Subscribe to Our Youtube Channel

Summary of Contents for Time Electronics 5075

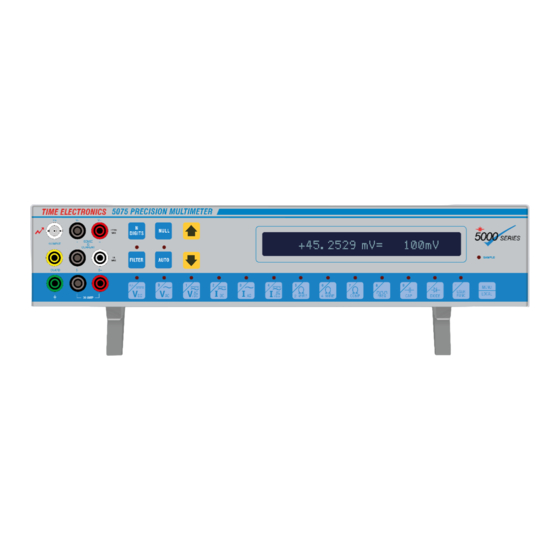

- Page 1 5075 Precision Digital Multimeter Calibration Manual Time Electronics Ltd BOTANY INDUSTRIAL ESTATE TONBRIDGE, KENT, TN9 1RH, UK Tel: 01732 355993 Fax: 01732 770312 Email: mail@TimeElectronics.co.uk Website: www.TimeElectronics.co.uk V17 16/11/06...

-

Page 2: Table Of Contents

2.1 Calibration key 2.2 GPIB(IEEE) Address 2.3 INTCAL 2.3 Menu options 8 - 9 2.4 5075 push buttons 2.5 Calibration Initialize 2.6 Calibration of DC Volt Ranges Set Zero - Low DC Volt ranges Set Full-Scale - Low DC Volt ranges... - Page 3 5075 Calibration Manual Page 3 Contents continued Page 3.2 Calibration Data Entry Certification Number entry Calibration Date entry Calibration Temperature entry Calibration Due Date entry Calibration Period entry Sample Certificate of Calibration 36 - 40...

-

Page 4: General Calibration Information

If any of the ranges are a long way out it indicates that the 5075 might be faulty. Please refer to the Time Electronics example calibration certificate at the end of this document, for details of the allowed errors of the calibration adjustment points. -

Page 5: Calibration Factors

When calibration is complete, it is good practice to keep a written record of all the calibration factors for future reference. Should the 5075 lose its internal memory or the calibration factors become corrupted for any reason, it will be possible to re-enter them without having to go to length of a full re-calibration. -

Page 6: Other Errors

The shield should be connected to the yellow guard terminal. If difficalties are being experianced and readings are unstable or not repeatable, please read the ‘Measurement Techniques’ chapter in the 5075 technical manual carefully. -

Page 7: Calibration Procedure

The 5075 is now ready to be re-calibrated as described below. 2.1 Calibration key The 5075 has a separate calibration key (referred to as Cal Key). It is plugged in a rear panel socket (near the GPIB switch). The calibration factors in the 5075 can not be modified or deleted without this key inserted. -

Page 8: Menu Options

Page 8 2.3 Menu options The 5075 menu is entered by using the ‘MENU’ key, it can be navigated through the options by using the ’UP’ and ‘DOWN’ arrow keys, and selection is then confirmed using the ‘USER FUNC’ key, also referred to as the ‘E’ key. -

Page 9: 5075 Push Buttons

Used to set the cal factor with full scale input 2.4 5075 push buttons In this manual the 5075 push buttons will be referred to as the legends as printed on them, e.g ‘MENU’. However throughout this document we will use the shorthand for... -

Page 10: Calibration Initialize

2.5 Calibration Initialize Make a note of original IEEE switch setting. • Change IEEE address of the 5075 to 16 ( refer to page 39 of 5075 tech • manual) to enter calibration mode. Power-up the 5075 and go into the menu by pressing ‘Menu’ then select the •... -

Page 11: Calibration Of Dc Volt Ranges

5075 Calibration Manual Page 11 Calibration of DC Volt Ranges Press ‘Vdc’ to enter DC volts function. • Set the address switch, see section 2.2. • Insert the Cal key, a small ‘c’ will appear on the display. • It is important that the filter is set as described in section 2.5. - Page 12 5075 Calibration Manual Page 12 Set Full-Scale - Low DC Volt ranges (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select 3V range. • Apply +3V full scale voltage to the input sense terminals. • Enter the ‘Menu’ and navigate to find “Cal to full scale” press ‘E’ to set the •...

-

Page 13: Set Zero - High Dc Volt Ranges

5075 Calibration Manual Page 13 Set Full-Scale - Low DC Volt ranges (continued) Apply -3mV full scale voltage to the input sense terminals. • Enter the ‘Menu’ and navigate to find “Cal to full scale” press ‘E’ to set the •... -

Page 14: Set Zero - Extra High Dc Volt Ranges

BNC cable is earth, as with the supplied HV cable a short flying lead connects the shield to the negative sense input socket. Refer to 5075 technical manual for connection advice on using the BNC input. Change range using the ‘ ’ and ‘ ’ arrow keys, select 3kV range. - Page 15 If a multifunction calibrator is not available which is capable of producing a 10kV and 3kV signal to calibrate the full scale of the 5075. A calibrator that can produce a accurate 1kV signal can be used. Hence a different process in this situation would need to be used to calibrate the 10kV and 3kV ranges.

