Table of Contents

Advertisement

Installation and maintenance instructions

Type:

DO1140.en

Document:

INSTALLATION AND MAINTENANCE

Q-FLOW

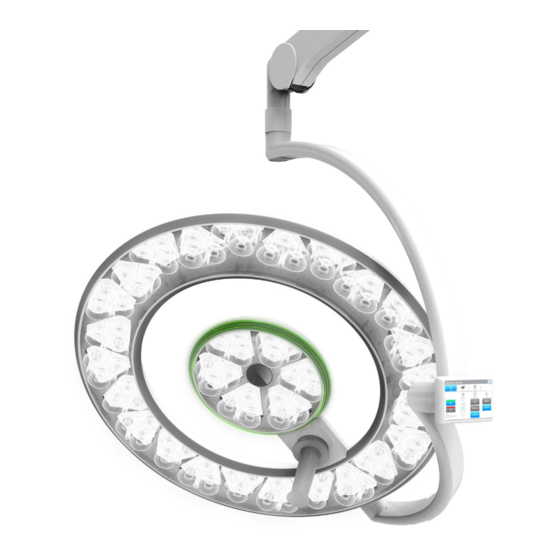

Surgical lighting system

First release:

Version: 2-1

Merivaara Corp.

-

Puustellintie 2, Fl

15150 LAHTI, FINLAND

Tel. +358 3 3394 611• Fax +358 3 3394 6144

merivaara@merivaara.com

www.merivaara.com

28.1.2016

18.11.2019

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Merivaara Q-FLOW

- Page 1 INSTALLATION AND MAINTENANCE Q-FLOW Surgical lighting system Installation and maintenance instructions Type: First release: 28.1.2016 DO1140.en Document: Version: 2-1 18.11.2019 Merivaara Corp. Puustellintie 2, Fl 15150 LAHTI, FINLAND Tel. +358 3 3394 611• Fax +358 3 3394 6144 merivaara@merivaara.com www.merivaara.com...

-

Page 2: Table Of Contents

3.5 Power supply unit (PSU, for all models) 3.5.1 Replacing fuses 3.6 Installing the Q-Flow - 6 point fixing 3.6.1 Ceiling tube D110 with welded flange - Q-Flow DUO and Q-Flow TRIO 3.6.2 Installing extension arms to the ceiling tube D110 - Q-Flow DUO and Q-Flow TRIO... - Page 3 3.7 Installing the balance arms - Q-Flow SOLO, DUO and TRIO 3.7.1 Dismantling the circlip (Lock ring) from the balance arm 3.7.2 Balance arm adjustments (5202005) 3.7.2.1 Movement range of balance arm (5202005) 3.7.3 Low ceiling height versions of balance arms (LCH) 3.7.3.1 LCH (5202006) type balance arm installation with the Q-Flow...

- Page 4 6.2.8 Technical specifications of HD camera 6.3 Dimensioning and connection diagrams 6.3.1 Q-Flow SOLO ceiling mounted system 6.3.1.1 Connection diagram - Q-Flow SOLO lighting systems 6.3.2 Q-Flow SOLO ceiling mounted monitor 6.3.3 Q-Flow DUO ceiling mounted system 6.3.3.1 Q-Flow DUO 360 6.3.3.2 Q-Flow DUO 320 ceiling mounted system...

-

Page 5: General

When installing additional equipment into the system, supplement these instructions with the user instructions that came with the additional equipment. The EN 60601-2-41 standard has been applied in the structural design of the Q-Flow system and luminaires. The device is classified as belonging to product category I according to the directive 93/42/EEC (MDD) including amending directive 2007/47/EC, and thus has a CE marking. -

Page 6: Intended Use

Mandatory personnel training for the use of Merivaara Q-Flow system must be carried out. Make sure that the training of your personnel complies with the guidelines presented in the document no. T404474. -

Page 7: Liability

Merivaara. Merivaara reserves the right to change, cancel or otherwise amend the data contained in this document at any time and for any reason without prior notice as much as Merivaara is constantly seeking new solutions which lead to product evolution. -

Page 8: Warning And Notes

Merivaara surgical lights! In order to replace the Q-Flow parts, read carefully all instructions before start any operation especially which regards opening of the sealed cover or other inner parts of the luminaire. List of spare parts is available separately. - Page 9 Offenders are liable to the payment of damages. All rights are reserved by Merivaara Corp. in the event of the grant of a patent or the registration of a model or design. The Q-Flow surgical lighting system must be equipped with a power supply backup system which prevents use interruptions if failure of power supply network occurs.

