Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Huvitz HPE-8000

- Page 1 User Manual EDGER HPE-8000...

- Page 2 HUVITZ reserves the right to make changes in its products or product specifications at any time and without prior notice, and is not required to update this documentation to reflect such changes.

-

Page 3: Table Of Contents

2.2. 2.3. Environmental Considerations ....................11 Safety Precautions ....................... 13 2.4. System Overview ..........................17 3.1. Edger (HPE-8000) ........................ 17 Frame Reader (HFR-8000) ....................21 3.2. Blocker (HMB-8000) ......................22 3.3. 3.4. Standard Accessory (Tool Box) .................... 23 Installation Procedure ........................24 Edger ........................... - Page 4 HUVITZ KAIZER HPE-8000 Global Modification .......................... 55 6.2.3. Partial Modification ........................... 55 6.2.4. Reset & Apply Button ........................56 6.2.5. 6.3. Partial Grooving Screen ....................... 57 Region Selection ..........................58 6.3.1. Processing Type Selection ........................ 60 6.3.2. Safety Bevel Button ........................... 61 6.3.3.

- Page 5 Frame Change ........................96 6.10. Frame Change Lens Registration ....................96 6.10.1. Frame Change Mode ........................977 6.10.2. Frame Change Procedure ....................... 988 6.10.3. Configuration ..........................999 Configuration of Frame Reader ..................999 7.1. 7.2. Configuration of Edger ....................... 100 Preferences .............................

- Page 6 HUVITZ KAIZER HPE-8000 Specifications ........................146 10.2. Specifications of Edger ........................146 10.2.1. Specifications of Frame Reader ....................146 10.2.2. Specifications of Blocker ....................... 146 10.2.3. 10.3. Drawings of System ......................147 Drawings of Edger .......................... 147 10.3.1. Drawings of Frame Reader......................148 10.3.2.

-

Page 7: Introduction

Introduction 1.1. Main Functions This product is for processing lenses fit into eyeglasses frame, which automatically covers from tracing to edging. Edging Flat Safety Beveling Grooving Polishing Milling Drilling Material Edging Beveling ○ ○ ○ ○ ○ ○ ○ Plastic ○... -

Page 8: System Configuration

HUVITZ KAIZER HPE-8000 1.2. System Configuration Edger (HPE-8000) Frame Reader (HFR-8000) Blocker (HMB-8000) 1.3. Classification This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation. -

Page 9: Safety Information

Safety Information 2.1. Introduction Safety is everyone’s responsibility. The safe use of this machine is largely dependent upon the installers, users, operators, and managers. It is prerequisite to read and understand these specifications before installing, using, cleaning, fixing or revising. Fully understanding the whole instructions must be the first priority. -

Page 10: Safety Symbols

HUVITZ KAIZER HPE-8000 2.2. Safety Symbols The International Electrotechnical Commission (IEC) has established a set of symbols, which are listed below. This applies only to the instrument that has the certification symbol printed explicitly on the product label or sticker. -

Page 11: Environmental Considerations

2.3. Environmental Considerations Avoid the following environments for operation or storage: Where the machine is exposed to water vapor. Don’t operate the machine with wet hands Indoor use only Where the machine is exposed to direct sunlight. Where there are big changes in temperature. Optimal temperature range for normal operation is from 10C to 40C. - Page 12 HUVITZ KAIZER HPE-8000 Don’t disassemble or open the product. HUVITZ does not take responsibility for the possible problems Be careful not to block the fan located on the backside of the machine. Don’t plug the AC power cord into the outlet unless all parts of the machine are completely connected.

-

Page 13: Safety Precautions

Such tampering will forfeit any rights to receive services during the term of guarantee. This machine must be connected with the accessories supplied by HUVITZ. If you are to use other accessories, their safety or usability must be checked and proved by their manufacturers or HUVITZ. - Page 14 HUVITZ KAIZER HPE-8000 use, operate, and maintain this machine. Keep the User’s Manual and Service Manual in a place easily accessible at all times for persons operating and maintaining the equipment. Do not apply excessive force to cable connections. If the cable does not connect easily, make sure that the connector (plug) is appropriate for the receptacle (socket).

- Page 15 lens may be fallen and broken by the wheel, and cause a serious injury If you find any crack on the edging wheel or on the bottom of the machine, immediately stop the operation and ask for the service. If the edging wheel is broken during the operation, the broken pieces may cause a serious injury ...

- Page 16 HUVITZ KAIZER HPE-8000 Be sure to use the standard accessories or tools provided together with the product for the maintenance. Otherwise, it may cause the malfunction of the product. When processing wheel dressing, be sure to use dressing sticks that fit each wheel. The dressing stick should be replaced when its length becomes so short that you cannot hold it easily.

