Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Mercedes-Benz OM 470 Euro VI

- Page 1 OM 470, OM 471 and OM 473 Euro VI Operating Instructions Mercedes-Benz...

- Page 2 Symbols WARNING Warning notes make you aware of dangers which could pose a threat to your health or life, or to the health and life of others. Environmental note Environmental notes provide you with infor- mation on environmentally aware actions or disposal.

- Page 3 This is described on the data card. The engine systems are constantly updated to be state of the art. Mercedes-Benz reserves the right to make changes to the following: design equipment technical features Descriptions may therefore differ in individual cases from your engine system.

-

Page 4: Table Of Contents

Protection of the environment ....6 Maintenance ........41 Assembly equipment ....... 6 General notes ........41 Genuine Mercedes-Benz parts ....6 Service products ........42 Modifying the engine output ....7 Cleaning and care ........47 Safety/emergency running program ..7 Correct use .......... -

Page 5: Index

Index Correct use ..........7 Corrosion inhibitor/antifreeze ® AdBlue /DEF agent ............ 43 Consumption ........36 Gauge ..........27 Important safety notes ....38 Data card ..........61 Refuelling ......... 38 Data storage in the vehicle Service product ....... 46 Fault data ........... - Page 6 Poly-V-belt Replacing ......... 58 Gauge Routing ..........58 ® AdBlue /DEF ........27 Preparing for starting operation Genuine Mercedes-Benz parts ..... 6 see Starting operation Protection of the environment ..... 6 High-pressure cleaning ....... 47 Qualified specialist workshop ....8...

- Page 7 Index Engine, general ........ 15 Warning buzzer ........37 Refuelling Weights ..........62 ® AdBlue /DEF ........38 Winter diesel ........45 Fuels ..........37 Winter operation ......... 39 Requirements of the personnel ..18 Rev counter .......... 26 Roadside Assistance ......50 Running the vehicle in ......

-

Page 8: Introduction

® well as the AdBlue supply system. If you use parts which have not been approved by Mercedes-Benz, the operational safety of the engine system may be jeopardised. This could lead to malfunctions in safety-relevant systems. Protection of the environment Use only genuine Mercedes-Benz parts or parts of equal quality. -

Page 9: Modifying The Engine Output

The engine and the exhaust gas aftertreatment faults and defects system may not be modified. In the event of modification, Mercedes-Benz does not accept analyse vehicle functions, e.g. after an acci- responsibility for any damage arising as a result. dent... -

Page 10: Qualified Specialist Workshop

Mercedes-Benz recommends you visit a Mercedes-Benz Service Centre, (see addresses in the publication details on the inside of the back cover). -

Page 11: General Information

General information The engine brake is a decompression brake. It General information has a controlled exhaust valve which gives it high braking power. The engine brake is con- The engine is a four-stroke, water-cooled diesel trollable in steps or modulated. engine with direct injection. -

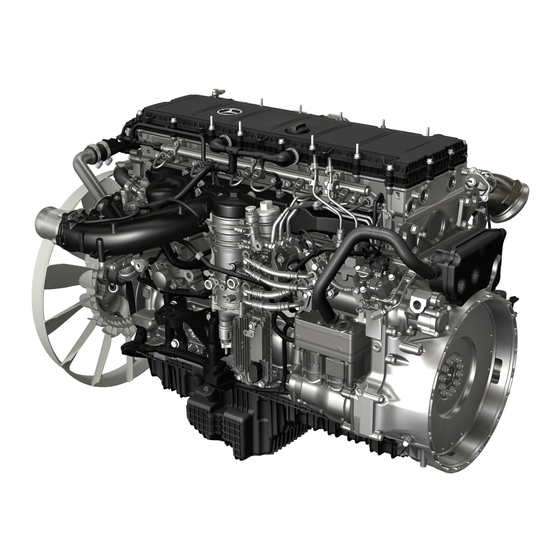

Page 12: Engine Overview

Engine overview Engine overview OM 471 engine overview Rail Oil filter Fuel filter Fuel hand pump High-pressure fuel pump Diesel fuel metering unit for active regeneration of diesel particle filter (DPF) Power-steering pump External engine start/engine stop button Air compressor Drain plug for water separator Dipstick Oil pan... - Page 13 Engine overview OM 471 engine overview Exhaust gas recirculation cooler Exhaust gas recirculation pipe (cold) Charge-air pipe (hot) Refrigerant compressor Belt tensioner for poly-V-belt Alternator Fan clutch Fresh air intake from air filter Crankcase ventilation system Starter motor Exhaust gas turbocharger Exhaust pipe to exhaust gas aftertreatment unit Nozzle unit for regeneration (DPF)

