Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for BUNNING 180

- Page 1 180 - 230 Widebody Manure Spreader Owners Manual...

- Page 3 By providing us with your telephone number or e-mail address you consent to being contacted by these methods. If you do not wish to receive marketing information by these methods from GT Bunning or our business partners please tick this box.

- Page 4 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Bunning Lowlander Widebody Pre-Delivery Inspection sheet The purpose of this document is to ensure that the operator, hirer or owner is fully appraised of all safey guidelines and operating and maintenance methods before taking possession of the machine.

-

Page 5: Table Of Contents

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL CHASSIS SERIAL NUMBER ................PAGE SECTION & CONTENTS Preface How to use this manual Operating on public roads Introduction Disposal EC Declaration of Conformity Machine over view OPERATING INSTRUCTIONS Hitching to tractor. - Page 6 Comer PTO guard safety chain fixing. 5.10 PTO stowage. BRAKE & AXLE ARRANGEMENTS Brake arrangment EUR 1510 414S – 180. Axle hub and bearing parts 180. Tandem axle hub parts EUR 1130 axle 230. Tandem axle brake parts EUR1130 axle 230.

- Page 7 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AXLES & SPRUNG DRAWBAR Safety notice. General information. Axle, maintenance and adjustment. Sprung drawbar spring information Minimum program of maintenance sheet. TYRES AND WHEELS Tyre and wheel maintenance. Tyre pressure settings. Wheel type and torque settings.

- Page 8 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HEALTH AND SAFETY & POTENTIAL HAZARDS 11.1 Hazardous machinery warning. 11.2 Loss of control. 11.3 Operation around bystanders. 11.4 Hydraulic fluid penetration or burning. 11.5 Electrocution. 11.6 Body entry. 11.7 Coupling / decoupling.

-

Page 9: Preface

This may impair its operating safety, as well as safety at work for the operator and could invalidate warranty. GT Bunning will in no way be liable for damage or personal injury caused by the use of other than original GT Bunning parts, accessories and additional equipment. -

Page 10: Introduction

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL INTRODUCTION This manual provides information on the use, adjustment and servicing of the GT Bunning range of Lowlander spreader. Following the advice on the correct maintenance and servicing procedures will ensure maximum performance and a long service life of your machine. -

Page 11: Ec Declaration Of Conformity

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL G.T.BUNNING & SONS LIMITED SPREADERS, TRAILERS & TANKS Telephone: 01362 860352 Registered Office: Fax: 01362 860930 Smithy House, TheGreen E-mail: sales@gtbunning.co.uk Gressenhall, Dereham Norfolk, NR20 4DT www.gtbunning.co.uk EC MACHINERY DIRECTIVE... -

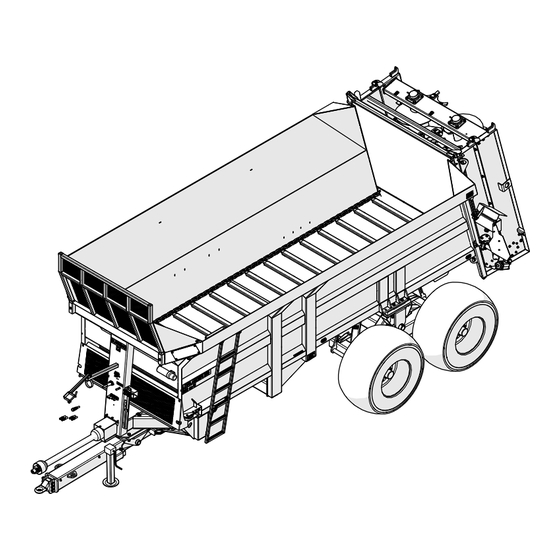

Page 12: Machine Over View

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL MACHINE OVER VIEW DESCRIPTION BODY DRAWBAR STONE GUARD FRONT PILLAR PTO DRIVE LINE FINGER GUARD SUPPORT LEG LADDER WHEEL & TYRE ASSEMBLY AUGER GEARBOX FLOOR DRIVE GEARBOX, MOTOR AND VALVE AUGER LAMP ASSEMBLY AXLE... -

