Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for SIRAIR GS-CAS18ID-INV/1P

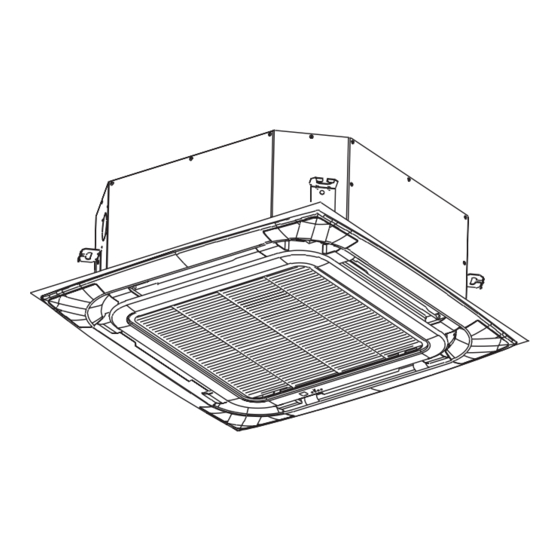

- Page 1 Engineered for comfort Operation Manual & Installation Round Flow Cassette Model GS-CAS18ID-INV/1P GS-CAS24ID-INV/1P GS-CAS36ID-INV/1P GS-CAS48ID-INV/1P GS-CAS48ID-INV/3P GS-CAS60ID-INV/3P Thank you for purchasing our product, please keep and read this maual carefully before you install.

-

Page 2: Table Of Contents

Technical Manual Indoor Unit Round Flow Cassette Type Features ..................9 Specification .................. 12 3. Dimension ..................17 4. Service Space ................19 5. Wiring Diagrams ................20 6. Capacity Table ................23 7. Electric Characteristics ..............26 8. Exploded View ................27 9. -

Page 3: Features

Technical Manual 1. Features Round flow cassette 1.1 Round flow cassette (1) Brand-new panel design. Indoor unit use uniform panel, simple and convenient. (2) Simple, featly and voguish appearance suit for different requirements, it’s mostly used for office, shopping center, restaurant, meeting room and etc. 18kBtu/h~60kBtu/h, standard type, 950mm*950mm... - Page 4 Technical Manual (3) Ultra-thin body design, the min. height is only 230mm, save installation space. (4) 360 air flow, cold air can reach each corner of the room, providing a stable and comfortable environment. (5) 3 fan speed,meet for different requirement. New streamlined fan design.

- Page 5 Technical Manual (9) Built-in water pump, water head up to 1200mm. (10) Integrated electric control box, The E-box is safely covered by metal plate, for better fire-resistance, save using. (11) Add 4 interfaces in body, can be connected with duct to another room, fresh air makes air quality more healthy and comfortable.

- Page 6 Standard for wireless controller; option for wired controller. Standard optional (15) DC inverter motor, operate in ultra-low frequency and to precisely control the indoor temperature. 2.1 Specification of round flow cassette Model GS-CAS18ID-INV/1P GS-CAS24ID-INV/1P Indoor power supply V/Ph/Hz 220~240/1/50 220~240/1/50 Capacity Power input...

- Page 7 Technical Manual Max pressure Refrigerant type R410A R410A Refrigerant Φ6.35/Φ12.7 Φ9.52/Φ15.88 Liquid side/Gas side piping Drainage pipe DN25 DN25 Standard controller Standard for remote controller(wired controller for option) Operation temp °C 16~32 16~32 cooling °C -15~50 -15~50 Ambient temp heating °C -15~30 -15~30...

- Page 8 Technical Manual GS-CAS48ID-INV/1P OR Model GS-CAS36ID-INV/1P GS-CAS48ID-INV/3P Indoor power supply V/Ph/Hz 220~240/1/50 220~240/1/50 Capacity 10.5 Power input Cooling Current input Capacity 10.5 10.5 Input Heating Rated current Max. power input Max. current input Model YDK-75Q-6P3-1 YDK-75Q-6P3-1 Power output Indoor fan μF motor Capacitor...

- Page 9 Technical Manual 2.2 Specification of 4-way cassette Model GS-CAS60ID-INV/3P Indoor power supply V/Ph/Hz 220~240/1/50 Capacity Power input Cooling Current input 2.91 Capacity 17.6 Input Heating Rated current 3.31 Max. power input Max. current input Model YDK-75Q-6P3-1 Power output Indoor fan μF motor Capacitor...