-

Page 14: Exhaust Gas Aftertreatment Overview

Exhaust gas aftertreatment overview Exhaust gas aftertreatment overview Exhaust gas pressure sensor upstream of the diesel oxidation catalytic converter Exhaust gas temperature sensors downstream of the diesel oxidation catalytic converter (top, bottom) Cover for diesel particle filter access (maintenance) Exhaust gas outlet Exhaust gas temperature sensor upstream of the diesel oxidation catalytic converter NOx sensor on exhaust gas aftertreatment unit inlet... -

Page 15: Electronic Engine Management

Electronic engine management Mounting bracket Mounting bracket Control unit for NOx sensor on exhaust gas aftertreatment unit inlet Exhaust gas aftertreatment control unit (ACM) Exhaust gas temperature sensor downstream of the SCR catalytic converter NOx sensor on exhaust gas aftertreatment unit outlet Control unit for NOx sensor at exhaust gas aftertreatment unit outlet Exhaust gas aftertreatment unit inlet Exhaust gas temperature sensor downstream of the diesel particle filter... - Page 16 Electronic engine management emergency mode is automatically selected In optional fan regulation, the solenoid valve page 26). If the electronic engine manage- on the fan clutch is activated according to ment control detects a fault, the fault code is coolant temperature. stored in the control units.

-

Page 17: Bluetec ® Exhaust Gas Aftertreatment

Warning and indicator lamps Daimler invalidates the engine's operation cer- Exhaust gas aftertreatment control tification/approval. unit (ACM) The exhaust gas aftertreatment control module (ACM) is secured to the exhaust gas aftertreat- Exhaust gas recirculation ment unit with a bracket or is secured to the vehicle in a protected location. - Page 18 Warning and indicator lamps During the display check, the indicator lamps Indicator Description are briefly actuated after the ignition is switched lamp é Cruise control The following warning and indicator lamps may be available on the instrument panel: (optional) È Indicator Description Speed limiter...

-

Page 19: Operating Safety

Always have the prescribed service/mainte- when taking measurements from electrical nance work as well as necessary repairs car- connectors (e.g. a Mercedes-Benz connec- ried out at a qualified specialist workshop. tion set). Telephones and two-way radio devices that are not connected to an exter-... -

Page 20: Staff Qualifications

Mercedes-Benz. Always keep the Operating Instructions and the Maintenance Booklet readily accessible, in the If the engine is switched off and devices con- area of engine operation. -

Page 21: Transport

Installation Transport WARNING If you do not lift the engine as described, the lugs intended for the purpose may be torn out or snap. This may be the case especially if the maximum permissible lug load is exceeded. The engine could then drop uncontrolled, causing serious or even fatal injury. -

Page 22: Installation

System (WIS) must be taken into account page 8). Observe the sections "Qualified specialist work- shop" ( page 8) and "Further applicable docu- ments" ( page 8). Please consult a Mercedes-Benz Service Centre if you have any questions ( page 8). -

Page 23: Preparation For Operation

Preparation for operation Switch the ignition lock to the drive position. Preparation for operation Wait for at least five minutes after switching Engine with initial operation oil from off the engine. the factory The current oil level information can only be The engine is filled at the factory with an initial called up when the vehicle is stationary and at operation oil. - Page 24 Preparation for operation The oil level must be corrected immediately; Checking the decoupling element there is a risk of engine failure. Checking the oil level with the dipstick Do not add too much oil. If you add too much oil, the engine or the exhaust aftertreatment unit could be damaged.

-

Page 25: Starting And Stopping The Engine

Starting and stopping the engine these exhaust gases leads to poisoning. There is a risk of fatal injury. Therefore never leave the engine running in enclosed spaces with- out sufficient ventilation. If the oil pressure in the engine is too low, a warning light lights up on the instrument panel. - Page 26 Starting and stopping the engine Stopping the engine WARNING When switching off the equipment or parking the vehicle, make sure that the exhaust sys- tem does not come into contact with com- bustible objects, e.g. dry leaves, grass or other highly flammable materials. WARNING If you switch off the ignition while the vehicle Example: ignition lock...