Page 13: Operating Instructions

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL OPERATING INSTRUCTIONS The intended purpose of the vehicle is to tow and spread manure and other materials. Hitching to tractor. Attach spreader to pick-up hook or static hitch stub. Do not attach to swinging drawbar or pick-up hook in extended position. -

Page 14: Coupling Of Hydraulic Hoses

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Coupling of hydraulic hoses. Fit the two hoses for the floor drive hydraulic motor (one to feed and one for return) to double spool valve on tractor. Choose position of spool lever for ease of control to obtain floor movement to rear. Reversing of floor is done by selecting the opposite position of the hydraulic control lever. -

Page 15: Hand Brake

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Hand brake. The handbrake is a multi-stroke ratchet type. To apply the handbrake give the handle short pumps (a clicking of the ratchet will be heard) until resistance occurs and subsequent tightening of the cable. To release the handbrake give the handle one sharp movement in the opposite direction. -

Page 16: Installation And Use Of Detachable Spinning Deck

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL INSTALLATION AND GENERAL USE OF DETACHABLE SPINNER DECK GENERAL USE The detachable spinner deck is designed purely for wider spread patterns and low application rates of between 1 and 3 ton per acre. It must NEVER be used to spread long straw based material or heavy applications beyond 5 ton per acre. - Page 17 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL REMOVING THE SPINNER DECK Clean all material from spinners and decks. Remove 4 bolts from the flexi coupling. Loosen hook bolts No. 14 and hinge back to clear anchors. Using approved lifting apparatus lift from lower lifting eye on the canopy firstly pulling the bottom of the deck assembly away from rear of spreader to the clear auger blades.

-

Page 18: Horizontal Beater Operation

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL OPERATING INSTRUCTIONS FOR HORIZONTAL BEATERS General use The horizontal beater with spinner discs is designed primarily for wider spread patterns and lower application rates for product such as chicken and turkey manure, however long straw based materials can be spread effectively. -

Page 19: Maintenance

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL MAINTENANCE Lubrication of spreader. DAILY GREASE Front and rear floor shaft Overrun clutch to front of main ‘T’ gearbox Hitch eye WEEKLY GREASE All sealed bearing – 1/2 pump of grease gun maximum. TAKE CARE NOT TO DAMAGE GREASE SEAL BY OVERGREASING Sliding tube of PTO shaft. - Page 20 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL b. Rear Shaft. • Grease both left and right bearings. 3. Grease the Overrun Clutch to front of the auger gearbox. WEEKLY (40 HRS) 1. Check wheel nuts. Re-torque as needed. 2.

- Page 21 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 4. Grease PTO input drive system. a. Input shaft. b. Cross joint fittings. c. Guard bearings. d. Shear bolt housing. e. Over-running clutch (5 pumps). 5. Grease the implement jack top. 6.

-

Page 22: Amount Of Oil Required To Fill Gearboxes

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Grease brake pivot bushings (Tandem Suspension machines). Grease parking brake leaver joint. Check and adjust the apron chain tension. ANNUALLY 1. Change oil to all gearboxes. 2. Check the condition of the frame sealing flaps. Replace if not sealing the sides or bottom. a. -

Page 23: Service Record

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL SERVICE RECORD See Lubrication and Mainteneance sections for details of service. Copy this page to continue record. ACTION CODE CK = CHECK CL = CLEAN G = GREASE Page 21... -

Page 24: Shearbolt Protection

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Shearbolt Protection. Only one shearbolt is fitted to the spreader. This is located on the spreader end of the PTO shaft. The bolt is M10 x 60 grade 6.8 mild steel. ON NO ACCOUNT MUST A BOLT OF HIGHER GRADE THAN 6.8 TENSILE STRENGTH BE FITTED. -

Page 25: Floor Drive

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FLOOR DRIVE HYDRAULIC CIRCUIT FOR FLOOR DRIVE Page 23... -

Page 26: Floor Control Unit

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FLOOR SPEED CONTROL UNIT – B3030 61 LPM MANUAL Page 24... - Page 27 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL B3034 76 LPM ELECTRIC Page 25...

