Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for Mercedes-Benz OM 904-926 LA BlueTec

- Page 1 ® OM 904-926 LA BlueTec , OM 904-926 LA Operating Instructions...

- Page 2 Symbols Warning Environmental note Possible vehicle damage Instructions Continuation symbol (Y page) Page reference...

- Page 3 Welcome to the world of Mercedes-Benz Familiarise yourself with your engine and read the Operating Instructions before you use the engine. This will help you to avoid endanger- ing yourself or others. The standard equipment and product descrip- tion of your engine may vary, depending on individual specifications.

-

Page 5: Contents

Contents Index ............4 At a glance ........... 13 General information ......7 Safety ........... 29 Driving mode/working mode ..... 33 Maintenance and care ......45 Notes on maintenance ....... 59 Decommission and protection ... 79 Breakdown assistance ....... 85 Technical data ........ -

Page 6: Index

Index Coolant (engine) Topping up ........76 Adaptation module ......21 Coolant additive ........48 ® AdBlue /DEF Cooling system Components ........19 Degreasing ........76 Consumption ........41 Flushing ........... 76 Refuelling ......... 42 Correct use ..........9 Replacing the filter ......69 Corrosion inhibitor/antifreeze Service product ....... -

Page 7: Index

Adding ..........63 For winter operation ......46 Mixing ..........48 Maintenance ........56 Oil change ........47 Mercedes-Benz Service Centre Siphoning and draining ....62 see Qualified specialist workshop Topping up ........48 Modifications and changes ....7 Engine oil consumption ...... 41 Engine overview ........ - Page 8 Index Preparing for starting operation Sulphur content of fuel ....... 51 see Starting operation Protection of the environment ..... 7 Protective treatment ......81 Technical data ........101 Dimensions ........101 Filling capacities ......104 Qualified specialist workshop ... 11 Operating data .......

-

Page 9: General Information

Malfunctions such as these can Mercedes-Benz or MTU Service Centre. seriously jeopardise the vehicle's operating safety and therefore your own safety. Other work or modifications incorrectly car-... -

Page 10: Emergency Running Program

Mercedes-Benz recommends a Mercedes- the work required. Mercedes-Benz recom- Benz or MTU Service Centre. mends that you use a Mercedes-Benz or MTU The Daimler diagnostic tester can be Service Centre for this purpose. attached to the 14-pin diagnostic socket on... -

Page 11: Correct Use

Mercedes-Benz parts. You can find the num- aftertreatment system bers on the identification plate of your engine You can find details in the “Engine diagnostics page 100) and on the engine data card indicator lamp”... -

Page 12: Installation

Data" section" ( page 101). Only use Mercedes-Benz transport equip- Please consult a Mercedes-Benz or MTU ment intended for this purpose. Service Centre if you have any questions Only lift and transport the engine in the page 11). -

Page 13: Specialist Workshop

Maintenance work does not include repair work. Repair work requires a separate order. You may also consult a Mercedes-Benz or MTU Service Centre for further information. Qualified specialist workshop A qualified specialist workshop has the nec-... - Page 15 Exterior view ........14 General information ......21...

-

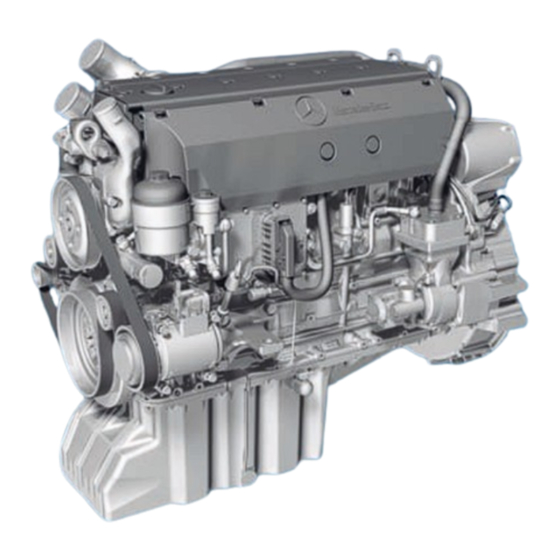

Page 16: Engine Overview

Exterior view Exterior view Engine overview Engine overview OM 904 LA Filler neck Stop button Start button Air compressor Power-steering pump Engine control (MR) control unit Oil dipstick Refrigerant compressor Tensioning pulley Coolant pump Fuel prefilter Fuel filter... - Page 17 Exterior view Engine overview OM 904 LA ® AdBlue /DEF metering unit Charge air pipe of the charge-air cooler Charge air pipe to the charge-air cooler Crankcase ventilation hose Oil filter Tensioning pulley Alternator Starter Intake air inlet Engine brake...

