Summary of Contents for Endress+Hauser micropilot S FMR 532

- Page 1 micropilot S BA 208F/00/en/04.04 Nr. 52006311 FMR 532 Valid as of software version: V 01.02.00 (amplifier) V 01.02.00 (communication) Level-Radar Operating Instructions...

- Page 2 Brief operating instructions Micropilot S FMR 532 Brief operating instructions KA 161F/00/a2/12.01 Micropilot S - Quick Setup 52006294 Contrast: measured value history dist./ reset meas value Group selection basic setup tank medium process empty full pipe dist./ check range of...

-

Page 3: Table Of Contents

Software history ..... . . 79 Contact addresses of Endress+Hauser ..79 Quick wiring guide ..... 26 Connecting the measuring unit . -

Page 4: Safety Instructions

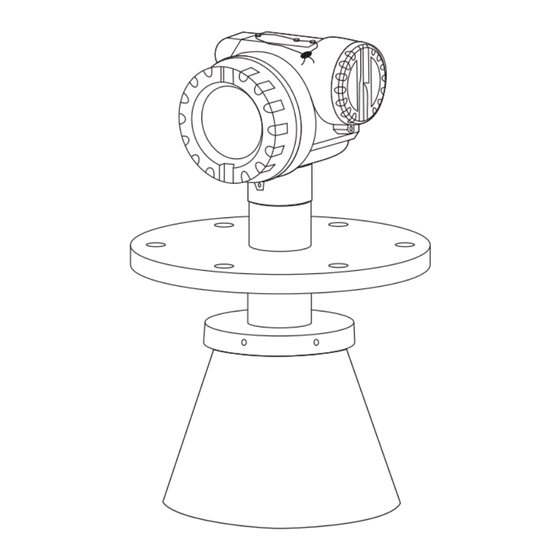

Safety instructions Designated use The Micropilot S FMR 532 is a compact radar level transmitter for the continuous, contactless measurement of liquids, pastes and sludge in stilling wells. The device can also be freely mounted outside closed metal vessels because of its operating frequency of about 6 GHz and a maximum radiated pulsed energy of 1mW (average µ... -

Page 5: Return

Micropilot S FMR 532 1 Safety instructions Return The following procedures must be carried out before a transmitter is sent to Endress+Hauser for repair: • Always enclose a duly completed "Declaration of contamination" form. Only then can Endress +Hauser transport, examine and repair a returned device. -

Page 6: Safety Instructions

1 Safety instructions Micropilot S FMR 532 Notes on safety conventions and symbols In order to highlight safety-relevant or alternative operating procedures in the manual, the following conventions have been used, each indicated by a corresponding symbol in the margin. -

Page 7: Identification

Registration No Dat./Insp.: X X X X X X ATEX Safety information Fig. 1 Information on the nameplate of the Micropilot S FMR 532 (example) Year of construction Tank reference height Tank-no. Certification no Hersteller / Producer : ENDRESS+HAUSER MICROPILOT S FMR Zertifikat-Nr. - Page 8 2 Identification Micropilot S FMR 532 2.1.2 Ordering structure Ordering structure Micropilot S FMR 532 Certificates Basic weight A For non-hazardous areas 6.5 kg G ATEX II 3G EEx nA II T6 K TIIS Ex ia IIC T3 TIIS Ex ia IIC T6...

- Page 9 Micropilot S FMR 532 2 Identification Output and operation A 4…20 mA HART with VU 331, 4-line alphanumeric display Y Special version Housing C Aluminium T12-housing with separate connection compartment, coated, IP65 Y Special version Gland / Entry Pg13.5 cable gland M20x1.5 cable gland...

