Subscribe to Our Youtube Channel

Summary of Contents for Crane NOZ-CHEK Cryogenic

- Page 1 OPERATION AND MAINTENANCE INSTRUCTIONS NOZ-CHEK®Cryogenic Valves www.cranecpe.com Crane ChemPharma & Energy...

-

Page 2: Introduction And Background

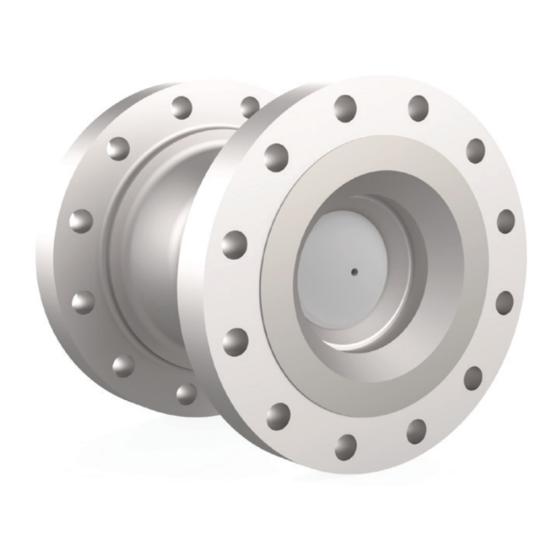

The Cryo Noz-Chek® valve is capable of achieving reduced leak rates of less than 300cc/min/inch at -196°C which Crane Stockham Valve has been an innovative leader fully complies with BS6364 and ISO 28921-1. in non-return valve design since 1960. The design of... -

Page 3: Initial / Commissioning Procedure

This phenomenon A Crane Stockham Valve Noz-Chek® check valve is a is not exclusive to Crane equipment, and should be precision built product, specifically designed for the applied to any pipe layout as good practice. -

Page 4: Operation

NOZ-CHEK®Cryogenic Installation, Operation & Maintenance (e) Welded End Valves 4.0 OPERATION (Bevelled per ASME B16.25 figure 2 (a) or 3 (a) depending on wall thickness). 4.1 OPENING Valves with end connections prepared for welding into a Reduced pressure, generated by increased velocity in pipeline should be lowered into position between mating the minimal flow area results in additional force to assist pipe ends after removal of any debris or foreign matter. -

Page 5: Maintenance

(20) from the valve (1). This process of applied heat and pressure for bonding rubber will eliminate the need for draining the valve prior to to metal and can only be replaced by Crane Stockham disassembly. Simply unscrew the cable gland (22), whilst Valve. -

Page 6: Valve Assembly

NOZ-CHEK®Cryogenic Installation, Operation & Maintenance 5.5 VALVE ASSEMBLY presence of a magnetic field, there is no preference in the polarity of the field, therefore the magnet can Assemble all components in reverse order to 5.3. be inserted into the housing either pole first). Ensure the magnets (24) are positioned in the centre of the Lubricate generously with suitable ‘Anti Seize’... - Page 7 Doc No.: ESB 3268 Revision: 0 Installation, Operating and Maintenance manual for NOZ-CHEK®Cryogenic Installation, Operation & Maintenance Checked: P Burns Crane Stockham Noz-chek ® valves for use in Revision Date: 25/08/20 Cryogenic Service Page 11 of 16 FIGURE 1 Item...

- Page 8 Revision: 0 Installation, Operating and Maintenance manual for Checked: P Burns Crane Stockham Noz-chek ® valves for use in Revision Date: 25/08/20 Cryogenic Service Page 12 of 16 NOZ-CHEK®Cryogenic Installation, Operation & Maintenance FIGURE 2 FIGURE 2 Crane Stockham Valve Ltd Registered Number : L549383 Eng.

- Page 9 Installation, Operating and Maintenance manual for NOZ-CHEK®Cryogenic Installation, Operation & Maintenance Subject Doc No.: ESB 3268 Checked: P Burns Crane Stockham Noz-chek ® valves for use in Revision: 0 Installation, Operating and Maintenance manual for Revision Date: 25/08/20 Cryogenic Service Checked: P Burns Crane Stockham Noz-chek ®...

- Page 10 Doc No.: ESB 3268 NOZ-CHEK®Cryogenic Installation, Operation & Maintenance Revision: 0 Installation, Operating and Maintenance manual for Checked: P Burns Crane Stockham Noz-chek ® valves for use in Revision Date: 25/08/20 Cryogenic Service Page 14 of 16 FIGURE 4 Item...

- Page 11 NOZ-CHEK®Cryogenic Installation, Operation & Maintenance 6.0 FAULT FINDING AND CORRECTION 6.5 There is no flow through the line a) The valve is installed backwards. b) The valve is new and the disc has not been broken One should keep in mind the purpose of the Noz-Chek® loose from the valve seat.

- Page 12 Crane Co., and its subsidiaries cannot accept responsibility for possible errors in catalogues, brochures, other printed materials, and website information. Crane Co. reserves the right to alter its products without notice, including products already on order provided that such alteration can be made without changes being necessary in specifications already agreed. All trademarks in this material are property of the Crane Co.

Need help?

Do you have a question about the NOZ-CHEK Cryogenic and is the answer not in the manual?

Questions and answers