- Page 18 Exterior view Engine overview OM 906 LA Filler neck Stop button Start button Air compressor Power-steering pump Engine control (MR) control unit Oil dipstick Refrigerant compressor Tensioning pulley Fuel filter Coolant pump Fuel prefilter Coolant outlet to the radiator...

- Page 19 Exterior view Engine overview OM 906 LA ® AdBlue /DEF metering unit Charge air pipe of the charge-air cooler Charge air pipe to the charge-air cooler Crankcase ventilation hose Oil filter Tensioning pulley Alternator Starter Intake air inlet Exhaust gas turbocharger Engine brake...

-

Page 20: Overview, Sensors

Exterior view Sensors overview Sensors, general Example: OM 926 LA Oil temperature Oil pressure Coolant temperature Charge-air temperature/charge-air pressure TDC sensor (on camshaft gear) Crankshaft position sensor (on flywheel) Oil level Fuel temperature... -

Page 21: Components

Exterior view ® AdBlue /DEF components ® BlueTec sensors, overview OM 924 LA ® Valve preheating, AdBlue /DEF system Silencer Temperature and humidity sensor (air filter, clean air side) Metering unit Temperature sensor downstream of catalytic converter NOx sensor Temperature sensor upstream of catalytic converter SCR frame module Supply unit ®... - Page 22 Exterior view ® BlueTec sensors, overview OM 926 LA ® Valve preheating, AdBlue /DEF system Silencer Temperature and humidity sensor (air filter, clean air side) Metering unit Temperature sensor downstream of catalytic converter NOx sensor Temperature sensor upstream of catalytic converter SCR frame module Supply unit ®...

-

Page 23: Description Of The Engine

General information ® BlueTec sensors and test connection on the metering unit. Example: OM 926 LA ® AdBlue /DEF pressure sensor ® AdBlue /DEF temperature sensor Pressure sensor for compressed air Metering unit test connection Metering unit heater Metering valve pumps sit directly in the crankcase and are General information driven by the camshaft. -

Page 24: Electronic Drive Control

General information These values are analysed together with data Electronic drive control from the engine sensors. They are compared The engine has a fully electronic control sys- with the charts or characteristic curves tem which, along with the engine and its asso- stored in the engine control unit. -

Page 25: Adaptation Module

General information FR (drive control) unit or ADM (on the Mercedes-Benz diagnostic testers can be equipment) connected to the 14-pin diagnostic socket on the equipment or with the EU compliant The engine can be adapted to the various service connector. Both fault memory and... - Page 26 General information Example: EU compliant service connector...

-

Page 27: Cold-Start Aid

General information Warning and indicator lamps Engine, general Reason for display/displayed message Symbol Fault lamps Impermissible operating conditions Text in the engine symbol: "CHECK" STOP lamp Serious fault Text in the engine symbol: "STOP" Electronic Lights up in the event of an electronic engine con- engine control trol malfunction. -

Page 28: Continuous Brake

General information ® BlueTec exhaust gas aftertreatment off-highway version The following indicator lamps could be available on the instrument panel: Reason for display/displayed message Symbol Fault message/action required (warning þ ® AdBlue /DEF level before reduction in operating performance) Check engine/exhaust gas Fault and misuse (failure in the monitoring aftertreatment system) -

Page 29: Cold-Start Aid

General information exhaust port. This brings about the desired The cold-start aid is automatically deactiva- decompression during the power stroke. ted if: When the engine brake is activated, the con- the engine is not started within 30 seconds stant throttle valves are opened. For of the % indicator lamp going out. -

Page 31: Safety

Safety precautions ......30 Staff qualifications ......30 Organisational measures ....30... -

Page 32: Organisational Measures

Only use the appropriate testing probes injure yourself or others. when taking measurements from electri- Instruct personnel on how to operate the cal connectors (e.g. a Mercedes-Benz engine using the Operating Instructions. connection set). Telephones and two- When doing so, put special emphasis on way radio devices that are not connected safety-relevant information. - Page 33 Organisational measures larly important for personnel that only work occasionally on the engine. Always keep the Operating Instructions and the Maintenance Booklet readily accessible, in the area of engine operation. In addition to the Operating Instructions, other general, country-specific, legal and other binding regulations on accident preven- tion and environmental protection must be adhered to.