-

Page 17: System Overview

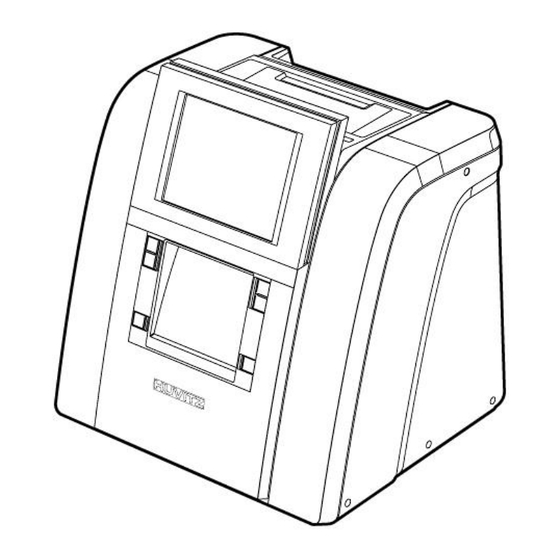

System Overview 3.1. Edger (HPE-8000) Front View Main Display (Touch Screen) SD Card Slot Control Button Edging Room Control Button Edging Room Window (Auto) Edging Room Feeler Feeler Main Wheel Clamp Wheel for Safety Beveling & Grooving Milling Cutter Rear View... - Page 18 HUVITZ KAIZER HPE-8000 Devices for Edging Polycarbonate...

- Page 19 NOTE User can choose one of four kinds of wheel types, which provide four different types of processing respectively RPG Type : Bevel, Flat edging (It processes glass lens) ① ② ③ ④ ① Glass Roughing Wheel ② Roughing Wheel ③...

- Page 20 HUVITZ KAIZER HPE-8000 RPW Type : Bevel, Flat edging (It cannot process glass lens) ① ② ③ spacer ① Wide Roughing Wheel ② Finishing Wheel ③ Polishing Wheel RPGA Type : Bevel, Asymmetric Bevel, Flat edging (For all types of lenses. But it cannot process Bevel Polishing) ①...

-

Page 21: Frame Reader (Hfr-8000)

3.2. Frame Reader (HFR-8000) Front View Cover Work Space for Stylus Control Panel Display Window Gripper Gripping Bar Stylus Rear View Main Switch Main Power Input and Fuse Interface Terminal - EDGER 1 - EDGER 2 - Barcode Reader S/W Upgrade... -

Page 22: Blocker (Hmb-8000)

HUVITZ KAIZER HPE-8000 3.3. Blocker (HMB-8000) Front View Switch Lever Horizontal Scale Plate Lens Adapter Setter Vertical Scale Plate Lens Holder Brightness Adjustment Bottom View Power Input... -

Page 23: Standard Accessory (Tool Box)

3.4. Standard Accessory (Tool Box) Lens Adaptor Spanner(10-11) LEAP-III Tape Clamp Adaptor Lens Adaptor Remover Fuse(250V, 10A) Standard Frame Standard Pattern Pattern Holder Standard JIG for Edger Wrench Set Carriage-Fixing Bracket Feeler Tip Dressing Sticks NOTE Only 3M LEAP-III™ is available for this product. Otherwise, the lens axis may move ... -

Page 24: Installation Procedure

HUVITZ KAIZER HPE-8000 Installation Procedure 4.1. Edger ① Remove the shock-absorbing material from the packing box and take the Edger out of the box carefully. ② Loosen the screw at the Edger Front Cover and open the cover ③ Open the edging room window with hands ④... -

Page 25: Frame Reader

NOTE Keep the removed fixing materials in the tool box and use them again when you move the machine Fill up more than 2/3 of the tank with water. Make sure that the water supply hose is located upper than the pump. Check if water in the hose circulates without any interference. -

Page 26: Operation

HUVITZ KAIZER HPE-8000 Operation 5.1. Frame Reader 5.1.1. Control Panel MENU FRAME STOP Material Selection - FRAME Button You must press FRAME button and select one of the following options (frame materials) before the frame is traced. METAL ... -

Page 27: Frame Tracing

Frame Tracing 5.1.2. ① Place the frame between the upper grippers and the lower grippers. ② Move the frame in order that the bridge of frame is located at the central position between the left and right side grippers. ③ Press the FRAME button and select the frame material. -

Page 28: Blocker

HUVITZ KAIZER HPE-8000 5.2. Blocker Scale Plate 5.2.1. Vertical Scale (unit:mm) Horizontal Scale (unit:mm) Near Vision guide for Bi- Focal Lens 5.2.2. Lens Adapter Setter Lens Adapter should be inserted into the Lens Adapter Setter as shown like (a). 5.2.3. - Page 29 The edger shows movement amount of the optical center for blocking on the screen. Active blocking is much easier than Passive blocking for blocking. However, active blocking has some limitations, which may result in unexpected outputs. The following table compares active blocking and passive blocking and summarizes the advantages and disadvantages of them.

-

Page 30: Operation

HUVITZ KAIZER HPE-8000 Operation 5.2.4. ① Plug the Power Cable into the socket at the rear side of the machine. ② Put the Lens Adapter into the Lens Adapter Setter (Pay attention to the direction). ③ Place the marked Lens on the Lens Holder. - Page 31 Blockings according to the lens types Single Vision Progressive Lens Far Vision Eye Point Adjust the marking point of the lens to the Adjust the Far Vision Eye Point of the center of scale plate progressive lens to the center of scale plate Bi-Focal Lens Boxing Center...