-

Page 16: Calibration Of Dc Current Ranges

5075 Calibration Manual Page 16 Calibration of DC Current Ranges Press ‘Idc’ to enter DC current function. • Press ‘Auto’ until the auto range facility is turned off. • Set the address switch, see section 2.2. • Insert the Cal key, see section 2.1. -

Page 17: Set Full-Scale - Dc Current Ranges To 1 Amp

5075 Calibration Manual Page 17 Set Zero - DC Current ranges (continued) Press the ‘Null’ key to zero the reading. The ‘Null’ key may need pressing • several times. Change range using the ‘ ’ and ‘ ’ arrow keys, select 30uA range. - Page 18 5075 Calibration Manual Page 18 Set Full-Scale - DC Current ranges to 1 amp (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select 10mA range. • Apply +10mA full scale current to the current input terminals.

-

Page 19: Set Full-Scale - Dc High Current Ranges

5075 Calibration Manual Page 19 Set Full-Scale - DC Current ranges to 1 amp (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select 10µA range. • Apply +10µA full scale current to the current input terminals. - Page 20 If a multifunction calibrator is not available which is capable of producing a 30A signal to calibrate the full scale of the 5075. Then a signal of 10A can be used. Hence a different process in this situation would need to be used.

-

Page 21: Calibration Of Ac Voltage Ranges

Decrease displayed value by 100ppm Set Full Scale - AC Volt range. Use screened leads with the screen connected to the earth on the 5075 Where the full scale value is not available, it is possible to use a value that is not less than 1/3 of full scale. -

Page 22: Set Full Scale - Extra High Ac Volt Range

BNC cable is earth, as with the supplied HV cable a short flying lead connects the shield to the negative sense input socket. Refer to 5075 technical manual for connection advice on using the BNC input. Change range using the ‘ ’ and ‘ ’ arrow keys, select 3kV range. -

Page 23: Calibration Of Ac Current Ranges

Set Full-Scale - Low AC Current ranges 60Hz (use 1amp sockets) Use screened leads with the earth connected to the earth on the 5075 Where the full scale value is not available, it is possible to use a value that is not less than 1/3 of full scale. -

Page 24: Set Full-Scale - High Ac Current Ranges 60Hz

5075 Calibration Manual Page 24 Set Full-Scale - High AC Current ranges 60Hz (use 30amp sockets) Whilst calibrating the 30 Amp range, do not leave the current on for longer then required to take a reading as self heating via the internal current shunts will cause thermal drift. -

Page 25: Calibration Of Capacitance

5075 Calibration Manual Page 25 3.0 Calibration of Capacitance. Press ‘CAP’ to enter Capacitance function. • Press ‘Auto’ until the auto range facility is turned off. • Set the address switch, see section 2.2. • Insert the Cal key, see section 2.1. - Page 26 5075 Calibration Manual Page 26 Set Full Scale Capacitance (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select 30nF range. • Connect the 30nF ‘capacitance standard’ to the sense terminals. Enter the • ‘Menu’ and using the ‘ ’ and ‘ ’ arrow keys navigate to find ‘Adjust to value’, press the ’E’...

-

Page 27: Calibration Of Resistance

5075 Calibration Manual Page 27 3.1 Calibration of Resistance: A full scale resistance standard is required for each range • 4 wire resistors must be used up to 300KΩ and 2 wire resistors for 1MΩ and • above. Good quality screened test leads must be used, the screen must be connected •... - Page 28 5075 Calibration Manual Page 28 Set Zero calibration factors (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select the 3Ω range. • Connect 3Ω 4 wire standard resistor to sense and current terminals. • Remove the connection to the blue –ve current terminal.

- Page 29 5075 Calibration Manual Page 29 Set Zero calibration factors (continued) Change range using the ‘ ’ and ‘ ’ arrow keys, select the 30KΩ range. • Connect 30KΩ 4 wire standard resistor to sense and current terminals. • Remove the connection to the blue –ve current terminal.

-

Page 30: Set Full Scale Resistance

5075 Calibration Manual Page 30 Set Full Scale Resistance: Select ‘Ω 4 wire’. • Connect 4 wire test leads. • Select and connect 100mΩ 4 wire resistance standard. • Change range using the ‘ ’ and ‘ ’ arrow keys, select the 100mΩ range. - Page 31 5075 Calibration Manual Page 31 Set Full Scale Resistance (continued) Select and connect 1KΩ 4 wire resistance standard. • Change range using the ‘ ’ and ‘ ’ arrow keys, select the 1KΩ range. • Enter the ‘Menu’ and using the ‘ ’ and ‘ ’ arrow keys navigate to find ‘Adjust •...

- Page 32 5075 Calibration Manual Page 32 Set Full Scale Resistance (continued) Change to 2 wire test leads for 1MΩ and above. • Select ‘Ω 2 Wire’ • Select and connect 1MΩ 2 wire resistance standard. • Change range using the ‘ ’ and ‘ ’ arrow keys, select the 1MΩ range.

- Page 33 5075 Calibration Manual Page 33 Set Full Scale Resistance (continued) Resistance calibration complete. • Remove calibration key. • Set address switch back to your normal address when calibration is • complete.

- Page 34 Certification Number entry: If a certificate of calibration is produced, or a calibration number has been assigned to the 5075 for its recalibration, then this number can be entered into the 5075. Enter the ‘Menu’ and using the ‘ ’ and ‘ ’ arrow keys navigate to find •...

- Page 35 Press the ’E’ key to store. Calibration Due Date entry: The date that the next calibration is due can be entered into the 5075`s memory. Enter the ‘Menu’ and using the ‘ ’ and ‘ ’ arrow keys navigate to find •...

- Page 36 5075 Calibration Manual Page 36...

- Page 37 5075 Calibration Manual Page 37...

- Page 38 5075 Calibration Manual Page 38...

- Page 39 5075 Calibration Manual Page 39...

- Page 40 5075 Calibration Manual Page 40...

Need help?

Do you have a question about the 5075 and is the answer not in the manual?

Questions and answers