-

Page 27: Switching The Continuous Brake On And Off

Idling speed When the engine is switched off, the system If the continuous brake is deactivated and may continue to run for a short while. Depend- the à indicator lamp in the instrument ing on the installation position, operating cluster does not go out, have the continuous state and ambient temperature, circulation of brake checked at a qualified specialist work- shop. -

Page 28: Climate Control

Mercedes-Benz. Daimler AG recom- Searching for and eliminating the cause of the mends that the vehicle manufacturer uses a rev malfunction ( page 54). -

Page 29: Warning And Indicator Lamps

/DEF display is the responsibility of approximately 5 seconds. the vehicle manufacturer and is not necessarily In the third phase, the indicator lamp indicates supplied by Mercedes-Benz. Daimler AG recom- whether any emissions-related malfunctions mends that the vehicle manufacturer uses an have been detected. - Page 30 Warning and indicator lamps differ from those symbols displayed in the vehicle. Depending on the priority of the fault or warning, the warning and indicator lamps light up in different combinations. If you ignore warning and indicator lamps, you will not be able to recognise failures and malfunctions in components or systems.

- Page 31 Warning and indicator lamps Problem Possible causes/consequences and M M Solutions The 1 indicator lamp A malfunction was detected in the supply of engine lubricating oil. The lights up. operating safety of the engine is in danger. Stop the vehicle immediately, paying attention to road traffic con- ditions.

- Page 32 Warning and indicator lamps Problem Possible causes/consequences and M M Solutions indicator lamp The indicator lamp shows the status of the continuous brake. lights up. The indicator lamp lights up after activation of the continuous brake. Please also observe the information in the vehicle operating instruc- tions.

- Page 33 Warning and indicator lamps Problem Possible causes/consequences and M M Solutions The  and ٠indi- The diesel particle filter is in need of regeneration. cator lamps are lit. Deactivate the regeneration block ( page 35) and drive on a motorway or for a longer distance until the indicator lamp goes out.

- Page 34 Warning and indicator lamps Problem Possible causes/consequences and M M Solutions The ·, Ø and ® The AdBlue /DEF level has dropped to approximately 0%. The vehicle speed limiter has been activated. Vehicle speed is limited to approx- indicator lamps are imately 20 km/h.

- Page 35 Warning and indicator lamps ® Only vehicles without the AdBlue /DEF reserve warning light Problem Possible causes/consequences and M M Solutions The ; and · indi- An emissions-relevant malfunction in the exhaust gas aftertreatment cator lamps are lit. ® system or in the AdBlue /DEF supply has been detected.

-

Page 36: Operating Instructions

Operating instructions Vehicle version Operating instructions The following components affect fuel consump- Running-in tion: Vehicles tyres, e.g. tyre pressure, tyre condition, tyre size Observe the device manufacturer's running-in add-on equipment and vehicle cab version, notes. e.g. open platform, box-type body, platform The running-in period of the engine has a signif- with tarpaulin, bus body icant effect on the vehicle, especially with... -

Page 37: Important Safety Notes

Operating instructions Fuel-saving driving styles If too many particles collect in the diesel particle filter, the  indicator lamp in the instrument Environmental note cluster lights up. The exhaust gas aftertreat- ment system prompts you to start manual Only switch on the air-conditioning system regeneration. - Page 38 Operating instructions particles collecting quickly in the diesel particle The engine speed may rise and the engine filter. noise may change while regeneration is in process. Observe the increased engine speed To switch on/off: press the Ê button or when operating with an engine-connected switch.

- Page 39 Refuelling Warning buzzer WARNING Fuel is highly flammable. Improper handing of If the warning buzzer sounds and the 5 sym- fuel creates a risk of fire and explosion. bol on the instrument panel is displayed, the engine's operating safety is jeopardised. Avoid fire, naked flames, smoking and creat- Do not pull away, or stop the vehicle as soon as ing sparks under all circumstances.

