Table of Contents

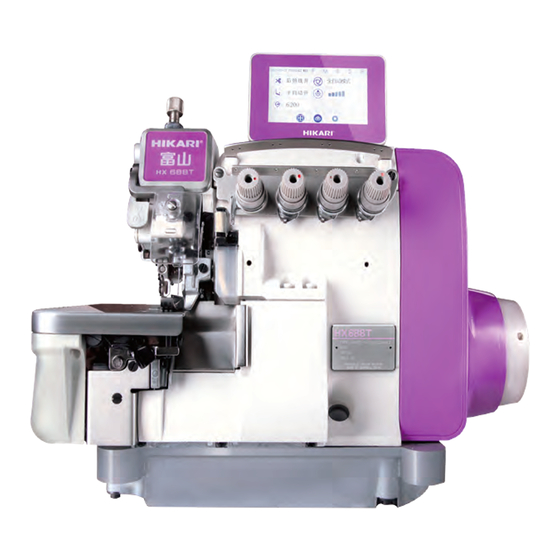

Advertisement

Advertisement

Chapters

Table of Contents

Summary of Contents for Hikari HX688T

- Page 2 安全须知请先仔细阅读 -------------------------------- 重要安全事项 ----------------------------------------- 1. 使用此缝纫机时,必须遵守包括如下项目的基本安全措施。 2. 使用此缝纫机之前,请 阅 读本使用说明书内的所有指示文件。同时应该将本使用说明书妥善保管,以便能 够随时查阅。 3. 使用此缝纫机前,所有的安全装置应安装到规定的位置。未按规定安装安全装置的缝纫机禁止使用。 此缝纫机应由接受过培训的操作人员来操作。 5. 使用缝纫机时,建议配戴安全防护眼镜。 6. 发生下列情况时,应立即关掉电源开关,或拔下电源线插头。 6-1 机针、弯针等穿线时。 6-2 更换机针、压脚,针板,弯针、送布牙、护指器等时。 6-3 修理时。 6-4 工作场所无人看管或工作人员离开工作场所时。 7. 缝纫机以及附属装置使用的机油、润滑剂等液体流入眼睛或沾到皮肤上时,或被误饮时,应立即清洗有 关部位并去医院治疗。 8. 禁止油手触摸正在通电使用中缝纫机的零件或装置。 9. 有关缝纫机的修理、改造、调整应由受过专门训练的技术人员或专家来进行。 10. —般的维修保养应由受过训练的人员来进行。 11.有关缝纫机的电器方面的修理、维修应由有资格的电器技术人员或在专家的监督和指挥下进行。 12.修理、保养有关电气、汽缸等压缩空气的零件时,应切断空气压缩机提供的气源后再进行。 13. 缝纫机的使用期间应定期进行清扫。 14. 为了正常安全运转,应安装地线。同时应在不受高频焊接机等强噪音源影响的环境下使用。 15.

- Page 3 安全须知请先仔细阅读 安全上需要特别加以注意的事项。 安全使用缝纫机的注意事项 危险 为了防止触电事故的发生,请不要在接通电源的状态下打开控制箱的外壳或接触控制箱内的零件。 注意 为了防止人身事故的发生,请不要在拆开控制箱外壳,眼镜防护罩等安全装置的状态下运转缝纫机。 2. 为了防止被卷入的人身亊故的发生,请使用带电机防护罩的马达。 3. 为了防止触电事故的发生,请不要在卸下电源地线的状态下运转缝纫机。 4. 为了防止被卷入的人身事故的发生,缝纫机运转状态下请不要将手指、头发、衣服靠近手轮。 为了防止人身事故的发生,打开电源后或缝纫机运转中请不要把手指放到切布刀或机针的附近。 6. 为了防止人身事故的发生,缝纫机运转中请不要把手指放到眼镜防护罩内。 7. 为了防止触电、漏电、火灾事故,拔插电源线前一定先关掉缝纫机电源,再将电源插头拔下。 8. 为了防止突然启动造成人身事故,离开缝纫机时请一定关掉电源。 9. 为了防止突然启动造成人身事故,发生停电后请一定关上电源。 10. 为了防止突然启动造成人身事故,拆卸电机防护罩时,请一定关掉电源,用脚前踩踏板确认不 动后再拆卸。 11. 为了防止突然启动造成人身事故,检修、调整、清扫、穿线、换针时,请一定先关掉电源,用脚前踩踏板 确认不动后再拆卸。 12. 为了防止缝纫机落下造成人身事故,搬运缝纫机时请不要手拿布台护罩。拿布台护罩后护罩会打开,缝纫 机会掉下来。...

-

Page 4: Table Of Contents

安全须知请先仔细阅读 目录 1.前言................5 2.警告标记 ................5 3.安全措施 使用环境..............6 安全措施...............6 4.各操作过程的注意事项 开箱................7 搬运................8 安装•准备..............8 使用缝纫机油..............9 运转缝纫机前的注意亊项............9 运转缝纫机中的注意事项............9 维护、检査、修理..............10 5.警告标签粘贴的位置与安全保护装置 ..........11 6.安全保护装置 护眼板................12 护指架 ................12 压脚.................12 前护盖................12 缝台.................12 7.日常操作中了解的常识问题 台板的加工图..............13 关于供油 .................14 给 HR 装置供油 ................1 5 机... - Page 5 请先仔 安全须知 细阅读 针 打 线 片 的 标 推 安 装 位 置 和 调 节 ........2 0 针...