-

Page 28: Floor Drive Relief Valves

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FLOOR DRIVE RELIEF VALVES This valve is cross line type and fitted to the hydraulic motor on the floor drive gearbox. The pressure can be varied to suit the material being spread. -

Page 29: Floor Drive Gearbox B3122

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FLOOR DRIVE GEARBOX B3122 Page 27... - Page 30 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FLOOR DRIVE GEARBOX B3122 PARTS LIST PART No. DESCRIPTION B3204 CASING B3230 SLEEVE B4030 CIRCLIP B3236 GEAR BR325 BEARING B4016 CIRCLIP B3240 PINION B2276 B3244 GEAR BR365 BEARING B4012 CIRCLIP B3242 PINION...

-

Page 31: Rear Floor Shaft Assembly

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL REAR SHAFT ASSEMBLY WIDEBODY Page 29... - Page 32 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL REAR SHAFT ASSEMBLY PARTS LIST PART No. DESCRIPTION NGTB0569 REAR SHAFT NAMS0268 GYPSY WHEEL 90-17-2002 KEY 18x11x80 90-17-2003 KEY 18x11x190 90-33-0008 GEARBOX NDMS0574 TORQUE PLATE 90-35-0010 HYDRAULIC MOTOR 250CL NAMS0204-LW LH BEARING FLANGE NAMS0204-RW RH BEARING FLANGE 90-24-4017...

-

Page 33: Front Shaft And Chains

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL FRONT SHAFT AND CHAIN ASSEMBLY PART No. DESCRIPTION N315TUBE-2 FLOOR SLAT BOX TYPE NGTB0323 ADJUSTER M30 90-19-4004 JOINER LINK ASSEMBLY NAMS0042 CLEANER FRONT GYPSY 90-10-0393 BOLT M8 x 12 90-24-4017 ACM BUSH M60 NAMS0635... -

Page 34: Augers & Drives

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AUGERS AND DRIVES SHREDDING AUGER Page 32... - Page 35 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL SHREDDING AUGER BODY PARTS LIST QTY PART No. DESCRIPTION NAMS3684 AUGER L.H NAMS3685 AUGER R.H NAMS0249 DRIVE FLANGE 90-48-2002 RUBBER DRIVE BLOCK W.B MK2 NDMS2985 AUGER BLADE 90-10-1613 1/2-13 x 1 3/4" BOLT 90-13-2045 1/2-13 CENTERLOCK NUT NDMS2472...

-

Page 36: Horizontal Beater With Spinning Discs

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HORIZONTAL BEATER x 2 WITH SPINNING DISC PART No. DESCRIPTION B4127 RUBBER SEAL CANOPY DMS3669 CLAMP ANGLE DMS3670-1 CANOPY LID AMS1188 TOP BEATER ASSEMBLY AMS1189 BOTTOM BEATER ASSEMBLY B1178/1 BEARING UCFX10-50mm BC120 1"... - Page 37 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HORIZONTAL BEATER x 2 WITH SPINNING DISC PART No. DESCRIPTION DMS3781 WEAR END PLATE BC442 TAPERLOCK BUSH 3020/50 B3192 SPINNING DISC GEARBOX DMS1328-12 DRIVE SHAFT B1178/1 BEARING UCF10-50mm BC290/B442 23T SPROCKET &...

- Page 38 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HORIZONTAL BEATER x 2 WITH SPINNING DISC PART No. DESCRIPTION B1101/4A BEATER KNIFE TOP CUTTER B1101/7A BEATER KNIFE BOTTOM CUTTER BC294 25T DUPLEX SPROCKET B2322 ACM BEARING B4176 SPINNER DECK RUBBER HARDOX WEAR PAD WRAP B3004 RUBBER CLAMP STRIP...