- Page 10 LASER RADIATION! DO NOT STARE INTO BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS, CLASS 2M LASER PRODUCT! The laser UI feature is only on the Q-Flow i-series! WARNING! When using the laser UI, keep the laser beam away from patient’s and employee’s eyes.

-

Page 11: Caution

Chapter 6.2.1 Environmental Conditions on page 68. If you use other supplier’s components, e.g an other power supply with Q-Flow luminaires, please read the instructions carefully provided by the component supplier. Merivaara does not take responsibility of consequences if the system contains other supplier’s material or components. -

Page 12: Installation

During the concrete pouring stage, wedge anchors or threaded rods with screw anchors must be installed to the ceiling in accordance of the instructions given in the Q-Flow Site Preparation Manual T404230. If the system is installed into a ceiling that does not have fixings (post-installation), holes for supplied wedge anchors has to be drilled. - Page 13 WARNING! If not installed properly, the ceiling flange mounting may fail and the whole Q-Flow system might fall. WARNING! The moment of the long extension arm places a stress on the ceiling tubes that is greater than the weight of the luminaire, and because of this, the installation of the system must be performed carefully.

-

Page 14: Wall Installation Of The System

WARNING! Before starting the installation, the structural engineer must sign off the Q-Flow Ceiling Flange installation Sign Off document T404360. This document must be archived by the Q-FLow light installing party. After the installation site is prepared according to the instructions of the Q-Flow Site Preparation Manual T404230, the system can be installed to the superstructure of the installation site by following the steps presented below (the numbers in brackets refer to the Picture 1. - Page 15 WARNING! Requirements concerning the wedge anchors and the site preparation procedure before the installation is presented in the Q-Flow Site preparation manual, document number T404230. NOTE! The 3-point fixing is only allowed on the triangular flange of the Q-Flow DUO with the D70 ceiling tube.

-

Page 16: Fixing Bracket For 1-3 Psu

2. Take a close look to the PSU unit installation in chapter 3.5 Power supply unit (PSU, for all models) on page 3. Direct mount the Q-Flow luminaire PSU with 4 pcs of M5 screws to the bracket plate. 3. There are alternative 2 pcs of securing plates for the PSU units for the use of other end devices such as displays and monitors. -

Page 17: Raw Ceiling Installation With Intermediate Tube Set

520 mm Picture 2. Intermediate tube set for raw ceiling installation 1. After the installation site is prepared according to the instructions in the Q-Flow Site Preparation Manual T404230, the system can be installed to the superstructure of the installation site. -

Page 18: Installing Q-Flow Solo And Q-Flow Duo

Q-Flow Site preparation manual, document number T404230. 3.3.3.1 Installing the tube to the adapting flange (Q-Flow SOLO and Q-Flow DUO 320) 1. Remove the screw (1) and nut/washer (2) from the adapting flange (3). 2. Loosen the screws (4) such a way they are almost off (6 pcs of screws). -

Page 19: Q-Flow Solo And Q-Flow Duo 320 With Reinforced Ceiling Flange

2.25–2.35 m from the floor. 3.3.3.2 Q-Flow SOLO and Q-Flow DUO 320 with reinforced ceiling flange This type of reinforced ceiling tube with a welded flange can be used for the light duty systems if the raw ceiling height is over 4.4 m. It can be also replaced by using a intermediate tube set. -

Page 20: Q-Flow Duo - 3 Point Fixing

3.3 Ceiling installation of the system on page 14, then follow the instructions presented in this chapter. WARNING! Requirements concerning the wedge anchors and the site preparation procedure before the installation is presented in the Q-Flow Site preparation manual, document number T404230. 3.4.1 Installing the ceiling tube assembly Prepare the assembly by cutting the ceiling tube to proper length matching it with the intermediate tubes and the interface plate assembly. -

Page 21: Locking Of The Ceiling Tube With The Groove Pin

WARNING! Electric shock hazard! If the insulation is defective, the pendant system Central Axis system may be live. The Central Axis system must always be grounded! Connect the grounding wire with the grounding point next to the grounding sign of the ceiling flange plate! Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 22: Installing Extension Arms And Protective Hood

10. Loosen the clip-mechanism on the inside of the cover carefully by using a small screw driver. To install the balance arms, refer to 3.7 Installing the balance arms - Q-Flow SOLO, DUO, and TRIO on page Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 23: Power Supply Unit (Psu, For All Models)