-

Page 32: Edger

HUVITZ KAIZER HPE-8000 5.3. Edger Control Button 5.3.1. (LEFT) CLAMP CLAMP (RIGHT) START START WINDOW STOP START Start Edging STOP Stop Edging WINDOW Open/Close Edging Room Window CLAMP Open/Close Clamp (Lens Position) NOTE Clamp Buttons on left and right sides serve identical function. Even when you use your hand to hold a lens, you can press the Clamp Button with the other hand. -

Page 33: Edger User Interface

Edger User Interface 6.1. Main Screen Side Button Frame Information Job Management Layout Option Function Button Edging Option Function Button Side Button 6.1.1. ① Press the R button to select right side. ② Press the L button to select left side. - Page 34 HUVITZ KAIZER HPE-8000 NOTE Each side of frame shape is exchanged by pressing the R button for a while. The function of exchange R/L is useful when you selected wrong side while reading demo lens or patterns. (Message pops up when press the R button for a while)

-

Page 35: Job Management

Job Management 6.1.2. ① New : Clear current job screen and wait new job. ② Job Number : Display current job number (Press the button to change job number) ③ Job Manager : Press the job manager button to load a new job or move on to another job NOTE ... - Page 36 HUVITZ KAIZER HPE-8000 NOTE Following additional functions are available by pressing ‘Job Management’ button for a while. If you press ‘New’ button for a while, you can delete the current job on display immediately. You can save current job on SD card by pressing ‘Job Number’ for a while.

-

Page 37: Frame Information

The function of job request works only when communication option on configuration menu is set properly. Frame Information 6.1.3. ① Frame Curve ② Circumference ③ Minimum Lens Diameter ④ Width/Height Layout Option 6.1.4. ① Binocular PD: Input prescribed binocular PD value. ②... - Page 38 HUVITZ KAIZER HPE-8000 ④ FPD: Input value of FPD. ⑤ OH Type: Select one of three, ΔY, Box Height, Mix Height. ⑥ OH (Optical Height): Input OH value. ⑦ Frame Material : Display frame material ⑧ Touch Screen Lock On/Off ⑨...

- Page 39 NOTE In layout information, dialog PD, OH, Bridge Size, FPD are mandatory value. The color of input box of these values is changed when you input value. The box which is not changed from Default value is colored yellow. It changes into white when you input value.

-

Page 40: Edging Option

HUVITZ KAIZER HPE-8000 NOTE Numeric Keypad Click the value you want to change then this numeric keypad will pop up. ① Name of the value ② Range of the value ③ Value ④ Increase/Decrease ⑤ Backspace ⑥ Reset (Cancel) – If you press it, the value goes back to original value. - Page 41 NOTE Available edging types can vary by wheel types of the edger. RPG, RPW RPA, RPGA NOTE You can input additional parameters according to the selected edging type. Grooving ① Groove Depth ② Groove Width Mini Bevel ①...

- Page 42 HUVITZ KAIZER HPE-8000 Semi U Bevel ① Tip Width ② Rear Height NOTE After you’ve selected grooving as the edging type, you can select partial grooving by pressing ‘Edging type’ button for a while. There are three ways of partial grooving.

- Page 43 To cancel the partial grooving mode, press the edging type button and change into another mode. Processing with partial grooving needs an editing step of partial grooving for set boundary position after feeling process. ② Bevel/Groove Position Front % Front mm Rear mm Base Curve...

- Page 44 HUVITZ KAIZER HPE-8000 NOTE Polishing / Safety Beveling touch screen area ② Polishing On/Off ③ Front Safety Beveling On/Off ④ Rear Safety Beveling Off/Small/Large When you selected ‘Asymmetric Bevel’ or ‘Semi-U Bevel’, Rear Safety Beveling is not available.

- Page 45 ⑨ Blocking Mode Optical Center Boxing(Frame) Center ⑩ Roughing Mode Normal Spiral Axial Milling NOTE Normal mode is a mode where a lens contacts the wheel directly while processing. Spiral mode is a mode where a lens contacts the wheel gradually with spiral rotation. ...

- Page 46 HUVITZ KAIZER HPE-8000 When you choose the options for Bi-Focal, Near Vision Shape will be displayed on the screen. If you input the diameter, you can see the frame shape similar to the actual lens shape and check the interference.

- Page 47 Base Curve (-) Lens (+) Lens [Base curve mode] In the base curve mode, base curves of (+) lenses and (-) lenses exist the opposite side. In this mode, the bevel or grooving line always passes the mid of the thinnest parts, one of which is located at the midst zone of (-) lens and the other is located at the edged zone of (+) lens.

-

Page 48: Detailed Edging Option

HUVITZ KAIZER HPE-8000 Detailed Edging Option 6.1.6. ① Feeling after roughing ② Pre-Roughing ③ Feeling Position Normal Frame Change Outside of Bevel ④ Clamp Pressure Normal Strong Weak... - Page 49 NOTE If you use the function of feeling after roughing, you are provided with a more precise information with double-checked lens thickness after the roughing. You can change feeling mode to one-side feeling mode by pressing the feeler icon for a while.

-

Page 50: Function Button

HUVITZ KAIZER HPE-8000 Function Button 6.1.7. ① Expert Job Editor ② Menu ③ Digital Designer (Digital Pattern + Hole Editor) ④ Retouch Mode ⑤ Drilling Assignment (HDM-8000) NOTE The expert user can work more quickly by using ‘Expert Job Editor’. -

Page 51: Manual Bevel/Groove Position Modification

6.2. Manual Bevel/Groove Position Modification The manual position adjustment screen will be displayed after feeling process is finished when edging position mode is manual. Base Position Region Selection Global Modification Partial Modification Reset & Apply Button... -

Page 52: Base Position

HUVITZ KAIZER HPE-8000 Base Position 6.2.1. ① Front % ② Front mm ③ Rear mm ④ Base Curve ⑤ Auto ⑥ Curve NOTE The default base position is as follows Frame (with frame curve value) – Auto Demo lens, Pattern (without frame curve value) – 50% ... -

Page 53: Region Selection

Region Selection 6.2.2. ① Blue Circle – Start Point ② Orange Circle – End Point ③ Green Dot – Current Location ④ Red Line – Selected Region ⑤ Move region clockwise (fine adjustment) ⑥ Move region counterclockwise (fine adjustment) ⑦ Move region clockwise ⑧... - Page 54 HUVITZ KAIZER HPE-8000 To see the shape in actual size, touch the upper right icon. Touch Area (Actual measurement) (Auto – Shape is automatically resized fitting the screen.) Angle guideline function is turned on or off by touching the center of the shape.