-

Page 39: Gearbox 1000/350 B3180

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX STD 1000/350 PART No. B3180 Page 37... - Page 40 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX 1000/350 PART No. B3180 PARTS LIST PART No. DESCRIPTION B3510 B3520 LOCKING WASHER B3460 PINION GEAR BR175 BEARING BR410 BEARING B3470 CROWN GEAR B4020 CIRCLIP B3510 B3448 CROSS SHAFT B3482 SPACER SLEEVE B3939...

-

Page 41: Gearbox Spinner Deck - Through Drive 1000/350 B3185

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX SPINNER DECK 1000/350 B3185 Page 39... - Page 42 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX SPINNER DECK 1000/350 B3185 PART LIST PART No. DESCRIPTION B3510 NUT LH THREAD B3520 WASHER B3456 PINION GEAR BR175 BEARING BR410 BEARING B3466 CROWN GEAR B4020 CIRCLIP B3512 NUT RH THREAD B3448 CROSS SHAFT...

-

Page 43: Gearbox Detachable Spinner Deck 1000/520 B3190

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX DETACHABLE SPINNER DECK 1000/520 PART No. B3190 Page 41... - Page 44 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX DETACHABLE SPINNER DECK 1000/520 PART No. B3190 PARTS LIST PART No. DESCRIPTION B3405 CASING B3494 GASKET B3410 EXTENSION BR175 BEARING B3458 SHAFT B3454 PINION GEAR B3510 SL165 SEAL B3520 WASHER B3492...

-

Page 45: Transverse Gearbox Horizontal Beaters B3183

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX HORIZONTAL BEATER 1000/590/520-BN MKIV PART No. B3183 Page 43... - Page 46 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GEARBOX HORIZONTAL BEATER 1000/590/520-BN PART No. B3183 PARTS LIST PART No. DESCRIPTION B3511 BACK GEAR BOX B3494 GASKET 73125 SCREW, HEX-HD M14x35 B3514 SPACER L = 573.5 B3512 THREADED RING B3520 WASHER B3454...

-

Page 47: Transverse Drive Assembly Horizontal Beaters

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL TRANSVERSE DRIVE ASSEMBLY HORIZONTAL BEATERS CAM CLUTCH PART No. DESCRIPTION 42505 TORQUE LIMITER ASSEMBLY 1-3/4" TO 6 SPLINE DMS1328-12 DRIVE SAFT WIDEBODY DMS0263-03 KEY 12x8 73898 GRUB SCREW M12 x 16LG DMS0326 KEY 14x9 Page 45... -

Page 48: And Transmission

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL P.T.O AND TRANSMISSION TRANSMISSION MODEL 180 & 230 T60 SHAFT PART No. DESCRIPTION 90-32-4001 PTO SHAFT F/M 90-32-4006 PTO SHAFT M/M 90-32-4007 PTO SHAFT F/M 90-32-4003 PTO SHAFT F/F... -

Page 49: Problems And Possible Solutions

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL PROBLEMS AND POSSIBLE SOLUTIONS PROBLEM PROBABLE CAUSE POSSIBLE SOLUTION Page 47... - Page 50 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL PROBLEMS AND POSSIBLE SOLUTIONS PROBLEM PROBABLE CAUSE POSSIBLE SOLUTION Page 48...

