Advertisement

Quick Links

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page: www.vikinggroupinc.com

1. DESCRIPTION

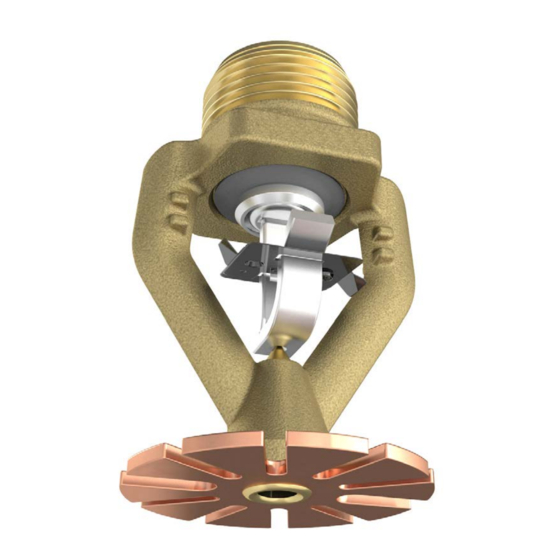

Viking Early Suppression Fast Response (ESFR) Pendent Sprinkler VK500 is a fast

response fusible element type sprinkler designed for early fire suppression. With a 14.0

(202 metric*) nominal K-Factor and special deflector, this sprinkler produces large,

high-momentum water droplets in a hemispheric pattern below the deflector. This

permits penetration of the fire plume and direct wetting of the burning fuel surface while

cooling the atmosphere early in the development of a high-challenge fire.

Viking VK500 ESFR Pendent Sprinklers may be used in the protection of ordinary types

of storage. However, they are primarily intended to protect the following types of stor-

age, which tend to produce severe-challenge fires: palletized and solid pile storage and

single, double, multiple row, and portable open rack storage (no open-top containers

or solid shelves).

Viking ESFR Pendent VK500 Sprinklers provide protection of most common storage

materials, including:

--Encapsulated or unencapsulated Class I, II, III, and IV commodities*.

--Cartoned and uncartoned unexpanded plastics*.

--Cartoned and uncartoned expanded plastics*.

* Refer the Approval Charts and Commodity Selection and Design Criteria Overview for cULus

Listing and FM Approval requirements that must be followed.

In addition, some storage arrangements of rolled paper, aerosols, and rub-

ber tires may be protected by Viking ESFR Pendent Sprinkler VK500.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNWH

FM Approved: Class 2008

NYC Approved: MEA 89-92-E, Volume 18

VdS Approved: Certificate G4010001

China Approval: Approved according to China GB Standard

NOTE: Other International approval certificates are available upon request.

Refer to the Approval Charts and Commodity Selection and Design Criteria

Overview for cULus Listing and FM Approval requirements that must be

followed.

3. TECHNICAL DATA

Specifications:

Available since 2000.

Minimum Operating Pressure: Refer to NFPA 13 or FM Global Loss Prevention Data Sheets.

Maximum Working Pressure: 175 psi (12 bar). Factory tested hydrostatically to 500 psi (34.5 bar).

Thread size: 3/4" NPT or 20 mm BSPT

Nominal K-Factor: 14.0 U.S. (202 metric**)

**Metric K-factor measurement shown is when pressure is measured in bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Overall Length: 2-7/8" (73 mm)

Deflector Diameter: 1-3/4" (44.5 mm)

Material Standards:

Frame Casting: Brass UNS-C84400

Deflector: Phosphor Bronze UNS-C51000

Seat for Sprinkler 11350: Stainless Steel UNS-S31603

Seat and Insert Assembly for Sprinkler 10284: Copper UNS-C11000 and Stainless Steel UNS-S30400

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE Tape

Compression Screw: Stainless Steel UNS-S31603

Form No. F_060198

22.04.13

TECHNICAL DATA

Rev 22.1

ESFR PENDENT

SPRINKLER

VK500 (K14.0)

TABLE 1

SPRINKLER GENERAL INFORMATION

Item

Sprinkler Identification

Number (SIN)

K-factor, gpm/psi

(lpm/bar

)

½

½

Thread Size

Sprinkler Orientation

Maximum Working Pressure

Replaces Form No. F_060198 Rev 19.2

(Updated FM references to non-storage sprinklers)

Page 1 of 6

Description

VK500

14.0 (202)

3/4" NPT (20mm BSPT)

Pendent

175 psi (12 bar)

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for Viking 10284

- Page 1 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page: www.vikinggroupinc.com 1. DESCRIPTION Viking Early Suppression Fast Response (ESFR) Pendent Sprinkler VK500 is a fast response fusible element type sprinkler designed for early fire suppression.

