Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Hafco Metalmaster S829

- Page 1 S829 S830 CS-350V COLD SAW INSTRUCTION & PARTS MANUAL 13-3-12...

-

Page 2: Table Of Contents

Table of Contents 1 SAFETY REGULATIONS ......2 8.1 Disk Head........10 1.1 General Safety Advice.......2 8.2 Adjusting the Mitering Lock Lever ... 10 1.2 Blade Guard Safety ......2 8.3 Changing the Disk ......10 1.3 Emergencies ........2 8.4 Cleaning and Accessing the Coolant 2 MACHINE DIMENSIONS......2 System .......... -

Page 3: Safety Regulations

This machine complies with the national and local accident prevention regulations. Improper use and/or tampering of the machine will relieve the manufacturer of all responsibility. 1.1 General Safety Advice Always wear suitable eye protection. Always disconnect the machine from the power source before changing the saw ... -

Page 4: Technical Characteristics

3.1 General Characteristics Cutting Capacity 105 x 105mm 160 x 90mm 0 ْ ◌ 85mm 3.5” 120mm 4.7” 4” x 4” 6.3” x 3.5” 85x 85mm 85 x 70mm 45 ْ ◌ 75mm 3” 100mm 4” 3.5“ x 3.5” 3.5” x 2.8” Main Motor 3 HP / 4pole Spindle Speed... -

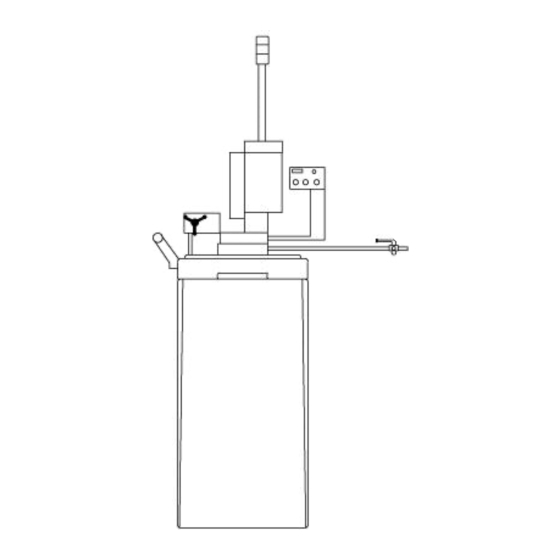

Page 5: Machine Base

5.2 Machine Base A heavy cast iron structure that supports the miter system, vise system, and head assembly. 5.3 Vice clamping system that provides the basic support and security for the work material. Operations are conducted by hand-wheel, which opens and closes the vise jaws. The clamping vise can be adjusted forward and backward to clamp workpiece of various sizes. -

Page 6: Getting Started

Make sure that the electrical supply and the machine’s voltage are the same. Refer to the identification plate on the motor for the correct voltage. Use a good quality grounded electrical system. All internal and/or internal operations, maintenance or repairs, must be performed in a ... - Page 7 The machine has been fixed on the stand already to use. Giving the picture by appearing the foxing points for reference. Align the four setscrews (G) on the underside of the machine base to their corresponding holes in the stand. Direct the setscrews (G) into their matching holes while ...

- Page 8 Attach the bar stop to the vise. Insert the thread end of the long rod (R) into the side of the vise. Turn the long rod clockwise until snug. Use a hex wrench 5mm to lock the screw M12x10 (Q) on the ...

-

Page 9: Electrical Connection Of The Machine

6.4 Electrical Connection of the Machine Make sure whether the voltage of the acquired machine is 220V/ 1 phase or (220V,380V,400,440V)/ 3 phase prior to connection. The control electrical box is located at the front of the stand with a latching door. -

Page 10: Deactivating The Machine

7.3 Deactivating the Machine If the machine is to be inactive for a long period, prepare the machine as follows: Detach the plug from the electric supply panel Release the head return spring Empty the coolant tank Carefully clean and grease the machine ... -

Page 11: Adjusting The Machine

BEFORE PERFORMING THE FOLLOWING OPERATIONS, THE ELECTRIC POWER SUPPLY AND THE POWER CABLE MUST BE COMPLETELY DISCONNECTED. 8.1 Disk Head If excessive axial play is found on the hinge, it will be sufficient to tighten the screws. Pay attention and avoid making the joint too tight. 8.2 Adjusting the Mitering Lock Lever The lock lever may require adjustment when the lever is limited by the machine base and it fail to adequately secure the miter angle... -

Page 12: Troubleshooting The Inverter

8.5 Troubleshooting the inverter Troubleshooting the inverter Prior to operating all electronic parts, the following aspects should be taken into consideration first Note: Only eligible and qualified personnel can make electronic adjustments. Disconnect machine from power supply. Electronic parts are extremely sensitive, do not use hands or metal tools to remove or install such parts. -