-

Page 10: Scope Of Delivery

"Protection Measures for Electrical Equipment for Measurement, Control, Regulation and Laboratory Procedures". The instrument described in this manual thus complies with the statutory requirements of the EG directives. Endress+Hauser confirms the successful testing of the instrument by affixing to it the CE mark. -

Page 11: Mounting

No special alignment is required. However, make sure that the planar antenna is installed vertically relative to the stilling well axis. Note! The Micropilot S FMR 532 with planar antenna is designed for use on stilling-wells only! Endress+Hauser... -

Page 12: Incoming Acceptance, Transport, Storage

3 Mounting Micropilot S FMR 532 Incoming acceptance, transport, storage 3.2.1 Incoming acceptance Check the packing and contents for any signs of damage. Check the shipment, make sure nothing is missing and that the scope of supply matches your order. -

Page 13: Installation Conditions

O-Ring 85.3 x 3.53, included (same material as sensor seal) flange hub Ø 99,5 (3.92") Fig. 4 Dimensions Micropilot S FMR 532 Antenna version DN150 / 6" DN200 / 8" DN250 / 10" DN300 / 12" L [mm] Ø D [mm]... - Page 14 3 Mounting Micropilot S FMR 532 3.3.2 Engineering hints Measuring conditions • The measuring range starts at the bottom end of the stilling well. • In case of media with a low dielectric constant (groups A and B), the pipe end can be visible through the medium at low levels.

- Page 15 1) Treat Ammonia NH3 as a medium of group A, e.g. always use a stilling well. Measuring range depending on product class for Micropilot S FMR 532: Product class Stilling well/ Bypass...

- Page 16 3 Mounting Micropilot S FMR 532 Blocking distance The blocking distance (= BD) is the minimum distance from the reference point of the measurement (mounting flange) to the medium surface at maximum level. reference point of measurement 20 mA Max.

-

Page 17: Installation Instructions

Micropilot S FMR 532 3 Mounting Installation instructions 3.4.1 Mounting kit In addition to the tool needed for flange mounting, you will require the following tool: • 4 mm Allen wrench for turning the housing. 3.4.2 Installation in stilling well... - Page 18 3 Mounting Micropilot S FMR 532 Examples for the construction of stilling wells Endress+Hauser...

- Page 19 Micropilot S FMR 532 3 Mounting 3.4.3 Turn housing After mounting, the housing can be turned 350° in order to simplify access to the display and the terminal compartment. Proceed as follows to turn the housing to the required position: •...

- Page 20 3 Mounting Micropilot S FMR 532 3.4.4 Installation with E+H UNI flange Installation hints E+H UNI flanges are designed for non-pressurized operation respectively max. 1 bar absolute pressure. The number of bolts has sometimes been reduced. The bolt-holes have been enlarged for adaption of dimensions, therefore, the flange needs to be properly aligned to the counterflange before the bolts are tightened.

- Page 21 Micropilot S FMR 532 3 Mounting Preparation for the installation of the E+H UNi flange Endress+Hauser...

- Page 22 3 Mounting Micropilot S FMR 532 pull off housing mount E+H UNI flange E+H UNI flange (max. 1 bar) detail A: flange adapter (see under) detail A flange hub for the connection to flanges provided by the customer mounting: 4 bolts M6 / 90°...

- Page 23 The lower edge of the opening is the reference for the gauging. The construction is only suitable for non-pressurized operation. Note! The nozzle for manual gauging is not part of the standard offering from Endress+Hauser. Please contact Endress+Hauser for further information. Flange DN150 DN200...

- Page 24 The Pivoting element serves to swivel the Micropilot S from the measuring position, e.g. to clean the antenna or dip the tank. The pivoting element is not part of the standard offering from Endress+Hauser, special offers available under ref. number MVTFM0422.

-

Page 25: Post-Installation Check

Micropilot S FMR 532 3 Mounting Post-installation check After the measuring instrument has been installed, perform the following checks: • Is the measuring instrument damaged (visual check)? • Does the measuring instrument correspond to the measuring point specifications such as process temperature/pressure, ambient temperature, measuring range, etc.? •... -

Page 26: Wiring

4 Wiring Micropilot S FMR 532 Wiring Quick wiring guide When grounding conductive screens, the corresponding directives EN 60079-14 and EN 1127-1 must be observed. Recommendation for safe grounding of conductive screens: Wiring " Before connection please note the following:... - Page 27 Micropilot S FMR 532 4 Wiring Wiring with Tank Side Monitor NRF 590 " Before connection please note the following: ENDRESS+HAUSER MICROPILOT S 0560 The power supply must be identical to the data on the Order Code: Caution! if modification nameplate (1).