-

Page 55: Global Modification

Global Modification 6.2.3. ① Blue Circle – Start Point ② Orange Circle – End Point ③ Green Line – Current Location ④ Red Line – Current Position ⑤ Cyan Line – Base Position ⑥ Front curve of the lens ⑦ Rear curve of the lens ⑧... -

Page 56: Reset & Apply Button

HUVITZ KAIZER HPE-8000 Reset & Apply Button 6.2.5. ① Reset Button – Cancel the changes ② Apply button – Apply modified position and continue to processing NOTE If you press the base position button while changing base position, previously selected base position is initialized to selected base position. -

Page 57: Partial Grooving Screen

6.3. Partial Grooving Screen When you select Partial Grooving mode, partial grooving screen pops up after the feeling process. Region Selection Processing Type Safety Bevel Button Reset & Apply Button... -

Page 58: Region Selection

HUVITZ KAIZER HPE-8000 Region Selection 6.3.1. ① Orange Circle – Start Point ② Blue Circle – End Point ③ Red Line – Bevel / Flat edging Area ④ White Line – Grooving Area ⑤ Move start point clockwise ⑥ Move start point counterclockwise ⑦... - Page 59 NOTE To see the shape in actual size, press the upper right icon. Touch Area (Actual measurement) (Auto – Shape resized to fit to the screen) Angle guideline pops up when you touch the center of the shape. (Guideline spacing - 10 °)

-

Page 60: Processing Type Selection

HUVITZ KAIZER HPE-8000 Touch Area Processing Type Selection 6.3.2. ① Angle of the start point ② Angle of the end point ③ Grooving (Cancel Partial Grooving) ④ Flat Edging + Grooving ⑤ Beveling + Grooving ⑥ Beveling + Flat Edging NOTE ... -

Page 61: Safety Bevel Button

Safety Bevel Button 6.3.3. ① Front Safety Bevel OFF ② Front Safety Bevel ON ③ Rear Safety Bevel OFF ④ Rear Safety Bevel Small ⑤ Rear Safety Bevel Large. NOTE Safety Bevel button is only for Flat Edging + Grooving mode. ... -

Page 62: Job Manager

HUVITZ KAIZER HPE-8000 6.4. Job Manager Job selection tab Exit Job list Function button Job selection tab 6.4.1. ① Waiting Job: Newly received Job data from Frame Reader or Auto Blocker. ② Working Job: Edging job or Editing job. ③... -

Page 63: Function Button

Function Button 6.4.2. ① Open : Load the selected job ② Save : Save the selected job to the SD memory card ③ Search : Search Job number (currently not available) ④ Delete : Delete selected job NOTE Save function is only available on Waiting/Working/Completed list. ... -

Page 64: Working Job

HUVITZ KAIZER HPE-8000 Working Job 6.4.4. ① Edging: Displays the Edging Processing state. ② Drilling: Displays the Drilling Processing state. ③ Time: Displays the job start time. Completed Job 6.4.5. ① Time: Displays the job finish time. NOTE You can check current processing state with the following icons. -

Page 65: Job Search

Job Search 6.4.6. You can search for a job on the job list. ① Start ‘Job Search Mode’ by pressing the search button. ② Enter the job number you want with the virtual keyboard. ③ Check the list. Enter Job Number Search Button... - Page 66 You can search with only few letters, not the whole words. For example, you can search the Job Number ‘HUVITZ_123’ only with ‘HUVITZ’ or ‘123’. You can look at the other research results with ‘Next’ and ‘Prev’ button ...

-

Page 67: Digital Pattern

6.5. Digital Pattern The “Digital Pattern” modifies the lens shape in left/right, top/bottom as well as rotation and optimizes the fitting for Rimless and Semi-Rimless. To use Digital Pattern, press the Digital Designer button on the bottom right of the main screen and then select Digital Pattern tab at top left of the screen. - Page 68 HUVITZ KAIZER HPE-8000 Touch Interface To modify lens shape, make use of the 8 touch points around the lens shape. Horizontal + Vertical Horizontal Vertical Horizontal + Vertical Horizontal Vertical Value Input You can modify the lens shape by entering the values directly in the Input Area.

-

Page 69: Near Vision Area Enlargement/Reduction

Near Vision Area Enlargement/Reduction 6.5.2. Lens shape can be changed in four directions (Bottom - Near Vision Area, Top, Left, Right). Touch Interface To modify lens shape, make use of 4 touch points around the lens shape. Left or Right Top or Bottom Near Vision Area (Bottom) Left... -

Page 70: Rotation

HUVITZ KAIZER HPE-8000 Value Input You can modify the lens shape by entering the values directly in the Input Area. ① Left ② Right ③ Near Vision Area (Bottom) ④ After selecting the item to change, enter the value using the numeric keypad. - Page 71 Clockwise Counterclockwise Value Input You can modify the lens shape by entering value directly in the Input Area. ① Width ② Height ③ Angle (Clockwise, 0 ~ 360) Function of ① and ② are same with that Enlargement/ Reduction mode.