-

Page 35: Table Of Contents

Operation ..........34 Continuous brake ........ 40 Driving tips .......... 40 Refuelling ..........41 Winter operation ......... 43... -

Page 36: Operation

The extended maintenance intervals can only Information on coolant mixture ratio be observed if engine oils complying with page 76). Sheet 228.5 of the Mercedes-Benz Specifi- cations for Service Products are used. Filling the cooling system ( page 48). Refuelling... -

Page 37: Starting The Engine For The First Time

Operation Use the integrated hand pump Therefore you should: page 68) to bleed the heated-fuel pre- keep a safe distance between yourself and filter with water separator mounted on the rotating engine parts, including when the vehicle or equipment. engine is being started. wait until all engine parts have stopped moving before carrying out any work on the Starting the engine for the first time... -

Page 38: Starting

Operation coolant in the coolant circuit after it is filled. To start the engine: turn the key in the Only close the heating system valves once the ignition lock to drive position 2. engine has been running for a brief period Vehicles/equipment with a hot-water aux- and, where applicable, the coolant has been iliary heater: preheat the engine at outside... -

Page 39: Charge Current

Operation Engine with one button To start the engine: press start but- ton ;. The engine starts and runs at engine idling speed. To increase the engine speed: while the engine is running, press start button ; again and hold it down until the desired engine speed is reached. -

Page 40: Electronic Engine Control

Operation Oil pressure Make sure that the poly-V-belt contact surfaces are not damaged (e.g. torn), oily Once the operating temperature has been or glazed, as this could cause the poly-V- reached, the engine oil pressure may not belt to slip. Do not run the engine without drop below the following values: a poly-V-belt. -

Page 41: Stopping

Operation tem, the torque is reduced automatically after override function is also used to reset the 36 operating hours of the engine. operating restriction after the fault is correc- ted. This is the case, for example, after filling ® Operating restrictions for off-highway up with AdBlue /DEF of the correct quality. -

Page 42: Continuous Brake

Driving tips Let the engine idle for approximately two Continuous brake minutes before switching off the engine if: The airbrake and the constantly open throttle the coolant temperature is very high (over valves are employed as continuous brakes. 90 †). the engine has been operated at full output. -

Page 43: Refuelling

Refuelling Operating conditions pedal beyond the point of resistance (kick- down) and only engage the shift ranges 4, Fuel consumption can increase due to poor 3, 2, or 1 when driving slowly. operating conditions. After 2000 km (30 operating hours), you can Observe the following notes: gradually bring the vehicle up to full road and avoid driving in mountainous terrain. - Page 44 Refuelling You will find further information on fuel in the fuel does not come into contact with skin, "Service products" section ( page 50). eyes or clothing. you do not inhale fuel vapours. Environmental note children are kept away from fuel. If fuels are handled improperly, they pose a If you or anyone else comes into contact with danger to persons and the environment.

-

Page 45: Winter Operation

Winter operation Bleeding the fuel system WARNING ® AdBlue /DEF must not come into contact If the fuel system is run dry, the system will with skin, eyes or clothing. be bled the next time the engine is started after refuelling. Automatic continuous bleed- ®... - Page 46 Winter operation Coolant gloves, an apron and a face mask. WARNING Immediately rinse acid When opening the coolant expansion tank, splashes off with clean there is a risk of scalding due to hot coolant water. Consult a doctor if spraying out. The cooling system and coolant necessary.

- Page 47 Service products ......... 46 Cleaning and care ....... 55 Maintenance ........56...

