Table of Contents

Advertisement

Quick Links

Operator's Manual

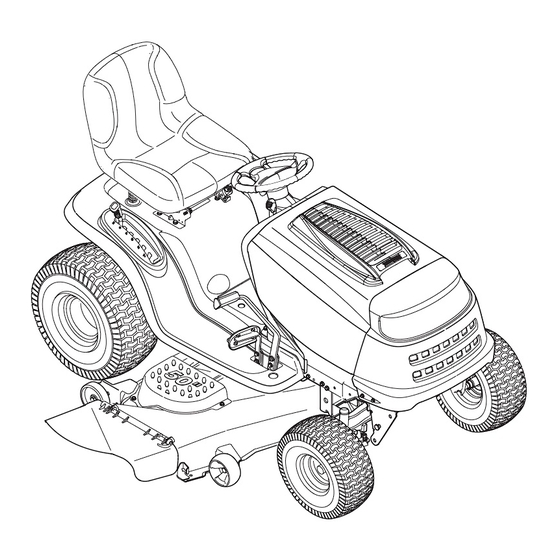

Hydrostatic Lawn Tractor

MODEL 615

IMPORTANT: Read safety rules and instructions carefully before operating equipment.

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved forest-covered, brush-

covered or grass-covered land unless the engine's exhaust system is equipped with a spark arrester meeting applicable local or state laws (if

any). If a spark arrester is used, it should be maintained in effective working order by the operator. In the State of California the above is required

by law (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark

arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131

Cleveland, Ohio 44136-9722.

MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-9722

FORM NO. 769-01628.fm

PRINTED IN U.S.A.

(12/29/2004)

Advertisement

Table of Contents

Summary of Contents for MTD YARD-MAN 615

- Page 1 (Section 4442 of the California Public Resources Code). Other states may have similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-9722. MTD LLC, P.O. BOX 361131 CLEVELAND, OHIO 44136-9722 FORM NO. 769-01628.fm PRINTED IN U.S.A.

-

Page 2: Table Of Contents

This information will be necessary to use the manufacturer’s web site and/or help from the Customer Support Department or an authorized service dealer. Copy the model number here: Copy the serial number here: MTD LLC P. O. BOX 361131 CLEVELAND,OH 44136 www.yardman.com... -

Page 3: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFE OPERATION PRACTICES WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructions in this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 Contact an 3. Do not try to stabilize the machine by putting your authorized MTD service dealer for assistance. foot on the ground. 4. Do not use a grass catcher on steep slopes.

- Page 5 Wash your skin and change clothes immediately. frame, your unit should be serviced professionally a. Use only an approved gasoline container. by an authorized MTD Service dealer. b. Never fill containers inside a vehicle or on a 4. Check brake operation frequently as it is subjected truck or trailer bed with a plastic liner.

- Page 6 6. Replace the blade(s) with the original equipment 12. Grass catcher components and the discharge manufacturer’s (O.E.M.) blade(s) only, listed in this cover are subject to wear and damage which could manual. “Use of parts which do not meet the expose moving parts or allow objects to be thrown.

- Page 7 SECTION 2: SLOPE GAUGE...

-

Page 8: Tractor Set-Up

SECTION 3: TRACTOR SET-UP Attaching the Battery Cables • With the wheels of the tractor pointing straight forward, place the steering wheel over the steering shaft. NOTE: The positive battery terminal is marked Pos. • Place the washer (with the cupped side down) over (+). - Page 9 Seat Stop Pivot Bracket Warning Shipping Brace Figure 4 • While holding the discharge chute with your left Figure 3 hand, remove the shipping brace with your right hand by grasping it between your thumb and index Gas and Oil Fill-up finger and rotating it clockwise.

-

Page 10: Know Your Lawn Tractor

SECTION 4: KNOW YOUR LAWN TRACTOR NOTE: Steering Wheel not shown for clarity. PTO (Power Take-off) Knob G Cruise Control Button Choke Control Ignition Switch Module Parking Brake Button Brake Pedal Cup Holder Drive Pedal Hour Meter Deck Lift Lever Throttle Control Lever Seat Adjustment Lever NOTE:... - Page 11 Throttle Control Lever Fast Position The throttle control lever is located on the right side of the tractor’s dash panel. This lever controls the speed of the engine. When set in a given position, the throttle will maintain a uniform engine speed. When IMPORTANT: operating the tractor with...