-

Page 51: Waltersheid Wide Angle Pto

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL WALTERSCHIED WIDE ANGLE PTO 6 SPLINE – 43006 21 SPLINE - 43005 WALTERSCHEID TORQUE LIMITER COMPLETE 6 SPLINE W/A PART No. 43006TL Page 49... -

Page 52: Comer T60 Underbody Shaft

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL COMER T60 UNDERBODY DRIVESHAFT. DESCRIPTION PART No. SPLINED BAR 42041 T60 INNER TUBE (PER METER) 42775 T60 OUTER TUBE(PER METER) 42770 YOKE TO OUTER 42745 ROLL PIN 42030 JOURNAL 42701 YOKE 6 SPLINE CLAMP BOLT 42715... -

Page 53: Walterschied Pto Shaft

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL WALTERSCHEID P.T.O SHAFT PART No. DESCRIPTION 43312 YOKE TO 6 SPLINE 43313 YOKE TO 21 SPLINE 43325 JOURNAL 43314 YOKE TO S4 TUBE 43315 YOKE TO S5 TUBE 43317 YOKE TO SHEAR BOLT CLUTCH B1310 SHEAR BOLT 6.8 HARDNESS... -

Page 54: Walterschied W/A Pto Shaft Part No. 43102

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL WALTERSCHEID WIDE ANGLE P.T.O SHAFT PART No. 43102 Page 52... - Page 55 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL WALTERSCHEID WIDE ANGLE P.T.O SHAFT PART No. 43102 PARTS LIST PART No. DESCRIPTION 43005 W/A P.T.O SHAFT COMPLETE 21 SPLINE 43006 W/A P.T.O SHAFT COMPLETE 6 SPLINE 43007 W/A P.T.O SHAFT COMPLETE 20 SPLINE 43390 21 SPLINE INNER W/A HALF SHAFT WITH OUTER GUARD 43391...

-

Page 56: Comer Pto Guard Safety Chain Fixing

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 5.10 COMER PTO GUARD SAFETY CHAIN FIXING Care should be taken when fixing the PTO safety chains, by following the guidelines below you can help avoid unnecessary and possibly expensive damage to the PTO guard and its component parts. The purpose of the safety chain is to stop the guarding from rotating during its normal operation thus preventing foreign objects becoming entangled in it including you!, the safety chains must be fixed in a position that limits the risk of damage to both operator and shaft guarding. - Page 57 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL The following pointers should help keep your guard serviceable for many hours. 1. Don't leave the chains too long allowing them to wrap around the guard it will damage the guard. 2.

-

Page 58: Pto Stowage

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 5.11 PTO STOWAGE When the spreader is not in use stow PTO as shown to prevent damage. Please check the condition of the PTO guard regularly, if damaged replace as soon as possible. Page 56... -

Page 59: Brake & Axle Arrangements Brake Arrangment Eur 1510 414S

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL BRAKE & AXLE ARRANGEMENTS BRAKE ARRANGMENT EUR 1510 414S - 180 10 11 Page 57... - Page 60 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL BRAKE ARRANGMENT EUR 1510 414S – 180 PARTS LIST DESCRIPTION PART No. DRUM F10017/7 LINING 97726013 S' CAM ROD 97831 SEAL 97770008 BUSH 97610568 GREASER 98608A1 CIRCLIP 98900042 BACK COVER...

-

Page 61: Axle Hub And Bearing Parts

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AXLE HUB AND BEARING PARTS 180 Page 59... - Page 62 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AXLE HUB AND BEARING PARTS 180 PARTS LIST MODEL AXLE TYPE EUR 1520 AXLE SIZE 6" DESCRIPTION PART No. AXLE 2 4 6 SEAL KIT F10061/6 BEARING BR245 F10016/3...

-

Page 63: Tandem Axle Hub Parts Eur 1130 Axle

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL TANDEM AXLE HUB PARTS EUR 1130 AXLE 230 F100490 F10061/3 F10066/2 F00606 F10016/2 Page 61... -

Page 64: Tandem Axle Brake Parts Eur1130 Axle

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL TANDEM AXLE BRAKE PARTS EUR 1130 AXLE 230 F10108/1 F10316 F10317 F10119/4 Page 62... - Page 65 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 26 TONNE TANDEM AXLE 230 PART No. DESCRIPTION 1 PR B5026 ROCKING BEAM ASSEMBLY STUB AXLE 130 BEAM F00620 BRAKE LEVER B5130 PIVOT BLOCK M60 73164 BOLT & NUT B5115 RETAINING COLLAR B5117...