- Page 6 安全须 须知请先仔细阅 阅读 1 . 前 言 •本操作说 说明书将描述 述如何注意产 产品的安全使 使用。 •在使用本 本机器之前, 请务必仔细 细阅读本使 用 用 说明书。充 充分理解及掌握 握缝纫机的操 操作、检察、 调整、维修 修等方法 之后,再 再进行使用。 2 . 警 告 告 标 记 在本公司 司的产品及本 本使用说明书 中,为了安全 全使用产品, ,根据危险程 程度将警告标 标记分别表示...

-

Page 7: 使用环境

安全须知请先仔细阅读 3 . 安 全 措 施 使 用 环 境 使用的环境有可能给缝纫机的寿命、性能及安全性带来不良影响。 为了安全保护,请勿在 下 述环境条件之下使用。 1. 在靠近高频焊接机等产生干扰的机器设备旁边。 2. 产生药品蒸汽气氛的地方,及受药品飞溅等地方使用或保管。 3. 室外、高温高湿、直接曝晒阳光的地方。 4. 周围的温度、湿度很大,会给缝纫机带来坏影响的地方。 5. 额定电压常超过±10%以上的电压变动较大的地方。 6. 电源容量无法确保控制马达规格上所需要的容量时。 安 全 措 施 (1)进行维修保养、检验时的安全保护 • 在对缝纫机进行检察、修理、清扫等维护作业时,请关掉电源开关,将电源插销从插座上拔下, 并确认踩缝纫机踏板也不会转动之后再进行作业。 但是,有必要接通电源进行作业时,请制定防止缝纫机以外转动或操作者错误而导致危险的安全 操作准则,并遵守一切安全防护准则。 • 在进行以下作业时,务必关掉电源开关,将电源插销从插座上拔下之后进行。 加油 •... - Page 8 安全须知请先仔细阅读 (2)开始运转前的检验事项 •在开始操作运转缝纫机前,先检验缝纫机缝纫部分,看是否有损伤、功能不良 等问题。一旦发现有异常现象,应马上修理或采取必要的措施。 •务必先确认针箍是否固定好。 ※请注意针尖有危险。 •在使用缝纫机之前,务必确认压脚是否在正确的位置。(用手轻轻转动手轮, 看针尖是否落在压脚的针孔中心)(图 1) •务必检查压脚是否固定好。(使用抬压脚机构抬起压脚,用手前后左右扳动, 检查看压脚是否松动)(图 2) (3)培训 •为了防止事故发生,操作人员及维修员应先掌握机器的使用和学习有关技能。 (图 1) (图 2) 4.各操作过程的注意事项 开箱 1 . 缝纫机机头出厂时是包装好后装入纸箱运出的。从印刷在纸箱上的标记字样确认缝纫机的摆放方向后,请从 上到下按顺序开箱。 2 . 把缝纫机机头从缓冲包装材料拿出时,绝对不要提拿与机针部位或过线器有关的部件,否则会发生危险或损 伤机器。 3 . 在取出缝纫机机头时,请注意重心的位置,小心谨慎地取出。 4 . 包装使用的纸箱如果后面继续使用,请妥善保存。 包装材料的处理 • 包装材料包括木头、纸张、纸箱、VCE 纤维,请顾客将包装材料正确适当的进行处理。 缝纫机废物的处理 1. 缝纫机的产生废物,请客户负责进行处理。 2.

-

Page 9: 安装•准备

读 安全须知请先仔细阅 警告 搬运 缝纫机机头的搬运一定要两个人以上进行。另外,用人直接搬运应只限于搬往缝纫机台板或小台车。 移动缝纫机机头时,用右手抓住手轮及电机罩,左手垮在机头里,扎实牢固的搬起。(图 3) 缝纫机上沾有油污在搬运时容易滑脱摔坏,搬运请仔细擦净机头上的油污。 在往缝纫机台板上或小台车上搬运时,请注意不要过分冲击或震动, 以免缝纫机倒斜造成危险。 如果要第二次运送缝纫机并要包装时,请一定擦净机头上的油污。否则,搬运时会滑脱摔坏机头或穿底(油 污使包装材料变质)。 (图 3) 注意 安 装 • 准 备 缝纫机台板 1.请使用能充分承受缝纫机机头及搬运时产生的反作用力的缝纫机台板(台板、铁架)。 2.应充分考虑缝纫机装配部件所需空间和操作所需的光线,放置在容易作业的坏境中。如果光线不足,应根据 需要安装照明灯。 3.在运转缝纫机时,为防止操作者踩踏板时脚滑脱造成事故,一定要在缝纫机踏板上安装防止滑脱的垫子。 4 . 根 据 操 作 者 操 作 的 姿 势 , 调 整 台 板 面 的 高 度 ( 工 作 时 的 高 度 ) 。 + 警... -