- Page 10 Technical Manual Notes: 1. Nominal cooling capacities are based on the following conditions: Indoor temp: 27°CDB, 19°CWB; Outdoor temp: 35°CDB; Equivalent ref. piping: 5m (horizontal) 2. Nominal heating capacities are based on the following conditions: Indoor temp: 20°CDB; Outdoor temp: 7°CDB, 6°CWB; Equivalent ref. piping: 5m (horizontal) 3.

-

Page 11: Dimension

Technical Manual 3 Dimension 3.1 GS-CAS18ID-INV/1P, GS-CAS24ID-INV/1P... - Page 12 Technical Manual 3.2 GS-CAS36ID-INV/1P, GS-CAS48ID-INV/1P OR GS-CAS48ID-INV/3P, GS-CAS60ID-INV/3P.

-

Page 13: Service Space

Technical Manual 4. Service Space The indoor unit should be installed in a location that meets the following requirements: 4.1 There is enough interspace for installation and maintenance. 4.2 The ceiling is horizontal, and its structure can endure the weight of the indoor unit. 4.3 The outlet and the inlet are not impeded, and the influence of external air is the least. -

Page 14: Wiring Diagrams

Technical Manual 5. Wiring Diagrams GS-CAS18ID-INV/1P, GS-CAS24ID-INV/1P GS-CAS36ID-INV/1P,GS-CAS48ID-INV/1P OR GS-CAS48ID-INV/3P... - Page 15 Technical Manual...

- Page 16 Technical Manual GS-CAS60ID-INV/3P...

-

Page 17: Capacity Table

Technical Manual Capacity Table Cooling 6.1 GS-CAS18ID-INV/1P MODEL GS-CAS18ID-INV/1P COOLING OUTDOOR TEMPERATURE DRY Indoor Conditions 21ºC 28ºC 32ºC 35ºC 42ºC 49 ºC Total capacity kW 5.09 5.06 5.04 5.01 4.99 4.93 4.88 21ºC D 15ºC W Input kW. 1.50 1.51 1.52... - Page 18 Total capacity kW 32ºC D 23ºC W Input kW. 5.36 5.40 5.46 5.50 5.53 5.81 6.11 Heating 6.6 GS-CAS18ID-INV/1P MODEL GS-CAS18ID-INV/1P HEATING OUTDOOR CONDITIONS 24ºC D 15ºC D 7ºC D 3ºC DB -5ºC D -7ºC D -14ºC D Indoor Conditions 18ºC W...

- Page 19 Technical Manual 6.7 GS-CAS24ID-INV/1P MODEL GS-CAS24ID-INV/1P HEATING OUTDOOR CONDITIONS 24ºC D 15ºC D 7ºC D 3ºC DB -5ºC D -7ºC D -14ºC D Indoor Conditions 18ºC W 14ºC W 6ºC W 2ºC WB -6ºC W -8ºC W -15ºC W Capacity kW 7.95 7.83 7.81...

-

Page 20: Electric Characteristics

Technical Manual 6.10 GS-CAS60ID-INV/3P MODEL GS-CAS60ID-INV/3P HEATING OUTDOOR CONDITIONS 24ºC D 15ºC D 7ºC D 3ºC DB -5ºC D -7ºC D -14ºC D Indoor Conditions 18ºC W 14ºC W 6ºC W 2ºC WB -6ºC W -8ºC W -15ºC W 18.05 17.90 17.84 17.33... -

Page 21: Exploded View

Technical Manual 8.Exploded View 8.1GS-CAS18ID-INV/1P Part Name Part Name E-parts box cover 8.4.3 collecting pipe welding assy... - Page 22 Technical Manual Eletric control components for indoor unit 8.4.4 Current divider capillary assy E-parts board for indoor unit Upper foam components Pre-assembling assy for water pump Temperature sensor Terminal 10.1 water pump support Welded chasis for E-parts box 10.2 Water pump Duct tape assembly 10.3 Underlay for water pump support...

- Page 23 Technical Manual 8.2GS-CAS24ID-INV/1P...

