Table of Contents

Advertisement

Quick Links

Read and follow these instructions and all

safety blocks carefully.

Have only trained and qualified persons

install, operate, or service this unit.

Call your distributor if you do not understand

the directions.

auto_arc 7/93 − ST-145 104

OWNER'S

MANUAL

AASW 1510M

Manually Operated, 1.5 kVA Portable Spot Welder

For Resistance Spot Welding

Rated Output Varies With Tong Length

Uses 110 V, 60 Hz, Single-Phase Input Power

Equipped With A 10 ft (3 m) Input Power Cord With Plug

1994 MILLER Electric Mfg. Co.

October 1994

Form: OM-118 044C

Effective With Serial No. KE664390

Give this manual to the operator.

For

help,

MILLER Electric Mfg. Co., P.O. Box 1079,

Appleton, WI 54912

call

your

distributor,

414-734-9821

PRINTED IN USA

or:

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for AUTO ARC AASW 1510M

- Page 1 Form: OM-118 044C Effective With Serial No. KE664390 OWNER’S MANUAL AASW 1510M Manually Operated, 1.5 kVA Portable Spot Welder For Resistance Spot Welding Rated Output Varies With Tong Length Uses 110 V, 60 Hz, Single-Phase Input Power Equipped With A 10 ft (3 m) Input Power Cord With Plug Read and follow these instructions and all Give this manual to the operator.

- Page 3 RESISTANCE SPOT WELDING SAFETY PRECAUTIONS WARNING SPOT WELDING can be hazardous. PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN AWAY. PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING YOUR DOCTOR. In resistance spot welding, as in most jobs, exposure to certain hazards occurs. Spot welding is safe when precautions are taken.

- Page 4 PRINCIPAL SAFETY STANDARDS Safety in Welding and Cutting, ANSI Standard Z49.1, from American Code for Safety in Welding and Cutting, CSA Standard W117.2, from Welding Society, 550 N.W. LeJeune Rd, Miami FL 33126 Canadian Standards Association, Standards Sales, 178 Rexdale Bou- levard, Rexdale, Ontario, Canada M9W 1R3.

-

Page 5: Section 1 − Safety Information

SECTION 1 − SAFETY INFORMATION mod1.2 4/93 Read all safety messages throughout this manual. Obey all safety messages to avoid injury. Learn the meaning of WARNING and CAUTION. Safety Alert Symbol Signal Word WARNING means possible death or serious injury can happen. WARNING CAUTION CAUTION means possible minor... -

Page 6: Section 3 − Installation

2-1. Duty Cycle CAUTION EXCEEDING DUTY CYCLE RATINGS will damage unit. • Do not exceed 50% duty cycle. warn7.1* 2/92 The duty cycle of a resistance spot welder is the percentage of a one minute period that a resistance spot welder can be operated without causing overheating or damage to the unit. - Page 7 3-2. Tong Pressure Adjustment WARNING ELECTRIC SHOCK can kill. EXCESSIVE TONG PRESSURE can • damage tips. Do not touch live electrical parts. • • Do not use tongs as a clamp or vice to hold Turn Off unit, and disconnect input power cord plug workpiece together.

-

Page 8: Connecting Input Power

3-3. Connecting Input Power WARNING ELECTRIC SHOCK can kill. • Do not touch live electrical parts. • Do not cut ground terminal off plug. • Input supply wiring and receptacle must meet National Electrical Code and all other codes. swarn3.1* 2/93 Operate spot welder from a sepa- rately fused or circuit breaker pro- tected circuit, and use correct size... -

Page 9: Section 5 − Maintenance & Troubleshooting

Install & Put On Connect Personal Safety Begin Welding Equipment Equipment Figure 4-2. Sequence Of Resistance Spot Welding SECTION 5 − MAINTENANCE & TROUBLESHOOTING WARNING ELECTRIC SHOCK can kill. MOVING PARTS can injure. • • Do not touch live electrical parts. Do not put hands between tips. -

Page 10: Troubleshooting

5-4. Changing Tongs For changing resistance spot welder tongs, see Section 3-1. 5-5. Cleaning Tongs READ SAFETY BLOCKS at start of WARNING Section 5 before proceeding. Wipe both tongs and tong holders clean. Bends or nicks near the tong ends that insert into the tong holders may reduce the maximum efficiency and capacity of the spot welder. -

Page 11: Section 6 − Electrical Diagrams

SECTION 6 − ELECTRICAL DIAGRAMS SA-162 467 Figure 6-1. Circuit Diagram For Spot Welders OM-118 044 Page 7... -

Page 12: Section 7 − Parts List

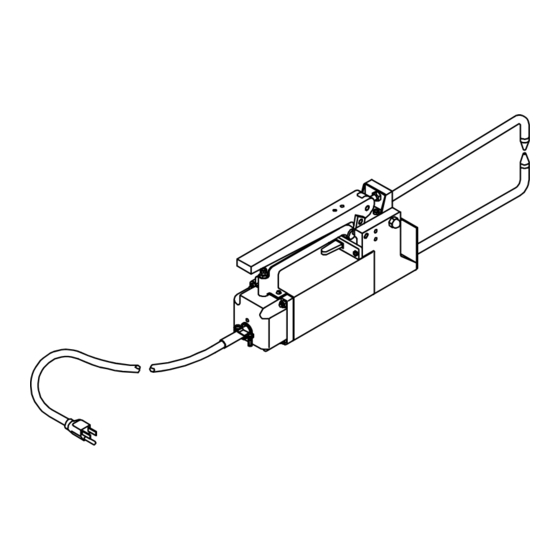

SECTION 7 − PARTS LIST Fig 7-2 ST-145 048 Figure 7-1. Main Assembly OM-118 044 Page 8... - Page 13 Item Dia. Part Mkgs. Description Quantity Figure 7-1. Main Assembly ....019 643 HANDLE, carrying ..........

- Page 14 Replace Coils At Factory Or Factory Authorized Service Station Item Part Description Quantity 095 347 Figure 7-2. Transformer, Power Main (Fig 7-1 Item 38) ..026 601 INSULATION .............

- Page 15 Warranty Effective January 1, 1997 (Equipment with a serial number preface of “KH” or newer) This limited warranty supersedes all previous manufacturers Limited Warranty shall not apply to: warranties and is exclusive with no other guarantees or Items furnished by manufacturer, but manufactured by warranties expressed or implied.

-

Page 16: Owner's Record

Owner’s Record Please complete and retain with your personal records. Model Name Serial/Style Number Purchase Date (Date which equipment was delivered to original customer.) Distributor Address City State Resources Available Always provide Model Name and Serial/Style Number. Welding Supplies and Consumables Contact your Distributor for: Options and Accessories Personal Safety Equipment...

Need help?

Do you have a question about the AASW 1510M and is the answer not in the manual?

Questions and answers