battery charged or battery charges at high rate, charging system or battery might be causing problems.

- Page 56 Electrical System 3 Amp/70 Watt Lighting Stator NOTE: Always zero ohmmeter on each scale before testing to ensure accurate readings. Voltage tests should be made with engine running at 3600 RPM with no load. Battery must be good and fully charged. To test charging system for no charge to battery: To test charging system for no lights: 1.

- Page 57 Starter System NOTE: Do not crank engine continuously for more than 10 seconds. Allow a 60 second cool down period between starting attempts. Failure to follow these guidelines can burn out starter motor. NOTE: If engine develops suffi cient speed to disengage starter but does not keep running (a false start), engine rotation must be allowed to come to a complete stop before attempting to restart engine.

- Page 58 4. Clean splines on drive shaft thoroughly with solvent. Dry splines thoroughly. 5. Apply a small amount of Kohler electric starter drive lubricant, to splines. Use of other lubricants may cause drive pinion to stick or bind.

- Page 59 A brush holder tool can easily be made 5. Install thru bolts and tighten securely. from thin sheet metal. 6. Lubricate drive shaft with Kohler starter drive 1. Remove brush springs from pockets in brush holder. lubricant. Install drive components following 2.

- Page 60 Starter System SOLENOID SHIFT ELECTRIC STARTERS Nippondenso Starters Solenoid Shift Starter Components Starter Disassembly NOTE: When removing lever and armature be careful not to lose thrust washer. 1. Disconnect lead wire from solenoid. 2. Remove nuts securing solenoid, and remove solenoid from starter assembly.

- Page 61 Brush Replacement 4 brushes and springs are serviced as a set. Use a new Kohler brush and spring kit if replacement is necessary. 1. Perform steps 1-5 in Starter Disassembly. 2. Remove screws securing brush holder assembly to end cap (plate).

- Page 62 Starter System 10. Starter reassembly when replacing brushes/brush Starter Reassembly holder assembly: NOTE: Always use a new retainer. Do not reuse old a. Hold starter assembly vertically on end housing, retainers that have been removed. and carefully position assembled brush holder NOTE: Correctly installed, center pivot section of drive assembly, with supplied protective tube, against lever will be fl...

- Page 63 Starter System Solenoid Tests NOTE: DO NOT leave 12 volt test leads connected to solenoid for any time over what is necessary for performing each of individual tests. Internal damage to solenoid may occur. Disconnect all leads from solenoid including positive brush lead attached to lower stud terminal. Remove mounting hardware and separate solenoid from starter for testing.

-

Page 64: Retractable Starters

Starter System RETRACTABLE STARTERS Remove Starter 1. Remove screws securing starter to blower housing. WARNING 2. Remove starter assembly. Uncoiling Spring can cause severe injury. Rope Replacement Wear safety goggles or face protection when servicing retractable starter. NOTE: Do not allow pulley/spring to unwind. Enlist aid of a helper if necessary. - Page 65 Starter System Pawls (dogs) Replacement 1. Install a clamp to hold pulley in starter housing and prevent if from rotating. 2. Remove center screw, washer, and pawl retainer. 3. Note position of pawls and pawl springs before removing. Remove pawls, pawls springs, brake spring and brake washer from pulley.

- Page 66 Clutch WET DISC TYPE CLUTCH (if equipped) Wet Disc Type Clutch Components Shifting Lever Gasket Seal Shaft (Yoke) Nameplate Clutch Housing Adjusting Ring Driven Member Bearing Release Release Sleeve Pressure Plate Pilot Bearing Assembly Adjusting Lock Clutch Assembly Power Shaft Retaining Rings Yoke Roll Pin...

- Page 67 Clutch Service 1. Release clutch and remove nameplate. Using a On this clutch type, an oil splash type lubrication system large screwdriver, turn adjusting ring clockwise, one is used. Proper oil level must be maintained to provide notch at a time, until fi rm pressure is required to effi...

- Page 68 Disassembly/Inspection and Service WARNING Before working on engine or equipment, disable engine as Accidental Starts can cause severe injury or follows: 1) Disconnect spark plug lead(s). 2) Disconnect death. negative (–) battery cable from battery. Disconnect and ground spark plug lead(s) before servicing.

- Page 69 Disassembly/Inspection and Service Clean all parts thoroughly as engine is disassembled. 4. Remove heavy-duty air cleaner as an assembly from Only clean parts can be accurately inspected engine. and gauged for wear or damage. There are many commercially available cleaners that will quickly remove Remove Fuel Pump grease, oil, and grime from engine parts.