- Page 24 Technical Manual Part Name Part Name E-parts box cover 8.4.3 collecting pipe welding assy Eletric control components for indoor unit 8.4.4 Current divider capillary assy E-parts board for indoor unit Upper foam components Pre-assembling assy for water pump Temperature sensor Terminal 10.1 water pump support...

- Page 25 Technical Manual 8.3GS-CAS36ID-INV/1P...

- Page 26 Technical Manual Part Name Part Name E-parts box cover Current collecting assy for evaporator 5.4.3 Eletric control components for indoor unit Current divider capillary assy for evaporator 5.4.4 Upper foam components Water pump components Terminal E-parts board for indoor unit Water pump Underlay for water pump support Temperature sensor group...

- Page 27 Technical Manual 8.4GS-CAS48ID-INV/1P OR GS-CAS48ID-INV/3P...

- Page 28 Technical Manual Part Name Part Name E-parts box cover Current collecting assy for evaporator 5.4.3 Eletric control components for indoor unit Current divider capillary assy for evaporator 5.4.4 Upper foam components Water pump components Terminal E-parts board for indoor unit Water pump Underlay for water pump support Temperature sensor group...

-

Page 29: Accessories

Technical Manual 9. Accessories Name Shape Quantity Expansible hook Installation Installation hook Fittings Installation paper board Bolt M5 Out-let pipe sheath Drainpipe Fittings Tightening band Remote controller Remote controller Mounting screw(ST2.9×10- C-H) Alkaline dry batteries (AM4) Operation&installation Others instruction manual... -

Page 30: The Specification Of Wiring

Technical Manual 10. The Specification of Wiring 11. Field Wiring... -

Page 31: Trouble Shooting

Technical Manual 12. Trouble shooting Fault codes table Table 1:Indoor unit(digital display) When unit is standby after first time power on, running light flash slowly, after operation, all the lights off when the unit is off or standby. When unit is running, running light ON, digital tube shows setting temperature in cooling and heating mode, digital tube shows indoor temperature in fan only mode;... - Page 32 Technical Manual Outdoor unit error Outdoor EEPROM error Condenser temperature T3 sensor error Condenser temperature T3 too high protection Anti-typhoon protection Defrost warning lights flash DC side over-voltage DC side over-current Mode conflict Inverter 1PM protection 3 times P4 protection (Reserved) 3 times P2 protection (Reserved) Timing warning lights flash Communication error between indoor and outdoor unit...

- Page 33 Technical Manual Outdoor Units 1.Specification ............130 2.Dimensions ............134 3.Service Space ............. 136 4.Wiring Diagrams ..........138 5.Electric Characteristics ........142 6.Operation Limits ..........143 7.Sound Levels ............144 8.Exploded View ............ 144 9.Troubleshooting ..........150...

- Page 34 Technical Manual Outdoor Unit 1 Specification Model GS-180D-INV/1P GS-240D-INV/1P Outdoor power supply V/Ph/Hz 220~240/1/50 220~240/1/50 Cooling Capacity Heating Capacity Max. input consumption 2200 3220 Max. current Model KSN98D22UFZ KSN140D21UFZ Type DC/Rotary DC/Rotary Brand GMCC GMCC Compressor Frequency range 10-120 10-120 Capacity 3095 4370...

- Page 35 Technical Manual GS-360D-INV/1P GS-360D-INV/3P Model Outdoor power supply V/Ph/Hz 220~240/1/50 380~415/3/50 Cooling Capacity 10.5 10.5 Heating Capacity 10.5 10.5 Max. input consumption 3800 3800 Max. current 16.5 Model KTM240D43UMT KTM240D43UMT Type DC/Twin-rotary DC/Twin-rotary Brand GMCC GMCC Compressor Frequency range 12-120 12-120 Capacity 7760...

- Page 36 Technical Manual GS-480D-INV/1P GS-480D-INV/3P Model Outdoor power supply V/Ph/Hz 380~415/3/50 380~415/3/50 Cooling Capacity Heating Capacity 17.6 Max. input consumption 4900 6800 Max. current 12.8 Model KTM240D43UMT MNB40FEQMC Type DC/Twin-rotary DC/Twin-rotary Brand GMCC Mitsubishi Compressor Frequency range 12-120 10-120 Capacity 7760 12900 Input 2055...