-

Page 66: Hydraulic Brake Ram Assembly 35Mm Bore

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HYDRAULIC BRAKE RAM ASSEMBLY – 180 35mm BORE – 70830.3 PART No. DESCRIPTION 70830/3 RAM ASSEMBLY 70831/3 SEAL KIT 70830/4 SPRING & PIN KIT 70836 SELLOCK PIN 70835/3 CYLINDER... -

Page 67: Hydraulic Brake Ram Assembly 25Mm Bore

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HYDRAULIC BRAKE RAM ASSEMBLY – 230 25mm PART No. 70830/1 PART No. DESCRIPTION 70835/1 RAM ASSEMBLY 70831 SEAL KIT 70832 SPRING & PIN KIT 70836 SELLOCK PIN 70834 ADJUSTER Page 65... -

Page 68: Hydraulic Brake Circuit Single Axle

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HYDRAULIC BRAKE CIRCUIT SINGLE AXLE 216” PART No. DESCRIPTION 90-38-0177 COUPLING 3/8 FEMALE SELF SEAL DUMMY 3/8 MALE 90-38-0155 3/8"-3/8" NPT BULKHEAD 90-38-0172 3/8"-3/8"-3/8" NPT MALE TEE 90-37-1182 INTER-CONNECTING HOSE 90-37-1190 AXLE HOSE 90-37-1247... -

Page 69: Hydraulic Brake Circuit - Tandem Axles

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HYDRAULIC BRAKE CIRCUIT TANDEM AXLE HOSE LENGTH 216” PART No. DESCRIPTION 90-38-0177 COUPLING 3/8 FEMALE SELF SEAL DUMMY 3/8 MALE 90-38-0155 3/8"-3/8" NPT BULHKHEAD 90-37-1182 INTER-CONNECTING HOSE 90-37-1193 AXLE HOSE 90-37-1198 LONG HOSE 90-36-0021... - Page 70 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AXLES Page 68...

-

Page 71: General Information

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL General information. Page 69... -

Page 72: Axle, Maintenance And Adjustment

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Axle, maintenance and adjustment. Page 70... - Page 73 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 71...

- Page 74 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 72...

- Page 75 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 73...

- Page 76 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 74...

- Page 77 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 75...

- Page 78 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 76...

- Page 79 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 77...

- Page 80 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 78...

- Page 81 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 79...

- Page 82 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 80...

-

Page 83: Sprung Drawbar Spring Information

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 81... -

Page 84: Minimum Program Of Maintenance Sheet

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Page 82... -

Page 85: Tyres And Wheels

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL TYRES AND WHEELS Tyre and wheel maintenance. Maintenance of correct inflation pressure is the basic essential factor in obtaining the best performance and life from a pneumatic tyre. The air inside the tyre enables it to carry a load. It is only when the inflation pressure is correctly matched that the tyre adopts its optimum cross-sectional shape and the tread rests correctly on the road surface with the correct pressure distribution across its whole width, thus allowing the sidewalls to provide the required degree of flexibility. -

Page 86: Tyre Pressure Settings

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL TYRE PRESSURE SETTINGS - GENERAL 6 MPH/10 KPH - Bar/PSI 20 MPH/30 KPH - Bar/PSI TYRE TYPE 16.9-14 x 34 P14 3.0/44 2.5/36 18.4 x 34 PR14 2.5/36 2.5/36 580/70 R38 2.0/29 2.5/36 2.8/41 3.0/44 2.0/29... - Page 87 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 580/70 R38 STANDARD 170/A8 HIGH LOAD 180/A8 710/70 R38 Page 85...

- Page 88 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 560/60 R22.5 600/55 R22.5 Page 86...

