Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for coesia FlexLink X85X

- Page 1 CONVEYOR SYSTEM X85X Assembly manual...

-

Page 2: Table Of Contents

Safety System information Important safety conditions Introduction Assembly information Scope Audience Prerequisites Hints and tips Reference symbols Support assembly Support systems assembly Polyamide foot, 2-point Polyamide foot, 3-point Beam support bracket, Beam support bracket, straight beam 21 Beam support bracket, drive unit Beam support bracket, wheel bend Beam support bracket, plain bends Conveyor assembly... - Page 3 4.10 End drive unit, guided chain no slip clutch 4.11 Bridge 4.12 X-bend 4.13 Side transfer 4.14 Slack protection kit 4.15 Wheel bend 4.16 Vertical bend 4.17 Plain bend Assembly Slide Rail Mounting slide rail Mounting slide rails Joining slide rail ends Fixing slide rails Changing support rail for plain bends 91 Mounting Conveyor Chain...

- Page 4 © Flexlink AB 2015 All Rights Reserved No part of this program and manual may be used, reproduced, stored or transmitted in any form or by any means without the written permission of FlexLink AB. The contents of this manual are for informational use only. All information and specifications contained in this document have been care- fully checked to the best efforts of FlexLink AB, and are believed to be true and accurate as of time of publishing.

- Page 5 This page is intentionally left blank X85X System...

-

Page 6: Safety

Safety Safety The conveyor system has been designed in such a way, that it can be used and maintained in a safe way. This holds for the application, the circum- stances and the instructions described in the manual. Any person working with or on this machine, should study this manual and follow the instruc- tions. - Page 7 Safety General • Incorrect use of the equipment can cause personal injury. • Do not stand or climb on the equipment. • Do not wear loose clothing or other articles that can get caught in the machine. • Follow the instructions in this user manual when transporting the machine.

-

Page 8: Introduction

Introduction Introduction Assembly information Assembly Maintenance Disposal Scope This information is part of an information collection describing the imple- mentation of the X85X, system like assembling of hardware, software in- stallation, verifying safety equipment etc. Audience This information is mainly written for application engineers and installation personnel involved in the installation. -

Page 9: Reference Symbols

Introduction Reference symbols In most cases of assembling the drive units in chapter 4, Conveyor assem- bly, the slide rail and chain needs to be installed before the assembly can be completed. Therefor the underlying symbols will be used to refer the reader to the chapters concerning mounting of slide rail and chain, instead of showing the steps repeatedly. -

Page 10: Support Assembly

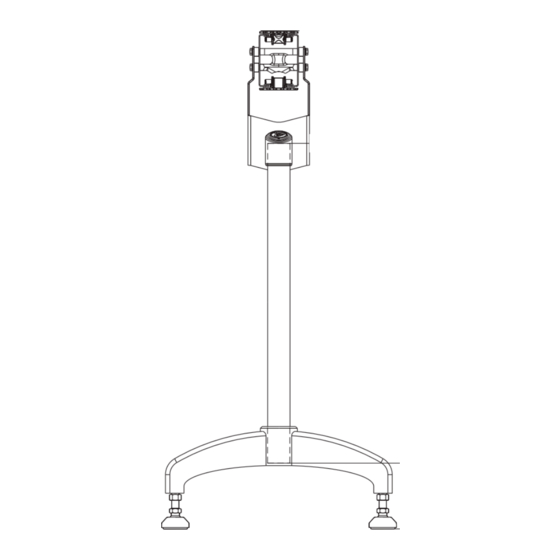

Support assembly Support assembly Support systems assembly Most conveyor support designs are based on vertical support beams com- bined, if necessary, with horizontal support beams. The conveyor must be supported at regular intervals not exceeding 3 000 mm, and always place a support as close to the drive unit as possible. - Page 11 Support assembly In the formula H represents the height from the floor to the top of a stan- dard plain chain. Most support combinations permit height adjustments, both at the foot, and at the beam support brackets. X85X System...

