Table of Contents

Advertisement

SERVICE MANUAL

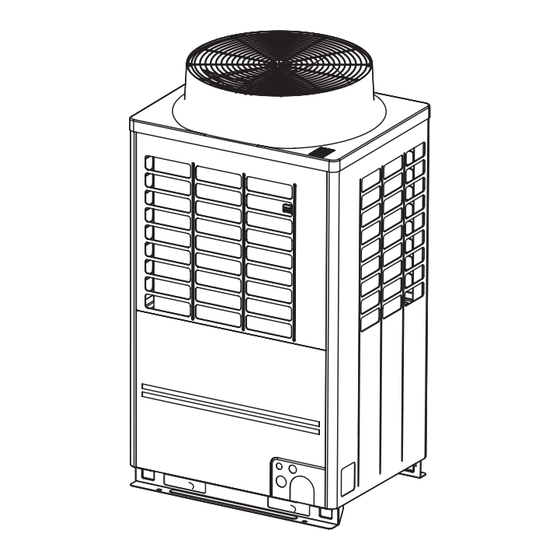

AIR-CONDITIONER (MULTI TYPE)

<SUPER HEAT RECOVERY MULTI-e>

Outdoor Unit

Model name:

MMY-MAP0726FT2P-UL

Flow Selector Unit (FS unit)

Model name:

RBM-Y0383FUL

RBM-Y0613FUL

RBM-Y0963FUL

RBM-Y0384FUL

RBM-Y0614FUL

RBM-Y0964FUL

RBM-Y0611F4PUL

RBM-Y0611F6PUL

FILE NO. SVM-16082-12

Revised on Jan, 2023

Advertisement

Table of Contents

Troubleshooting

Need help?

Do you have a question about the MMY-MAP0726FT2P-UL and is the answer not in the manual?

Questions and answers