-

Page 48: Engine Oil

Do not inhale the vapours. When indoors, You can recognise service products approved always ensure there is sufficient ventilation by Mercedes-Benz by the following inscrip- to prevent intoxication. tion on the container: Do not let service products come into con- MB Approval (e.g. -

Page 49: Oil Change

Maintenance Booklet. engine oils that comply with Sheet no. 228.5 Single-grade engine oils compliant with Sheet of the Mercedes-Benz Specifications for no. 228.2 / 228.0 only cover an SAE class Service Products. (viscosity) for a certain temperature range. -

Page 50: Service Product

Coolants change intervals by using engine oils of particularly high quality (e.g. in accordance Coolant additive with antifreeze prop- with Sheet no. 228.5 of the Mercedes-Benz erties Specifications for Service Products). The coolant is a mixture of water and corro- Environmental note sion inhibitor/antifreeze. -

Page 51: Corrosion Inhibitor/Antifreeze Agent

Further information about operating and road Before topping up, observe the quality of the safety for your engine/vehicle/equipment is corrosion inhibitor/antifreeze agent in the available from any Mercedes-Benz or MTU cooling system (Sheet no.). Corrosion inhibi- Service Centre ( page 11). -

Page 52: Fuels

You may obtain informa- tion about current country-specific fuel sul- WARNING phur contents from any Mercedes-Benz or Avoid contact with fuels. MTU Service Centre ( page 11). It is hazardous to your health if your skin... -

Page 53: Sulphur Content Table

(% by weight). You can find a continually updated table of fuel sulphur contents in specific countries in the Mercedes-Benz Specification for Service Products, Sheets 136.1 and 136.2 at http:// bevo.mercedes-benz.com. Countries that are mentioned more than once offer different fuel grades with varying fuel sulphur contents in parallel. -

Page 54: Low Outside Temperatures

Service products Fuel sulphur content (proportion by weight, in percent) Continent Country % by weight Iran, Iraq, Jordan, Yemen 0.8 ... North America Canada, Mexico, USA 0 ... 0.1 Central Amer- 0 ... 0.1 Argentina , Bolivia, Brazil, Chile ica, South Argentina, Brazil, Columbia, Costa Rica, Ecuador, Suri- 0.1 ... -

Page 55: Fame Fatty Acid Methyl Ester Fuel

Service products from all Mercedes-Benz or MTU Service Cen- if the vehicle is not used for long periods tres ( page 11). of time, FAME fatty acid methyl ester fuel can clog fuel system components. For If you add a flow improver to the FAME fatty... -

Page 56: Service Product

Ammonia vapours have a pungent odour and exhaust gas aftertreatment. particularly irritate: Observe the specifications in accordance skin with Sheet no. 135.0 of the Mercedes-Benz mucous membranes Specifications for Service Products for oper- eyes ation with FAME fatty acid methyl ester fuel. -

Page 57: Care Products

BlueTec exhaust Mercedes-Benz recommends that you only gas aftertreatment beyond repair. use care products that have been approved for Mercedes-Benz. You can obtain these Disposal care products from any Mercedes-Benz or MTU Service Centre ( page 11). -

Page 58: Maintenance

Do not point the water jet at: carry out the work required. Mercedes-Benz recommends that you use a electrical components Mercedes-Benz or MTU Service Centre for plug connectors this purpose. All work relevant to safety or on... - Page 59 Maintenance Mercedes-Benz or MTU Service Centre. Dis- pose of empty containers, cleaning cloths and care products in an environmentally respon- sible manner. Observe the instructions for care products. Do not let the engine run lon- ger than necessary when stationary.

- Page 61 Work schedule overview ....60 Work schedules ........62...

-

Page 62: Replacing The Filter

Fuel filter: replace fuel filter element. For operation with FAME fuels (bio-diesel): replace fuel filter at the same time as renewing the engine oil and replacing the filter. Engine brake: check condition and setting. • • Work item number of the Mercedes-Benz workshop information system (WIS). - Page 63 Replace air filter element according to equipment/vehicle manufacturer's specifications. Observe installation date. Final inspection Visual check/road test/test rig: check that the equipment is safe to operate/ • • check that the vehicle is roadworthy. Work item number of the Mercedes-Benz workshop information system (WIS).

-

Page 64: Siphoning And Draining

Work schedules Siphoning and draining engine oil Work schedules Environmental note Changing the engine oil and filter Dispose of engine oil and filters in accordance Temperature for oil and filter change with the applicable regulations for your loca- tion. Only change the engine oil when the engine is at normal operating temperature. - Page 65 Work schedules engine oil in accordance with outside tem- peratures. Start the engine without depressing the accelerator pedal. When running at idling speed, observe the oil pressure display. Keep the engine running at idling speed until an oil pressure reading is displayed. If no oil pressure is displayed after approx- imately 10 seconds, switch off the engine.