- Page 12 Deck Lift Lever If the Brake light or PTO light illuminates when attempting to start the unit, proceed as follows: Found on your tractor’s right fender, the deck lift lever is BRAKE — Depress the brake pedal. used to change the height of the cutting deck. To use, PTO —...

-

Page 13: Operating Your Lawn Tractor

ON while should ever malfunction, do not operate the tractor. activated. See Figure 8. Contact an authorized MTD service dealer. 4. Once activated (indicator light ON), the tractor can • The safety interlock system prevents the engine... - Page 14 • If the blades are engaged, place the PTO knob in WARNING the disengaged (OFF) position. • Turn the ignition key counterclockwise to the STOP position. AVOID SERIOUS INJURY OR DEATH • Remove the key from the ignition switch to prevent •...

- Page 15 To disengage the parking brake: To change the direction of travel to reverse when operating with cruise control, depress the brake pedal • Slightly depress the brake pedal. to disengage the cruise control and bring the tractor to a NOTE: The parking brake must be engaged if the complete stop.

- Page 16 • Pull the PTO knob outward into the engaged (ON) • Do not cut the grass too short. Short grass invites position. See Figure 11. weed growth and yellows quickly in dry weather. • Mowing should always be done with the engine at full throttle.

-

Page 17: Making Adjustments

• Pivot the discharge chute up to access the deck • Lightly tab on the plug with your hand so that the opening. See Figure 12. notches fit properly under the chute tabs and the plug is secure. Raise discharge chute this way Operating The Headlights On some models, the lamps are ON whenever the... - Page 18 • With the tractor parked on a firm, level surface, • Looking at the transmission from the right side of place the deck lift lever in the top notch (highest the tractor, locate the compression spring and position) and rotate both blades so that they are brake disc.

-

Page 19: Maintaining Your Lawn Tractor

• Thread the ball joint toward the jam nut to shorten • Replace hex nut and lock washer and retighten the the drag link. Thread the ball joint away from the jam nut after proper adjustment is achieved. jam nut to lengthen the drag link. NOTE: Threading the ball joints too far onto the drag Hex Nut and... -

Page 20: Service

Air Cleaner Rear Wheels Service the pre-cleaner, if so equipped, and cartridge/ The rear wheels should be removed from the axles air cleaner element as instructed in the Briggs & once a season. Lubricate the axles and the rims well Stratton Operator/Owner Manual (or Kohler engine’s with an all-purpose grease before re-installing them. - Page 21 • Rotate the pin slightly toward the rear of the tractor To properly sharpen the cutting blades, remove equal and release the pin into the hole provided. amounts of metal from both ends of the blades along • Repeat the above steps on the tractor’s right side. the cutting edges, parallel to the trailing edge, at a 25°...

- Page 22 Battery Cleaning Clean the battery by removing it from the tractor and The battery is sealed and is maintenance-free. Acid washing with a baking soda and water solution. If levels cannot be checked. necessary, scrape the battery terminals with a wire •...

- Page 23 (i.e. air/impact wrench) in order to change the and is maintenance free. The fluid level cannot be tractor’s drive belts. See an authorized MTD Service checked nor can the oil be changed. Always keep the Dealer to have your drive belts replaced or phone...

-

Page 24: Off-Season Storage

SECTION 10: ATTACHMENTS & ACCESSORIES The following attachments and accessories are compatible for Lawn Tractor Model 615. See the retailer from which you purchased your tractor, an authorized MTD Service Dealer or phone (800) 800-7310 for information regarding price and availability. -

Page 25: Troubleshooting

SECTION 11: TROUBLESHOOTING Trouble Possible Cause(s) Corrective Action Engine fails to start PTO knob engaged. Disengage PTO. Parking brake not engaged. Engage parking brake. Spark plug wire(s) disconnected. Connect wire(s) to spark plug. Throttle control lever not in correct Place throttle lever to FAST position. starting position. - Page 26 NOTES...