- Page 40 Refuelling Special fuel additives can lead to: ® If AdBlue /DEF comes into contact with pain- ted or aluminium surfaces when filling the malfunctions tank, rinse the affected area immediately with damage to the catalytic converter plenty of water. engine damage ®...

- Page 41 Winter operation Coolant preheating plenty of water. Seek medical attention immediately. DANGER change clothing that has come into contact ® with AdBlue /DEF immediately. There is high voltage in the 230 V power ® socket if: AdBlue /DEF is not refilled as part of the main- tenance work.

- Page 42 Winter operation Diesel fuels Notes on diesel fuel at low temperatures page 45).

- Page 43 Always have the prescribed service/mainte- All maintenance intervals and work refer to nance work as well as necessary repairs car- genuine Mercedes-Benz parts. They also refer ried out at a qualified specialist workshop. to accessory parts and service products that...

- Page 44 Mercedes-Benz Service products Service Centre. Important safety notes Information about service products which have been tested by Mercedes-Benz and WARNING approved for your engine system can be Service product can be poisonous and haz- found in the Mercedes-Benz Specifications ardous to health.

- Page 45 Have excess oil drained off. engine oil of identical grade. When topping up, Mercedes-Benz recommends Therefore, only mix engine oils of differing that you only use engine oil of the same grade grade in exceptional circumstances.

- Page 46 When you have to refill coolant, only use approved corrosion inhibitor/antifreeze agents If you or others come into contact with fuel, page 64). Please note the Mercedes-Benz observe the following: Specifications for Service Products ( page 42). Wash the fuel off any affected areas of skin This prevents damage to the engine cooling sys- with water and soap immediately.

- Page 47 Mercedes-Benz Service Centre( page 8) or can fuel to improve its flow characteristics. Petrol be found in the Mercedes-Benz Specifications or kerosene impairs the lubricity of the diesel for Service Products in accordance with Sheet fuel. This can cause damage to the injection No.

- Page 48 Service products Avoid inhaling ammonia vapours. Only fill the ® AdBlue /DEF ® AdBlue /DEF tank in well-ventilated areas. Important safety notes ® AdBlue /DEF should not come into contact with skin, eyes or clothing, and should not be WARNING ®...

- Page 49 Regular care helps to maintain the value of the copper alloys engine. unalloyed steel Mercedes-Benz recommends that you only use galvanised steel care products that have been tested and approved for Mercedes-Benz. You can obtain If stored in these types of containers, constit-...

- Page 50 Only use wax-based protective agents for engines that comply with Sheet No. 385.4 of the Mercedes-Benz Specifications for Service Products. In addition, observe the notes in the "High-pres- sure cleaning" section (...

- Page 51 15 - 30 minutes at around 900 rpm. If the vehicle is to be decommissioned for longer than 6 months, further measures are required. For additional details, consult a Mercedes-Benz Service Centre ( page 8). Further information can be obtained from any Mercedes-Benz Service Centre.

- Page 52 Important safety notes When working on the vehicle, always comply Important safety notes with all safety regulations, such as operating instructions, regulations concerning hazardous WARNING materials, environmental protection measures, work safety and accident prevention regula- If you do not have the prescribed service/ tions.

- Page 53 Bleeding and draining the fuel system Starting the engine and increasing the Bleeding the fuel system without a engine speed fuel prefilter on the chassis frame Hold down external engine start/engine stop Bleed the fuel system with the manual fuel pump button : until the desired engine speed is on the engine.

- Page 54 You can obtain further information from any Then bleed the fuel circuit on the engine Mercedes-Benz Service Centre ( page 8). using the manual fuel pump at the main filter The vehicle-specific fuse allocation chart is pro- as described under "Bleeding the fuel system...

- Page 55 Jump-starting ist workshop, e.g. a Mercedes-Benz Service Wear eye protection. Centre. If a circuit fails, switch off the consumer equipment and switch the ignition lock to position 0. Keep children away. Checking and replacing a safety fuse Observe this Owner's Man- Pull the fuse out of the module using the pliers ual.

- Page 56 Troubleshooting Observe the following notes. You could oth- Vehicles without a jump-starting con- erwise damage the battery or electronic com- nection point ponents in the vehicle: do not use a battery quick-charge unit for jump-starting. if you use a mobile battery charger (battery device with mains power stage), remove the mains plug before jump-starting.