- Page 37 Technical Manual GS-600D-INV/3P Model Outdoor power supply V/Ph/Hz 380~415/3/50 Cooling Capacity Heating Capacity 17.6 Max. input consumption 6800 Max. current 12.8 Model MNB40FEQMC Type DC/Twin-rotary Brand Mitsubishi Compressor Frequency range 10-120 Capacity 12900 Input 3960 Refrigerant oil 1100 Model YDK-80-6P3-1 Brand WEILING Outdoor fan...

-

Page 38: Dimensions

Technical Manual 2 Dimensions 2.1 GS-180D-INV/1P,GS-240D-INV/1P 2.2 GS-360D-INV/1P,GS-360D-INV/3P,GS-480D-INV/3P GS-480D-INV/1P 2.3 GS-600D-INV/3P... - Page 39 Technical Manual...

-

Page 40: Service Space

Technical Manual 3 Service Space (Wall or obstacle) Obstacle Air inlet >30cm Fix with bolt Air inlet Maintain channel >60cm Air outlet Deep foundation Necessary width Install dimension requirements for outdoor unit 300mm is necessary between 2 outdoor units 300mm M10 bolt 4pieces per unit... - Page 41 Technical Manual In order to ensure the unit to run well, in the choice of installation location, the following guidelines must be followed: 1. Upon installation of the outdoor unit, the air discharged outdoor should not return, and enough space for maintenance must be remained around the machine.

-

Page 42: Wiring Diagrams

Technical Manual 4 Wiring Diagrams 4.1 GS-180D-INV/1P,GS-240D-INV/1P... - Page 43 Technical Manual 4.2 GS-360D-INV/1P, GS-480D-INV/1P...

- Page 44 Technical Manual 4.3 GS-360D-INV/3P, GS-480D-INV/3P...

- Page 45 Technical Manual 4.4 GS-600D-INV/3P LOAD Filter BRD CN11 INPUT CN17 N 15V...

-

Page 46: Electric Characteristics

Technical Manual 5 Electric Characteristics Outdoor Unit Model Outdoor Voltage Min. Max. motor (kw) GS-180D-INV/1P 220~240V 0.04 GS-240D-INV/1P 220~240V 0.04 GS-360D-INV/1P 220~240V GS-360D-INV/3P 380~415V GS-480D-INV/1P 220~240V GS-480D-INV/3P 380~415V GS-600D-INV/3P 380~415V 0.08*2... -

Page 47: Operation Limits

Technical Manual 6 Operation Limits Operation mode Outdoor temperature(℃) Room temperature(℃) Cooling operation -15~50 16~32 Heating operation -15~30 16~32... -

Page 48: Sound Levels

Technical Manual 7.Sound Levels 12kBtu/h-60kBtu/h Microphone Microphone Rear side Front side 1.2 m (body height +1 )/2 m Model Power level dB(A) Pressure level GS-180D-INV/1P GS-240D-INV/1P GS-360D-INV/1P GS-360D-INV/3P GS-480D-INV/1P GS-480D-INV/3P GS-600D-INV/3P Note: Sound level is measured at a point 1 m in front of the unit, at a height of (Unit body height +1)/2 m. -

Page 49: Exploded View

Technical Manual 8. Exploded View 8.1 GS-180D-INV/1P Part Name Quantity No. Part Name Quantity Front panel assembly Handle Panel Valve seat plate assembly Front grille Valve seat plate Front net buckle Gas stop valve Left column Liquid stop valve Motor bracket parts Right plate Motor bracket assembly Circuit component... - Page 50 Technical Manual 8.2GS-180D-INV/1P...

- Page 51 Technical Manual Part Name Part Name Repair board (with convex cover) with cotton Top cover plate parts patch assembly Electronic components Chassis components Outdoor inverter module integrated board Front panel (with plastic mesh) Terminal bedplate Left side panel Terminal 11.1 left side plate Line pressing buttons 11.2...

- Page 52 Technical Manual 8.3GS-240D-INV/1P...

- Page 53 Technical Manual Part Name Part Name Top cover pasted with cotton components Seat plate Electronic components stop valve Integrated panel of outdoor inverter module stop valve (explosion proof) Terminal bedplate liquid accumulator Terminal maintenance panel Line pressing buttons DC inverter compressor Middle partition unit Chassis components medium septum...

