Table of Contents

Advertisement

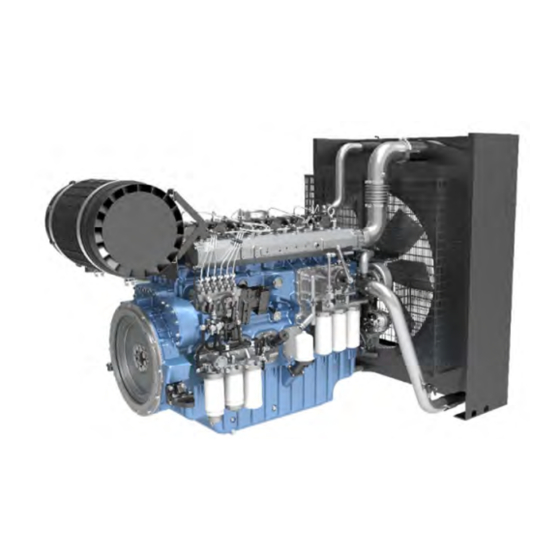

M33 PowerKit Engine

Operation and Maintenance Manual

DPK‐MAN‐EN‐M33‐0000‐19‐12‐20

Société Internationale des Moteurs Baudouin

Baudouin.com

Technoparc du Brégadan, 13260 Cassis, France (T) +33 488 688 500 (F) +33 488 688 501

SAS au capital de 33 311 180 € │R.C. Marseille 509 985 735 │Siret 509 985 735 00026

TVA intracommunautaire: FR 79 509 985 735 │APE : 28111 – 08

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for WEICHAI Baudouin M33 PowerKit

- Page 1 M33 PowerKit Engine Operation and Maintenance Manual DPK‐MAN‐EN‐M33‐0000‐19‐12‐20 Société Internationale des Moteurs Baudouin Baudouin.com Technoparc du Brégadan, 13260 Cassis, France (T) +33 488 688 500 (F) +33 488 688 501 SAS au capital de 33 311 180 € │R.C. Marseille 509 985 735 │Siret 509 985 735 00026 TVA intracommunautaire: FR 79 509 985 735 │APE : 28111 –...

-

Page 2: Table Of Contents

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Contents Section A - General Information Foreword ........................3 A10 Safety & Security ..................... 4 A20 Warranty Policy ..................... 15 Section B - Engine Information B10 Engine Description ....................18 B20 Engine Identification ....................19 B30 Engine Overview .................... -

Page 3: Section A - General Information

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section A - General Information Foreword Please be advised, do not operate or perform any operation, maintenance or repair on your PowerKit engine until you have read and understood the information in this Manual in its entirety. -

Page 4: A10 Safety & Security

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 A 10 Safety & Security Safety Information SAFETY WARNING Failure to comply with the preventive measures and safety instructions included in this manual and with warnings indicated on the engine may lead to injury or even death. - Page 5 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Symbols Used in the operation and maintenance manual As you read this Manual, take note of the warnings indicating the precautions to be taken to avoid unsafe practices and conditions. In this Manual, the following symbols are used to highlight specific information. Clearly these safety instructions alone are not sufficient to avoid danger.

- Page 6 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Safety symbols Symbol Definition Wear hand protection Wear ear protection Wear eye protection Wear head protection Wear foot protection Wear a protective mask Wear overalls Avoid naked flames Do not smoke Do not use a mobile phone Keep an extinguisher close by Danger: battery acid Danger: live cables, electrical risks...

- Page 7 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Universal Warning Typical locations of the Universal Warning labels are illustrated below. M33 Series Do not operate or perform maintenance on this engine unless you have read and understood the instructions and warnings in this Operation and Maintenance Manual.

- Page 8 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Personal Safety These Personal Safety precautions are designed to reduce the risk of contamination, serious injury or even death. Wear personal protective equipment (PPE) as required. Avoid prolonged and repeated contact with oil and diesel fuel. Do not put oily rags in pockets.

- Page 9 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Environmental safety There are laws regarding environmental protection and the disposal of waste of hydrocarbons. To ensure compliance with environmental protection laws, consult your local authorities who will advise you. Obey all local regulations for the handling and disposal of liquids.

- Page 10 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Batteries Wear personal protective equipment (PPE) as required. Do not smoke in areas where batteries are charged or near fuel circuits. The batteries release flammable fumes that can explode. Ensure there are no open flames or sparks near the battery.

- Page 11 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Electrical Risks Electrical checks must be carried out regularly. Electric wiring must be kept in good condition, properly positioned and soundly attached. All wires should be of the recommended size. Wires and cables must be protected by a fuse or calibrated circuit breaker. Do not short-circuit fuses and/or circuit breakers.