-

Page 27: Illustrated Parts List

SECTION 12: ILLUSTRATED PARTS LIST B&S OHV V-Twin Kohler V-Twin (for throttle) (for choke) (deflector must face forward) Ref. Part Ref. Part Description Description 710-0227 Self-tapping Screw, #8-18 x.50 751-0564A Muffler Deflector 710-0599 Self-tapping Screw, 1/4-20 x.50 751-0616A Muffler, Twin Inlet (B&S OHV V-Twin) 710-0726 Self-tapping Screw, 5/16-18 x.625 751-0805... - Page 28 Model 615...

- Page 29 Model 615 Ref. Part Ref. Part Description Description 710-0726 Screw, 5/16-12 x.750 731-04217 Parking Brake Button 710-0599 Self-tapping Screw, 1/4-20 x.5 736-0142 Flat Washer, 9/32 x 1/2 x 1/16 710-0751 Hex Cap Screw, 1/4-20 x.62 747-1196 Brake/Cruise Pivot Rod 746-1086 Throttle Cable 629-04083†...

- Page 30 Model 615...

- Page 31 Model 615 REF. PART DESCRIPTION 710-1268 Screw, #10-16 x.375 712-04063 Nut, Flange Lock, 5/16-18, GrF, Nylon 712-3027 Nut, Flange Lock, 1/4-20 720-0309A Seat Adjuster Grip 726-0201 Nut, Speed,.3125 ID 731-04074 Spacer 732-0499 Compression Spring,.41 x 1.5 732-1184 Spring, Extension,.84 Dia. x 4.6 736-0275 Wash, Flat,.344 x.688 x.065 736-3019...

- Page 32 Model 615...

- Page 33 Model 615 REF. PART DESCRIPTION 710-04095 Hex Screw, 3/8-16, 1.00, Gr5 710-0514 Hex Screw, 3/8-16, 1.00, Gr5 710-0643 Hex Screw, 5/16-18, 1.00, Gr5 711-1408 Link, Drag, RH 711-1409A Link, Drag, LH 712-0214 Nut, Hex Lock, 3/8-24 712-04065 Nut, Flange Lock, 3/8-16, Grf, Nylon 712-0459 Nut, Flange Lock, 7/16-20 712-3004A...

- Page 34 Model 615 For a proper IMPORTANT: working machine, use Factory Approved Parts. V-belts are designed to engage and disengage safely. A substitute (non OEM) V-belt can be dangerous by not disengaging completely. 52 22...

- Page 35 Model 615 Ref. Part Ref. Part Description Description 17840 Transmission Mounting Bracket 754-0461 V Belt, A x 78” Lg 618-0319 Hydrostatic Transmission 756-0116A Idler Pulley 710-0627 Screw, 5/16-24 x.750 756-0981B Flat Idler Pulley 710-0227 AB Screw #8-18 x 0.5 756-04111 Input Pulley 710-0344 Hex Bolt 3/8-16 x 1.5...

- Page 36 Model 615...

- Page 37 Model 615 REF. PART DESCRIPTION 710-0726 Screw, 5/16-12, 0.75 710-0859 Screw, 3/8-16, 2.50, Gr5 710-3157A Screw, 7/16-20, 3.25, Gr5, Lock 712-04065 Nut, Flange Lock, 3/8-16, GrF, Nylon 717-04174 PTO Clutch, Electric 736-0277 Washer, Flat, 1.031 x 1.620 x.095 748-0415B Spacer,.385 ID x.635 OD x 1.54 756-0639A Pulley, Engine, 3.56 Diameter 783-04419A...

- Page 38 Model 615 Deck Lift Spring Attach to RH Lift...

- Page 39 Model 615 REF. PART REF. PART DESCRIPTION DESCRIPTION 16606 Hook, Retainer 734-04039 Deck Wheel, 5.0 618-04125 Spindle Assembly 734-0973 Deck Wheel, 5.0 683-0254B Hanger Bracket Assembly 736-0119 Washer, Lock, 5/16, Regular Duty 683-04098 Idler Bracket 736-0407 Washer, Bell,.45 x 1.0 x.062 683-04075 Weldment, 50-inch Deck 736-0406...

- Page 40 MANUFACTURER’S LIMITED WARRANTY FOR: The limited warranty set forth below is given by MTD LLC with MTD does not extend any warranty for products sold or respect to new merchandise purchased and used in the exported outside of the United States, its possessions United States, its possessions and territories.

Need help?

Do you have a question about the YARD-MAN 615 and is the answer not in the manual?

Questions and answers