-

Page 12: Polyamide Foot, 2-Point

Polyamide foot, 2-point 16 mm 24 mm X85X System... - Page 13 X85X System...

- Page 14 Polyamide foot, 3-point, XCFG 48 T 16 mm 24 mm X85X System...

- Page 15 X85X System...

-

Page 16: Beam Support Bracket

Beam support bracket, XBCSX 48 4 mm X85X System... - Page 17 X85X System...

-

Page 18: Beam Support Bracket, Straight Beam

Beam support bracket, straight beam 13 mm X85X System... - Page 19 X85X System...

- Page 20 X85X System...

- Page 21 This page is intentionally left blank X85X System...

-

Page 22: Beam Support Bracket, Drive Unit

Beam support bracket, drive unit, 5114999 13 mm X85X System... - Page 23 X85X System...

- Page 24 X85X System...

- Page 25 This page is intentionally left blank X85X System...

-

Page 26: Beam Support Bracket, Wheel Bend

Beam support bracket, wheel bend, 5115171 13 mm X85X System... - Page 27 X85X System...

- Page 28 X85X System...

- Page 29 This page is intentionally left blank X85X System...

-

Page 30: Beam Support Bracket, Plain Bends

Beam support bracket, plain bends, 5115162 13 mm X85X System... - Page 31 X85X System...

-

Page 32: Conveyor Assembly

Conveyor assembly Conveyor assembly Drill fixture, 5114621 4,2 mm 8,3 mm 11,0 mm X85X System... - Page 33 Conveyor assembly X85X System...

- Page 34 Conveyor assembly X85X System...

- Page 35 Conveyor assembly This page is intentionally left blank X85X System...

-

Page 36: Nut, Stainless Steel

Nut, stainless steel, 5113998/5114181 8 mm X85X System... - Page 37 X85X System...

-

Page 38: Beam Spacer Kit

Beam spacer kit, XBCEX A85 13 mm X85X System... - Page 39 X85X System...

-

Page 40: Drip Catcher Kit

Drip catcher kit, 5114763 5 mm X85X System... - Page 41 X85X System...

-

Page 42: Beam Section For Chain Installation

Beam section for chain installation, XBCCX 300A85 13 mm X85X System... - Page 43 X85X System...

-

Page 44: Idler End Unit

Idler end unit, XBEJX A85/XBEJX A85 S 13 mm X85X System... - Page 45 X85X System...

-

Page 46: Protective Cover For Idler End Units

Protective cover for idler end units, XBSJX A85/XBSJX A85 S 8 mm X85X System... - Page 47 X85X System...

-

Page 48: End Drive Unit, Direct Drive

End drive unit, direct drive, XBEBX 0A85HN_P NOCO-Fluid 8 mm Snap ring plier 10 mm or similar 10 mm 13 mm X85X System... - Page 49 X85X System...

- Page 50 X85X System...

- Page 51 X85X System...

-

Page 52: Guide Wheel Kit

Guide wheel kit, 5055635 13 mm X85X System... - Page 53 X85X System...

-

Page 54: End Drive Unit, Guided Chain No Slip Clutch

4.10 End drive unit, guided chain, no slip clutch, XBEBX 0A85HN_GP NOCO-Fluid 10 mm Snap ring plier 10 mm or similar 13 mm X85X System... - Page 55 5.1 - 5.4 X85X System...

- Page 56 X85X System...

- Page 57 X85X System...

-

Page 58: Bridge

4.11 Bridge, 5115194/5115195 10 mm X85X System... - Page 59 X85X System...

-

Page 60: X-Bend

4.12 X-bend, XBCXX 85 D_ 13 mm X85X System... - Page 61 If distance piece are removed X85X System...

- Page 62 X85X System...

- Page 63 This page is intentionally left blank X85X System...