- Page 12 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Cleaning the Engine Use personal protective equipment when cleaning an engine. Regularly clean the engine surface to remove any greasy deposits that may be flammable. Do not wash an engine in operation or which has just stopped. Use the safety equipment required by your cleaning equipment.

- Page 13 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 General Precautions for Operation Before any operation or maintenance on any Baudouin product Wear personal protective equipment (PPE) where required. For maintenance, place a “Do not use” or similar sign on the starter switches. Access to the equipment is only for authorised and qualified personnel.

- Page 14 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Starting the Engine Before the first start up, whether a new engine or immediately after a service, check that all alarms and shutdown sensors are working well according to the commissioning. Make provisions to be able to stop the engine if a fault occurs. This can be done by shutting off the fuel or air supply to the engine or if equipped, pushing the emergency stop button..

-

Page 15: A20 Warranty Policy

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 A20 Warranty policy Warranty Coverage Société Internationale des Moteurs Baudouin (hereinafter referred to as ‘SIMB’) guarantees the absence of manufacturing defects or defects detectable with current technology of the ordered products (hereinafter referred to as ‘Engine’). The Warranty covers failures and defects due to poor quality of raw materials, poor manufacturing, or a design fault (hereinafter referred to as a ‘Warrantable Failure’). - Page 16 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 SIMB Responsibilities and Obligations In the event of a Warrantable Failure, SIMB will be responsible for the following: Handling, parts and labour required to repair the Engine. Owner Responsibilities and Obligations. The Owner will be responsible for the following: ...

- Page 17 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Warranty Limitations The Warranty does not cover Product failures or defects resulting from: Inappropriate use of the product relative to the Rating Definitions. Normal wear and tear, and corrosion. Failures due to inadequate maintenance not in accordance with the Operating and Maintenance Manual.

-

Page 18: Section B - Engine Information

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section B - Engine Information B10 Engine Description Rating Definitions Rating definitions Running conditions Engines of this rating provide unlimited hours of usage in a Continuous power constant 100% load. No overload capability is allowed. Engines of this rating provide unlimited hours of usage in a Unlimited Prime... -

Page 19: B20 Engine Identification

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B20 Engine Identification Engine identification Plate The M33 engine is fitted with an Engine Identification Plate. The plate can be found in a visible location and will supply the information below. Identification Plate Example 6M33 Series Diesel Engine 12M33 Series Diesel Engine Société... -

Page 20: B30 Engine Overview

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B30 Engine Overview Schematic Diagrams of 6M33CR (Common rail injection pump) 1- Fan 2- Rocker Arm Cover 3- Turbocharger 4- Flywheel Cover 5- Starter 6- Oil sump 7- Oil-Gas Separator Left hand view 8- Air Filter 9- High Pressure Fuel Pipe 10- ECU Wire... - Page 21 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Schematic Diagrams of 6M33MP (Mechanical injection pump) 1- Fan 2- Rocker Arm Cover 3- Turbocharger 4- Flywheel Cover 5- Starter 6- Oil sump 7- Oil-Gas Separator Left Hand View 10 11 8- Air Filter 9- Fuel Pipe 10- Thermostat 11- Water Pump...

- Page 22 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Schematic Diagrams of 12M33MP (Mechanical injection pump) 1- Manual Oil Pump (Optional) 2- Rocker Arm Cover 3- Turbocharger 4- Flywheel Cover 5- Starter 6- Oil Sump 7- Oil Filler Left Hand View 8- Air Filter 9- Clogging Indicator 10- Thermostat...

-

Page 23: B40 Cooling System

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B40 Cooling System 6M33 Series Diesel Engine Overall Layout of cooling circuits 1- Thermostat Assembly 2- Water Outlet Pipe 3- Radiator 4- Fan 5- Water Inlet Pipe 6- Water Pump 7- Water Gallery 8- Lube Oil Cooler 9- Cylinder Block Cooling 10- Cylinder Head Cooling... - Page 24 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 12M33 Series Diesel Engine Overall Layout of cooling circuits 1- Water-Outlet pipe 2- Thermostat assembly 3- Outlet pipe 4- Radiator 5- Water-inlet pipe 6- Water pump 7- Lube Oil Cooler 8- Cylinder block cooling 9- Cylinder head cooling 12M33 series diesel Engine is equipped with 2 cooling circuits.

