Summary of Contents for SKF ST-102-C2P

- Page 1 Assembly Instructions SKF ST-102-C2P Control Centre Date: 8.6.2022 Document no.: ST-102-C2P Version: 1G Read this manual before installing or commissioning the product and keep it at hand for later reference!

- Page 2 Product Specialist SKF Lubrication Management Electronic Manufacturer: Oy SKF Ab Finland Teollisuustie 6 40951 Muurame FINLAND UK Declaration of Conformity pursuant to the Electromagnetic Compatibility Ordinance 2016 No. 1091 The manufacturer hereby declares under its sole responsibility conformity of the product described below with all relevant harmonization legislation of the United Kingdom at the time of placing on the market.

-

Page 3: Masthead

The instructions contain no statements regarding the warranty or liability for defects. That information can be found in our General Terms of Payment and Delivery. Training We conduct detailed training in order to enable maximum safety and efficiency. We recommend taking advantage of this training. For further information, contact your authorized SKF dealer or the manufacturer. -

Page 4: Table Of Contents

Settings of the lubrication system ............................20 4.7.1 Lubrication programme selector switches ........................20 Electrical connections ......................Error! Bookmark not defined. 4.8.1 ST-102-C2P power input and signal connector, X3 ....................21 4.8.2 External alarm indicators (J6) ............................ 21 Technical information ................................22 Troubleshooting table ................................ -

Page 5: Safety Alerts, Visual Presentation, And Layout

Safety alerts, visual presentation, and layout While reading these instructions, you will encounter various symbols, illustrations, and text layouts intended to help you navigate and understand the instructions. Their meaning is explained below. Safety alerts: Activities that present specific hazards (to life and limb or possible damage to property) are indicated by safety alerts. Always be sure to follow the instructions given in the safety alerts. -

Page 6: Safety Instructions

" Unauthorized modifications and changes can have an unpredictable effect on safety and operation. Unauthorized modifications and changes are therefore prohibited. Only original SKF spare parts and SKF accessories may be used. " Any unclear points regarding proper condition or correct assembly/operation must be clarified. Operation is prohibited until issues have been clarified. -

Page 7: Persons Authorized To Use The Product

Persons authorized to use the product Operator A person who is qualified by training, knowledge and experience to carry out the functions and activities related to normal operation. This includes avoiding possible hazards that may arise during operation. Specialist in mechanics Person with appropriate professional education, knowledge and experience to detect and avoid the hazards that may arise during transport, installation, start-up, operation, maintenance, repair and disassembly. -

Page 8: Notes On The Type Plate

Notes on the type plate The type plate provides important data such as the type designation, order number, and sometimes regulatory characteristics. To avoid loss of this data in case the type plate becomes illegible, it should be entered in the manual. Fig. -

Page 9: Assembly, Maintenance, Fault, Repair

Assembly, maintenance, fault, repair Prior to the start of this work, all relevant persons must be notified of it. At a minimum, the following safety measures must be taken before any work is done: " Unauthorized persons must be kept away "... -

Page 10: Delivery, Returns, Storage

2. Delivery, returns, storage Delivery After receipt of the shipment, it must be inspected for any shipping damage and for completeness according to the shipping documents. Immediately inform the transport carrier of any shipping damage. The packaging material must be preserved until any discrepancies are resolved. -

Page 11: Cleaning

3. Cleaning Basics Cleaning should be carried out in accordance with the operator's own company rules, and cleaning agents and devices and the personal protective equipment to be used should likewise be selected in accordance with those rules. Only cleaning agents compatible with the materials may be used for cleaning. Completely remove any cleaning agent residue left on the product and rinse with clear water. -

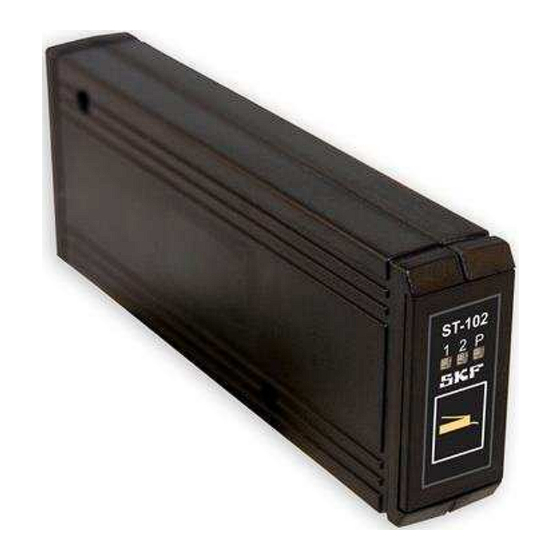

Page 12: Skf St-102-C2P Control Centre

4. SKF ST-102-C2P control centre Operation Control centre ST-102-C2P controls two progressive (ProFlex) lubrication channels implemented with a Multilube pump according to the lubrication parameters set. Lubrication cycle, maximum pressurisation time and the desired number of pulses generated by the progressive distributor sensor are set for both channels as parameters during pressurisation. -