The compliance of the installation must be verified against the Q-Flow Site Preparation Manual T404230 by the licensed electrician. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 24: Replacing Fuses

5. Assemble the luminaire parts in reverse order, spare parts. More detailed information available from Merivaara After sales or from your local dealer. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 25: Installing The Q-Flow - 6 Point Fixing

3.6 Installing the Q-Flow - 6 point fixing Q-Flow central axis is presented with a ceiling tube D110 with a welded flange in the pictures below. Central axis assembly with a interface plate 6 point fixing with 6 pcs M16 threaded... -

Page 26: Ceiling Tube D110 With Welded Flange - Q-Flow Duo And Q-Flow Trio

- ( 7 ) M16 spring washers 13 pcs 3.6.2 Installing extension arms to the ceiling tube D110 - Q-Flow DUO and TRIO 1. Remove screws (1) from the ceiling tube (2). 2. Lift the extension arm(s) (3) close to the tube and feed the cables through. -

Page 27: Installing The Protective Hood D600

1. Put halves of the protective hood (1a-b) against each other and fix with screws (2) 6 pcs. 2. After installing the protective hood, secure it with the fixing collar (3) by using locking screws (4) and (5). Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 28: Installing The Balance Arms - Q-Flow Solo, Duo And Trio

NOTE! Special circlip pliers needed! Pliers must be set to a 8 mm strut limitation to prevent deforming or over stretching the lock ring (circlip). Picture 10. Installing the balance arms - Q-Flow SOLO, DUO and TRIO NOTE! Never install a damaged product or fixing part. -

Page 29: Dismantling The Circlip (Lock Ring) From The Balance Arm

Flow SOLO, DUO and TRIO on page 28) is mounted to the bottom of the balance arm shaft base. NOTE! The washer disc Ø 48 mm is not installed if the balance arm with limit stop is used. The Q-Flow Mobile balance arm uses a specialised limitter and separate Ø... -

Page 30: Balance Arm Adjustments (5202005)

Picture 11. Balance arm adjustments After the Q-Flow luminaire or other appliance has been installed, you can adjust the balance to suit the weight of the end device. Adjust the balance by tightening or loosening the hex screws inside the balance arm’s pivot (3). -

Page 31: Low Ceiling Height Versions Of Balance Arms (Lch)

Use the lock ring (circlip) dismantled during initial installation as described in chapter 3.7 Installing the balance arms - Q-Flow SOLO, DUO, and TRIO on page 28. A new, unused securing ring must always be used for service or maintenance. (Lock rings (circlips) are available from System Manufacturer (Merivaara Corp.)). -

Page 32: Lch (5202006) Type Balance Arm Installation With The Q-Flow

LCH (5202006) type balance arm installation with the Q-Flow The brake force of the balance arm is set to hold the end device (Q-Flow mobile with a single yoke) in the adjusted position. The balance arm is supplied in horizontal position. The end device of the LCH type balance arms is secured with the wedge and securing ring, with this system after the luminaire has been set in place. -

Page 33: Adjustment Of The Extension Arm Brake Force

Picture 14. Adjusting the extension arm brake force NOTE! Do not strain the Q-Flow ceiling arms by loading the arms in such a way that the force is directed against its adjustment range limits. Be aware of the existing limits of the system presented in this Q-Flow Installation and maintenance manual. -

Page 34: Installation Of The Q-Flow Mobile

2 pcs • balance arm (in own package), 1 pcs • luminaire (Q-Flow 4 or 6) in own package, 1 pcs • fixing part set, 1 pcs. NOTE! Lift the upper packaging first away and remove the lower card board packaging sides, then check that all parts from the list in the next Chapter 3.10.2 Fixing... -

Page 35: Installing The Lower And Upper Vertical Tubes

5. Align the upper vertical tube fixings and tighten the screws 2 pcs, part no. 5 in Picture 15. Fixing parts for the assembly on page 34. NOTE! Do not touch the two retaining screws on the lower vertical arm. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 36: Installing The Balance Arm

Fixing parts for the assembly on page 34). 9. Secure the top connection with a plastic cover supplied. Updated design contains a bracket over the top tube opening for a securing M5X20 screw for the top cover. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 37: Installing The Luminaire

Follow the instructions given for the LCH type balance arm in chapter 3.7.3.1 LCH (5202006) type balance arm installation with the Q-Flow on page 32. 1. Remove the balance arm front end covers. -

