Summary of Contents for Epiroc SB 102

- Page 1 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, 552 Safety and operating instructions Hydraulic breakers © Construction Tools PC AB | 9800 0648 01 | 2018-01-01 Original instructions...

-

Page 3: Table Of Contents

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Contents Contents Introduction ..............................5 About the Safety and operating instructions ....................5 Safety instructions ............................5 Safety signal words ..........................5 Personal precautions and qualifications ....................5 Transport ............................... 5 Installation, storage, maintenance and disposal .................. - Page 4 Noise declaration statement ........................27 Flow diagrams for the correct operating pressure ................28 SB 52: 100–150 bar ..........................28 SB 102: 100–150 bar ........................... 29 SB 152: 100–150 bar ........................... 29 SB 202: 100–150 bar ........................... 30 SB 302: 100-150 bar ..........................30 SB 452: 100–150 bar ...........................

-

Page 5: Introduction

Introduction will result in death or serious injury. WARNING Indicates a hazardous Epiroc is a leading productivity partner for the situation which, if not avoided, could result in death or mining, infrastructure and natural resources serious injury. industries. With cutting-edge technology, Epiroc... -

Page 6: Testing

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Testing Installation, precautions Testing of the hydraulic installation must only be carried out by professional technicians. The Hydraulic system technicians must be authorised to approve a hydraulic installation in accordance with national directives. -

Page 7: Operation, Precautions

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Never check bores or passages with hands or ► WARNING Dust and fume hazard fingers. Dusts and/or fumes generated or dispersed when Any boom movements must only be done in ►... -

Page 8: Maintenance, Precautions

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, instructions. Incorrect selection or lack of WARNING Projectiles maintenance of consumables/ inserted tools/ Failure of the work piece, of accessories, or even other accessories may cause an unnecessary of the hydraulic breaker itself may generate high increase in dust or fumes. -

Page 9: Storage, Precautions

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Storage, precautions Installation of a start circuit on the hydraulic ► breaker must be made in a way that avoids any unintentional starts. WARNING Heavy hydraulic breaker and A foot pedal on the carrier must be equipped ►... -

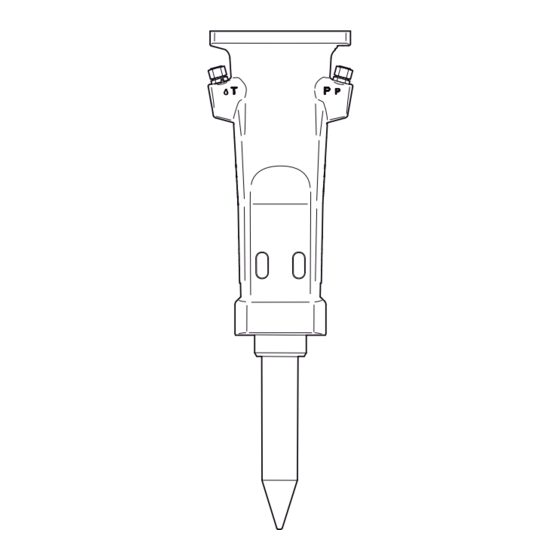

Page 10: Overview

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Overview To reduce the risk of serious injury or death to yourself or others, read the Safety instructions section found on the previous pages of this manual before operating the machine. Design and function SB is a range of rig mounted hydraulic breakers designed for all kinds of demolition works. -

Page 11: Data Plate

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Data plate The accumulator must only be charged with Nitrogen. NOTICE Only certified personnel are allowed to work with the accumulator. A. Machine type B. Maximum hydraulic pressure Guarantee C. -

Page 12: Transport Using A Forklift

Symbol lorry. Secure the machine to the loading surface with straps. Observe all the applicable national and regional SB 52 ⁄ ⁄ ⁄ regulations on securing loads. SB 102 ⁄ ⁄ ⁄ SB 152 ⁄ ⁄ ⁄ Installation SB 202 ⁄... -

Page 13: Hydraulic Oil

For further Tightening torque for pressure and return hoses information see section "Hydraulic oil". SB 52 60 Nm 1. Connect the pressure and return hoses. SB 102 150 Nm SB 152 150 Nm SB 202 150 Nm... - Page 14 2. Carefully lower the stick of the boom into the adapter. Adapter plate Tightening torque WARNING Moving parts can crush and SB 52 240 Nm SB 102 170 Nm Never check bores or passages with hands ► SB 152 170 Nm or fingers.

-

Page 15: Pressure Adjustment

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Pressure adjustment Use a ¼ in. hydraulic hose with a JIC connection as a proper water hose. Contact your nearest authorised workshop for further instructions. The hydraulic breaker is equipped with a pressure NOTICE It is recommended to use water flushing relief valve which secures the breaker. - Page 16 Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, 5. Mount the working tool, use a lifting strap to 3. Remove and check the lock buffer. Change reduce the risk of personal injury worn or damaged parts. 6.