-

Page 72: Partial Modification

HUVITZ KAIZER HPE-8000 Partial Modification 6.5.4. Lens shape can be modified partially. Touch Interface Set modification area by touching any point on lens shape. The point becomes the center of the modification area. To adjust modification range, touch and drag one of... -

Page 73: Reset

Modification range/ Lens shape change You can modify the lens shape with Input button. ① Position change (counter clockwise, clockwise) ② Range change (enlargement, reduction) ③ Wide Partial Modification (concave, convex) ④ Partial Modification (concave, convex) During partial modification, where is not able to process physically is colored red. - Page 74 HUVITZ KAIZER HPE-8000 NOTE “Copy” button ( ) is available when R/L sync option is turned off. Shape of the current side is copied to the other side by pressing this button. Press button to change the side.

-

Page 75: Exit

Exit 6.5.7. Quit digital pattern and return to the main screen. To apply modified lens shape, Press the “Apply” button on the confirm dialog box. NOTE You can modify half-framed lens or rimless lens conveniently by using the digital pattern. ... -

Page 76: Retouch Mode

HUVITZ KAIZER HPE-8000 6.6. Retouch Mode If the processed lens is too large to be to the frame, you can process the lens again with the Retouch Mode. ① Retouch Size(minus value ~ 0.0) - Input retouch size ② Activate/Cancel Polishing - You can activate polishing even if the lens has not been polished before. -

Page 77: Hole Editor

6.7. Hole Editor This screen is for the edition of hole position for drilling. To use the hole editor, click the button on the main screen right below, and then select the hole editor button in the upper left. Top of hole editor Working Area Preview Function Buttons... -

Page 78: Upper Side Of Hole Editor

HUVITZ KAIZER HPE-8000 Upper Side of Hole Editor 6.7.1. ① Hole Editor: Starts the hole editor. If the button is green, hole editor is now available. ② Digital Pattern: Starts the digital pattern. ③ Job Number: Displays the job number of currently working job. You can modify the number by touching here. -

Page 79: Preview

NOTE Elements required for drilling are displayed on working area. The figure below describes each element. Hole Frame Center Horz. Coordinate Notch or Slot Undrillable area Vert. Coordinate Preview 6.7.3. ① Select Right/Left: You can change the selection of the left/right. ②... -

Page 80: Function Buttons

HUVITZ KAIZER HPE-8000 Function Buttons 6.7.4. ① Select / deselect all: You can select or deselect all of the holes/slots at once. ② Retouch hole / slot: You can register the selected holes/slots for retouching. ③ Hole / Slot Easy Moving: You can move the selected holes/slots. - Page 81 The details of how to move the hole / slot by moving type are like below. This provides the function of parallel movement. The movement of hole / slot is like below. (Hole) (Slot) (Slot only) This provides the function to move the start position of a slot.

- Page 82 HUVITZ KAIZER HPE-8000 (Slot only) This provides the function to change the length of a slot. (Slot only) This provides the function to change a slot to a notch and to move the notch. The slot will be moved to the edge of a frame close to current position, and become a notch.

- Page 83 List of hole / slot data: This displays a list of hole / slot data in the SD card. File name: You can set the file name of the hole / slot data to be saved. Save: You can save the hole / slot data by pressing this button.

- Page 84 HUVITZ KAIZER HPE-8000 Select preset button: Select the preset button to apply the hole / slot data. And then choose hole / slot data you want. List of hole / slot data: This displays the list of hole / slot data in SD card.

- Page 85 [Mirroring the slot] [Mirroring the group of hole / slot]...

-

Page 86: List Of Hole/Slot

HUVITZ KAIZER HPE-8000 List of Hole/Slot 6.7.5. It displays the hole / slot list of the current job. You can change the position of the hole / slot by pressing the coordinates displayed on the list. ① Select the hole / slot: You can select the holes / slots to make a group by pressing here. The green circle is the selected one. - Page 87 NOTE Display options for X coordinate Center of frame Frame edge Display options for Y coordinate Center of frame Bottom of box...

-

Page 88: Property Of Hole/Slot

HUVITZ KAIZER HPE-8000 Property of Hole/Slot 6.7.6. It displays the properties of the selected hole / slot. ① Group: If selected hole / slot belongs to a group, it displays the group id. If selected hole / slot does not belongs to a group, it displays with the ‘-’. -

Page 89: Job Editor

6.8. Job Editor Job editor provides the whole edging options at once, so it is useful for the skillful users. Layout Option Basic Edging Option Detail Layout Option Layout Option 6.8.1. ① PD (Binocular PD, R/L Monocular PD) ② OH (ΔY, Box, Mix) ③... -

Page 90: Basic Edging Option

HUVITZ KAIZER HPE-8000 Basic Edging option 6.8.2. ① Lens type (Bi-focal Round, Bi-focal flat, Normal) ② Near vision area diameter ③ Lens type ④ Edging type ⑤ Bevel/Grooving position ⑥ Partial grooving Detail Edging Option 6.8.3. ① Polishing ② Front safety beveling ③... -