Page 38: Preparing The Q-Flow Mobile Ready For Use

9. Tighten the cover screws (Part no. (1)) with Philips head screwdriver. 3.10.6 Preparing the Q-Flow Mobile ready for use 1. Connect the mains cable to the base appliance inlet and then to the wall socket. 2. Switch on the luminaire from the mains switch located on the base and then power up the luminaire using an I/O-switch on the luminaire yoke. -

Page 39: Q-Flow Luminaire With Wireless Hd Camera Module (Optional)

WARNING! Switch OFF the luminaire on the main switch before removing or installing the camera. Possibility for electric shock or product damage. Use only equipment that has been accepted for medical use.The Q-Flow luminaire with an optional high definition camera and its video transmission must be configured for the supplied central axis before the system is ordered. -

Page 40: Installing The Rf Unit

In case it is not possible, install it onto the wall as close as possible beneath the roof. Ensure that the line of sight between the signal receiver box and the camera is as clear as possible. Copyright © 2019 Merivaara Corp. All rights reserved. - Page 41 When the RF unit is installed beside the ceiling tube, Merivaara recommends the following (see the image below): • the operating table is located under the arm assembly • the luminaires are located at the end of seat or leg section •...

- Page 42 6. Pair the signal receiver box with the camera (refer to chapter 3.13.5 Pairing the camera with the network on page 57). Picture 20. Connectors and the signal button of the signal receiver box. Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 43: Removing The Camera

(refer to Chapter 3.7.2 Balance arm adjustments (5202005) on page 30.). 1. Switch Off the power on luminaire from the main switch. 2. Remove the camera cover: open the cover by using a slotted screwdriver. Carefully lift the cover. Copyright © 2019 Merivaara Corp. All rights reserved. - Page 44 5. Pull the camera carefully out. 6. Put the cover firmly back onto the luminaire. NOTE! Check that the cover is firmly in place. Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 45: Installing The Camera

3.11.4 Installing the camera 1. Switch Off the power on the luminaire from the main switch. 2. Remove the camera cover: open the cover by using a slotted screwdriver. Carefully lift the cover. Copyright © 2019 Merivaara Corp. All rights reserved. - Page 46 Turn the camera module to a correct position. Ensure also that the mark on the lock ring and the camera module fixture assembly line up. Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 47: Installing The Wall Mounted Control Panel (Optional)

3.11.5 Installing the wall mounted control panel (optional) The Q-Flow system can be complemented with the wall mounted control panel covered with a casing, which can be installed to the wall with a bracket. Cabling is fed to the casing connection port. -

Page 48: Definition Of User Interface Icons

3.12 Definition of user interface icons Switch On Switch Off Color temperature Brightness Light area Increase value (%) — Decrease value (%) — rotate right/left Pause- Still image snap shot Icon of luminaire Icon of camera Copyright © 2019 Merivaara Corp. All rights reserved. - Page 49 Yellow NOTE! icon for the action needed by user Red WARNING! icon of critical error (may occur only on OpenOR or Merimote) Synchronization Selection tickbox Back to previous menu Add device Remove device — Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 50: User Interface Of The Q-Flow Luminaire

The Standby key on the upper right corner returns the panel into the idle screen and switches off the light or lights without missing the last settings. The UI laser of the Q-Flow i-series sets off automatically when the luminaire is switched off or on in the standby mode. -

Page 51: Luminaire (Lamp) Menu

If other devices or luminaires have been synchronized to the system, you can control all via one touch screen by selecting Control all in the main lamp view (see picture below) Picture 24. The Lamp view with maximum amount of devices Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 52: Setup Menu In The Lamp Menu

Set PIN - Opens a pop up window for changing the PIN 3.13.2.2 Changing the language in the user interface In the Lamp view, select Setup -Language, and press the desired language to change it. Picture 26. Language options of the user interface Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 53: Camera Menu

Setup – Opens the Setup menu in which you can pair the camera with the internet connection. The Setup menu requires a PIN code. Pause – Still image snap shot NOTE! Recording is only possible via the Merivaara OpenOR system. °. Rotate –Arrow buttons for rotating the camera. The rotation of the camera is 350 Zoom –... -

Page 54: 4Settings Menu

If devices have been connected, the first devices in the list are devices which are controlled by this lamp, after that are listed devices and lamps that are controlling this lamp. More devices may be available by selecting “More devices”. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 55: Synchronizing/Adding A Lamp