- Page 54 Technical Manual 8.4GS-360D-INV/1P, GS-360D-INV/3P Part Name Quantity Part Name Quantity Small Handle panel Left side board Motor bracket component Condenser assy 14.1 Axial flow blade Condenser 14.2 Motor bracket assembly Gas collection tube assembly 14.3 fan motor Split capillary assembly Handle Connecting pipe Maintenance board...

- Page 55 Technical Manual 8.5 GS-480D-INV/1P, GS-480D-INV/1P Part Name Quantity Part Name Quantity Small Handle panel Left side board Motor bracket component Condenser assy 14.1 Axial flow blade Condenser 14.2 Motor bracket assembly Gas collection tube assembly 14.3 fan motor Split capillary assembly Handle Connecting pipe Maintenance board...

- Page 56 Technical Manual 8.6 GS-600D-INV/3P...

- Page 57 Technical Manual Part Name Quantity Part Name Quantity Chassis assy 12.3 Three phase filter board The right side of the valve panel 12.4 Contactor Rear side of the valve panel 12.5 Current Transformer After backplane Condenser Right clapboard 13.1 Condenser assy Separating board welding assy 13.2 Flute shunt components...

-

Page 58: Troubleshooting

Technical Manual 9 Troubleshooting 9.1 Fault display(12-48Kbtu/h) Display Error description Display Error description Phase protection (reserve) Communication error between outdoor unit (reserve) and indoor unit Indoor room temperature (T1) sensor error (reserve) Indoor coil middle temperature (T2) sensor Outdoor unit current error cannot recover error Display P3 error for 3 times within 60 minutes Indoor coil outlet temperature (T2B) sensor... - Page 59 Technical Manual Wired controller: Spot check Spot check Content Content Indoor unit capacity Opening of EXV Indoor unit capacity demand Running frequency of compressor Indoor demand after T4 amendment Primary voltage/4 Indoor demand after T2 amendment Indoor room temperature (T1) temperature Indoor coil middle temperature (T2) temperature...

- Page 60 Technical Manual 9.2Fault display (36-60Kbtu/h) Display Definition of fault or protection Remark content Three-phase power phase sequence fault Communication is interrupted for more than 2 Communication fault between the outdoor unit and minutes20minutes after the initial power-on or within the mast 20 minutes Temperature sensor fault Condenser tube temperature sensor fault...

- Page 61 Technical Manual 9.3 Parameter table for outdoor unit check and maintenance(36-60Kbtu/h) Display content Remark Current frequency / Indoor unit Quantity at power on displayed on standby Normal display quantity Outdoor unit local capacity Total capacity needs of indoor unit Total capacity of the outdoor unit after correction;...

- Page 62 Technical Manual Part 4 Installation 1.Precaution on Installation ............160 2.Vacuum Dry and Leakage Checking ........... 161 3.Additional Refrigerant Charge ............. 163 4.Water Drainage ................164 5.Insulation Work ................167 6.Test Operation ................169...

- Page 63 Technical Manual 1. Precaution on Installation 1.1. Measure the necessary length of the connecting pipe, and make it by the following way. Connect the indoor unit at first, then the outdoor unit. Bend the tubing in proper way. Do not harm them. CAUTIONS: ...

- Page 64 Technical Manual 2 Vacuum Dry and Leakage Checking 2.1 Vacuum Dry: use vacuum pump to change the moisture (liquid) into steam (gas) in the pipe and discharge it out of the pipe to make the pipe dry. Under one atmospheric pressure, the boiling point of water(steam temperature) is 100℃.

- Page 65 Technical Manual ②. Special vacuum dry procedure This vacuum dry method is used in the following conditions: There’s moisture when flushing the refrigerant pipe. Rainwater may enter into the pipe. Vacuum dry for the first time ······ 2h pumping ③.

- Page 66 Technical Manual 3 Additional Refrigerant Charge Caution ● Refrigerant cannot be charged until field wiring has been completed. ● Refrigerant may only be charged after performing the leak test and the vacuum pumping. ● When charging a system, care shall be taken that its maximum permissible charge is never exceeded, in view of the danger of liquid hammer.