-

Page 28: Connecting The Measuring Unit

4 Wiring Micropilot S FMR 532 Connecting the measuring unit Terminal compartment The housing comes with a separate terminal compartment. Load HART Ω Minimum load for Hart communication: 250 Cable entry Cable gland: M20x1.5 or Pg13.5 Cable entry: G ½ or ½ NPT Supply voltage Direct current voltage: 16…36 VDC... - Page 29 Micropilot S FMR 532 4 Wiring 4.2.1 Connection to Tank Side Monitor NRF590 See Page 27. 4.2.2 HART connection with two E+H RN 221 N - ToF Tool FXA 193 power supply 4...20 mA signal dsdmdm df das. dsdmdm df das.

-

Page 30: Equipotential Bonding

4 Wiring Micropilot S FMR 532 Equipotential bonding Connect the Equipotential bonding to the external ground terminal of the transmitter. " Caution! In Ex applications, the instrument must only be grounded on the sensor side. Further safety instructions are given in the separate documentation for applications in explosion hazardous areas. -

Page 31: Operation

Micropilot S FMR 532 5 Operation Operation Quick operation guide ENDRESS + HAUSER – >3 s Return to basic setup tank shape medium property Group Selection dome ceiling unknown safety settings horizontal cyl DC: < 1.9 bypass DC: 1.9 ... 4... - Page 32 5 Operation Micropilot S FMR 532 5.1.1 General structure of the operating menu The operating menu is made up of two levels: • Function groups (00, 01, 03, …, 0C, 0D): The individual operating options of the instrument are split up roughly into different function groups.

-

Page 33: Display And Operating Elements

Micropilot S FMR 532 5 Operation Display and operating elements Fig. 5 Layout of the display and operating elements 5.2.1 Display Liquid crystal display (LCD): Four lines with 20 characters each. Display contrast adjustable through key combination. Headline Position indicator... - Page 34 5 Operation Micropilot S FMR 532 5.2.2 Display symbols The following table describes the symbols that appear on the liquid crystal display: Symbols Meaning ALARM_SYMBOL This alarm symbol appears when the instrument is in an alarm state. If the symbol flashes, this indicates a warning.

- Page 35 Micropilot S FMR 532 5 Operation 5.2.3 Key assignment The operating elements are located inside the housing and are accessible for operation by opening the lid of the housing. Function of the keys Key(s) Meaning Navigate upwards in the selection list...

-

Page 36: Local Operation

5 Operation Micropilot S FMR 532 Local operation 5.3.1 Locking of the configuration mode The Micropilot can be protected in two ways against unauthorised changing of instrument data, numerical values or factory settings: "unlock parameter" (0A4): A value <> 100 (e.g. 99) must be entered in "unlock parameter" (0A4) in the "diagnostics"... - Page 37 There is no need to change these parameters under normal circumstances and consequently, they are protected by a special code known only to the E+H service organization. Please contact Endress+Hauser if you have any questions. Endress+Hauser...

- Page 38 5 Operation Micropilot S FMR 532 5.3.3 Factory settings (Reset) " Caution! A reset sets the instrument back to the factory settings. This can lead to an impairment of the measurement. Generally, you should perform a basic setup again following a reset.

-

Page 39: Display And Acknowledging Error Messages

Micropilot S FMR 532 5 Operation Display and acknowledging error messages Type of error Errors that occur during commissioning or measuring are displayed immediately on the local display. If two or more system or process errors occur, the error with the highest priority is the one shown on the display. -

Page 40: Hart Communication

5.5.2 ToF Tool operating program The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on the time-of-flight principle. It is used to support commissioning, securing of data, signal analysis and documentation of the instruments. It is compatible with the following operating systems: Win95, Win98, WinNT4.0, Win2000 and... - Page 41 Micropilot S FMR 532 5 Operation Menu-guided commissioning Signal analysis via envelope curve Connection options: • Service-interface with adapter FXA 193 (see Page 29) • HART with Commubox FXA 191 (see Page 29) Endress+Hauser...