-

Page 89: Wheel Type And Torque Settings

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL WHEEL TYPE & TORQUE SETTINGS TYRE TYPE WHEEL TYPE WHEEL STUD TYPE & SIZE TORQUE SETTINGS 580/70 R38 10 x M22 - 1.5 335 PCD 510 Nm/375 Ib/ft W18A x 38 - 45 offset 280 bore 710/70 R38 10 x M22 - 1.5 335 PCD 510 Nm/375 Ib/ft... -

Page 90: Options

90-21-0027 SPRING 13 LEAF UP TO 18 TONNE & OVER 90-20-0509 U-BOLT 30mm FOR 13 LEAF SPRING 90-42-0021 3-BOLT HITCH 90-10-3811 1-8 x 8" BOLT SWIVEL EYE TO 9000Kg VERTICAL LOAD RATED . DRAW PIN SIZE 1-1/2” OR 2” PLEASE CONTACT YOUR BUNNING DEALER FOR DETAILS. Page 88... -

Page 91: Guillotine Slurry Door

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GUILLOTINE SLURRY DOOR WIDEBODY PART No. DESCRIPTION NGTB1100 GUILLOTINE DOOR 90-39-0036 HYDRAULIC RAM 90-16-3360 TOP RAM PIN DIA 5/8" 90-16-3401 BOTTOM RAM PIN DIA 3/4" NGTB0205 RUBBER SKIRT W.B NGTB0206-2 CLAMP STRIP 90-16-0160 SPLIT PIN... -

Page 92: Guillotine Slurry Door Horizontal Beaters

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GUILLOTINE SLURRY DOOR HORIZONTAL BEATERS PART No. DESCRIPTION B4115 DOOR B4138 HYDRAULIC RAM 65520 SEAL KIT 50mm BORE B4130 TOP RAM PIN DIA 5/8" B4132 BOTTOM RAM PIN DIA 3/4" B4166/1 RUBBER SEAL WITH WB AUGERS B4184... -

Page 93: Guillotine Slurry Door Hydraulic Circuit Drawing

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL GUILLOTINE SLURRY DOOR HYDRAULIC CIRCUIT. PART No. DESCRIPTION 90-38-0118 Male Quck Coupler, 8FP 90-38-0022 DUMMY 1/2" FEMALE 90-38-0180 3/8"-3/8"- BPT BULKHEAD 90-37-1182 Hose, 06 x 100, 08MP x 06FJX 90-37-1194 Hose, 06 x 360, 06FJX x 06FJX90 90-37-1195 Hose, 06 x 360, 06FJX90 x 06FJX90 Note: This slurry door has longer legs then the standard. -

Page 94: Support Leg

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL SUPPORT LEG PART No. 70306 Page 92... -

Page 95: Detachable Spinner Deck Kit

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL DETACHABLE SPINNER DECK Page 93... - Page 96 LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL DETACHABLE SPINNER DECK PART No. PART No. DESCRIPTION NGTB1153 CANOPY FRAME NGTB1229 CANOPY GATE NGTB1158 BLADE MOUNT RH NGTB1156 BLADE MOUNT LH NBUN1036 SPINNER DISK RH NBUN1035 SPINNER DISK LH NGTB0565 SPINNER BLADE NGTB1160...

-

Page 97: Simple Canopy

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL SIMPLE CANOPY Page 95... -

Page 98: Auto Rear Lamp Covers

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL AUTO REAR LAMPS PART No. DESCRIPTION AUTO LAMP COVER COMPLETE ASSEMBLY 90-46-0010 REAR LAMP 90-46-0022 SMV REFLECTOR NGTB0133-2 LAMP BRACKET LH NGTB0133-1 LAMP BRACKET RH NGTB1079 LAMP COVER LH NGTB1079-1 LAMP COVER RH NGTB0166... -