Page 13: Indicators Above The Function Button

Indicators above the function button Status Meaning Indicator 1 is lit Channel 1 is selected for display. Lubrication interval for channel 1. Indicator 2 is lit Channel 2 is selected for display. Lubrication interval for channel 2. Indicators 1 and P are lit Lubrication is in progress in channel 1. -

Page 14: Starting The Functions

Depending on the lubrication programme status, the function button can be used for performing various actions: Lubrication programme status Action Lubrication interval Initiate extra lubrication Pressurisation Interrupt pressurisation Alarm Reset alarm The function is run by pressing the button until all three indicators are lit (approximately 2 seconds). ST-102-C2P function button... -

Page 15: Changing Lubrication Parameter Settings Using The Function Button

The button allows users to set the lubrication interval, maximum pressurisation time and the required number of lubrication pulses. ST-102-C2P control centre9s circuit board selector switch J8 is used for selecting the lubrication cycle and maximum pressurisation timetables. When J8 is in position 1, the time settings in accordance with tables J8:1 are in use. -

Page 16: Setting The Lubrication Cycle

4.5.1 Setting the lubrication cycle Select channel 1 or 2 by pressing the button briefly. Press the button for 5 seconds until the indicator 1 begins to flash rapidly. Now the lubrication interval can be set. Indicator P indicates the current value of the lubrication cycle. P flashes 1-10 times. -

Page 17: Setting The Maximum Pressurisation Time

4.5.2 Setting the maximum pressurisation time Select channel 1 or 2 by pressing the button briefly. Press the button for approximately 10 seconds in normal operation mode until the indicator 2 begins to flash quickly. Now the maximum pressurisation time can be set. The number of flashes of indicator P shows the current lubrication cycle according to the following table. -

Page 18: Setting The Progressive Distributor Pulse Count Setting

4.5.3 Setting the progressive distributor pulse count setting Select channel 1 or 2 by pressing the button briefly. When the system is in its normal status, hold the button for approximately 15 seconds until indicators 1 and 2 start flashing rapidly. Now the pulse count can be set. -

Page 19: St-102-C2P Control Centre Components

ST-102-C2P control centre components Image 1. ST102 control centre components Symbol Component Function Button User interface Connector User interface connector Jumper Programme selector switch Jumper Programme selector switch Jumper Programme selector switch Jumper Programme selector switch Jumper Programme selector switch... -

Page 20: Settings Of The Lubrication System

Changes in the circuit board options will take effect after the system has been restarted. It is recommended to make adjustments in the control centre with the power turned off. 4.7.1 Lubrication programme selector switches ST-102-C2P control centre settings: J4:A Open... -

Page 21: Electrical Connections

4.7.2 ST-102-C2P power input and signal connector, X3 Image 2. Connector X3 Electrical connections, Molex connector (X3) Connector X3 Signal X3:1 X3:2 Supply voltage (+), 12 V DC or 24 V DC X3:3 Supply voltage (3), 0 V DC X3:4... -

Page 22: Technical Information

Technical information 330...+80 °C Operating temperature range Protection class IP30 Dimensions 26 x 60 x 160 mm (w x h x d) Operating voltage 12 or 24 VDC (10.5 to 32 VDC) Power consumption Depends on the lubrication system being controlled, 0...4 A Fuse Self-resetting fuse, 4 A, on the circuit board Control inputs... -

Page 23: Troubleshooting Table

The pulse sensor is faulty. Replace the pulse sensor. The pulse sensor cable is Repair or replace the cable. damaged. Malfunction in the SKF Multilube Locate and repair the malfunction or pumping centre. contact the equipment supplier. - Page 24 Replace the pulse sensor. The pulse sensor cable is Repair or replace the cable. damaged. Malfunction in the SKF Multilube Locate and repair the malfunction or pumping centre. contact the equipment supplier. Indicator 1 is lit and P is flashing.

-

Page 25: Appendix

5. Appendix Wiring diagram... -

Page 26: China Rohs Table

China RoHS Table...

Need help?

Do you have a question about the ST-102-C2P and is the answer not in the manual?

Questions and answers