-

Page 66: Valve Clearance

Work schedules Special tool WARNING If the engine starts automatically, there is a risk of injury by limbs being crushed between the moving parts. Secure the engine against unintentional start- ing before carrying out maintenance or repair work. WARNING The engine becomes very hot while it is run- ning and remains so for some time after it has stopped. - Page 67 Work schedules Clean very dirty cylinder head covers I – inlet valve before removal. E – exhaust valve Remove engine ventilation hose : from Valve clearance setting OM 906/926 LA cylinder head cover ;. Crankshaft Cylinder/valves to be Remove cylinder head cover ;. position adjusted Remove seal A between the cylinder head...

-

Page 68: Damage Patterns

Work schedules Measure the valve clearance between the Check the poly-V-belt condition regu- rocker arm and valve bridge using a feeler larly. gauge (arrow). It should be possible to pull Replace the poly-V-belt concerned through the feeler gauge with only light immediately if there are any signs of resistance. -

Page 69: Fuel Filter

Work schedules New condition (for comparison; trapezoi- Rib detached from the base of the belt dal ribs) Single-sided wear: wedge-shaped ribs Cord visible at the base of the belt Cord torn out of the side Outer cord frayed Breaks in the ribs Transverse cracks in several ribs Transverse cracks on the back of the belt Transverse cracks in several ribs... - Page 70 Work schedules Leakage fuel from the engine Vehicle with fuel prefilter at tank level: To the fuel pump close shutoff valve ?. From the fuel tank Place a collector under water drain valve Fuel return line to the fuel tank Open water drain valve E and bleed screw Fuel pump =.

-

Page 71: Replacing The Fuel Filter

Work schedules Start the engine and bleed the fuel system. Clean the outside of the filter housing. Run the engine for approximately 1 minute. Open the fuel filler cap to prevent excess The fuel system bleeds automatically. pressure in the fuel tank. If the engine stalls or does not start, bleed Unscrew fuel filter cap : using a socket the fuel system manually (... - Page 72 Work schedules ® If AdBlue /DEF gets into the coolant cir- Ammonia vapours have a pungent odour and cuit (even minute amounts), thermostats particularly irritate: and temperature sensors will be damaged. skin ® Always keep AdBlue /DEF completely mucous membranes separate from other service products.

-

Page 73: Important Safety Notes

Work schedules Insert new filter element ; into filter bowl ?. Use MB silicon grease as a lubri- cant. Screw filter bowl ? into pump module : and tighten. Tightening torque: 32 Nm. Only MB silicon grease is permissible as a lubricant. - Page 74 Work schedules ing hose is disconnected from the valve, a ® Keep AdBlue /DEF out of the reach of chil- pressure loss of 0.2 bar takes place. dren. To reduce the pressure: press but- ton ; several times. Environmental note ®...

-

Page 75: Antifreeze

Work schedules Engine cooling system Checking and correcting the fluid level and the antifreeze/corrosion inhibitor WARNING When opening the coolant expansion tank, there is a risk of scalding, due to hot coolant spraying out. The cooling system and coolant expansion tank are pressurised when the engine is at operating temperature. - Page 76 Mercedes-Benz recommends that you use a Mercedes-Benz or MTU Service Centre for this purpose ( page 11). Work relevant to safety or on safety-related systems must...

-

Page 77: Renewing

Work schedules Check the coolant level and correct if nec- essary. Replace coolant expansion tank cap and tighten it. Renewing the coolant WARNING When opening the coolant expansion tank, there is a risk of scalding, due to hot coolant spraying out. The cooling system and coolant expansion tank are pressurised when the engine is at operating temperature. -

Page 78: Flushing

If necessary, degrease the cooling system Coolant contains glycol and is therefore toxic. with a suitable cleaning agent. Information Do not swallow the coolant. See a doctor is available from any Mercedes-Benz or immediately if you swallow coolant. MTU Service Centre ( page 11). -

Page 79: Condition

Work schedules Checking for leaks and general condi- WARNING tion – assemblies There is a danger of limbs being caught, pulled in and thereby crushed or severed by rotating Carry out a visual inspection of the engine engine parts. Therefore you should: for signs of leaks. - Page 81 Decommissioning the engine .... 80 Protecting the engine ......81...

