Advertisement

Quick Links

Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com

1. DESCRIPTION

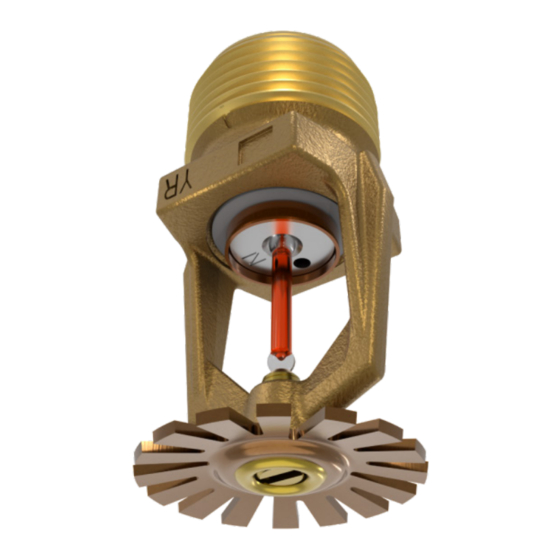

The Viking Standard Response ELO Pendent Sprinkler VK536 is a thermosensitive

glass bulb spray sprinkler available in several different finishes and temperature rat-

ings to meet design requirements. The special Polyester and Electroless Nickel PTFE

(ENT) coatings can be used in decorative applications where colors are desired. In

addition, these coatings have been investigated for installation in corrosive atmos-

pheres and are listed/approved as corrosion resistant as indicated in the Approval

Charts.

The extra-large orifice provides greater flows at lower pressures than standard orifice or

large orifice sprinklers. This feature allows reduced pipe sizing for hydraulically calculated

sprinkler systems, which require high densities of water. Viking Standard Response Extra-

Large Orifice Sprinklers may eliminate the need for a fire pump or reduce the size of the

pump if it is required. On existing systems, replacing large orifice sprinklers with extra-large

orifice sprinklers may provide the higher densities required to allow an increase in the hazard

classification of an occupancy.

Viking standard response sprinklers may be ordered and/or used as open sprinklers (glass

bulb and pip cap assembly removed) on deluge systems. Refer to

below.

2. LISTINGS AND APPROVALS

cULus Listed: Category VNIV

FM Approved: Class 2009

NYC Approved: MEA 89-92-E, Volume 3

Refer to Approval Charts and Design Criteria for requirements that must be followed.

3. TECHNICAL DATA

Specifications:

Available since 1992.

Maximum Working Pressure: 175 psi (12 bar). Factory tested hydrostatically to 500 psi (34.5 bar).

Thread size: 3/4" NPT or 20 mm BSP

Nominal K-Factor: 11.2 U.S. (161.3 metric

*Metric K-factor measurement shown is when pressure is measured in Bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Glass-bulb fluid temperature rated to -65 °F (-55 °C)

Overall Length: 2-5/16" (58.7 mm)

Material Standards:

Sprinkler Frame: Brass UNS-C84400

Deflector: Brass UNS-C51000

Bulb: Glass, nominal 5 mm diameter

Pip Cap and Insert Assembly: Copper UNS-C11000 and Stainless Steel UNS-S30400

Compression Screw: Brass UNS-C36000

Belleville Spring Sealing Assembly: Nickel Alloy, coated on both sides with PTFE Tape

For Polyester Coated Sprinklers: Belleville Spring-Exposed

For ENT Coated Sprinklers: Belleville Spring-Exposed, Screw and Pipcap-ENT plated

Ordering Information:

Order Standard Response Extra-Large Orifice Pendent Sprinkler VK536 by first adding the appropriate suffix for the sprinkler fin-

ish and then the appropriate suffix for the temperature rating to the sprinkler base part number.

Finish Suffix: Brass = A, Chrome = F, White Polyester = M-W, Black Polyester = M-B, Wax Coated = C, and ENT = JN

Form No. F_072213

22.04.14

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

)

*

(Also refer to the current Viking price list.)

Rev 22.1

STANDARD RESPONSE

ELO PENDENT SPRINKLER

(STORAGE-DENSITY/AREA)

Ordering Instructions

Replaces Form No. F_072213 Rev 21.1

(Updated FM references to non-storage sprinklers.)