Page 91: Edging Process

6.9. Edging Process Edging Start 6.9.1. Start process with following procedures after all edging option settings are completed. ① Open the edging room window by pressing ‘WINDOW’ button. ② Release the clamp by pressing ‘CLAMP’ button, and then set blocked lens. ③... -

Page 92: Edging Screen

HUVITZ KAIZER HPE-8000 Edging Screen 6.9.2. NOTE Some buttons are unlocked after a while. Then, you can handle multi-tasking with ‘Job Manager’. According to edging state, following icons are displayed on screen. Edging Icons Processing Processed ... -

Page 93: Edging Stop

Edging Stop 6.9.3. Edging process stops by pressing ‘STOP’ button at any time. Edging process stops when an unexpected situation happens. CAUTION In case of emergency, stop the machine immediately by pressing the ‘STOP’ button. Motor needs some time to stop its working when you stop the machine while processing. ... -

Page 94: Edging Error

HUVITZ KAIZER HPE-8000 Edging Error 6.9.4. In case of an unexpected situation, error message will pop up and the process will stop immediately. NOTE Please check the error message and take a proper step. And then, restart the process. -

Page 95: Edging Finish

Edging Finish 6.9.5. After edging process is finished, beep sound and finish message will be provided with activated main screen. Follow these steps to take out the processed lens. ① After edging finishes, window is open automatically. ② Press the ‘CLAMP’ button. Take out the processed lens from edging room ③... -

Page 96: 6.10. Frame Change

HUVITZ KAIZER HPE-8000 6.10. Frame Change Frame Change Lens Registration 6.10.1. This function is for registration of the frame change lens for frame change processing. To register the frame change lens, double-click the job number area after selecting the frame change lens on waiting tab. -

Page 97: Frame Change Mode

Frame Change Mode 6.10.2. You can activate the frame change mode by touching the feeler icon on detail edging options at the right bottom of main screen. In this mode, feeler reads the lens 1mm inner than its actual size. So even when the size of the frame change lens and the edging size are similar, it helps to process without problems. -

Page 98: Frame Change Procedure

HUVITZ KAIZER HPE-8000 Frame Change Procedure 6.10.3. ① Frame reader reads the lens which will be used in frame change. (when you hold the lens at pattern holder, you must block the lens adaptor at optical center of lens) ②... -

Page 99: Configuration

Configuration 7.1. Configuration of Frame Reader How to start the configuration ① Press these buttons sequentially : ‘MENU’ >> ‘BOTH’ ② Press ‘FRAME’ button, then you can navigate all setting options. ③ Press the ‘BOTH’ button to execute a specific option. ④... -

Page 100: Configuration Of Edger

HUVITZ KAIZER HPE-8000 7.2. Configuration of Edger Press the MENU button at the bottom left of the Main screen. MENU Screen ① Preferences ② Adjustments ③ Software Version ④ Exit NOTE Refer to ‘Chapter 8. System Maintenance’ for the other functions. -

Page 101: Preferences

Preferences 7.2.1. User Interface can be customized to the user’s preference. General Default settings for user interface Language – Sets default language Beep Sound – Turns on or off the beep sound Frame Fitting Mode – Applies frame fitting values R/L separately or R/L equally ... - Page 102 HUVITZ KAIZER HPE-8000 NOTE Setting Screen ① Tab Menu ② Radio Button – Choose only one of a predefined sets of options List Box – Choose a list from existing options ③ Input Box – Input value to be used by the program ④...

- Page 103 Layout Default settings for main screen layout option Default Side – Set default editing side Lens Type – Set default layout mode of main screen Blocking Mode – Set default blocking method OH Type – Set default OH display method ...

- Page 104 HUVITZ KAIZER HPE-8000 Edging Default settings for main screen edging option Edging Start Side –Select left or right to start edging. Warning message will pop up if the processing is not started from the selected side. Default Lens Material – Set default lens material ...

- Page 105 Digital Pattern Default settings for digital pattern screen Digital Pattern Apply Method Fix FPD – Calculates bridge size value based on FPD Fix Bridge Size – Calculates FPD value based on bridge size Zoom Ratio – Set default zoom ratio of touch input area...

- Page 106 HUVITZ KAIZER HPE-8000 Hole Editor Default settings for hole editor screen Hole Depth – Set default hole/slot depth value Hole Diameter – Set default hole/slot diameter value Angle Default Options – Set default tilting angle mode and manual tilting value ...

- Page 107 Frame Fitting Frame Fitting values are used to adjust the size variation caused by frame material difference. Master Size – Input size adjustment value for all frame material Metal – Input size adjustment value for metal frame Hard Plastic –...

- Page 108 HUVITZ KAIZER HPE-8000 Comm. Port Set the communication options Barcode Reader - Use the barcode reader Baud Rate – Set communication speed Tracer Port – Use tracer(frame reader) port Protocol – Set communication protocol Baud Rate – Set communication speed ...

- Page 109 Adjustment settings are closely related to the edging quality, so keep the system default values as much as possible. If you want to change adjustment values, ask to the service technician of HUVITZ or the technician authorized by HUVITZ. ...

- Page 110 HUVITZ KAIZER HPE-8000 Change GL Roughing Rotation – Each time the glass lens rotates, direction of rotation is changed. Frame Change Mode : Feeler Offset – Set the feeling offset for the frame change mode Lens Adaptor – You can choose the type of lens adaptor. The size of it can be set, of...