-

Page 25: B50 Lubrication System

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B50 Lubrication System M33 Series Diesel Engine Overall Layout of lubrication system Oil Sump Suction strainer Oil pump 4a- Centrifuge filter 4b- Oil Filter Oil Cooler 5a- Bypass Valve 5b- Pressure Relief Valve Main Oil Gallery 7a- Piston Spray... -

Page 26: B60 Fuel System

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B60 Fuel System Fuel circuit diagram of 6M33CR The feed pump draws the fuel from the genset through the pre-filter/water-separator and then through full flow filter to the injection pump. Injection pump delivers fuel under high pressure to the common rail by the PRV (>2000 Bar) Excess fuel not sprayed is returned to the genset. - Page 27 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Fuel circuit diagrams of 6M33MP The feed pump draws the fuel from the genset through pre-filter/water-separator and through full flow filter to the injection pump. Injection pump delivers fuel under high pressure to the injectors. Excess fuel not sprayed is returned to the genset.

- Page 28 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Fuel circuit diagrams of 12M33MP The feed pump draws the fuel from the genset through pre-filter/water-separator and through full flow filter to the injection pump. Injection pump delivers fuel under high pressure to the injectors. Excess fuel not sprayed is returned to the genset.

-

Page 29: B70 Electronic Control Unit (Ecu)

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 B70 Electronic control unit (ECU) This section is only relevant to applicable products. The ECU is not present on engines with Mechanical Fuel Pumps. Please check specific documentation on: www.baudouinbam.com Société Internationale des Moteurs Baudouin Baudouin.com Technoparc du Brégadan, 13260 Cassis, France (T) +33 488 688 500 (F) +33 488 688 501 29 of 55... -

Page 30: Section C - Commissioning C10 Commissioning

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section C - Commissioning C10 Commissioning Unpacking PowerKit After the diesel engine is unpacked, the user shall first check the diesel engine and its accessories as per the delivery packing list, and check the engine appearance for damage and loose connections before carrying out the following tasks: Check the water plug and oil plug, check for water temperature and oil temperature sensors, and ensure that all parts to be self-provided are completely fitted. - Page 31 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Adding of coolant The coolant is mixed from softened clean water and an anticorrosive agent or antifreeze. Ensure to strictly abide by the specification of the additive manufacturer during mixing. Before adding the coolant, ensure that the components of the coolant circuit have cooled down and the engine has stopped.

-

Page 32: Section D - Operation D10 Starting The Engine

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section D - Operation D10 Starting the Engine Before starting the engine, double check the emergency stop works. Press the emergency stop button and try to start the engine. The engine should not start. Rotate the crankshaft of diesel engine for several turns to ensure smooth rotation. -

Page 33: D20 Operating The Engine

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 D20 Operating the Engine After the engine has started, keep it running with no load for 5-10 minutes to become warm. Only when the engine is warm, apply the load on the engine. The load should be increased gradually. -

Page 34: D30 Stopping The Engine

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 D30 Stopping the Engine Avoid shutting down the engine at full load. Before the shut-down, engine load should be reduced, and the engine should operate under a low-load condition for 3 to 5 minutes, or at idle for 1 to 2 minutes as mentioned above. -

Page 35: Section E - Maintenance

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section E - Maintenance E10 General safety conditions for maintenance SAFETY WARNING Users should carefully read the safety instructions before installation and operating the engine. Electrical insulation controls must NOT be carried out above 50 Vdc. Technician must check safety conditions for preventive and corrective maintenance operations. -

Page 36: E20 Maintenance Table

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 E20 Maintenance Table Check = • Mandatory maintenance, in operation working hours о Adjust = (h) or period (months - M), every, which occurs first Δ Clean = □ Replace = MD M1 M2 500 1.000 1.500 2.000 4.000 8.000 12.000 24.000 32.000 OPERATION... - Page 37 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Check = • Mandatory maintenance, in operation working hours о Adjust = (h) or period (months - M), every, which occurs first Δ Clean = □ Replace = MD M1 M2 500 1.000 1.500 2.000 4.000 8.000 12.000 24.000 32.000 OPERATION Centrifugal oil filter element(s) □...

- Page 38 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Check = • Mandatory maintenance, in operation working hours о Adjust = (h) or period (months - M), every, which occurs first Δ Clean = □ Replace = MD M1 M2 500 1.000 1.500 2.000 4.000 8.000 12.000 24.000 32.000 OPERATION □...

- Page 39 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Check = • Mandatory maintenance, in operation working hours о Adjust = (h) or period (months - M), every, which occurs first Δ Clean = □ Replace = MD M1 M2 500 1.000 1.500 2.000 4.000 8.000 12.000 24.000 32.000 OPERATION □...