Page 10: 使用缝纫机油

请 安全须知 先仔细阅读 注意 接地 1. 接地线是按每台缝纫机分别装设专用的接地线,不应与其他机器共用。 在缝纫机机头的规定地点准确地装设接地线。 警告 使用缝纫机油 1. 在油盘内没有注入油之前绝对不要运转机器,机油请使用指定的缝纫机专用润滑油(相当于 ISO 粘度等级 VG22)。 2. 机油进入眼睛会使眼睛发炎,所以在使用时请戴防护眼镜以免机油进入眼睛。 ※ 万 一 机 油 进 入 眼 睛 , 请 用 干 净水冲洗 15 分钟,再请医生治疗。 3. 接触皮肤后,请马上用水和肥皂清洗干净。 绝对不要使机油进入口腔。 5. 机油请保管在儿童摸不到的地方,万一进入口腔,不要硬性呕吐,马上请医生进行治疗。 6. 废油、废容器的处理方法必须遵照坏境保护法相关的措施正确处理,如不知道请与经销商联 系后,... - Page 11 读 安全须知请先仔细阅 3. 缝纫机在运转中有危险,手指、头发、衣服请勿靠近针杆和自动切线装置剪刀附近。 同时, 在上述场所 ,请勿放置剪刀、镊子、工具等。 4. 在不使用缝纫机时或者操作者离开缝纫时,一定要将电源开关关掉。 5. 停电时务必将电源关掉。 6. 在操作缝纫机时.请穿着不易被机械卷入的服装。 7. 缝纫机在运转中,请不要在缝纫机台板上放置工具及其他与缝纫无关的物品。 注意 维 护 、 检 查 、 修 理 1. 维护、检查、修理的作业应由受过特别训练的人并在充分理解本使用说明书的内容之后,再 进行作业。 2. 为了维护、检查、修理要将缝纫机机头放倒时,务必将电源开关关掉,把电源插头从插座上 拔下, 并确认即使踩缝纫机踏板缝纫机也不会转动之后,再进行操作。 3. 对于缝纫机机头的日常检查或定期检查,应按照本书及使使用说明书的指示,切实认真的进 行。 4. 缝纫机的修理或部件的更换请使用原装部件。对于不恰当的修理、调整或使用假冒伪劣部件 所造成的事故,本公司将不负一切责任。 5. 请不要根据顾客的判断对缝纫机进行改造, 否则因改造而发生事故, 本公司将不负一切责任。 6.

- Page 12 请 安全须知 先仔细阅读 5. 警告标签粘贴的位罝与安全保护装罝(图 4) (图 4)

-

Page 13: 护指架

读 安全须知请先仔细阅 6.安全保护装置 这个项目是为了使大家都知道各种安全保护装置.并记载了各部分的注意事项。 注意 安全保护装置 护 目 镜 组 件 不要打开 为了眼睛的安全, 绝对不要在打开护眼板的状态下操作缝纫机。 护眼板是为了在缝纫中针断了时, 使断针不会飞入眼睛而安装的护眼罩。 护 指 架 不要把手伸入 为了防止上下运动的机针与人接触而产生危险,在机针附近安装了护指架。但是,在护指架上方 为 了便于穿线而留有间隙,如果将手指从间隙伸入,机针有可能会刺伤手指造成危险。 压脚组件 不要把手伸入 从针板表面压脚的上升量是 5mm 以上,这个间隙有夹手指的危险,在用膝盖开关抬升压脚时或 用踏板自动抬升压脚时,请不要将手指伸入压脚上方。 前罩壳组件 不要把手伸入 弯针的运动从缝纫机正面看时,是进行左右往复的圆弧运动,为了避免进行圆弧运动的弯针与 人接触,务必请在前盖板闭合的状态下操作缝纫机。 缝台组件 请勿打开 缝纫机在运转中,为了避免链弯针打线凸轮和弯针发生热接触,请务必在关闭大盖的状态下操作 缝纫机。 护 指 片 不... -

Page 14: 台板的加工图

请 安全须知 先仔细阅读 7.日常操作中应了解的常识问题 台板的加工图 (图 5) 注意事项:本图纸为两款一体机台板通用图纸。( 带 吸 风装 置 和 不带吸 风 装 置)( 图 5 )... -

Page 15: 关于供油

读 安全须知请先仔细阅 关 于 供 油 注 意 在加机油或换机油时,务必使用本公司提供的机油,如果使用提供以外的机油,有可能损 坏缝纫机。 1.使用的油类 请使用本公司提供的“HIGH SPEED SEWING MACHINE OIL ”(高速低粘度润滑油) (ISO 粘皮等级/VG22) 2.供油的方法(图 6) 揭开供油口的盖子, 加油至油面到达油标尺的 H 线和 L 线中间。加完油后,请盖好供油口的盖子。 3 . 油 的 规 定 量 ( 图 6 ) 油 标 尺 2 的 H 线 和 L 线表示着油量的上限和下限。 为使油面经常保持在... - Page 16 请 安全须知 先仔细阅读 注意 在用手加油时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后在进行。 第一次使用缝纫机时,以及缝纫机放置一段时间未使用时,请用给油瓶在针杆 3 和上弯针台 4 处 分别给油 2〜3 滴。 5 . 检査机油的循环状况(图 8) 请在加完油后,踩下缝纫机踏板,使缝纫机运转,通过油窗 5 检查机油的循环状况是否良好。 (图 8)