- Page 111 Rotation You can set the number and the speed of rotation. Rotation Limit – Number of rotation is set according to the processing steps and lens materials. Rotation Speed –Speed of rotation is set according to the processing steps and lens materials.

- Page 112 HUVITZ KAIZER HPE-8000 Clamp You can set default clamping pressure value. Normal – value for Normal Pressure Mode High – value for High Pressure Mode Low – value for Low Pressure Mode NOTE You can input the value from 50% to 150%. 100% means 55kgf±3...

- Page 113 Size You can adjust the edging size. Finishing Size – Size adjustment value for finishing step. Polishing Size – Size adjustment value for polishing step NOTE How to adjust finishing size ① Load internal square pattern(40mm x 40mm) or circle pattern(Ø 50). ②...

- Page 114 HUVITZ KAIZER HPE-8000 circle (Ø 50) 52mm Edged lens Remember that the adjustment value is based on radius. (Do not confuse with the Frame Fitting value. Frame Fitting value is based on diameter) Adjust the value within the tolerance ±0.1mm.

- Page 115 Margin You can set margin for the following edging steps. Roughing Margin – Margin value for roughing Milling Margin – Margin value for milling Polishing Margin – Margin value for polishing CAUTION Margin values have influence on the lens material or edging quality. So it is recommended not to change the factory default settings as much as possible.

- Page 116 HUVITZ KAIZER HPE-8000 Axis You can adjust the distortion of axis. Main – Compensation value for main axis Polishing – Compensation value for polishing axis Grooving – Compensation value for grooving axis Safety Beveling – Compensation value for safety beveling Milling –...

- Page 117 The adjustment unit is degree(°). Add (–) value to shift axis clockwise. How to adjust main axis value Add (-) value Add (+) value How to adjust polishing axis value Add (-) value Add (+) value ...

- Page 118 HUVITZ KAIZER HPE-8000 Front Front Rear Add (-) value Add (+) value Add (+) value In main axis adjustment, use the digital pattern function to rotate square pattern 90 degrees before edging. Main axis distortion can be identified more easily.

- Page 119 Bevel / Groove You can adjust bevel / groove position Bevel – Set adjustment value for bevel position. Groove – Set adjustment value for groove position and depth. Mini Bevel – Set adjustment value for mini bevel position ...

- Page 120 HUVITZ KAIZER HPE-8000 Add (-) value How to adjust polished bevel position value Add (-) value NOTE How to adjust groove ① Load internal circle pattern (Ø 50). ② Set groove position 50% and execute grooving. ③ Check the groove position and depth.

- Page 121 Safety Bevel You can adjust safety bevel position Front – Adjust front safety bevel position Rear – Adjust rear safety bevel position NOTE How to adjust safety bevel ① Load internal circle pattern (Ø 50). ② Turn on front and rear safety bevel options and execute bevel edging(50% position) for all types of lens materials.

- Page 122 HUVITZ KAIZER HPE-8000 How to adjust rear safety bevel value Add (-) value How to adjust front safety bevel value Add (+) value Wheel You can set the options related to edging wheels. Polishing Wheel Size – Set size compensation value for polishing wheel Max Rimless Thickness –...

- Page 123 NOTE If the polishing wheel is worn out, you can improve polishing quality by adjusting the Polish Wheel Size value but if you adjust the value inappropriately, it may cause size problem or poor polishing quality. If the lens is thicker than Max Rimless Thickness value, it can be processed but the quality of the lens is not guaranteed because the lens may get out of the wheel.

-

Page 124: System Maintenance

HUVITZ KAIZER HPE-8000 System Maintenance 8.1. Automatic Calibration of Frame Reader Automatic Calibration of Frame Reader is required with the following cases, When the Size or Axis value of the traced data seems to have a problem, When the Frame Reader seems to have a problem in operating normally. -

Page 125: Pattern Calibration

Pattern Calibration 8.1.3. Procedures for pattern calibration ① Press MENU button and select CALIB. ② Press FRAME button and select PATTERN. ③ Press BOTH button. ④ Load the Standard Pattern. ⑤ Press BOTH button to start calibration. Next, follow the instructions on displayed. NOTE ... -

Page 126: Automatic Calibration Of Edger

You can execute size calibration and feeler calibration with standard edging Jig. CAUTION Calibration function has influence on the edging quality so ask advice of the service technician of HUVITZ or the technician authorized by HUVITZ if necessary. Size Calibration 8.2.1. -

Page 127: Test Mode

8.3. Test Mode Test Mode is efficient to find out whether the machine works properly or not. 8.3.1. Sensor It displays all sensor values of the edger. ① All sensor information ② Refresh sensor status ③ Initialize edger ④ Exit Test Mode NOTE ... -

Page 128: Y / R

HUVITZ KAIZER HPE-8000 SBG Contact – SBG calibration JIG contact state SBG Motor – SBG motor status (0 – Off, 1 – On) SBG Current – SBG motor current value Wheel Motor – Main wheel motor status (0 – Off, 1 – On) ... -

Page 129: Feeler

Feeler 8.3.3. You can check the Feeler. ① Initialize feeler ② Pull test ③ Push test ④ Feeler sensor and switch state... -

Page 130: Sbg / Wheel

HUVITZ KAIZER HPE-8000 SBG / Wheel 8.3.4. You can check SBG ass’y and wheel. ① SBG ass’y test ② SBG motor test ③ Wheel test ④ SBG and wheel sensor status... -