- Page 70 Disassembly/Inspection and Service 2. One-barrel carburetor models only: Remove Remove Throttle and Choke Controls carburetor mounting screws. Control Bracket Components Two-barrel carburetor models only: If required use nuts locked together and remove carburetor mounting studs on starter side of intake manifold and one stud on oil fi...

- Page 71 Disassembly/Inspection and Service 4. Pry under protruding edge of breather cover with a Remove Inner Baffl es and Breather Cover screwdriver to break RTV or gasket seal. Do not pry Inner (valley) baffl es are attached at one corner using on sealing surfaces as it could cause damage same fasteners as breather cover.

-

Page 72: Exhaust Valve

Disassembly/Inspection and Service 1. Remove screws or nuts and washers securing each Disassemble Cylinder Heads cylinder head. Unless screws are damaged or NOTE: These engines use valve stem seals on intake questionable, they can be reused. Discard nuts and valves. Use a new seal whenever valve is washers once removed;... - Page 73 Check base surface of hydraulic lifters for wear or Replace valves found to be in bad condition. damage. If lifters need to be replaced, apply a liberal coating of Kohler lubricant to base of each new lifter Valve Guides before it is installed.

- Page 74 Use a hook-end tool next to post and pull Inspect ring gear for cracks or damage. Kohler does not outward to separate small metal retainers. Then provide ring gear as a serviceable part. Replace fl ywheel unsnap fan from remaining mounting posts.

- Page 75 Disassembly/Inspection and Service Remove Stator and Backing Plates 1. Remove screws securing backing plates and stator wire bracket (if equipped). Remove backing plates and stator wire bracket. 2. Remove screws and stator. Crankcase Components Oil Seal Closure Plate (Style A) Gerotor Gear (Style A) Dipstick Tube Oil Pick-Up Tube...

- Page 76 Disassembly/Inspection and Service Inspection Governor Gear Assembly Inspect governor gear teeth. Replace gear if it is worn, chipped, or if any teeth are missing. Inspect governor Governor Shaft Component and Details weights. They should move freely in governor gear. Disassembly NOTE: Governor gear is held onto shaft by small molded tabs in gear.

- Page 77 Disassembly/Inspection and Service Oil Pump Assembly (Style A) Oil Pump Assembly (Style B) Oil pump is mounted inside closure plate. If service is Oil pump is mounted inside closure plate. If service is required, continue with Disassembly, Inspection, and required, continue with Disassembly, Inspection, and Reassembly.

- Page 78 Disassembly/Inspection and Service Ring failure is usually indicated by excessive oil Remove Connecting Rods with Pistons and Rings consumption and blue exhaust smoke. When rings fail, NOTE: If a carbon ridge is present at top of either oil is allowed to enter combustion chamber where it is cylinder bore, use a ridge reamer tool to remove burned along with fuel.

- Page 79 Disassembly/Inspection and Service Piston Style B Install New Piston Rings 1. Cylinder bore must be de-glazed before service ring Piston Ring Orientation sets are used. 2. If cylinder bore does not need re-boring and if old piston is within wear limits and free of score or scuff marks, old piston may be reused.

- Page 80 Disassembly/Inspection and Service Carefully pull crankshaft from crankcase. Note thrust Connecting Rods washers and shims if used. Offset, stepped-cap connecting rods are used in all Inspect gear teeth of crankshaft. If teeth are badly worn, these engines. chipped, or some are missing, replacement of crankshaft Inspection and Service will be necessary.

- Page 81 Install new seal to depth shown using a seal installer. NOTE: Kohler pistons are custom-machined to exacting tolerances. When oversizing a cylinder, it should Remove Flywheel End Oil Seal be machined exactly 0.25 mm (0.010 in.) or 0.50 mm (0.020 in.) over new diameter (refer to...

- Page 82 Disassembly/Inspection and Service 4. After resizing, check bore for roundness, taper, and Measuring Piston-to-Bore Clearance size. Use an inside micrometer, telescoping gauge, Piston Detail or bore gauge to take measurements. These measurements should be taken at 3 locations in cylinder–at top, middle, and bottom. There are 2 measurements that should be taken (perpendicular to each other) at all 3 locations.

- Page 83 Reassembly Crankcase Components Oil Seal Closure Plate (Style A) Gerotor Gear (Style A) Dipstick Tube Oil Pick-Up Tube Oil Pump Assembly Governor Gear Shaft Governor Gear (Style A) (Style A) Camshaft Piston Pin Piston Ring Set Piston Pin Retainer Connecting Rod End Piston (Style B) Connecting Rod Crankshaft...