- Page 42 5 Operation Micropilot S FMR 532 5.5.3 Commuwin II-Operating Programm Commuwin II is an operating software with graphical support for intelligent transmitters with the communication protocols Rackbus, Rackbus RS 485, INTENSOR, HART or PROFIBUS-PA. It is compatible with the operating systems Win 3.1/3.11, Win95, Win98 and WinNT4.0.

-

Page 43: Commissioning

Micropilot S FMR 532 6 Commissioning Commissioning Function check Make sure that all final checks have been completed before you start up your measuring point: • Checklist “Post installation check” (see Page 25 ff.). • Checklist “Post connection check” (see Page 30 ff.). -

Page 44: Basic Setup

6 Commissioning Micropilot S FMR 532 Basic Setup Commissioning flange: reference point of measurement measuring cond. measuring cond. empty calibr. full calibr. pipe diameter (for bypass/stilling well) E = empty calibr. (= zero) = full calibr. (= span) settings in 005... - Page 45 Micropilot S FMR 532 6 Commissioning To successfully commission a precise measurement to the nearest mm, it is important you carry out a history reset on first installation after mechanical installation and after the basic setup of the device (see Page 53). Only after a history reset the mounting calibration is carried out.

-

Page 46: Basic Setup With The Vu 331

6 Commissioning Micropilot S FMR 532 Basic Setup with the VU 331 Function "measured value" (000) ⇒ This function displays the current measured value in the selected unit (see "customer unit" (042) function). The number of digits after decimal point can be selected in the "no.of decimals"... - Page 47 Micropilot S FMR 532 6 Commissioning Function "medium property" (003) ⇒ This function is used to select the dielectric constant. Selection: • unknown • < 1.9 • 1.9 ... 4 • 4 ... 10 • > 10 ε Product class...

- Page 48 6 Commissioning Micropilot S FMR 532 Function "process cond." (004) ⇒ This function is used to select the process conditions. Selection: • standard • calm surface • turb. surface • agitator • fast change • test:no filter standard calm surface...

- Page 49 Micropilot S FMR 532 6 Commissioning Function "empty calibr." (005) ⇒ This function is used to enter the distance from the flange (reference point of the measurement) to the minimum level (=zero). " Caution! For dish bottoms or conical outlets, the zero point should be no lower than the point at which the radar beam hits the bottom of the tank.

- Page 50 6 Commissioning Micropilot S FMR 532 Note! If bypass or stilling well was selected in the "tank shape" (002) function, the pipe diameter is requested in the following step. Function "pipe diameter" (007) ⇒ This function is used to enter the pipe diameter of the stilling well or bypass pipe.

- Page 51 Micropilot S FMR 532 6 Commissioning Function "check distance" (051) ⇒ This function triggers the mapping of interference echoes. To do so, the measured distance must be compared with the actual distance to the product surface. The following options are available for selection: Selection: •...

- Page 52 6 Commissioning Micropilot S FMR 532 Function "range of mapping" (052) ⇒ This function displays the suggested range of mapping. The reference point is always the reference point of the measurement (see Page 44 ff.). This value can be edited by the operator.

- Page 53 Micropilot S FMR 532 6 Commissioning Display "dist./meas.value (008)" ⇒ The distance measured from the reference point to the product surface and the level calculated with the aid of the empty alignment are displayed again. Check whether the values correspond to the actual level or the actual distance. The following cases can occur: •...

-

Page 54: Mounting Calibration With Vu 331

6 Commissioning Micropilot S FMR 532 Mounting calibration with VU 331 6.5.1 Function group "mounting calibr." (03) ⇒ Function "tank gauging" (030) ⇒ Using this function, you can either enter a dip table or carry out an auto-correction. Function "auto-correction" (031) ⇒... - Page 55 Micropilot S FMR 532 6 Commissioning " Caution! During the learning period, fast filling/emptying or turbulent surfaces can result in switching off and on the phase evaluation. Subsequently observed measurement errors will disappear as soon as tank levels come back to areas measured by Micropilot S previously with activated phase evaluation.