Page 99: Body Rubber Seals

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL BODY SEAL RUBBERS PART No. DESCRIPTION NGTB0205 SLURRY DOOR RUBBER NGTB0205 FRONTWALL RUBBER NGTB0201 DOUBLE WIPER RUBBER STRIP NGTB0250 DECK RUBBER HORIZONTAL BEATER CANOPY LOWER HORIZONTAL BEATER TOP WIPER Page 97... -

Page 100: Weigh Cell Spares

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 9.10 WEIGH CELL SPARES Load cell 11” lead 90-46-2052 Load cell 40” lead 90-46-2051 Page 98... -

Page 101: Electrics

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL ELECTRICS 10.1 WIRING FOR 12v 7 PIN PLUG WHITE (EARTH) – R – STOP BLACK – G – R.H. INDICATOR YELLOW – BR – TAIL RED – W – EARTH GREEN –... -

Page 102: Rear Lamps

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 10.2 REAR LAMPS 10.3 MARKER LAMP Page... -

Page 103: Hazardous Machinery Warning

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL HEALTH AND SAFETY 11.1 Hazardous machinery warning This machine is hazardous if improperly used and may cause serious injury or death if not used in accordance with these operating instructions and safety warnings. Employers are required to train and supervise all operators and assistants to observe safety precautions described by this handbook, the installation process and by warning decals. -

Page 104: Machinery Start Up

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL 11.8 Machinery start up Sound the horn before starting this machine. 11.9 Machinery shut down This machine must be operated from a tractor driver’s seat. The tractor and machine must be shut down, the key removed and hydraulics lowered, before the driver leaves the seat or any adjustments or repairs are made. -

Page 105: 11.14 Operating Hazard Area

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL Danger – Keep hands clear of taildoor and mechanism during operation. 11.14 Operating hazard area Objects can be thrown out from the rotors with sufficient force • to severely injure people. Stay away from machine when it is running. -

Page 106: 11.15 Warnings

During the 3 year warranty period any failures which occur due to faulty components or workmanship must be reported to G.T. Bunning & Sons Ltd before any repairs or replacements of components is carried out. The warranty period commences on the despatch date from the factory. All parts not guaranteed by G.T. -

Page 107: Important Information

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL IMPORTANT INFORMATION When using the speader in conjunction with a tractor which has a fast and slow response control on the spool valves, check that the control on the spool valve is not in the slow position in respect of the floor drives, as this will over ride the variable floor speed. -

Page 108: Notes

LOWLANDER180 & 230 WIDEBODY MANURE SPREADER – INSTRUCTION & SPARES MANUAL NOTES Page... -

Page 109: Identification Plate

The machine number (VIN) is required with all orders for spare parts and technical enquires. This is necessary in order to ensure correct delivery of spare parts. The identification plate with the machine number is attached to the middle right side of the machine drawbar. 01/01/9999/U/MSL 180 Page... -

Page 110: Technical Data & Specifications

TARE WEIGHT lbs 15430 17630 PAYLOAD lbs 39680 50700 PAYLOAD + TARE lbs 50700 68340 AXLE SIZE 6" 5" Bunning tolerance +/- 2% MODEL Axle SINGLE TANDEM Axle beam size 6" 5" Carrying capcacity 39680 lbs 50700 lbs Cubic Feet... -

Page 111: Machine Dimensions

37.8" 84.6" 337" 132" 121.2" Bunning tolerance +/- 2% • FOR PROMPT SUPPLY OF SPARES, ALWAYS QUOTE THE CHASSIS SERIAL NUMBER, (FOUND ON THE CHASSIS IDENTIFICATION PLATE) This manual should stay with the machine/operator at all times. This manual is an original English language copy. - Page 112 • Toll Free: 800-446-0316 • www.norwoodsales.com Norwood Sales Inc. Cooperstown, ND 701-797-3684 701-797-3685 Norwood Sales Inc. Horace, ND 701-588-4000 701-588-4004 Norwood Sales Inc. Union, NE 402-263-2100 402-263-2104...

Need help?

Do you have a question about the 180 and is the answer not in the manual?

Questions and answers