The yellow light in the Sync button indicates that the synchronizing is in process. The light changes to light green, when the synchronizing process has been successfully completed. The red light indicates that the synchronizing process has failed. Copyright © 2019 Merivaara Corp. All rights reserved. - Page 56 After synchronizing is completed, the text “The devices successfully synchronized” is shown on the screen of the master lamp: Picture 35. The lamp 1122 has been synchronized with the master luminaire Picture 36. Slave lamp menu in the master lamp. Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 57: Removing A Lamp

NOTE! If you remove the lamp, you must re-synchronize it to be able to use it again. 3.13.5 Pairing the camera with the network Picture 39. Camera menu for pairing the camera with the networ 1. In the Camera menu, select Setup. Copyright © 2019 Merivaara Corp. All rights reserved. - Page 58 To reset the signal receiver box, press the video signal output button for ten (10) seconds. 5. Open the Camera mode menu to select the resolution to correspond with the display. Picture 41. Selecting the Camera Mode Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 59: Starting The Diagnostic Test

Picture 43. The diagnostic test of the touchscreen. 3. Confirm the diagnostic tests of the LCD backlight by answering Yes or No to the questions. Picture 44. LCD screen backlight diagnostic, steps 1 and 2 Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 60: Resetting The Lamp And Camera Counter

NOTE! If the diagnostic test fails, contact Merivaara's Customer Care. Picture 46. Diagnostic test results 3.13.7 Resetting the lamp and camera counter NOTE! The counter for the camera and lamp must only be reset by maintenance of Merivaara's Customer Care. Picture 47. Resetting the camera and lamp counter... -

Page 61: Cleaning

2.0 bar. The sterilization time has been calculated by determining when the part being sterilized has reached the sterilization temperature specified above. This does not include the heating and cooling times for the part being sterilized. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 62: Maintenance And Repair

WARNING! Always switch off the system from the power mains before maintenance procedures. WARNING! Maintenance allowed only by persons specialized and trained to Merivaara surgical lights service work. WARNING! Software update only allowed to persons from Merivaara After Sales or directly at the factory. 5.1.1 Daily maintenance •... - Page 63 Ambilite dimming mode is On. The camera of the • The camera is not configured/ • Contact service personnel. luminaire does not applied to the system correctly. work. Table 2. Part 2/2 Copyright © 2019 Merivaara Corp. All rights reserved.

- Page 64 Blurry image. • The lens of the camera is dirty • Clean the camera’s lens. Contact or damage. Merivaara's Customer Care for a replacement lens. Table 3. Troubleshooting part 3/3 Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 65: Technical Data

Weight CE mark Radio Frequency module inside (RF)! Input voltage Q-Flow receiver unit Serial number Product catalogue number Ingress protection (IP) Picture 49. Identification plates of HD camera unit and receiver unit Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 66: Labelling And Symbols Used On The Product

Power ON Main switch of the luminaire Power OFF WARNING! Observe to ensure user, maintenance personnel and patient safety. RECYCLING! Product must be recycled separately! Follow the instructions for use B-type device Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 67: Packaging Labels

This way-up • Fragile • Keep dry • Humidity limitation, atmospheric pressure limitation, temperature limits are described in chapter 6.2.1 Environmental Conditions on page 68. • Restrictions: Allowed only for indoor use. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 68: Specifications

Refer to Chapter 4. CLEANING on page 61. Usage type Continuous use Technical life time (from the date of purchase) 10 years WARNING! Q-Flow luminaires must not be used on premises where flammable/combustible gases are present! Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 69: Surface Materials

Central axis DUO; two extension 1600 2080 arms and two spring arms Central axis TRIO; three 2280 2630 extension arms and three spring arms Table 5. Load data Copyright © 2019 Merivaara Corp. All rights reserved. - Page 70 Total vertical load [N] Q-Flow SOLO with Q-Flow 4 or 4i 1152 Q-Flow TRIO with Q-Flow 6 series in all arms 1805 Table 6. Examples of total vertical loads of the system in [N] WARNING! Required regional safety factors must be taken into account with the maximum load data.

-

Page 71: Luminaire Specifications

95 klx, 80 klx, 80 klx, two masks (klx), 100% / 60% - / manual 60% 95% / 60% - / manual 60% (autom. % / manual %) Table 7. Part 1/3 Copyright © 2019 Merivaara Corp. All rights reserved. - Page 72 (RAL 9010 / (RAL 9010 / RAL (RAL 9010 / RAL 7012) RAL 7012) 7012) 7012) External dimensions 700 mm 700 mm 560 mm 560 mm (diameter mm) Table 8. Part 2/3 Copyright © 2019 Merivaara Corp. All rights reserved.