-

Page 82: Decommissioning The Engine

Decommissioning the engine ® Fill up the AdBlue /DEF supply reservoir Decommissioning the engine ® completely so that AdBlue cannot crys- Particular measures are necessary when the tallise out. engine/vehicle/equipment is to be decom- Fuel prefilter with heated water separator: missioned. -

Page 83: Decommissioning

Protecting the engine Leave the engine running until the air com- Check that the electrical system, steering pressor cutoff pressure is reached. system and brakes are functioning cor- rectly. Fuel prefilter with heated water separator: drain off the water separator. Clean the engine/vehicle/equipment thor- oughly. - Page 84 Protecting the engine Close off all openings on the engine (e.g. 15 – 20 cm initial operation oil into each on the charge-air housing, exhaust etc.) cylinder. with an oil-soaked rag. Drain off the coolant completely for Protecting the air compressor engines that have been removed.

-

Page 85: Re-Commissioning

Protecting the engine The following work is required for engines viously filled anticorrosion/antifreeze that have been run in (distance of over page 48). 300 km or running time of over 6 operating New engines: add initial operation oil com- hours): pliant with Sheet 225.6. - Page 87 General notes ........86 Bleeding the fuel system ....86 Activating engine emergency run- ning mode ..........87 Troubleshooting ........89 ® BlueTec exhaust gas aftertreat- ment indicator (on-highway ver- sion) ............. 94 ® BlueTec exhaust gas aftertreat- ment indicator (off-highway ver- sion) .............

-

Page 88: General Notes

Have malfunctions that you cannot eliminate yourself rectified at a qualified specialist workshop. Mercedes-Benz recommends that you go to a Mercedes-Benz or MTU Service Centre, as they have the necessary knowledge and tools to carry out the required work ( page 11). -

Page 89: Activating Engine Emergency Running Mode

Activating engine emergency running mode Draining the fuel prefilter Activating engine emergency running mode Environmental note Emergency mode for on-highway Dispose of the water-fuel mixture in an envi- applications ronmentally responsible manner. Emergency mode can be activated for road Drain the fuel prefilter regularly. vehicles with Euro 4/5 certified engines (on- Place a collector under water release valve highway engines). - Page 90 Activating engine emergency running mode using this diagnostic equipment. Informa- tion is available from any Mercedes-Benz or MTU Service Centre ( page 11). Emergency mode for off-highway applications Full engine output can be activated with an emergency switch for devices with Euromot 3B or Tier 4i certified engines (off-highway applications).

-

Page 91: Troubleshooting

Mercedes- Benz recommends that you use a Mercedes-Benz or MTU Service Centre for this purpose. In particular, work relevant to safety or on safety-related systems must be carried out at a qualified specialist workshop. - Page 92 Troubleshooting Problem Possible causes/consequences and M Solutions Fuel is not resistant to cold. Replace the fuel prefilter ( page 68). Replace the fuel filter ( page 69). Use winter fuel ( page 52). Incorrect engine oil viscosity. Alter the engine oil viscosity to the conditions of use page 47).

- Page 93 Troubleshooting Problem Possible causes/consequences and M Solutions The engine's output is Air filter is dirty or blocked. poor (lack of power). Replace the air filter element. Charge-air temperature is too high - charge-air cooler or radiator exterior is dirty. Clean the outsides of the charge-air cooler and radiator. Coolant temperature is too high.

- Page 94 Troubleshooting Problem Possible causes/consequences and M Solutions Engine braking effect is There is an engine brake flap malfunction or a fault in the actua- poor. tion. Carry out a function check/visual check. Consult a qualified specialist workshop. Fuel consumption is Connection points (unit pump - line and fuel injectors) are leaking too high.

- Page 95 Troubleshooting Problem Possible causes/consequences and M Solutions Poly-V-belt is torn. Replace poly-V-belt ( page 97). Alternator or sensor is defective. Check alternator or sensor. Consult a qualified specialist workshop. Engine emits black Air filter is very dirty. smoke. Replace the air filter element. Engine brake is faulty.

-

Page 96: Bluetec ® Exhaust Gas Aftertreatment Indicator (On-Highway Version)

Mercedes- Benz recommends that you use a Mercedes-Benz or MTU Service Centre for this purpose. In particular, work relevant to safety or on safety-related systems must be carried out at a qualified... -

Page 97: Bluetec ® Exhaust Gas Aftertreatment Indicator (Off-Highway Version)

® BlueTec exhaust gas aftertreatment indicator (off-highway version) Problem Possible causes/consequences and M Solutions The ; indicator if there are no malfunctions, the ; indicator lamp lights up lamp lights up briefly briefly during the instrument cluster's display check and then goes and goes out again. - Page 98 ® BlueTec exhaust gas aftertreatment indicator (off-highway version) System message ® AdBlue /DEF level 30 minutes after trigger 2 ® The å AdBlue /DEF indicator lamp flashes. The È torque limitation indicator lamp lights 60 minutes after trigger 2 ® The å...