Page 15: The Operation Cycle

Before operating all the main parts of the machine must be set to optimum conditions (see the chapter on “regulating the machine”) 9.1 Miter Angle Use the miter lock lever (A) to release the disk head assembly. Rotate the disk head assembly to the correct miter angle. ... -

Page 16: Loading The Work-Piece

9.3 Loading the Work-piece Use the vise hand-wheel to open the vise wider than the width of the work-piece. Measure and mark off the length of material desired to be cut-off. Place the work-piece on the flat surface in between the vise jaws. ... -

Page 17: Routine And Special Maintenance

Set the speed (C), read the speed displayed on the window (H). Set the coolant switch (B). Grasp the control handle (G). Press the trigger switch (F) to start. Pull down the control handle (G). Apply a steady and ... -

Page 18: Monthly Maintenance

10.3 Monthly Maintenance Check that all screws on the motor, the pump, the vise jaws, and the guard are tight and secure. Check that the guard is free from defect. Grease the hinge pin for the head assembly. 10.4 Six-Monthly Maintenance Change the oil in the reduction unit using oil type DN SUPER GEAR 460 by IDEMITSU or DAPHON or equivalent oil, proceeding as follows: Remove the connecting plug from the electric box and unscrew... -

Page 19: Troubleshootion

This chapter lists the probable faults and malfunctions that could occur while the machine is being used and suggests possible remedies for solving them. The first paragraph provides diagnosis for TOOLS and CUTS, the second for ELECTRICAL COMPONENTS. 11.1 Blade and cut diagnosis FAULT PROBABLE CAUSE REMEDY... - Page 20 FAULT PROBABLE CAUSE REMEDY CHIPPED DISK Hardness, shape or flaws in the material Reduce the cutting pressure and/or the (oxides, inclusions, lack of homogeneity, advance. etc…) Wrong cutting speed. Change disk speed and/or diameter. See Chapter ”Material classification and choice of disks” and the Table of cutting speeds according to disk diameter.

- Page 21 FAULT PROBABLE CAUSE REMEDY CUT OFF THE Too fast advance. Decrease advance, exerting less cutting pressure. STRAIGHT Ineffective gripping of the part in the vise. Check the gripping of the part which may Disk head off the straight. be moving sideways. Disk sides differently sharpened.

-

Page 22: Wiring Diaram And Parts List

12.1 WIRING DIARAM... -

Page 23: Parts List

12.2 PARTS LIST Item Description and Technical Suppliers Quantity Supplier Remarks name function data reference 30x6.2mm 250V Fuses 0.5A BOSSING JMC-63 0.5A ROHS Fuses base 10A 1P CHIA WEI FSB-104 AC 24V KR 1 250VAC Relay BETA BMY-5-4C-5 KR 2 BMY-5-2C-5 460V 4A Variable speed... - Page 24 12.3 Explosion draw...

- Page 25 12.4 Parts List- Part A Index Description Size Q'TY Index Description Size Q'TY Lock handle Vise bench Lock Nut Hex socket cap screw M5x25 Hex socket cap screw Small grooved jaw Hex socket cap screw M8x25 Grooved jaw Washer 5/16" Stopper Drainage Hex socket cap screw M8x20...

- Page 26 12.5 Parts List- Part A Index NO. Description Size Q'TY Index NO. Description Size Q'TY Lower length setting Taper roller 32008 A112 Spindle sleeve A113 Lock bolt with knob Star washer A114 Locking nut Locking nut A115 Shaft (right) Spacer A116 Shaft (left) Worm gear...

- Page 27 12.6 Explosion draw...

- Page 28 12.7 Parts List- Part B Index NO. Description Size Q'TY Index NO. Description Size Q'TY Stand, Hex cap screw M6x15 Washer 1/4" Washer 1/4" Suppot plate for tank Suppot plate Protector, plate Washer 1/4" Gooseneck tube Hex cap screw M6x15 Hex cap screw Coolant tank Washer...

- Page 29 General Machinery Safety Instructions Machinery House requires you to read this entire Manual before using this machine. 1. Read the entire Manual before starting 14. Use correct amperage extension cords. machinery. Machinery may cause serious injury if Undersized extension cords overheat and lose not correctly used.

- Page 30 Metal Cutting Coldsaw Safety Instructions Machinery House requires you to read this entire Manual before using this machine. 1. Maintenance. 9. Power outage. Make sure the saw is turned off and In the event of a power failure during disconnect from the main power supply and make use of the saw, turn off all switches to avoid possible sure all moving parts have come to a complete stop sudden start up once power is restored.

Need help?

Do you have a question about the S829 and is the answer not in the manual?

Questions and answers