Table of Contents

Advertisement

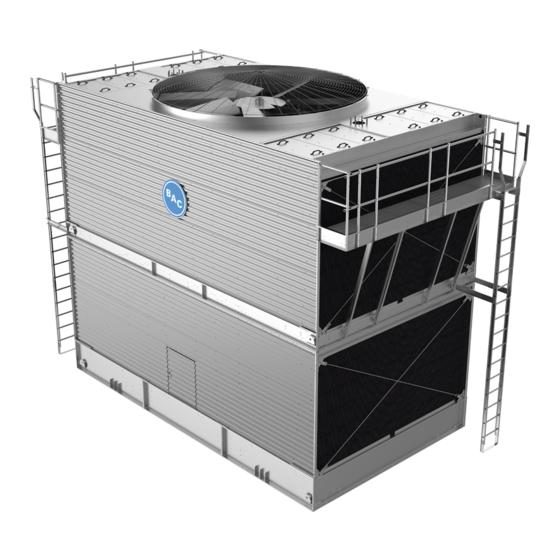

Series 3000 and Series 1500

Crossflow Cooling Towers

Operating and

Maintenance Instructions

altimore Aircoil Company Crossflow Cooling

B

Towers have been designed to give long, trouble-

free service when properly installed, operated, and

maintained. To obtain optimum performance and maxi-

mum service life, it is important that a program of regular

inspection and maintenance be developed and carried

out. This bulletin is published as a guide to establishing

such a program.

Included in the bulletin are the recommended services for

start-up, operation, and shutdown and the approximate

frequency for each. Note that the recommendations on

frequency of service are minimums and where operating

conditions are severe, the services should be performed

more often. For each required service, follow the proce-

dures outlined under the "Maintenance Procedures"

section of this bulletin. The cooling towers are illustrated

on page 2 with the major points of inspection and service

identified. A copy of the unit certified drawing should also

be available for reference. If you need additional informa-

tion about the operation or maintenance of this equip-

ment that is not covered in this bulletin, contact the local

B.A.C. Representative. Their name and telephone number

are on a label at the connection end of the unit.

Table of Contents

General Maintenance Information . . . . . . . . . . . . . . 2

Operation and Maintenance . . . . . . . . . . . . . . . . . . 3

Initial and Seasonal Start-Up . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Seasonal Shutdown . . . . . . . . . . . . . . . . . . . . . . . 4

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . 5

BALANCE-CLEAN

®

Chamber/Inlet Pre-Strainer . . . . . . . . . . . . . . . . . . . 5

Cold Water Basin . . . . . . . . . . . . . . . . . . . . . . . . . 5

Make-Up Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fan Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

®

Power

Train Drive System . . . . . . . . . . . . . . . . . . . . . . 6

Fan Shaft Bearings . . . . . . . . . . . . . . . . . . . . . . . . 7

Adjustable Motor Base . . . . . . . . . . . . . . . . . . . . . 7

Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . 8

Winter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Water Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Biological Control . . . . . . . . . . . . . . . . . . . . . . . . 11

Factory Authorized Parts . . . . . . . . . . . . . . . . . . . . 12

Page

BULLETIN M244/1-OAE

Advertisement

Table of Contents

Summary of Contents for Baltimore Aircoil Company 3000 Series

-

Page 1: Table Of Contents

Series 3000 and Series 1500 Crossflow Cooling Towers Operating and Maintenance Instructions altimore Aircoil Company Crossflow Cooling Table of Contents Page Towers have been designed to give long, trouble- General Maintenance Information ....2 free service when properly installed, operated, and Operation and Maintenance . -

Page 2: General Maintenance Information

General Maintenance Information WATER: The most harmful conditions develop as water evaporates he services required to maintain a cooling tower from the cooling tower, leaving behind the dissolved solids are primarily a function of the quality of the air and originally contained in the make-up water. -

Page 3: Operation And Maintenance

Operation and Maintenance escribed below are the recommended services for start-up, operation, and shutdown and the approximate frequency for each. TABLE 1: Recommended Maintenance Services for Series 3000, and Series 1500 Cooling Towers Type of Service Monthly Quarterly Start-Up Shutdown Annually Ref. -

Page 4: Initial And Seasonal Start-Up

Operation and 14. Check the voltage and current of all three legs of the fan motor. The current should not exceed the nameplate Maintenance rating. Note: Current should be measured during warm ambient conditions and with a heat load on the tower. After (continued) prolonged shutdowns, the motor insulation should be checked with a “megger”... -

Page 5: Maintenance Procedures

Maintenance Chamber. The device is equipped with an internal strainer. Located at the bottom of the EASY-CLEAN™ Chamber is Procedures a capped clean-out connection. This can be used to periodically purge the EASY-CLEAN™ Chamber of dirt and debris collected by the strainer. The strainer should be cleaned periodically as shown in the Recommended CONDUIT™... -

Page 6: Make-Up Valve

Maintenance Height of Water in Model No. the Cold Water Basin Procedures (in.) (continued) (continued) Series 3000 Models Quarterly, or more often if necessary, the entire cold- 33245 to 33501 ⁄ " water basin should be drained, cleaned, and flushed with fresh water to remove the silt and sediment which Series 3000 Models 33522 to 331328... -

Page 7: Baltidrive

Maintenance ADJUSTABLE MOTOR BASE: The motor base adjusting screw (See figure 4 & 5) should Procedures be coated twice a year using a good quality corrosion inhibiting grease such as one of those recommended for (continued) lubricating the fan shaft bearings. FAN SHAFT BEARINGS: The fan shaft is supported by two pillow block ball bearings, each equipped with a lubrication fitting and a... -

Page 8: Corrosion Protection

Corrosion Protection The Series 3000 and Series 1500 Cooling Towers are con- structed of corrosion-resistant materials. The wet deck sur- face is made of an inert synthetic material, which requires no protection against rot, decay, rust or biological attack. Other materials used in construction of the equipment, which are listed below, should be inspected regularly. -

Page 9: Winter Operation

Winter Operation 3. Remove the 1/2" plug from the 1/2" drain connection of the BALANCE CLEAN ® or EASY-CLEAN™ Chamber during cold weather operation. CAUTION: The plug must be he Series 3000 and Series 1500 Cooling Towers reinstalled during warm weather to obtain full thermal can be operated at ambient temperatures below performance. -

Page 10: Water Treatment

1. Ensure all controls for capacity and freeze protection 3. Discover any icing conditions that may develop before are set properly and functioning normally. they reach the point where the tower or supports are damaged or system performance is impaired. 2. -

Page 11: Biological Control

1. The chemicals must be compatible with the unit re-circulating pump. They should not be batch fed construction (zinc coated) steel as well as all other directly into the cold water basin. materials used in the system (pipe, heat exchanger, etc.) 3. -

Page 12: Factory Authorized Parts

Corby, Northants, England: Baltimore Aircoil Ltd., (44)(1536)200-312, FAX: (44)(1536)265-793 Sondrio, Italy: Baltimore Aircoil Italia S.R.L., (39)(0342)482-882, FAX: (39)(0342)483-022 Capetown, Republic of South Africa: Baltimore Aircoil Company, S.A. (Pty) Ltd., (27)(21)371-7121, FAX: (27)(21)(374-2081 Madrid, Spain: BAC Iberica, S.A., (34)(91)302-1732, FAX: (34)(1)302-2831 Joint Ventures: Dalia, China: Dailian Bingshan Baltimore Aircoil Refrigeration Company, Ltd., (86)(411)469-4854, FAX: (86)(411)(469-4844...

Need help?

Do you have a question about the 3000 Series and is the answer not in the manual?

Questions and answers