-

Page 17: 给 Hr 装置供油

读 安全须知请先仔细阅 给 HR 装置供油 注意 在给 HR 装置供油时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后再进行 。 在 HR 装置的硅油盒 1 和 2,为了防止机针断线加有硅油,请经常检查, 请 尽 早 补 充 硅 油。(图 9) 机油的更换 注意 更换油时,请专业技术人员进行操作。 缝纫机在开始使用 1 个月后更换一次机油。然后请 6 个月更换一次机油,如果不更换机 油继续使用,缝纫机有可能发生故障。 排 油 的 方 法 1.请卸开油箱底座排油孔螺丝 3,排出旧油。 2.排完油后,将排油孔螺丝... -

Page 18: 检修和更换过滤器

请 安全须知 先仔细阅读 检 修 和 更 换 过 滤 器 注意 检修和更换过滤器时,务必将缝纫机的电源关掉,将插头从电 源插销上拔下来之后,请专业技术人员 进行操作, 当过滤器 8 有赃物等堵塞时,就不能正常给油,请每 6 个月拆卸过滤器 8,进行清扫 或更换。 过滤器的拆卸方法(图 11) 请参考图,拆下 4〜8 后,检查过滤器。当发现过滤器 8 伤痕严重无法使用时。请更换新的过滤器。 缝纫机的清扫 注意 在清扫缝纫机时,务必将缝纫机的电源关掉,将插头从电源插 销上拔下来之后再进行。 请打扫针板的空槽和送布牙周围。(图 12) (图 11) (图 12) -

Page 19: 穿线的方法

读 安全须知请先仔细阅 穿 线 的 方 法 注意 在进行穿线时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之 后再进行。 1. 请打开大盖 1、护眼罩 2、前罩 3、抬压脚臂 4,穿过线以后,请回复到原来的位置。(图 13) 2. 如果已穿好线时(图 14) A 部:请将已穿好的线与缝纫机用线连接起来。 B 部:针线 把线的接头拉到针的眼前,先将接头剪 掉,再将线穿过针。 C 部:弯针线,链弯针线 可一直将连接的接头穿好后, 再用剪刀 剪掉线头并整好。 3. 当缝纫机上没有线时 看着贴在缝纫机上的穿线图,将线穿过去。 (图 13) (图 12) (图 14) - Page 20 请 安全须知 先仔细阅读 4.穿线标识 五线穿线标识 六线穿线标识 三线穿线标识 四线穿线标识...

-

Page 21: 线状态的调节

安全须知请先仔细阅读 机针的更换 注意 在更换机针时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后再进行(图 15) 请松动螺丝 1 (但不能拔出螺丝),更换机针。 (图 15, 图 16) 安装时,将针的凹槽部朝向正后方,插入针箍的针孔中于最底端,拧紧螺丝 1。(图 17) (五、六线) (三、四线) 请使用红色内六角扳手 (图 15) (图 16) 线状态的调节 线状态的调节请用针线调节旋钮 2、上弯针线调节旋钮 3 和下弯针线调节旋钮 4 进行调节。(图 18) 想将线拉紧一些时,可将各旋钮向右旋转,想松一些时 可向左旋转,在能取得均匀且漂亮缝纫效果 的情况下,尽量采用较松的夹线状态。 松线 紧线 (凹槽部分) (把针插到孔底部) (图 17) (图 18) -

Page 22: 针 脚 长 度 的 凋 节

安全须知请先仔细阅读 压脚的开和关 注意 开和关压脚时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后再进行。 打开压脚时:1.旋转手轮,将针置于最上边位置;2.压下压脚开关把手 1,打开抬压脚臂 2。 合上压脚时:1.旋转手轮,将针置于最上边位置;2.压脚下开关把手 1,将抬压脚臂 2 返回到原 来的位置。(图 19) (图 19) 压 脚压力 的调 节 压脚的压力在送布能正确的进行,并且能缝出稳定针脚的范围内,请尽量使用较小的压力为宜。 旋转调节螺丝 3,调节压脚的压力。(图 20) 差 动 比 的 调 节 1. 松动螺母 4,将把手 5 压下时差动比变大。缝好的布料会收缩。抬起把手时,差动比变小,缝好 的布料会伸长。 2.调节结束后,请拧紧螺母 4。(图 21) 大 (-) 伸长... -

Page 23: 上刀的更换

安全须知请先仔细阅读 针 脚长 度的调节 注意 在调节针脚长度时,务必将缝纫机的电源关掉,将插头从电源 插销上拔下来之后再进行。 1.一边按着按钮 1, 一边旋转手轮 2, 将按钮置于更深的状态。 (图 22) 2.顺时针方向旋转手轮,针距变大;逆时针方向旋转手轮,针 距变小。 注 缝纫针脚长度的调节,请务必在调节差动比之后进行。 注意 (图 22) 调节刀片时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后, 请专门的技术人员进行操作。 刀片的刃部有划破手指的危险,操作时要特别小心注意。 上 刀的更 换 1. 注意:当调刀时请注意,针板支座 9 的 B 面与机壳 10 的 A 面要贴齐,否则影响调 刀的效果。(图 2 3) 2. -

Page 24: 下刀的更换

安全须知请先仔细阅读 下 刀 的 更 换 1. 松动螺丝 1,将下刀架 2 置于最左边位置,用螺丝 1 临时固定。 2. 松动螺丝 5,取出下刀 6,更换新的下刀,调节下刀, 使下刀的刀刃与针板上面的间隙尺寸为 0〜0.3mm,拧紧螺丝 5。(图 27) 3. 根据更换上刀的项目 3 〜 4 进行操作。 链幅的调节 1.松动螺丝 1,将行刀架 2 置于最左边位置,用螺丝 1 临时固定。 2.松动螺丝 7,左右移动上刀座 8,调节链幅。 3.根据更换上刀的项目 3〜4 进行操作。 刀的研磨方法... - Page 25 安全须知请先仔细阅 针 打线片 的标 准安装 位置 和调节 注意 调节针打线片时, 务必将缝纫机的电源关掉, 将插头从电源插销上拔下来之后, 请技术人员进行操作。 转动手轮当针打 线 片 1 处 于 最 下 方 的 位 置 时,请调节上节 头 部 前 面 到 针 打线片的尺寸。 进行调节时,请 松 动 螺 丝 2 五线 进 行 调 节 。 (图 29、30) (图...

