Summary of Contents for ELKHART BRASS Scorpion RF 8294-07

- Page 1 Installation, Operating, & Maintenance Instructions Model 8294-07 Monitors 98291073 Rev. A 1-574-295-8330 www.elkhartbrass.com...

- Page 2 System Information: Monitor Serial Number: ___________________________________________ Monitor Accessories (nozzle gallonage and type, types of transmitters, Etc.) : _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________________________________________________________________ _____________...

-

Page 3: Table Of Contents

TABLE OF CONTENTS PRODUCT SAFETY ........................4 II. SYSTEM FEATURES ........................5 III. SYSTEM COMPONENT DESCRIPTIONS ................7 8294-07 S RF M ............................7 CORPION ONITORS RF R ..........................7 ECEIVER ONTROL ODULE RF T ..............................8 RANSMITTERS 81282001 Handheld RF Transmitter........................8 81327011 Primary Panel Mount RF Transmitter .................... -

Page 4: Product Safety

RODUCT AFETY Important: Before installing and operating this equipment, read and study this manual thoroughly. Proper installation is essential to safe operation. In addition, the following points should be adhered to in order to ensure the safety of equipment and personnel: 1. -

Page 5: System Features

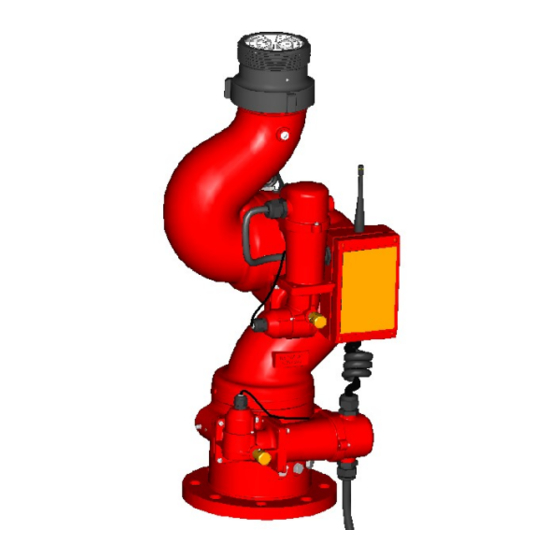

II. S YSTEM EATURES Optional SM-2000E Fog Nozzle (not shown) 284A Stream Shaper Up to ¼ Mile Range Remotely Programmable Oscillation Function Full Vane Cast Billions of Aluminum or Security Codes Brass Waterway and Frequency Combinations Horizontal and Relay/Receiver Vertical Rotation Box Is Integral With Monitor. - Page 6 Power Indicator Figure 2 81282001 Handheld RF transmitter Features Two-Button Stow Primary Control Function Only Activated Overrides by Primary Control Handheld and Secondary PUSH AND HOLD STOW AND FOG TOGETHER TO ACTIVATE Flush Mount NEMA 4 Sealed Hardwired to No Control Vehicle Power Wires to Run System...

-

Page 7: System Component Descriptions

III. S YSTEM OMPONENT ESCRIPTIONS 8294-07 Scorpion RF Monitors (Figure 4) The 8294-06 Scorpion is a cast aluminum monitor with 4" waterway. The waterway contains a central vane to minimize large-scale turbulence and provide superior fire streams. Monitor water supply connection is a 4 inch 150 lb. ANSI pattern flange. -

Page 8: Rf Transmitters

An encoder, part of the horizontal motor, provides horizontal motion control feedback. The counter in combination with the PIC controller enables the monitor to oscillate between programmable endpoints that are set directly from the remote transmitter. The ten turn potentiometer enables the PIC controller to remember a home or stow position. This stow position can be used as a storage position for the monitor during transport. -