- Page 73 TRIO TRIO TRIO Weight of luminaire 16 kg 16 kg 13 kg 13 kg Table 9. Part 3/3 *) Tolerance ±3, **) Tolerance ±300 °K, measured in test laboratory conditions, EN 60601-2-41 Copyright © 2019 Merivaara Corp. All rights reserved.

-

Page 74: Rf Unit Specifications

Dimensions (W x H x D)*2 60.0 x 64.0 x 105.0 mm (2 3/8 x 2 5/8 x 4 1/4 in) Mass Approx. 1200 g (Approx. 42.3 oz) Table 11. Electrical specifications of HD camera module Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 75: Technical Specifications Of Hd Camera

Dimensions (W x H x D)*2 60.0 x 64.0 x 105.0 mm (2 3/8 x 2 5/8 x 4 1/4 in) Mass Approx. 385 g (Approx. 13.6 oz) Table 12. Technical specifications of HD camera Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 76: Dimensioning And Connection Diagrams

6.3 Dimensioning and connection diagrams 6.3.1 Q-Flow SOLO ceiling mounted system Q-Flow SOLO single luminaire 45° 50° Picture 50. Dimensions of Q-Flow SOLO single luminaire Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 77: Q-Flow Solo Ceiling Mounted System

6.3.2 Q-Flow SOLO wall mounted system Picture 51. Q-Flow SOLO wall mounted system Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 78: Connection Diagram - Q-Flow Solo Lighting Systems

- one of the followings markings on the wire: PE or YELLOW-GREEN colour to PSU GND terminal NOTE! The luminaires of the Q-Flow system must always be connected in a such way that there is one power supply unit per luminaire. -

Page 79: Q-Flow Solo Ceiling Mounted Monitor

~348 850 mm (200 - 1200) Picture 53. Dimensions of Q-Flow SOLO ceiling mounted monitor ² NOTE! Merivaara recommends to use primary and secondary wiring at least 2.5 mm cables e.g. MMJ 3 x ² ². The 2.5 mm or MPLM 3 x 2.5 mm recommended maximum cable length is 15 m. -

Page 80: Q-Flow Duo Ceiling Mounted System

LATTIA / FLOOR Picture 54. Dimensions of Q-Flow DUO ceiling mounted system NOTE! Installation above illustrated with the fixing method as in section 3.3.2 Raw ceiling installation with intermediate tube set on page 17. Notice that the instructions concern the raw ceiling installation with 6-point fixing. - Page 81 50° 50° Picture 55. Dimensions of Q-Flow DUO 360 NOTE! The installation in the above picture has been made by using the fixing method described in section 3.3.1 Raw ceiling installation on page 14. Note a special type of installation with the 3-point fixing!

-

Page 82: Q-Flow Duo 320 Ceiling Mounted System

6.3.4.2 Q-Flow DUO 320 ceiling mounted system Q-Flow DUO 320 system 45° 50° FLOOR Picture 56. Q-Flow DUO 320 ceiling mounted system Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 83: Q-Flow Duo - Low Ceiling Height System

6.3.4.3 Q-Flow DUO - Low ceiling height system max 275 1000 30° 30° 45° 45° measures in mm FLOOR Picture 57. Q-Flow DUO - Low ceiling height Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 84: Q-Flow Trio Lighting Systems

- one of the followings markings on the wire: PE or YELLOW-GREEN colour to PSU GND terminal NOTE! The luminaires of the Q-Flow system must always be connected in a such way there is one power supply unit per luminaire. -

Page 85: Q-Flow Trio Ceiling Mounted System

(5202005), and it is a standard model which spring force is selected to suit with the used end device. NOTE! The luminaires of the Q-Flow system must always be connected in a such way there is one power supply or battery backup unit per luminaire. -

Page 86: Connection Diagram - Q-Flow Solo, Duo And

- one of the followings markings on the wire: PE or YELLOW-GREEN colour to PSU GND terminal NOTE! When using a BBU, the luminaires of the Q-Flow system must always be connected in a such way there is one power supply and battery backup unit per luminaire. -

Page 87: Weights Of The Q-Flow System Components

6.3.7 Weights of the Q-Flow system components Model Q-Flow Q-Flow TRIO Q-Flow Q-Flow Q-Flow DUO 320 central axis SOLO SOLO Light duty Medium Medium duty duty Weight of ceiling flange / wall mount 3 kg 3 kg 7 kg 7 kg... -