- Page 84 Reassembly NOTE: Cylinders are numbered on crankcase. Make Install Governor Cross Shaft sure to install piston, connecting rod and end 1. Lubricate governor cross shaft bearing surfaces in cap into its appropriate cylinder bore as crankcase with engine oil. previously marked at disassembly. Do not mix end caps and connecting rods.

- Page 85 Reassembly Determining Camshaft End Play Thrust Bearing, Washer and Shim 1. Install shim removed during disassembly onto Thrust Bearing, Washer, and Shim Sequence camshaft. 2. Position camshaft end play checking tool on camshaft. 3. Apply pressure on camshaft end play checking tool (pushing camshaft toward crankshaft).

- Page 86 Reassembly Remove closure plate. If end play requires adjustment, Install Closure Plate Assembly remove original spacer and install appropriate size shim spacer in its place. Then follow procedure under Install Sealant Pattern and Torque Sequence Closure Plate Assembly. Install Closure Plate Oil Seal Oil Seal Depth RTV sealant is used as a gasket between closure plate and crankcase.

- Page 87 Reassembly Flywheel/Ignition Components Debris Screen Flywheel Screw Washer Flywheel Magnet Stator Ignition Module Backing Plate Woodruff Key Spring Washer Spacer Metal Debris Screen Ring Support Metal Debris Screen Washer Assembly NOTE: Make sure fl ywheel key is installed properly in Install Stator and Backing Plates keyway.

- Page 88 Reassembly Install Plastic Debris Screen Install Supports for Metal Debris Screen 1. If a metal debris screen is used, with threaded CAUTION individual supports, install a spacer washer on external threads. Apply Loctite (removable) ® ® Failure to utilize or reassemble debris screen onto threads.

- Page 89 Reassembly 3. Install new mounting stud(s) into crankcase. Assemble Cylinder Heads a. Thread and lock two mounting nuts together on Prior to installation, lubricate all components with engine smaller diameter threads. oil, paying particular attention to lip of valve stem seal, valve stems and valve guides.

- Page 90 Reassembly Install Spark Plugs Install Intake Manifold 1. Check gap using wire feeler gauge. Adjust gap to Torque Sequence 0.76 mm (0.03 in.). 2. Install plug into cylinder head. 3. Torque plug to 27 N·m (20 ft. lb.). Install Ignition Modules 1.

- Page 91 Reassembly External Engine Components Intake Manifold Gasket Carburetor Outer Baffl e Breather Tube Oil Sentry Breather Cover Breather Gasket ™ Inner Baffl e Breather Reed Filter Electric Starter Lifting Bracket Fixed Guard Blower Housing Debris Shield Wire Clip Oil fi lter Nipple Oil Cooler Valve Cover Fuel...

- Page 92 Reassembly 3. Position outer baffl es and loosely start mounting Install Breather Cover and Inner Baffl es screws. M6 screws go into back of cylinders. Short Breather Cover Torque Sequence M5 screws go into lower holes closest to blower housing. Short screw on oil fi lter side is also used to mount wire harness clip.

- Page 93 Reassembly Install Fuel Pump Control Bracket Components WARNING Explosive Fuel can cause fi res and severe burns. Do not fi ll fuel tank while engine is hot or running. Gasoline is extremely fl ammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well ventilated, unoccupied buildings, away from sparks or fl...

- Page 94 Reassembly 6 mm Governor Lever and Hole Position/RPM Chart Governor Lever Hole Position (6 mm) Governor Gov. Lever High Idle RPM Spring Color Hole No. Code 3801-4000 Clear 3601-3800 Clear 3451-3600 Clear 3301-3450 Clear 3101-3300 Purple 2951-3100 Purple 2800-2950 Purple 3750* Clear 3150*...

- Page 95 Reassembly 8 mm Governor Lever and Hole Position/RPM Chart for CH20-CH740 Engines Non-Accelerator Pump Intended Maximum RPM Accelerator Pump Carburetor Governor Shaft Carburetor Confi guration High Idle Spring Color Hole No. Spring Color Hole No. 3744 3600 Orange Needle Bearing 3120 3000 Clear...

- Page 96 Reassembly Torque Specifi cations-Covers Install Oil Filter and Fill Crankcase with Oil Gasket/RTV 3.4 N·m (30 in. lb.) NOTE: Make sure both oil drain plugs are installed and Black O-ring torqued to specifi cations to prevent oil leakage. w/shoulder screws 5.6 N·m (50 in.

Need help?

Do you have a question about the Command PRO CH620-CH740 and is the answer not in the manual?

Questions and answers