Page 131: Pump

Pump 8.3.5. You can check pump and vacuum cleaner. ① Stop all pumps ② Pump 1 test ③ Pump 2 test ④ Vacuum test ⑤ Pump and vacuum state... -

Page 132: Clamp / Window

HUVITZ KAIZER HPE-8000 Clamp / Window 8.3.6. You can check clamp and window. ① Clamp test ② Window test ③ Clamp and window sensor state... -

Page 133: Wheel Dressing

8.4. Wheel Dressing Wheel dressing is useful to maintain the wheel performance because it removes the lens debris in the wheel. Glass Roughing – Glass roughing wheel automatic dressing mode Finishing – Finishing wheel automatic dressing mode Asymmetric Beveling –... -

Page 134: Statistics

HUVITZ KAIZER HPE-8000 8.5. Statistics It shows statistic information of the processed lens. Current Statistics 8.5.1. It shows the number of lenses that have been processed since the reset point. NOTE The edging is counted only after the edging completes successfully. -

Page 135: Wheel Statistics

Wheel Statistics 8.5.2. It shows wheel usage NOTE Wheel statistics value is counted immediately after the lens has been processed on the appropriate wheel. You can reset wheel statistics values whenever you need. The wheel statistics values are for reference to determine replacement time, so it is not relevant to the actual lifetime of the wheel. -

Page 136: Total Statistics

HUVITZ KAIZER HPE-8000 Total Statistics 8.5.3. It shows the total number of lenses that have been processed since the very first time of the installment. NOTE The edging is counted only after the edging completes successfully. Total statistics values cannot be initialized. -

Page 137: Date & Time

8.6. Date & Time You can change the system time. Please set the date and time first after you install this machine. 8.7. Touch Test You can check the normal operation of the touch screen NOTE You must use the emergency touch screen test function of the touch test is not possible. ①... -

Page 138: Configuration Management

HUVITZ KAIZER HPE-8000 8.8. Configuration Management You can backup or restore system configuration data. ① Backup – Backup configuration data to SD card. ② Restore – Restore configuration data from SD card ③ Factory Reset – Reset to factory default setting NOTE ... -

Page 139: Sw Upgrade

8.9. SW Upgrade You can upgrade software. HPE-8000 consists of two kinds of software. GUI software handles user input and MOTOR software controls mechanical parts of the system. ① GUI – Upgrade GUI software ② MOTOR – Upgrade MOTOR software NOTE ... -

Page 140: 8.10. Maintenance Code

HUVITZ KAIZER HPE-8000 8.10. Maintenance Code Maintenance code is used for the engineer to diagnose the system. -

Page 141: 8.11. Maintenance Tips

Regular Maintenance 8.11.2. It is recommended to keep the regular maintenance cycle in order to maintain the Edging Performance. Be sure to carry out the regular maintenance by the service technician of HUVITZ or the technician authorized by HUVITZ. ... -

Page 142: Cleaning

HUVITZ KAIZER HPE-8000 Fuse Replacement in Edger and Frame Reader 8.11.4. Cleaning ① Sweep the outer surface and LCD panel with soft fabric material. ② When you do not use this device, wrap it with dust cover. -

Page 143: Troubleshooting Guide

Troubleshooting Guide If problems occur, Please review the following list and take remedial action as needed. If you cannot solve the problem after checking the entire list, please contact HUVITZ Problem Cause Solution Tracing size Tip abrasion, gap occurrence. Frame/pattern calibration. - Page 144 HUVITZ KAIZER HPE-8000 Milling mode is The lens is interference with wheel or feeler Apply Axial/Spiral mode. impossible. when edging. Cannot select the Enter the R/L frame curve values at job Do not have the information of frame curve. auto bevel position editor.

-

Page 145: 10. Specifications And Accessories

10. Specifications and Accessories 10.1. Standard Accessories User’s Manual ··············································································································· 1 Lens Adapter ················································································································ 26 LEAP-III Tape (500 Pads) ····································································································1 Lens Adapter Remover ·······································································································1 Standard Frame (for Frame Reader Calibration) ··········· ······ ···· ········ ····· ······ ······ ····· ······ ····· ······ · 1 Standard Pattern (for Frame Reader Calibration) ·... -

Page 146: 10.2. Specifications

HUVITZ KAIZER HPE-8000 10.2. Specifications Specifications of Edger 10.2.1. Beveling – Normal, Asymmetric, Mini, Auto, Manual Mode Flat Edging Grooving – Normal, Partial, Manual Mode Edging Mode Safety Beveling Polishing Milling Lens Material Plastic, Glass, High Index, Polycarbonate, Trivex Max : 90mm Edging Size Min : Rimless 18.5mm (without safety bevel) -

Page 147: 10.3. Drawings Of System

10.3. Drawings of System 10.3.1. Drawings of Edger... -

Page 148: Drawings Of Frame Reader

HUVITZ KAIZER HPE-8000 Drawings of Frame Reader 10.3.2. Drawings of Blocker 10.3.3. -

Page 149: 11. Service Information

If you can’t contact with your local distributor, you can directly get in touch with the service department of the HUVITZ using the phone number and the address written in the below table. How to Contact HUVITZ Co., Ltd Tel: +82-31-428-9100 HUVITZ Co., Ltd.(Headquarter)

Need help?

Do you have a question about the HPE-8000 and is the answer not in the manual?

Questions and answers