Page 88: Recycling

This symbol is affixed next to the type plate if the product contains an electric or electronic device. The symbol indicates that this product must be recycled/disposed of separately and must not be disposed with general waste. disposed with general waste. Copyright © 2019 Merivaara Corp. All rights reserved. -

Page 89: User Guidance For Emc

The Q-Flow surgical and examination luminaires have been tested according to EN60601-1-2 to ensure proper electromagnetic compatibility. Portable and mobile RF-communications equipment can affect the Q-Flow luminaires. Other products used in the vicinity of the Q-Flow luminaires should also comply with this standard. -

Page 90: Immunity And Emissions

Guidance and manufacturer's declaration - electromagnetic emissions The Q-Flow luminaires are intended for use in the electromagnetic environment specified below. The customer or the user of the Q-Flow luminaires and the system should assure that it is used in the fol- lowing environment. - Page 91 Guidance and manufacturer’s declaration - electromagnetic immunity The Q-Flow luminaires and the system is intended for use in the electromagnetic environment specified below. The customer or the user of the Q-Flow luminaires and the system should assure that it is used in the following environment:...

- Page 92 Guidance and Manufacturer’s declaration - electromagnetic immunity The Q-Flow luminaires and the system is intended for use in the electromagnetic environment specified below. The customer or the user of the Q-Flow luminaires and the system should assure that it is used in the following environment:...

- Page 93 The Q-Flow luminaires and the system is intended for use in the electromagnetic environment in which radiated RF disturbances are controlled. The customer or the user of the Q-Flow luminaires and the sys- tem can help prevent electromagnetic interference by maintaining a minimum distance between portable and mobile RF communications equipment (transmitters) and the Q-Flow luminaires and the system as recommended below, according to the maximum output power of the communications equipment.

- Page 94 NOTES Copyright © 2019 Merivaara Corp. All rights reserved.

- Page 96 PDM Nr: T404230 Rev Nr: Pvm – Date: 30.10.2019 Laatija: E. Autti-Ahrnberg, Hyväksyjä: Tuotemuutostiimi Accepted by: Written by: M. Haapaniemi Q-Flow | Site Preparation Manual...

- Page 97 (for example, electrician or IT personnel) need access to the area. 12. Provide removal of trash. 13. Sign and return the Installation Acceptance Form after the installation of the Q-Flow system is completed. 14. If the OpenOR system is included, please refer to OpenOR specific Site Preparation...

- Page 98 2. Provide requirements for electrical, structural, data, and other relevant details outlined in this document. 3. Unpack the equipment. 4. Pull low voltage cabling for the Q-Flow system within the Operating Room. Only a licensed electrician is allowed to make the connections. 5. Insert cables into connectors.

- Page 99 The maximum length of the cable conduit from a device (ID) to UPS location is 20 m At Battery backup location: 1x 110V/20A – 230V/13A AC / 50-60 Hz. Electrical outlets 230 VAC NOTE! Consult your Merivaara project manager for the suitable options (1 or 2) for your installation. Cable length Minimum cable cross section x <...

- Page 100 Size of the RF receiver: 180 mm x 180 mm x 50 mm. Refer to the drill guide in the Q-Flow Installation and Maintenance Manual DO1140.

- Page 101 WARNING! If the installation is not done properly, the whole Q-Flow system can fall. o Documentation for ceiling installation The structural design of the ceiling must ensure that the loads of the Q-Flow system as well as any other loads on the ceiling are absorbed and distributed safely.

- Page 102 Merivaara does not, cannot, and will not accept any legal responsibility for the inappropriate installation or corrupted material or faulty structure of the...

- Page 103 PDM Nr: T404230 Rev Nr: Pvm – Date: 30.10.2019 Laatija: E. Autti-Ahrnberg, Hyväksyjä: Tuotemuutostiimi Accepted by: Written by: M. Haapaniemi Appendix A: Ceiling mount specifications 1. Interface plate installation with a 6 point flange fixing Figure 1: Interface plate with threaded rods installation flush to raw ceiling NOTE! Installations of the flush below the plate installed to raw ceiling must be performed according to Q- Flow installation and maintenance manual DO1140 and by the personnel described in the manual...

- Page 104 Figure 2: Interface plate with threaded rods installation flush to raw ceiling NOTE! Installations of anything below the plate installed flush to raw ceiling must be performed according to Q-Flow installation and maintenance manual by personnel described in the manual...