-

Page 2: Technical Data

Temperature Suffix: 165 °F (74 °C) = C, 205 °F (96 °C) = E For example, sprinkler 10284 with a Brass finish and a 165 °F (74 °C) temperature rating = Part No. 10284AC. Accessories: (Also refer to the Viking website.) Sprinkler Wrench: Part No. - Page 3 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page: www.vikinggroupinc.com Approval Chart 1 - (UL) ESFR Pendent Sprinkler VK500...

- Page 4 IMPORTANT: Always refer to Bulletin Form No. F_091699 - Care and Handling of Sprinklers. Viking ESFR Pendent Sprinklers are to be installed in accordance with the latest edition of Viking technical data, the latest standards of NFPA, FM Global, VdS, LPCB, and any other Authorities Having Jurisdiction, and also with provisions of governmental codes, ordinances, and standards whenever applicable.

-

Page 5: Installation

4. INSTALLATION WARNING Viking sprinklers are manufactured and tested to meet rigid requirements of the approving agency. The sprinklers are designed to be installed in accordance with recognized installation standards. System design must be based on ESFR design guidelines described in the latest edition of Viking technical data, applicable FM Global Loss Prevention Data Sheets, the latest NFPA Standards, the latest standards of (VdS) Schadenverhütung, the Authorities Having Jurisdiction,... - Page 6 Installation standards require sprinklers to be tested and, if necessary, replaced after a specified term of service. For Viking ESFR Pendent Sprinklers, refer to the Installation Standards (e.g., NFPA 25) and the Authorities Having Jurisdiction for the specified period of time after which testing and/or replacement is required.

- Page 7 Refer to the appropriate technical data page and NFPA standards for complete care, handling, installation, and maintenance instructions. For additional product and system information Viking data pages and installation instructions are available on the Viking Web site at www.vikinggroupinc.com.

- Page 8 * Refer to the appropriate current technical data pages for complete care, handling, and installation instructions. Data pages are included with each shipment from Viking or Viking distributors. They can also be found on the Web site at www. vikinggroupinc.com.

- Page 9 • while ceiling finish work is being completed. Use only the designated Viking recessed sprinkler wrench (refer to the appropriate sprinkler data page) to install these sprinklers. NOTE: The protective cap is • temporarily removed during installation and then placed back on the sprinkler for protection until finish work is completed.

- Page 10 Take care not to crack the wax coating on the units. • For touching up the wax coating after installation, wax is available from Viking in bar form. Refer to Table 1 below. The coating MUST be repaired after •...

- Page 11 1. DESCRIPTION Viking fire sprinklers consist of a threaded frame with a specific waterway or orifice size and a deflector for distributing water in a specified pattern. A closed or sealed sprinkler refers to a complete assembly, including the thermosensitive operating element. An open sprinkler does not use an operating element and is open at all times.

- Page 12 TECHNICAL DATA SPRINKLER OVERVIEW The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com VERTICAL SIDEWALL (VSW) SPRINKLER: A sprinkler intended for installation near the wall and ceiling. The deflector provides a water spray pattern outward in a quarter-spherical pattern and can be installed in the upright or pendent position with the flow arrow in the direction of discharge.

- Page 13 Refer to NFPA 25 for Inspection, Testing and Maintenance requirements. 7. AVAILABILITY Viking sprinklers are available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. 8. GUARANTEE For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

- Page 14 Viking ESFR Upright Sprinklers: Use Viking Wrench Part Number 05118CW/B. • Viking ESFR Pendent K14 and K16.8 Sprinklers: Use Viking Wrench Part Number 10285W/B or double-ended 13635W/B (Side A). • Viking ESFR Pendent K25.2 Sprinklers: Use Viking Wrench Part Number 12143W/B or double-ended 13635W/B (Side B).

- Page 15 210 N Industrial Park Dr * Hastings, MI 49058 Declaration of Conformity The 10284 and 11350, VK500, ESFR Pendent Sprinkler Assembly conforms to the provision of EN12259-1 standard. Conditions applicable to the use of VK500 Sprinkler Assembly are defined in the technical data documentation.

-

Page 16: Warranty Terms And Conditions

For more information, go to www.P65Warnings.ca.gov 2. WARRANTY TERMS AND CONDITIONS For details of warranty, refer to Viking’s current list price schedule at www.vikinggroupinc.com or contact Viking directly. New Bulletin Form No. F_111218 18.11.15...

Need help?

Do you have a question about the 10284 and is the answer not in the manual?

Questions and answers