-

Page 40: E30 Maintenance Operations

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 E30 Maintenance Operations Daily maintenance Check the coolant level and water temperature once the engine has stopped and cooled down. Check the fuel level. Check the oil level when the engine has stopped. - Page 41 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Check the belt after the engine has stopped. The belt is automatically tensioned with a tensioner. Check the tension of the belt by pushing the belt with your hand. Check exhaust gas colour. Note: The normal colour of exhaust gas is light grey.

- Page 42 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Maintenance items Replace engine oil Check the oil level after filling. Replace engine oil filter or filter element Apply oil (not lubricating grease) to the sealing gasket Tighten the oil filter by hand and rotate by approximately 3/4 turn Check the oil level after finished.

- Page 43 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Drain/clean the fuel pre-filter / water separator filter. If in the transparent bottom part of the fuel pre- filter/ water separator filter (1) some water is present, drain it by turning the valve installed under the filter (2).

-

Page 44: E40 Engine Maintenance For Long Term Storage

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 E40 Engine Maintenance for Long Term Storage Clean the diesel engine Protection method: a) Warm up the engine and drain the oil, clean the oil filter, and add anti-rust oil; b) Discharge the fuel, and add anti-rust mixed oil;... -

Page 45: Section F - Appendix F10 Coolant Recommendations

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Section F - Appendix F10 Coolant Recommendations The coolant ensures the best efficiency of the cooling system and protection against corrosion (chemical and galvanic). It also improves boiling temperature, resistance to rust and avoids scale deposit formation. Therefore, it is necessary to use a coolant which uses a corrosion inhibitor. -

Page 46: F30 Fuel Recommendations

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Viscosity As the viscosity of lubricating oil is dependent on temperature, the choice of SAE grade should be governed by the ambient temperature prevailing at the engine operating site. Should the temperature fall temporarily below the limits of the SAE grade selected, cold starting may be affected but the engine will not be damaged. -

Page 47: F40 Troubleshooting

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 F40 Troubleshooting The following guide is intended to highlight potential faults and corrective actions for a range of performance issues. Only attempt to rectify issues if within your organisational capabilities to ensure damage does not occur to the system and your warranty is not invalidated. - Page 48 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Insufficient engine power Causes Troubleshooting Check the air filter and intake pipe. Clean Intake system (air filter) is clogged. or replace the filter element. Check and adjust the valve timing. Check Exhaust back pressure is too high.

- Page 49 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Excessive fuel consumption Causes Troubleshooting Check the air filter and intake pipe for Intake system clogged. clogging. Remove clogging if any. Exhaust back pressure is too high. Check and clean the exhaust pipe. Replace fuel in accordance with the Poor fuel quality.

- Page 50 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Engine exhaust gas is white or blue Causes Troubleshooting Poor fuel quality with excessive moisture. Replace fuel. Check the operating temperature of the Coolant temperature is too low. thermostat. Replace it if necessary. Instable atomization of fuel injector.

- Page 51 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Rotating speed is unstable Causes Troubleshooting Poor fuel quality with moisture or wax. Clean the fuel system, replace the fuel. Check the fuel suction pipe and its joint for Air is sucked into fuel suction pipe. tightness.

- Page 52 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Diesel engine is too hot Causes Troubleshooting Excessive overload of diesel engine. Reduce the load. Poor combustion. Check the injector. Add or discharge oil based on oil dipstick Insufficient or excessive lubricating oil. level.

- Page 53 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 Excessive noise level Causes Troubleshooting Replace fuel with suitable Poor fuel quality. specification. Check the thermostat and replace it if Coolant temperature is too low. necessary. Incorrect valve timing or fuel supply Check, repair or adjust.

-

Page 54: F50 Diagnostic Fault Codes

M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 F50 Diagnostic Fault Codes List for ECU This section is only relevant to applicable products. The ECU is not present on engines with Mechanical Fuel Pumps. Please check specific documentation on: www.baudouinbam.com Société... - Page 55 M33 PowerKit Engine Operating and Maintenance Manual DPK-MAN-EN-M33-0000-19-12-20 This Page Left Intentionally Blank Société Internationale des Moteurs Baudouin Baudouin.com Technoparc du Brégadan, 13260 Cassis, France (T) +33 488 688 500 (F) +33 488 688 501 55 of 55 SAS au capital de 33 311 180 € │R.C. Marseille 509 985 735 │Siret 509 985 735 00026 TVA intracommunautaire: FR 79 509 985 735 │...

Need help?

Do you have a question about the Baudouin M33 PowerKit and is the answer not in the manual?

Questions and answers