- Page 26 安全须知请先仔细阅读 五线系列 针过线件的标准安装位置 使螺纹中心对准长孔中心 (图 35) (图 32) • HX6816T-03 • HX6816T-04 针脚形式:516 针脚形式:516(粗斜纹布) 机针在最下边位置 机针在最下边位置 机针在最下边位置 机针在最下边位置 对准 使过线孔与件 1 相切 (图 33) • HX6818T-03 将过线孔中心对准件 1 的掉线 针脚形式:514+401 (图 36) 机针在最下边位置 机针在最下边位置 将过线孔中心对准 过线孔使与件 1 相切 件 1 的掉线 (图...

- Page 27 安全须知请先仔细阅 三、四线系列 针过线件调节标准(图 37) 松动螺丝 12 和 14,沿箭头方向移动针过线件和针 过线 件托架 13 进行调节。 向图中符号(+)的方向调节时,线的抽出量增多, 向 符 号 ( - ) 的 方 向 调 分 时 , 线 的 抽 出 量 减 少 。 调节后,请拧紧螺丝 12 和 14。 调节过线件 11 的左右位置, 使 (图...

- Page 28 请 安全须知 先仔细阅读 链 弯针打 线片 和过线 件的 标准安 装位 置与打线凸轮打线量的调节 注意 调节打线凸轮时,务必将缝纫机的电源关掉,将插头从电源插销上拔下来之后,请专业技术人员进行 操作。 1. 旋转手轮,将针置于最上边位置。 2. 松动螺丝 2,旋转链弯针打线凸轮 1 进行调节,使链弯针打 线凸轮 1 的 A 点以托架上面为准。(图 42) 托架的上面 3. 松动螺丝 4,上下移动打线导轮 3,进行调节,使打线导轮 3 的 B 点对准链弯针打线凸 轮 1 的 B 点。(图 42) (图...

- Page 29 安全须知请先仔细阅 弯针打线片和过线件的标准安装位置(图 45) 下弯针最右边位置 (图 45)

- Page 30 请 安全须知 先仔细阅读 调节基准表 五 、六线 系列 三 、四线 系列...

- Page 31 安全须知请先仔细阅读 五、六线系列 标准用针 三、四线系列 标准用针...

- Page 32 安全须知请先仔细阅读 HX 系列子型号规格表 五、六线系列 三、四线系列...

- Page 33 安全须知请先仔细阅读 拉 布 轮 的 应 用 注意 1.在操作面板的拉布轮 快捷键上选择拉布功能 的开启与关闭。 具体功能如下: ①. 前拉: 在缝纫的起始阶段有拉布功能。 ②. 后拉:在缝纫的末尾阶段有拉布功能。 ③. 全拉: 在缝纫的全程始终有拉布功能。 ④. 关闭:在缝纫的全程无拉布功能。 后拉和全拉功能可自动有效控制尾部送布速度,避免了切布现象。 2. 拉布轮抬起高度调节。 通过调节气缸压 头 1 高 度 可 以 调 整 拉 布 轮 2 抬起高度, 并使铜套 3 与拉布轮 2 间隙 dl=l.0mm ~1.5mm (图 46) 3.

- Page 34 安全须知请先仔细阅读 4.拉布轮送布速度调节。 调节方法:打开后窗板 9,松开螺母 10(开口扳手),旋转调整杆 11。按图 49 图中(+)旋转方向(顺 时针)旋转调整杆 11 时拉布轮 2 旋转速度加快,从而增大了拉布轮 2 单位针距的送布量;按图 49 图 中(-)旋转方向(逆时针)旋转调整杆 11 时拉布轮 2 旋转速度减慢,从而减小了拉布轮 2 单位针距 的送布量。调整杆 10 间接调节调整螺钉 12 左右移动,如图 50。 (图 50) (图 49) 5.拉布轮配置基准(HX688T-00 款一体机的拉布轮配置同 HX6800TC 款)...

- Page 35 安全须 须知请先仔 仔细阅读 侧吸 吸的应用 注意 1. 在操作 作面板 1 (图 51)上侧吸功 功能的选择, 具体操作如 如下: (1).机 机型选择:直 刀外剪线-0 ;侧吸刀剪线 线-1。 (2).松 松线开关:关 闭-0;开启- -1。 (3).中 中途间歇吸气 开关:关闭 (直刀)-0; ;开启(侧切 切)-1。 (4).自 由缝模式: 关闭-0;开启 启(人工模式 式半自动功能 能)-1。 2.松线板 板组件(图 52 (1). 松线 线板...