- Page 56 6 Commissioning Micropilot S FMR 532 Display "custody mode" (0A9) ⇒ This indicates the instrument calibration mode. The calibration mode (active) can be set using the hardware security lock on the electronics (see Page 33). Selection: • inactive • active pos.

- Page 57 Micropilot S FMR 532 6 Commissioning Dip table The dip table is used to correct the level readings of the Micropilot S using independently taken hand dips. The dip table is used in particular to adapt the level gauge to the specific application conditions as mechanical offset and tank/stilling well design.

- Page 58 6 Commissioning Micropilot S FMR 532 Note! The offset should NOT be determined and entered within the close range of the antenna (conf. definition of the safety distance) or immediately in the range of the tank bottom, because within these ranges interferences of the radar signal may occur.

- Page 59 Micropilot S FMR 532 6 Commissioning manual The value pairs in the dip table can be read and written. You can enter the measured value and the dip value. – uncorrected measured value: This is the measured value supplied by the instrument, NOT corrected by the dip table.

- Page 60 6 Commissioning Micropilot S FMR 532 Function "dip table handl." (036) ⇒ Use this function to enter the dip value (level or distance) which will correct the measurement values. Selection: • new point • edit point • store point • delete point •...

- Page 61 Micropilot S FMR 532 6 Commissioning return By selecting this point, you return to the function "dip table mode" (033). next point This scrolls down in the table. If the table is empty, you can still select this option. However, the displayed value does not change.

- Page 62 6 Commissioning Micropilot S FMR 532 6.5.2 Envelope curve with VU 331 After the basic setup, an evaluation of the measurement with the aid of the envelope curve ("display" (09) function group) is recommended. Function "plot settings" (09A) ⇒ Here you can select which information is shown on the display: •...

-

Page 63: Basic Setup With The Tof Tool

Micropilot S FMR 532 6 Commissioning Basic Setup with the ToF Tool To carry out the basic setup with the ToF Tool operating program, proceed as follows: • Start the ToF Tool operating program and establish a connection • Select the "basic setup" function group in the navigation bar... - Page 64 6 Commissioning Micropilot S FMR 532 Basic Setup step 2/5: • Enter the application parameters: – tank shape (for a description, see Page 46) – medium property (for a description, see Page 47) – process cond. (for a description, see Page 48) Basic Setup step 3/5: If "stilling well"...

- Page 65 Micropilot S FMR 532 6 Commissioning IBasic Setup step 4/5: • This step starts the tank mapping • The measured distance and the current measured value are always displayed in the header • A description is given on see Page 53...

- Page 66 6 Commissioning Micropilot S FMR 532 6.6.1 Envelope curve with the ToF Tool After the basic setup, an evaluation of the measurement using the envelope curve is recommended. 6.6.2 User-specific applications (operation) For details of setting the parameters of user-specific applications, see separate documentation BA 217F/00/en - description of the instrument functions of the Micropilot S.

-

Page 67: Mounting Calibration With The Tof Tool

Micropilot S FMR 532 6 Commissioning Mounting calibration with the ToF Tool To carry out the basic setup with the ToF Tool operating program, proceed as follows: • Start the ToF Tool operating program and establish a connection • Select the "mounting calibr." function group in the navigation bar... - Page 68 6 Commissioning Micropilot S FMR 532 Mounting calibration step 2/2: • dip table mode (description see Page 58) • meas. v. (description see Page 59) • dip value (see Page 59) • dip table handl. (description see Page 60) • dip table state (description see Page 58) •...