- Page 105 3. Intermediate tube set with interface plate Figure 3: Installation with the intermediate tube set NOTE! Installations of anything below the plate installed flush to raw ceiling must be performed according to the Q-Flow installation and maintenance manual by the personnel escribed in the manual...

- Page 106 PDM Nr: T404230 Rev Nr: Pvm – Date: 30.10.2019 Laatija: E. Autti-Ahrnberg, Hyväksyjä: Tuotemuutostiimi Accepted by: Written by: M. Haapaniemi 4. Through bolt fixing of the ceiling and interface plate Important: - Always use counter plate (steel material) fixing if the concrete ceiling thickness is less than 200 - Diameter of drilled holes is ø21 mm - The tightening torque of the M20 nut is 395 Nm...

- Page 107 PDM Nr: T404230 Rev Nr: Pvm – Date: 30.10.2019 Laatija: E. Autti-Ahrnberg, Hyväksyjä: Tuotemuutostiimi Accepted by: Written by: M. Haapaniemi Appendix B: HILTI HST 3 M20 x 170/30 heavy load anchor specifications...

- Page 108 In this form is presented the inspection measures to be completed at installation stage of the system. For annual maintenance, please use the Annual maintenance inspection form, Annex 2. In order to guarantee a safe use of the Q-Flow lighting system, perform the necessary actions and possible follow-ups before check out the box.

- Page 109 Fixed stopper for monitor arm 40 deg./320 deg. (if existing) is properly in place. Maximum height is adjusted properly. Load compensation/spring tension is correct, re-adjust it if required. Copyright © 2019 Merivaara Corp. All rights reserved. doc: T404338 rev.3, page 2 of 4...

- Page 110 Electrical inspections Protective conductor resistance and continuity checked (IEC/EN 62353) The compliance of the PSU installation must be verified against given instructions by an licensed electrician. Copyright © 2019 Merivaara Corp. All rights reserved. doc: T404338 rev.3, page 3 of 4...

- Page 111 (24) months from the date of delivery from Merivaara to the distributor, or twelve (12) months from the date of delivery from the distributor to the customer, whichever is shorter.

- Page 112 Date of product installment: implementation: Instructions In this form is presented the annual inspection measures to be completed to the Merivaara Q-Flow luminaires. In order to guarantee a safe use of the Q-Flow lighting system, perform the necessary actions and possible follow-ups before check out the box.

- Page 113 There is no visible flaking on the touch screen panel housing or on the seams caused by incorrectly made daily cleaning and disinfection. Copyright © 2019 Merivaara Corp. All rights reserved. doc: T404339 rev.2, page 2 of 4...

- Page 114 (Q-Flow i-series) functions responds correctly. The luminaire is configured correctly. The synchronized control feature of the Q-Flow does not control any other Q-Flow luminaire in the same building. Make sure that the synchronized control feature of the Q-Flow Master light and Slave light, if existing, is not synchronized to control any other Q- Flow luminaire.

- Page 115 I assure that the mentioned inspection measures are completed in accordance with the requirements given: Indicate the number of inspection year in question; 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Inspector's signature: Date Signature/Stamp Name Copyright © 2019 Merivaara Corp. All rights reserved. doc: T404339 rev.2, page 4 of 4...

- Page 116 This document is intended to be filled out by an authorized structural engineer to ensure safety. Merivaara does not, cannot, and will not accept any legal responsibility for the inappropriate installation or corrupted material or faulty structure of the ceiling.

- Page 117 T404474: User training guidelines Product/system: Date of implementation: Serial number: Customer reference number: Location of Date of product user installment: training: Scope The end user (nurse, anesthetist nurse CRNA, medical doctor, surgeon etc. or other personnel who is involved using the product) must be trained according these instructions by the person authorized or in charge of the end user´s organization before use of the product (IEC 62366).

- Page 118 Content of technical personnel training • Inspect all components supplied • Installation procedure and implementation according to the installation and maintenace manual • Patient and personnel safety factors • Start-up of the system, power supply mains switch and switching On-Off the luminaires •...

- Page 119 PRINT 1:1 50 mm 50 mm PRINT IN SCALE 1:1 USE THIS TEMPLATE TO DRILL 6MM MOUNTING HOLES FOR THE RECEIVER LEAVE 300mm (min. 100 mm) FREE FOR CONNECTIONS 300 mm min. 100 mm AND MAINTENANCE...

Need help?

Do you have a question about the Q-FLOW and is the answer not in the manual?

Questions and answers