- Page 36 Safety Instructions, Please Read Carefully ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐ Important Safety Instructions ‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐‐ 1. When using the machine, please strictly observe the safety measures as the following items. 2. Before using this machine, please read all instructions contained in the instruction manual .Please take care of the manual for handle consult. 3. Before using this machine, make sure that all the safety devices are installed to the required location .Forbid to use the machine if the safety devices are not in the right position. 4. The machine shall be operated by the trained operator. 5. When using the machine, safety glasses are recommended. 6. Please turn off the power or unplug the power plug when the following cases happen. 6‐1 When threading needles, curved needles, etc. 6‐2 When changing the needles, the presser foot, the throat plate, feed dog, finger protector, etc. 6‐3 Repairing work. 6‐4 Nobody in the working place or leaving the working place. 7. The oil, lubrication used in the machine and the peripheral device flow in eyes or skin, or drinking mistakenly, please wash the correlation parts and go to hospital. 8. Prohibit to touch the power on/off accessory and devices of the machine with oil hand. 9. The repair, alteration, adjustment about the machine should be carried out by professional staff. 10. General repair and maintenance of the machine should be carried out by trained staff. 11. Repair and maintenance about electrical aspects of the machine should be done by professional staff or experts. 12. When repairing, preserving the accessory about the air, compressed air cylinder, the air compressor to supply source should be cut off. 13.

- Page 37 Safety Instructions, Please Read Carefully 11. To prevent personal injury due to sudden starts, when repairing, adjusting, removing, threading, replacing stitch, be sure to turn off the power, and the foot pedal is firmly fixed. 12. To prevent personal injury due to falling the machine, please do not hand carry shield cover when sewing machine. Take shield cover off, the shield will result in the falling of the machine. ...

- Page 38 Safety Instructions, Please Read Carefully LIST 1. Introduction ....................5 2. Indications of dangers, warning and cautions ..........5 3. Safety precautions Circumstances..................6 Safety measures...................6 4. Notes for each procedure Unpacking................ .. .. ..7 Transportation..................8 Installation, preparation.......... ......8 Handing machine oil.......... ......9 Before using the machine..............9 Precautions while using machine............9 Maintenance、Check、Repair............10 5. Location of warning labels and safety devices.... ......11 6. Protectors for safety Eye guard............. .... ....12 Finger guard ....................12 Presser foot....................12 Front cover........................12 Cloth plate....................12 7. General issue of operation Schematic diagram of the sewing machine table........13 Lubrication............ .. ......14 Silicone oil for H.R. device.... .... .... .... ....1 5 ...

- Page 39 Safety In nstructions, Please Re ead Carefully 1. Intr roduction • This inst truction man nual describes s how to use our products s safety. • Read th his instruction n manual and d learn very ca arefully how to operate, a adjust and se rvice this sew wing machine e before begin nning any of the procedur res. 2. Indi ications of f dangers, , warnings s and caut tions To preven nt accidents a and ensure sa afety, warnin ng indications...

-

Page 40: Safety Precautions

Safety Instructions, Please Read Carefully Safety precautions C i r c u m s t a n c e s The environment in which our industrial sewing machines are used may seriously affect their lives, functions, performance and/or safety. For safety, do not use the machine under the circumstances below. 1. Do not use the machine near objects which make noise such as a high‐frequency welder, etc. 2. Do not use or store the machine in the air which has vapor from chemicals, or do not expose the device to chemicals. 3. Do not leave the machine outside, in high temperatures or direct sun. 4. Do not use the machine in the places of high ambient temperature and humidity that seriously affects sewing machines. ... -

Page 41: Notes For Each Procedure

Safety Instructions, Please Read Carefully •To check if the ferrule is secure. ※Please note that the tip is dangerous. •Before using the sewing machine, make sure that the presser foot is in the correct position. (Gently turn the handwheel to see if the needle falls on the center of the needle hole in the presser foot) (Figure 1) •Check the presser foot is fixed. (Use the lift foot mechanism to lift the presser foot, turn it around with your hands, to check whether the presser foot is loose) (Picture 2) (3)Training •In order to prevent accidents, operators and maintenance staff should have proper knowledge and skills for sate operation .To ensure so, managers must design and conduct training for these people. (Figure 2 ) 4. Notes for each procedure Unpacking 1 . The sewing machine head is shipped packed in a cardboard box and shipped. After confirming the orientation of the sewing machine from the words printed on the carton, unpack the cartons from top to bottom in order. 2 . When removing the sewing machine head from the cushioning packing material, do not lift the parts related to the needle part or the thread take‐up. Otherwise may cause danger or damage to the machine. ... -

Page 42: Transportation

Safety Instructions, Please Read Carefully WARNING Transportation The sewing machine head transport must be carried by more than two people. In addition, the direct handling of personnel should be limited to moving to the sewing machine table or small trolley. When moving the sewing machine head, grasp the hand wheel and motor cover with your right hand, the left hand collapse in the machine head, solid and firm move. (image 3) Stained oil on the sewing machine easy to slip off during handling, handling, please carefully clean the head of the oil. When moving to the sewing machine table or small trolley, be careful not to over‐shock or vibration to avoid danger of the sewing machine being tilted. If you are going to transport the sewing machine for the second time and want to pack, be sure to clean the oil on the machine head. Otherwise, the handle will slip off the head or wear the end (oil pollution will spoil the packaging materials). CAUTION Note (Figure 3) Installation ,preparation Machine table 1. Use a sewing machine table (table board, iron frame) that can fully withstand the reaction force generated by the sewing machine head and handling. 2. Careful consideration should be given to the space required for assembly of the sewing machine and the light required for its operation, placed in a workable environment. If there is insufficient light, install the lights as required. ... -