-

Page 69: Maintenance

Micropilot S FMR 532 7 Maintenance Maintenance The Micropilot S measuring instrument requires no special maintenance. Exterior cleaning When cleaning the exterior of measuring devices, always use cleaning agents that do not attack the surface of the housing and the seals. -

Page 70: Accessories

8 Accessories Micropilot S FMR 532 Accessories Various accessories, which can be ordered separately from Endress+Hauser, are available for the Micropilot S. Weather protection cover A Weather protection cover made of stainless steel is available for outdoor mounting (order code: 543199-0001). The shipment includes the protective cover and tension clamp. -

Page 71: Trouble-Shooting

Micropilot S FMR 532 9 Trouble-shooting Trouble-shooting Trouble-shooting instructions Endress+Hauser... -

Page 72: System Error Messages

9 Trouble-shooting Micropilot S FMR 532 System error messages Code Description Possible cause Remedy A102 checksum error device has been powered off reset; general reset & new before data could be stored; emc avoid emc problem; if alarm calibr.required problem; E²PROM defect... - Page 73 Micropilot S FMR 532 9 Trouble-shooting Code Description Possible cause Remedy A270 custody switch undef switch for custody transfer may be check position of custody check position defective switch exchange electronics inconsistency between phase and check basic calibration amplitude evaluation...

-

Page 74: Application Errors

9 Trouble-shooting Micropilot S FMR 532 Application errors Error Output Possible cause Remedy A warning or Depending on the configuration See table of 1. See table of error messages alarm has error messages (see page 72) occurred. (see page 72) →... - Page 75 Micropilot S FMR 532 9 Trouble-shooting Error Output Possible cause Remedy If the surface is Signal is weakened 1. Carry out tank mapping → not calm by the rough surface basic setup (e.g. filling, — the interference 2. Set the process cond. (004) to...

-

Page 76: Spare Parts

9 Trouble-shooting Micropilot S FMR 532 Spare parts Note! You can order spare parts directly from your E+H service organization by giving the order code and the serial number which is printed on the measuring transducer nameplate (see Page 7 ff.). The corresponding spare part number also appears on each spare part. - Page 77 Micropilot S FMR 532 9 Trouble-shooting Spare parts Micropilot S, FMR 532 Process connection without antenna Planar antenna FMR 532 - detailed order structure and variants see spare parts price list O-ring 49,21 x 3,53 EPDM (Seal set 52005628) O-ring 49,21 x 3,53 EPDM...

-

Page 78: Return

Return If you need to send a Micropilot back to Endress+Hauser for repair, please send a completed copy of the form printed on the last page. • An exact description of the application. -

Page 79: Software History

– HART communicator DXR 375 with Rev. 1, DD 1. Contact addresses of Endress+Hauser The addresses of Endress+Hauser are given on the back cover of this operating manual. If you have any questions, please do not hesitate to contact your E+H representative. -

Page 80: Technical Data

The Micropilot S can be used for measurement in a stilling well as well as in free space. The different instrument versions are applied as follows: • The Micropilot S FMR 532 with planar antenna is the preferred device in ≥... - Page 81 Micropilot S FMR 532 10 Technical data Auxiliary energy Electrical connection Housing T 12 with separate terminal compartment. Minimum load for HART communication: 250 Ω Load HART Cable entry Cable gland: M20x1.5 or Pg13.5 Cable entry: G ½ or ½ NPT Supply voltage see Page 28 ff.

- Page 82 10 Technical data Micropilot S FMR 532 Inventory Control All device types can be delivered as "Inventory Conctrol Versions" with a Versions reduced accuracy of ± 3mm (under reference conditions). To these versions, the calibration certificate or custody transfer type approval is NOT attached.

- Page 83 Page 31 Certificates and approvals CE approval The measuring system meets the legal requirements of the EC-guidelines. Endress+Hauser confirms the instrument passing the required tests by attaching the CE-mark. RF approvals R&TTE 1999/5/EG, FCC CRF 47, part 15 Overspill protection...