-

Page 99: Replacing The Poly-V-Belt

Replacing the poly-V-belt Fault in the monitoring system If faults occur, the system registers the following warnings: Fault System message Trigger 4: ® The å AdBlue /DEF indicator lamp lights up. The È torque limitation indicator lamp lights ® AdBlue /DEF tank sensor missing ®... -

Page 100: Routing

Replacing the poly-V-belt Releasing the poly-V-belt (example) Fit the spanner with extension element and 15 mm socket spanner insert into the ten- sioning device. Swing the tensioning pulley up and remove Poly-V-belt routing (engine with refrigerant com- the poly-V-belt. pressor) Swing back the tensioning device. - Page 101 Vehicle identification plate ....100 Information on the identification plate ........... 100 Engine model designation ....100 Engine data card ....... 100 Engine data ........101 Operating restriction - off-highway version ..........106...

-

Page 102: Data Card

Example: identification plate for road vehicles (on- The engine data card must be presented or highway engine) the complete engine number must be speci- Manufacturer's name fied for the procurement of genuine Engine type description Mercedes-Benz parts. Engine number... -

Page 103: Dimensions

Later changes to the scope of delivery are not recorded on the data card. Conversion parts on the engine which change the scope of the engine delivered by Mercedes-Benz must be recorded on the data card. In order to prevent incorrect ordering of replacement parts, the Mercedes-Benz replacement parts service must also be informed. -

Page 104: Weights

Engine data Weights OM 904 LA OM 906 LA OM 924 LA OM 926 LA Dry engine 395 kg 530 kg maximum Wet engine 420 kg 573 kg maximum... - Page 105 Engine data General data All data refers to the standard version of the respective engine type. Data for other versions is available on request. Engine Engine type OM 904 LA OM 906 LA OM 924 LA OM 926 LA Assembly model series 904.9 906.9 924.9...

-

Page 106: Capacities

Engine data Operating data Engine type OM 904 LA/OM 924 LA OM 906 LA/OM 926 LA Rated engine speed 2200 rpm 2200 rpm Effective engine speed range 2500 rpm 2500 rpm Idling speed Approximately 600 rpm Approximately 600 rpm Engine brake permissible up to 2700 rpm 2700 rpm Engine speed limiter (emergency... -

Page 107: Tightening Torques

Engine data Capacity Service product approx- (sheet no. imately – MB silicon grease ® AdBlue /DEF filter sealing rings Cooling sys- Total capacity OM 904/924 LA 8.5 litres Coolant (310.1, tem (with- 325.0/2, 326.0/2, OM 906/926 LA 12.5 litres out inter- 325.3, 326.3) Corrosion inhib- OM 904/924 LA... -

Page 108: Torque Reduction

Operating restriction - off-highway version Oil circuit Drain plug on the oil pan M 20 x 1.5 70 Nm M 26 x 1.5 90 Nm Oil filter cap on the oil filter housing 40 Nm Cooling system Coolant drain screw On the crankcase 60 Nm On the radiator... - Page 109 Operating restriction - off-highway version Recurring fault Regular operating restriction Operating restriction after first recurrence of fault Operating restriction after second recur- rence of fault...

- Page 111 Imprint Internet You will find further information about Mercedes-Benz engines, Daimler AG and Togum AG on the Internet at: www.mercedes-benz.com www.daimler.com www.mtu-online.com Editorial office You are welcome to forward any queries or suggestions you might have regarding these Operating Instructions to the technical docu-...

- Page 112 É9265840681ÁËÍ 9265840681 Order no. 6462 9820 02 Part no. 926 584 06 81 Edition A 06-11...

Need help?

Do you have a question about the OM 904-926 LA BlueTec and is the answer not in the manual?

Questions and answers

Двигатель OM 926 LA на автобусе МАЗ 103486 антифриз обнаружен в топливном баке, печка отопителя не запускается, не подскажите где искать причину

как антифриз может попасть в топливо