Page 43: Handing Machine Oil

Safety Instructions, Please Read Carefully 1. Please firmly plug the sewing machine head and motor cable plug. When connecting the sewing machine head to the motor connector, be sure to operate the power switch with the power switch off. 2. Do not strain the cables in use. Do not bend the cables in use. 4. The cables around the moving parts should be mounted at a minimum distance of 25mm. 5. If necessary, consider the connection position or add a protective cover to protect the cable. 6. Never use staples to fasten the cables .Otherwise it causes a short circuit and/or a fire. CAUTION Note About grounding 1. Grounding wire is installed according to each sewing machine dedicated grounding wire, should not be shared with other machines. ... -

Page 44: Maintenance、Check、Repair

M a i n t e n a n c e 、 C h e c k 、 R e p a i r 1. Maintenance, inspection and repair operations should be carried out by specially trained people and fully understand the contents of this manual before operating. 2. To maintain, inspect and repair the machine, turn off the power switch and unplug the power cord from the socket, and confirm that the sewing machine does not rotate even after the sewing machine treads, and then perform the operation. 3. The daily inspection of the sewing machine head or periodic inspection, should be in accordance with the instructions in this book and instruction manual, conscientiously carried out. 4. Employ HIKARI genuine parts when repairing the machine and/or replacing the parts. We are not responsible for accidents cause by any improper repair/adjustment and substituting other parts for those manufactured by HIKARI. 5. Please do not according to the customer's judgment on the transformation of the sewing machine, or due to the transformation of the accident, the Company will take full responsibility. 6. Temporarily removed due to repair, adjustment safety devices, safety guards, after the completion of the operation must be installed according to the original state. After the maintenance, inspection and repair work is completed, please check if there is no danger ... - Page 45 afety Instruct ctions, ease Read Car arefully 5. Loca ation of wa a rning label l s and safet t y devices (Figure 4) ...

-

Page 46: Protectors For Safety

Safety Instructions, Please Read Carefully Protectors for safety 6. This chapter describes each protector for safety Protectors for safety CAUTION Note E y e g u a r d Do not open it For eye safety, never operate the sewing machine with the eye shield open. Eye shields are eye shields that are installed so that the broken needles do not fly into the eyes when the needle is broken during sewing. F i n g e r g u a r d Do not reach into your hands ... -

Page 47: General Issue Of Operation

Safety Instructions, Please Read Carefully General issue of operation 7. Schematic diagram of the sewing machine table ... - Page 48 Safety Instructions, Please Read Carefully 2. Oil supply method (Figure 6) Open the fuel supply port cover, refueling to the oil level reached the rod and H line L middle. After adding oil, please cover the fuel filler cap. 3. T h e a m o u n t o f o i l ( F i g u r e 6 ) The ...

-

Page 49: Silicone Oil For H.r. Device

Safety Instructions, Please Read Carefully Silicone oil for H.R.devece Note CAUTION When supplying oil to the HR unit, be sure to turn the sewing machine off and unplug it from the power plug. In the case of the silicone oil boxes 1 and 2 of the HR unit, always check the silicone oil in order to prevent the needle from being disconnected. Replace the silicone oil as soon as possible. (Figure 9) Oil replacement CAUTION When changing oil, please professional technical personnel to operate The sewing machine needs to be changed once a month after it starts to be used. Then please change the oil 6 months, if you do not change the oil to continue using, the sewing machine may have failure. To drain the oil 1. Please uninstall the fuel tank base drain hole screws 3, discharge the old oil. 2. After draining the oil, tighten the drain hole screws 3. (Figure 10) [键入文字]... -

Page 50: Checking And Replacing The Filter

Safety Instructions, Please Read Carefully Checking and replacing the filter Note CAUTION Maintenance and replacement of filters, be sure to turn off the power of the sewing machine, unplug the plug from the power plug, the professional and technical personnel to operate when the filter 8 is clogged with clogs, you can not normally oil, please 6 months Remove the filter 8, to clean or replace. Filter removal method (Figure 11) Please refer to the figure, remove the 4~8, check the filter. When the filter 8 serious injury can’t be found .Please replace the new filter. Cleaning the machine Note CAUTION ... -

Page 51: Threading

Safety Instructions, Please Read Carefully Threading CAUTION Note When threading, be sure to turn off the power of the sewing machine and unplug it from the power plug. 1. O pen the cover 1, the eye shield 2, the front cover 3, lift the pressure arm 4, after passing through the line, please return to the original position. (Figure 13) 2.When the line is ready (Figure 14) Part A: Connect the thread to the sewing machine’s. Part B: Needlework Pull the connector of the cord to the front of the needle, cut the connector first, and then thread the needle through it. Part C: looper thread, hook thread You can always connect the connector to wear, and then use scissors to cut the thread and the whole good. 3. When there is no thread on the sewing machine, look at the threading pattern attached to the sewing machine and pass the thread through it. ... -

Page 52: Replacing The Needle

Safety Instructions, Please Read Carefully Replacing the needle CAUTION Note Always turn off the power and unplug the machine when you replace the needles. (Figure15) Loosen the screw 1 (but do not remove the screw) and change the needle. (Figure 15, Figure 16) When installing, insert the pin groove in the pin hole of the needle ferrule to the bottom right position and tighten the screw 1.(Figure 17) ... - Page 53 Safety Instruc uctions, Please Read Ca Carefully Opening/c closing the pr resser foot When openin ng and closin ng the presse er foot, be su re to turn of ff the power of the sewin ng machine a nd pull the plug from the e power plug . When openin ng the press ser ...