- Page 67 Technical Manual 4 Water Drainage 4.1 Gradient and Supporting 4.1.1 Keep the drainpipe sloping downwards at a gradient of at least 1/100. Keep the drainpipe as short as possible and eliminate the air bubble. 4.1.2 The horizontal drainpipe should be short. When the pipe is too long, a prop stand must be installed to keep the gradient of 1/100 and prevent bending.

- Page 68 Technical Manual 4.3 Upwards drainage (drain pump) For Four-way cassette (compact) For Four-way cassette 4.4Convergent drainage 4.4.1. The number of indoor units should be as small as possible to prevent the traverse main pipe overlong. 4.4.2. Indoor unit with drain pump and indoor unit without drain pump should be in different drainage system. 4.4.3.

- Page 69 Technical Manual 4.5Drainage test 4.5.1Drainage without drain pump After finishing drainpipe installation, pour some water into the water receiver plate to check if the water flows smoothly. 4.5.2 Drainage with drain pump ① Poke the Water Level Switch, remove the cover, use water pipe to pour 2000ml water into the water receipt plate through the water inlet.

- Page 70 Technical Manual 5 Insulation Work 5.1 Insulation material and thickness 5.1.1. Insulation material Insulation material should adopt the material which is able to endure the pipe’s temperature: no less than 70℃ in the high-pressure side, no less than 120℃ in the low-pressure side(For the cooling type machine, no requirements at the low-pressure side.) ...

- Page 71 Technical Manual For construction convenience, before laying pipes, use insulation material to insulate the pipes to be deal with, at the same time, at two ends of the pipe, remain some length not to be insulated, in order to be welded and check the leakage after laying the pipes.

- Page 72 Technical Manual 6. Test Operation (1) The test operation must be carried out after the entire installation has been completed. (2) Please confirm the following points before the test operation. The indoor unit and outdoor unit are installed properly. ...

- Page 73 Technical Manual Control Controller 1.Wireless Remote Controller ............171 2.Wired Controller ................179...

- Page 74 Technical Manual 1 Wireless Remote Controller 1.1 NT-03A...

- Page 75 Technical Manual 1.2 Instructions of remote controller “HVAC No.2” remote controller (compatibility with wire controller or lamp board): extension code, applicable to most VRV models. “HVAC No.3” remote controller (compatibility with wire controller or lamp board): general code, applicable to all models (except of Window machine).

- Page 76 Technical Manual 1.3 The icon meaning of remote controller 1)The remote controller is equipped with 15 buttons, and the LCD is newly made. All the icons are kept in touch with the touch-screen remote controller. 2)At the first power on, the LCD of the remote controller displays all the icons first and then enters the standby state, displaying only the clock 12:00 and the light icon.

- Page 77 Technical Manual 1.4Button function of remote controller (1) ON/OFF ① When pressing this key, the remote controller switches by "on, off, on" circularly. ② When the first power on, the working state is set by default: setting temperature 25℃ (77℉), automatic mode, automatic fan speed, internal and external pendulum wind, no TURBO, no sleep, no timer, no lock).

- Page 78 Technical Manual ① Pressing this key in the dehumidification mode, the external pendulum wind is forced to close. ② Pressing this key in the other modes, the external pendulum switches by "swing, fixed wind, swing" circularly. (6) Left and right swinging (Internal pendulum wind) ①...

- Page 79 Technical Manual ③ If the air conditioner has four gear wind speeds, the TURBO icon will light up and the fan will run in the fourth gear wind speed by pressing this key. (11) ECON ① The remote controller is no ECON by default, and the ECON key will not work in automatic mode, dehumidification mode and fan mode.

- Page 80 Technical Manual (16) Combinatorial key: “FAN -” +“FAN +” ① Extension code remote controller has the effect. Switch 3 gear wind and 6 gear wind. There is 6 gear wind on the LCD. If the 3 gear wind is switched, the first and second gear wind will be "low wind";...

- Page 81 Technical Manual 1.5 Battery replacement 1)If the air conditioner is unable to receive the signal from the wire controller, or the LCD of wire controller is blurred, it means that the battery is depleted and needs to be replaced. 2)Take off the back cover and remove the old batteries. When replacing batteries, please pay attention to the "+"...

- Page 82 Technical Manual 2 Wired Controller ZKX-C/TE-05...

- Page 83 Technical Manual...

Need help?

Do you have a question about the GS-CAS18ID-INV/1P and is the answer not in the manual?

Questions and answers