- Page 57 Troubleshooting Apart from careful operation and maintenance of the engine it is also important that malfunctions be rectified in good time. You can rectify certain faults yourself. Have malfunctions that you cannot eliminate yourself rectified at a qualified specialist workshop page 8).

- Page 58 Troubleshooting Problem Possible causes/consequences and M M Solutions The engine stops inad- The power supply to the engine management (MCM) or the exhaust vertently. gas aftertreatment (ACM) control modules is interrupted, or there is a short circuit in the wiring. Check the electrical fuses Have the power supply checked at a qualified specialist workshop.

- Page 59 Troubleshooting Problem Possible causes/consequences and M M Solutions An operating restriction is activated due to an emissions-relevant malfunction. Observe the notes on warning and indicator lamps ( page 27). There is an interruption The cause must be established in a qualified specialist workshop. in the tractive power.

- Page 60 Troubleshooting Problem Possible causes/consequences and M M Solutions The engine is "knock- The engine is misfiring. ing". The wrong fuel or fuel of lower quality has been refilled (see the service products section on diesel fuel) ( page 37). Exchange the fuel in the tank.

- Page 61 Troubleshooting Belt profile Engine with triple-belt system (fan on crankshaft) Refrigerant compressor or replacement pul- Engine with a dual-belt system (high-set fan) Refrigerant compressor or replacement pul- Guide pulley Coolant pump Guide pulley Belt drive B (fan) Coolant pump Tensioning pulley belt C Belt drive B (fan) Guide pulley Guide pulley...

- Page 62 Troubleshooting Belt drive A Belt drive C Refrigerant compressor or replacement pul- Belt drive C tensioner (fan) Guide pulley Crankshaft Coolant pump Poly-V-belt Poly-V-belt Guide pulley Fitting/removing poly-V-belts Crankshaft Insert the spanner, with the handle and exten- Alternator sion attached, 15 mm into the tensioner. Tensioning pulley (belt drive A) Swing back the tensioner.

- Page 63 The data card describes the scope of delivery from the Mercedes-Benz factory. Later changes to the scope of delivery are not recorded on the data card. Conversion parts on the engine system which...

- Page 64 Engine data Engine data OM 470 OM 471 Dimensions and weights A = engine 1551 All data refers to the standard version of the length with respective engine type. Deviations may occur, depending on the engine equipment and instal- lation situation in the vehicle/device. B = engine 1130 width...

- Page 65 Engine data General data All data refers to the standard version of the respective engine type. Data for other versions is available on request. Engine Engine type OM 470 OM 471 OM 473 Assembly model 470.9 471.9 473.9 series Type In-line engine with exhaust gas recirculation and charge-air pressure control Combustion prin-...

- Page 66 OM 473 Approx. 33 l (Sheet No. 326.5). Water quality (Sheet No. 310.1) Corrosion inhibitor/anti- Approx. 50% by volume freeze agent volume down to Ò 37 °C Mercedes-Benz Specifications for Service Products. Installation on the vehicle. Designed by the vehicle manufacturer.

- Page 67 Oil filter cap on the oil/coolant module 55 Nm Cooling system Coolant drain plug on the oil/coolant module 55 Nm OM 470 Cooling system Drain fitting on crankcase M18 x 1.5 30 Nm OM 471 and OM Mercedes-Benz Specifications for Service Products.

- Page 68 Engine data Exhaust gas Filter housing on the pump module 80 Nm aftertreatment Diesel particle filter V-band clamp on the exhaust gas after- 20 Nm treatment unit Diesel particle filter ribbon cable clamp on the exhaust gas 18 Nm aftertreatment unit Air dryer Granulate cartridge on the air dryer 15 Nm...

- Page 71 Publication details Internet Further information about Mercedes-Benz engines and Daimler AG can be found online at: www.mercedes-benz.com www.daimler.com www.powertrain.mercedes-benz.com Documentation team Should you have any questions or suggestions regarding this manual, you can reach the tech- nical documentation team at the following...

- Page 72 É4705843681!ËÍ 4705843681 Order no. 6462 9883 02 Part no. 470 584 36 81 Edition 12-16...

Need help?

Do you have a question about the OM 470 Euro VI and is the answer not in the manual?

Questions and answers

Timing marks gear engine