-

Page 54: Adjusting Stitch Length

Safety Instruc uctions, Please Read Ca Carefully Adjustin g stitch le ngth Atte ention When adju sting the stit ch length, be e sure to turn off the powe er of the sewing ma chine and un nplug it from t the power pl ug. 1. While ho olding down b button 1, tur n hand whee el 2 to place t he button dee eper. (Figure 2 22) 2. Turn the e handwheel c clockwise to increase the stitch pitch. T Turn the handwheel l countercloc ckwise to mak ke the stitch p... -

Page 55: Replacing The Lower Knife

Safety Instruc uctions, Please Read Ca Carefully Replacing the lower kn nife e screw 1. Loosen the screw 1, plac e the lower kn nife holder 2 i in the leftmos st position, an nd temporarily y fix it with th Loosen the e screw 5, re move the low wer knife 6, replace the new lower k nife, adjust t the lower kn ife, so that under the b blade and the e needle plat e clearance a above the size e of 0~0.3m mm, tighten th he screws 5. ( (Figure 27) According t to the replac ement knife ... - Page 56 Safety Instructions, Please Read Carefully...

- Page 57 Safety Instructions, Please Read Carefully Five thread series Standard installation position of thread wire ( Figure 35) Center the threaded center on the long hole center ( Figure 32) • HX6816T-03 • HX6816T-04 Stitches form:516 Stitches form:516(canvas with denim) The needle is at the bottom The needle is at the bottom alignment...

- Page 58 Safety Instructions, Please Read Carefully 三、Four thread series The needle cross thread adjustment standard (Figure37) Loose screws 12 and 14, move needle thread and needle thread bracket 13 to adjust along the arrow direction. When the direction of the symbol (+) in the graph is adjusted, the amount of the line is increased, and the line is reduced when the direction of the symbol (‐) is adjusted. After adjusting, tighten the screws 12 and 14. ( Figure 37) Adjust the left and right positions of the thread guide 11 so that the needle thread is in the center of the double rubber part...

- Page 59 Safety Instructions, Please Read Carefully HX6814T、HX6804T The standard mounting position of the needle HX6814T-03 thread guide HX6814T-53 HX6804T-02 HX6814T-83 HX6804T-32 Stitches form :504 Stitches form :514 The needle is at the bottom The needle is at the bottom alignment alignment ...

- Page 60 Safety Instructions, Please Read Carefully smaller. (Figure 43) Positioning the looper thread take‐up and thread guides .Adjusting the amount of thread to be supplied from the looper thread take‐up CAUTION When adjusting the line CAM, make sure to turn off the power of the sewing machine and pull the plug from the power plug. 1. Looper Threads 9 and 11 use the lowermost looper to adjust the rightmost position. The standard installation location is shown below. To join the illustration, loosen the screws 10 and 12 and adjust the ...

- Page 61 Safety I Instructions, Please R Read Carefull The standa ard installatio on position of f the curved n needle and th hread(Figur re45) he right posit tion of the low wer bending needle (Figu ure 45) ...

- Page 62 Safety Instructions, Please Read Carefully F ive , s ix thread ser ies Subclass Thre e,f our -thread se rie s Subclas...

- Page 63 Safety Instructions, Please Read Carefully Five、 six thread series Standard needle Subclass Three、 four‐ thread series Standard needle ...

- Page 64 Safety Instructions, Please Read Carefully HX series sub‐model specifications table Five, six thread series Three、 four thread series (Figure 48) Puller application CAUTION 1. SelectRab function on the Rabwheel shortcut on the control panel open and close. Specific functions are as follows: ①. Pull (front): at the beginning of the sewing, there is a labrador function. ...

- Page 65 fety Instruct tions, ease Read Car refully ②. Pull ( behind): at th he end of the e sewing, the re is a lab. igure 46) (full): The ③. Pull( whole proce ess of sewing has always b been in the pu uller. ④. Shut down: the w hole process of sewing is not available e. The pull a and pull function n can automatica ally control the sp peed of the tail a and avoid the cut tting phenomen non. 2.The pul ler‐wheel rais ses the heigh ht. Adjus st the cylinde er head 1 heig ght to adjust ...

- Page 66 Instruct tions, ease Read Car refully 5. Lab‐w wheel configuration datum m (HX688T ‐00 0 single‐body y lab‐wheel co onfiguration w withHX6800T TC) ...

- Page 67 fety Instruct tions, ease Read Car refully uller equip pment ttention 1. In oper ation panel 1 (figure 51 ), the select tion of suctio on function on the upper side e of the oper ration panel i s as follows: (1).Mo odel selection n: straight cut t line ‐ 0; Side e suction knif fe shear line ‐...

Need help?

Do you have a question about the HX688T and is the answer not in the manual?

Questions and answers