-

Page 17: Operation

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions If front shield or dust cover is worn out, change to new ones, otherwise reuse them. Mount the front shield and dust cover on the working tool. Mount the working tool in accordance with step 4 - 8. - Page 18 Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, ◆ Never run the hydraulic breaker longer then 15 seconds on the same spot. Move the working tool to a new position if the object does not break.

-

Page 19: Breaking Under Water

See "Hoses and connections" for information about connecting utilities. Other breakers in the SB series, with the exception of SB 52 and SB 102, can be retrofitted with water nozzles. More information about water nozzles can be found in the Spare parts list. -

Page 20: Cleaning

Hydraulic oil and chisel paste are environmentally and high temperatures a standard type of grease harmful and must not penetrate the ground or will melt and run. To avoid this always use Epiroc enter the water table or water supplies. chisel paste. -

Page 21: Wear Limits

Wear limits A mm (in.) B mm (in.) SB 52 42 (1.6) 38 (1.5) SB 102 47 (1.8) 43 (1.7) SB 152 52 (2.0) 48 (1.9) 2. Carefully clean the bore and the bushing seat SB 202 68 (2.7) -

Page 22: Disposal

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, 1. Clean the hydraulic breaker carefully. 2. Dismount the working tool and lubricate the front part of the piston, bushing and the tool retainer lock. 3. Store the hydraulic breaker in a dry place. Disposal A used machine must be treated and scrapped in such a way that the greatest possible portion of the... -

Page 23: Troubleshooting

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Troubleshooting Hydraulic breaker does not start Cause Remedy Pressure and tank hoses are mixed up. Check that the connections of the pressure and tank Carrier driver hoses are correct. See section "Hoses and connection". -

Page 24: Hydraulic Breaker Operates Too Slow

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Hydraulic breaker operates too slow Cause Remedy Insufficient hydraulic oil delivery volume. Check the engine speed and/or mode stage of the carrier Carrier driver and the operation pressure and adjust. Check the carrier's pressure and the size of the restrictor. -

Page 25: Technical Data

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Technical data Machine data SB 52 SB 102 SB 152 SB 202 SB 302 SB 452 SB 552 Tunnel Tunnel Part 8460 0300 8460 0300 8460 0300... -

Page 26: Capacities

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Capacities SB 52 SB 102 SB 152 SB 202 SB 302 SB 302 SB 452 SB 452 SB 552 Tunnel Tunnel Oil flow, 12–27 16–35 25–45 35–65 50–80... -

Page 27: Noise Declaration Statement

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions Noise declaration statement SB 52 SB 102 SB 152 SB 202 SB 302 SB 452 SB 552 Tunnel Tunnel Sound pressure 1 dB(A) Sound power 2 dB(A) 1 Sound pressure level according to EN ISO 3744 in accordance with directive 2000/14/EC at 10 metres distance. -

Page 28: Flow Diagrams For The Correct Operating Pressure

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Flow diagrams for the correct operating pressure The carrier’s oil flow can be restricted to achieve the right operating pressure. Restrictors can be ordered from the spare parts list. The diagrams show oil flow at viscosity 32 cSt. SB 52: 100–150 bar ©... -

Page 29: Sb 102: 100-150 Bar

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions SB 102: 100–150 bar Ø 3.0 mm Ø 3.3 mm Ø 3.8 mm Ø 4.5 mm l/min SB 152: 100–150 bar Ø 4.5 mm Ø 4.0 mm Ø... -

Page 30: Sb 202: 100-150 Bar

Safety and operating instructions SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, SB 202: 100–150 bar SB 302: 100-150 bar Ø 5.4 mm Ø 6.0 mm Ø 6.4 mm l/min SB 302 Tunnel is delivered with restrictor Ø6.7 for 110 bar operation. As an option, restrictor Ø6.4 for operation at higher pressure, is available. -

Page 31: Sb 452: 100-150 Bar

SB 52, 102, 152, 202, 302, 302Tunnel, 452, 452Tunnel, Safety and operating instructions SB 452: 100–150 bar Ø 6.0 mm Ø 6.7 mm Ø 7.5 mm l/min SB 452 Tunnel is delivered with restrictor Ø8.7 for 110 bar operation. As an option, restrictor Ø7.5 for operation at higher pressure, is available. -

Page 32: Ec Declaration Of Conformity

Hydraulic breaker Guaranteed sound Measured sound Pmax (bar) Weight (kg) power level [dB(A)] power level [dB(A)] SB 52 SB 102 SB 152 SB 202 SB 302 SB 302 Tunnel SB 452 SB 452 Tunnel SB 552 Technical Documentation authorised representative: Conny Sjöbäck... - Page 36 Any unauthorized use or copying of the contents or any part thereof is prohibited. This applies in particular to trademarks, model denominations, part numbers, and drawings. epiroc.com...

Need help?

Do you have a question about the SB 102 and is the answer not in the manual?

Questions and answers