-

Page 84: Appendix

11 Appendix Micropilot S FMR 532 Appendix 11.1 Operating menu HART (Display modul), ToF Tool basic setup tank shape medium property process cond. empty calibr. full calibr. dome ceiling unknown standard enter value enter value horizontal cyl. DK: < 1.9 calm surface DK: 1.9 …... - Page 85 Micropilot S FMR 532 11 Appendix dist./meas.value check distance range of mapping start mapping history reset distance = ok input of dist. too small mapping range D and L dist. too big are displayed manual dist. unknown safety distance in safety dist.

-

Page 86: Operating Matrix Hart / Commuwin Ii

11 Appendix Micropilot S FMR 532 11.2 Operating matrix HART / Commuwin II Endress+Hauser... -

Page 87: 11.3 Description Of Functions

Micropilot S FMR 532 11 Appendix 11.3 Description of functions Note! A detailed description of the function groups, functions and parameters is given in the documentation BA 217F/00/en - a description of the instrument functions of the Micropilot S. Endress+Hauser... -

Page 88: 11.4 Function And System Design

11 Appendix Micropilot S FMR 532 11.4 Function and system design 11.4.1 Measuring principle The Micropilot is a "downward-looking" measuring system, operating based on the time- of-flight method. It measures the distance from the reference point (process connection) to the product surface. Radar impulses are emitted by an antenna, reflected off the product surface and received again by the radar system. - Page 89 The Micropilot S can be used for measurement in a stilling well as well as in free space. The different instrument versions are applied as follows: • The Micropilot S FMR 532 with planar antenna is the preferred device in stilling wells ≥ 150 mm.

- Page 90 • with display and operating module VU 331, • with a Personal Computer, FXA 193 and the operating software ToF Tool. The ToF Tool is a graphical operating software for instruments from Endress+Hauser that operate based on the time-of-flight principle (radar, ultrasonic, guided micro- impulse).

- Page 91 Micropilot S FMR 532 11 Appendix 11.4.3 Custody transfer mode Micropilot S is a weight and measure approved level transmitter. Either the innage or the ullage can be selected as the custody transfer variable. The selected variable is the basis for the subsequent calculation of the current amount of product in a tank, along with other measured variables such as (average) temperature and pressure.

- Page 92 11 Appendix Micropilot S FMR 532 11.4.5 Particularities in "approved" operation The Micropilot S level radar is set to custody transfer mode after commissioning using a custody locking switch (see Page 35). The position of the custody locking switch is secured and sealed using the sealing pin.

- Page 93 11 Appendix 11.4.7 Integrated on tank gauging system The Endress+Hauser Tank Side Monitor NRF 590 provides integrated communications for sites with multiple tanks, each with one or more sensors on the tank, such as radar, spot or average temperature, capacitive probe for water detection and/or pressure sensors.

- Page 94 11 Appendix Micropilot S FMR 532 This product may be protected by at least one of the following patents. Further patents are pending. • US 5,387,918 EP 0 535 196 • US 5,689,265 EP 0 626 063 • US 5,659,321 •...

- Page 95 Micropilot S FMR 532 11 Appendix Endress+Hauser...

- Page 96 11 Appendix Micropilot S FMR 532 Endress+Hauser...

-

Page 97: Index

Micropilot S FMR 532 Index Index Accessories ....... 70 Green LED ....... . . 34 Alarm. - Page 98 Index Micropilot S FMR 532 Pivoting element ......24 Slots ........17 Post-installation check .

- Page 99 Micropilot S FMR 532 Index Declaration of contamination Dear costumer, Because of legal determinations and for the safety of our employes and operating equipment we need this “Declaration of contamination” with your signature before your order can be handled. Please put the completely filled in declaration to the instrument and to the shipping documents in any case.

- Page 100 Poland – Wroclaw Costa Rica – San Jose ❑ Sakura Endress Co. Ltd. ❑ Endress+Hauser Polska Sp. z o.o. Tel. (01) 88 05 60, Fax (01) 88 05 63 35 Euro-Tec S.A. Tel. (0422) 54 06 11, Fax (0422) 55 02 75 Tel.

Need help?

Do you have a question about the micropilot S FMR 532 and is the answer not in the manual?

Questions and answers