-

Page 64: Side Transfer

4.13 Side transfer, XBCPX 85 _ 8 mm 13 mm 17 mm X85X System... - Page 65 Excentric nut Down 3 Down 2 Up 2 Up At delivery Adjustable Excentric nut X85X System...

- Page 66 5113961 4.14 5115027 X85X System...

- Page 67 X85X System...

-

Page 68: Slack Protection Kit

4.14 Slack protection kit, 5115027 8 mm 3 mm X85X System... - Page 69 X85X System...

-

Page 70: Wheel Bend

4.15 Wheel bend, XBBHX A85 13 mm X85X System... - Page 71 X85X System...

-

Page 72: Vertical Bend

4.16 Vertical bend, XBBVX A85 13 mm X85X System... - Page 73 X85X System...

-

Page 74: Plain Bend

4.17 Plain bend, XBBPX A85 13 mm X85X System... - Page 75 X85X System...

-

Page 76: Assembly Slide Rail

Assembly Slide Rail Assembly Slide Rail Mounting slide rail Slide rails are available in two profile designs: 1. Narrow 2. Wide Not suitable in bends The guides are used as shown below: Note: It is recommended to avoid splicing as much as possible X85X System... - Page 77 Assembly Slide Rail This page is intentionally left blank X85X System...

-

Page 78: Mounting Slide Rails

Mounting slide rails Mounting tool X85X System... - Page 79 X85X System...

-

Page 80: Joining Slide Rail Ends

Joining slide rail ends Cutting Pliers X85X System... - Page 81 45° >10 >100 X85X System...

-

Page 82: Fixing Slide Rails

Fixing slide rails Drill fixture 4,2 mm Counter sinker Stainless steel 4,2 mm rivets Rivet crimping clamp X85X System... - Page 83 X85X System...

-

Page 84: Changing Support Rail For Plain Bends

Changing support rail for plain bends 13 mm X85X System... - Page 85 X85X System...

- Page 86 X85X System...

- Page 87 This page is intentionally left blank X85X System...

-

Page 88: Mounting Conveyor Chain

Mounting Conveyor Chain Mounting Conveyor Chain Mounting chain using a beam section 13 mm Pin insert tool X85X System... - Page 89 Mounting Conveyor Chain X85X System...

- Page 90 Mounting Conveyor Chain X85X System...

- Page 91 Mounting Conveyor Chain This page is intentionally left blank X85X System...

-

Page 92: Mounting Chain On End Drive Unit

Mounting chain on end drive unit Pin insert tool X85X System... - Page 93 X85X System...

- Page 94 X85X System...

- Page 95 X85X System...

-

Page 96: Assembly Guide Rail

Assembly Guide Rail Assembly Guide Rail 7 .1 Mounting guide rails Guide rails are supported by guide rail brackets attached to the sides of the conveyor beam. Brackets should be placed approximately 300 to 1500 mm apart depending on guide rail type, type of product and if there is accumulation or not. If brackets are spaced at greater distances than 1500 mm, there is a possi- bility that guide rails will become deformed due to excessive force. - Page 97 Assembly Guide Rail This page is intentionally left blank X85X System...

-

Page 98: Mounting Guide Rails Bracket, Wide

7 .2 Mounting guide rails bracket, wide 10 mm 13 mm X85X System... - Page 99 X85X System...

- Page 100 X85X System...

- Page 101 This page is intentionally left blank X85X System...

-

Page 102: Mounting Guide Rails Bracket, High And Low

7 .3 Mounting guide rails bracket, high and low 10 mm 13 mm X85X System... - Page 103 X85X System...

- Page 104 X85X System...

- Page 105 This page is intentionally left blank X85X System...

-

Page 106: Connecting Guide Rails

7 .4 Connecting guide rails Pliers X85X System... - Page 107 X85X System...

- Page 108 info@fl exlink.com fl exlink.com...

Need help?

Do you have a question about the FlexLink X85X and is the answer not in the manual?

Questions and answers