Page 1 of 6

VK536

Advertisement

Summary of Contents for Viking VK536

- Page 1 (Also refer to the current Viking price list.) Order Standard Response Extra-Large Orifice Pendent Sprinkler VK536 by first adding the appropriate suffix for the sprinkler fin- ish and then the appropriate suffix for the temperature rating to the sprinkler base part number.

-

Page 2: Technical Data

Temperature Suffix (°F/°C): 155°/68° = B, 175°/79° = D, 200°/93° = E, 286°/141° = G. For example, sprinkler VK536 with a Brass finish and a 155 °F/68 °C temperature rating = Part No. 07961AB Available Finishes And Temperature Ratings: Refer to Table 1 Accessories: (Also refer to the Viking website.) - Page 3 The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com TABLE 1: AVAILABLE SPRINKLER TEMPERATURE RATINGS AND FINISHES...

- Page 4 Designed for use in hazard occupancies up to and including Extra-Hazard Group II with a minimum operating pressure of 7 psi (0.5 bar). • • Sprinkler VK536 is also cULus Listed for use in High-Piled Storage Occupancies as defined in NFPA 13 with a minimum operating pressure of 7 psi (0.5 bar).

- Page 5 (Also refer to Approval Chart 2 above.) FM Approval Requirements: Standard Response Extra-Large Orifice Pendent Sprinkler VK536 is FM Approved for use as a standard response pendent Storage sprinkler as indi- cated in the FM Approval Guide. For specific application and installation requirements, reference the latest applicable FM Loss Prevention Data Sheets (including 2-0 and 8-9).

- Page 6 (STORAGE-DENSITY/AREA) The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com Figure 2: Sprinkler Dimensions Figure 3: Pendent Sprinkler VK536 Dimensions with the Model E-1 and E-2 Recessed Escutcheons Replaces Form No.

- Page 7 Refer to the appropriate technical data page and NFPA standards for complete care, handling, installation, and maintenance instructions. For additional product and system information Viking data pages and installation instructions are available on the Viking Web site at www.vikinggroupinc.com.

- Page 8 * Refer to the appropriate current technical data pages for complete care, handling, and installation instructions. Data pages are included with each shipment from Viking or Viking distributors. They can also be found on the Web site at www. vikinggroupinc.com.

- Page 9 • while ceiling finish work is being completed. Use only the designated Viking recessed sprinkler wrench (refer to the appropriate sprinkler data page) to install these sprinklers. NOTE: The protective cap is • temporarily removed during installation and then placed back on the sprinkler for protection until finish work is completed.

- Page 10 Take care not to crack the wax coating on the units. • For touching up the wax coating after installation, wax is available from Viking in bar form. Refer to Table 1 below. The coating MUST be repaired after •...

-

Page 11: Listings And Approvals

1. DESCRIPTION Viking fire sprinklers consist of a threaded frame with a specific waterway or orifice size and a deflector for distributing water in a specified pattern. A closed or sealed sprinkler refers to a complete assembly, including the thermosensitive operating element. An open sprinkler does not use an operating element and is open at all times. - Page 12 TECHNICAL DATA SPRINKLER OVERVIEW The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058 Telephone: 269-945-9501 Technical Services: 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com VERTICAL SIDEWALL (VSW) SPRINKLER: A sprinkler intended for installation near the wall and ceiling. The deflector provides a water spray pattern outward in a quarter-spherical pattern and can be installed in the upright or pendent position with the flow arrow in the direction of discharge.

- Page 13 Refer to NFPA 25 for Inspection, Testing and Maintenance requirements. 7. AVAILABILITY Viking sprinklers are available through a network of domestic and international distributors. See The Viking Corporation web site for the closest distributor or contact The Viking Corporation. 8. GUARANTEE For details of warranty, refer to Viking’s current list price schedule or contact Viking directly.

-

Page 14: Warranty Terms And Conditions

For more information, go to www.P65Warnings.ca.gov 2. WARRANTY TERMS AND CONDITIONS For details of warranty, refer to Viking’s current list price schedule at www.vikinggroupinc.com or contact Viking directly. New Bulletin Form No. F_111218 18.11.15...

Need help?

Do you have a question about the VK536 and is the answer not in the manual?

Questions and answers