Table of Contents

Advertisement

Quick Links

© Copyright 2000 Printed

5/31/2001

!

Read the operator's manual entirely. When you see this symbol, the subsequent in-

structions and warnings are serious - follow without exception. Your life and the lives of

others depend on it!

Cover illustration may show optional equipment not supplied with standard unit.

Operator's Manual

PH-15, PH-20, PFH-15 and PFH-20

Coulter Command System

Manufacturing, Inc.

P .O. Box 5060 Salina, Kansas 67402-5060

12611

148-384M

Advertisement

Table of Contents

Summary of Contents for GREAT PLAINS PH-15

- Page 1 Operator’s Manual PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System Manufacturing, Inc. P .O. Box 5060 Salina, Kansas 67402-5060 Read the operator’s manual entirely. When you see this symbol, the subsequent in- structions and warnings are serious - follow without exception. Your life and the lives of...

-

Page 2: Table Of Contents

Great Plains Manufacturing, Inc. assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the informa- tion contained herein. Great Plains Manufacturing, Inc. reserves the right to revise and improve its products as it sees fit. This publication describes the state of this product at the time of its publication, and may not reflect the product in the future. -

Page 3: Important Safety Information

Lower machine to ground, put tractor in park, turn off engine, and remove key. Detach and store implement in an area where children normally do not play. Secure implement with blocks and supports. 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... - Page 4 Allow only maintenance. enough slack in chain to permit turning. Replace chain if any links or end fittings are broken, stretched or damaged. safety chain for towing. PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004...

- Page 5 When removing and installing wheels. Do not dismount a moving tractor. wheels, wheel-handling Dismounting a moving tractor could equipment adequate for weight cause serious injury or death. involved. 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M...

-

Page 6: Introduction

Great Plains Mfg., Inc. Introduction Introduction Great Plains welcomes you to its growing family of new Owner Assistance product owners. This implement has been designed with If you need customer service or repair parts, contact a care and built by skilled workers using quality materials. -

Page 7: Section 1 Assembly And Setup

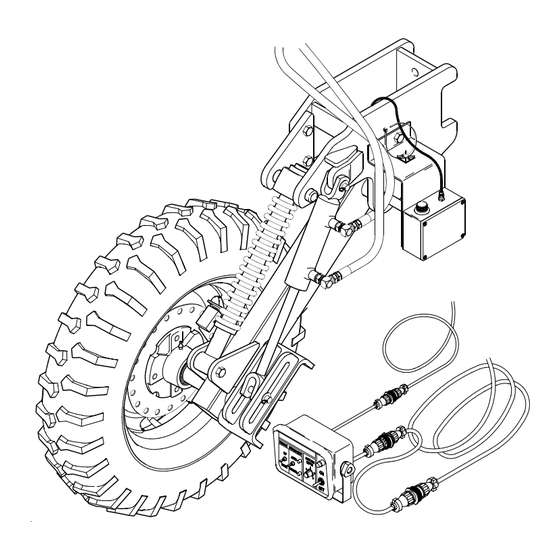

If you do not have the liquid fertilizer option (PFH), the coulter command will contain a coulter depth sensing wheel which is subassembled and preadjusted. Figure 1-1 Depth Sensing Wheel 18439 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 8: Sensor Box

Make sure the round bar link is in place and secured with a spring clip extension spring (17) that is connect- ed between the circular disk and the flat bar through the small holes. Figure 1-2 18427 Sensor Box PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 9: Gauge Wheel Lift Cylinder

(8) and cable ties (9). Make sure the cable does not rub anything as depth sensing wheel moves up and down. Figure 1-4 18429 Gauge Wheel Lift Cylinder 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 10: Lift Switch

4. Rotate the cam assembly so it hits the plunger when the hitch is raised just enough to begin to pick the openers off the ground. Figure 1-5 Lift Switch and Wiring Harness 18430 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 11: Tongue Cylinder

4. Connect rod end to tongue with clevis pin (6) and hair pin cotter (7). Figure 1-6 18432 Tongue Cylinder 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 12: Hydraulic Control Valve

Assemble the bolt through the pivot tube (11) located behind the tongue cylinder. Position valve mount so dual solenoids face toward rear of machine. Figure 1-7 19361 Hydraulic Control Valve PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 13: Hydraulic Connections

NOTE: The hose coming from the base end of the trans- port lift cylinders connects to port “C3”. The hose coming from the rod end of the transport lift cylinders connects to port “C4”. Figure 1-8 19360 Hydraulic Connections 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 14: Control Box

The white wire of the power cord must be connected to the "+" positive battery terminal and the black wire to the "-" negative battery terminal. Figure 1-9 12575 Control Box PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 15: Sensor Box Adjustments

WIRE) (#1) is 5 volts DC plus or minus 1/4 volt. Rotat- ing the circular disk counterclockwise increases volt- age potential, and rotating the circular disk clockwise Figure 1-10 12619 Sensor Box Adjustments 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 16: Section 2 Operating Instructions

Flow rates higher than 12 gallons per minute will not damage the valve, but may cause poor Coulter Command performance. The remote tractor hydraulic lever will have to be locked in PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 17: Operation Of Electronic Controls

(The markings Command circuit when it circulates this high flow of oil. on the knob settings are for reference only and do not represent a depth measurement.) 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 18: Field Adjustments

1/8 inch when the cam activates it. DO NOT "BOT- TOM OUT" THE LIFT SWITCH PLUNGER. PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 19: Speed Sensor

Rotate the depth sensing wheel to the position where the speed sensor plate is closest to the sensor mount, and retighten the sensor mount screws where the sensor just touches the speed sensor plate. 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 20: Section 3 Troubleshooting

Adjust the lift switch cam. See "Lift Switch" the lift switch cam on the rockshaft is not under Section 2 "Operating Instructions" properly adjusted. on Page 16.Check cable connections on lift switch leads. PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... - Page 21 For tractors with Pioneer quick couplers hydraulic flow through them. use Pioneer 8010-4P poppet style male couplers when operating in the OPEN CENTER mode. See Figure 2-2, page 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M...

-

Page 22: System Schematics

System Schematics If problems occur in the hydraulic or electric systems, refer to the schematics below and on page 21 to help locate the problem. Hydraulic Schematic 16313 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 23: Electrical Schematic

Great Plains Mfg., Inc. Section 3 Troubleshooting Electrical Schematic 16314 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... -

Page 24: Section 4 Maintenance & Lubrication

Type of Lubrication: Multi-Purpose Lithium Base Grease 12405 Quantity: Until grease begins to emerge 2 - 3 Years Axle Bearings Repack Type of Lubrication: Wheel Bearing Grease Quantity: Full Pack 12408 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M 6/21/2004... -

Page 25: Appendix

4820 3560 mm x pitch = nominal thread diameter in millimeters x thread pitch Torque tolerance + 0%, -15% of torquing values. Unless otherwise specified use torque values listed above. 6/21/2004 PH-15, PH-20, PFH-15 and PFH-20 Coulter Command System 148-384M... - Page 26 Great Plains Manufacturing, Inc. Corporate Office: PO. Box 5060 Salina, Kansas 67402-5060 USA...

Need help?

Do you have a question about the PH-15 and is the answer not in the manual?

Questions and answers