Page 9: 327011 Primary Panel Mount Rf Transmitter

81327011 Primary Panel Mount RF Transmitter (Figure 6) The fixed RF transmitter sends signals to the monitor via an encoded radio signal, requiring no wires between the RF transmitter and the monitor. It is powered by the 12V or 24V vehicle electrical system. The faceplate is intended for a flush mount onto the pump or aerial ladder control panel. -

Page 10: Control System Specifications

IV. C ONTROL YSTEM PECIFICATIONS Handheld Transmitter Specifications 2 AA batteries (Alkaline recommended) Input power Meets FCC part 15 requirements for license free Output power operation 6” x 3 1/4” x 1 3/8” Transmitter dimensions 10 ½ oz. Transmitter weight ... -

Page 11: Installation Instructions

V. I NSTALLATION NSTRUCTIONS A. Component Mounting 1. Monitor 4” NPT Base: Apply an appropriate thread sealant to the 4” NPT nipple. Thread the monitor base onto the nipple. Install with the "straight ahead" position properly aligned. Warning: When installing monitor on a raised face companion flange, it is critical that bolts be tightened uniformly to prevent cocking of the monitor relative to the flange or valve. - Page 12 Figure 8 81327001 and 81327011 Fixed RF Transmitter Panel Template...

-

Page 13: Monitor Wiring

2. Monitor Wiring a) Place a 10A fuse for the 8294-07 monitor between the red lead (pin C) of the monitor and a switched positive power lead on the vehicle. Attach the black lead (pin A) from the monitor base to the vehicle ground. -

Page 14: Communication Address Setup

Figure 9 Mounting Hole Pattern B. Communication Address Setup A RF transmitter controls one 8294-07 monitor. The transmitter is digitally encoded with a security code to ensure that it does not accidentally control the wrong monitor. The receiver has a matching decoder and security code that instantaneously decodes and interprets commands. -

Page 15: Rf Receiver/Control Module Settings

1. RF Receiver/Control Module Settings Remove the cover from the RF receiver/control module. SW4 (Figure 10) allows this board to be used in different product applications. The firmware has been programmed such that SW4 rotary position has no affect programming, so the dial should remain in position 1. Figure 10 24263001 Receiver Layout Caution:... -

Page 16: 327011 Primary Panel Mount Rf Transmitters

Caution: While reassembling the handheld remote, ensure both battery and antenna leads do not become pinched. Figure 11 Transmitter Security Settings 3. 81327011 Primary Panel Mount RF Transmitters a) Disconnect the power connector to the panel-mounted transmitter at the back of the panel. b) Open the back cover of the transmitter after loosening the screws. -

Page 17: Travel Limits And Stow Position Programming

D. Travel Limits and Stow Position Programming Caution: To prevent damage to the monitor controller, keep all metallic objects away from the receiver circuit board while it is energized. Ensure all O-ring and gaskets are properly installed when closing receiver enclosure. Monitor can be rotated 90... -

Page 18: Operating Instructions

VI. O PERATING NSTRUCTIONS A. Normal Operation The Scorpion Monitor uses the standard Left/Right, Up/Down, and Fog/Stream commands to provide stream direction and pattern adjustments. a) To move the monitor left or right, press and hold the left or right button until the monitor discharge is in the correct position or a mechanical stop is reached. -

Page 19: Manual Override

C. Manual Override In the event of power failure to the monitor, the motors may be actuated manually. To operate a function manually, simply apply a ¾” ratcheting type wrench (either socket type or ratcheting box end type) to the hex fitting on the motor shaft. Warning: Using the horizontal override nut when the power to the receiver is off or the horizontal motor is disconnected will move stow position from its original programmed position. - Page 20 Warning: Never activate the “Stow” feature while water is flowing. Serious injury to personnel and damage to apparatus could result. Warning: It is up to the system designer to appropriately handle the open circuit condition of the stow signal. In the open circuit mode there is no source to turn off the stow signal load; which may lead to erroneous signal indications if not handled properly.

-

Page 21: Maintenance & Inspection

VII. M & I AINTENANCE NSPECTION A. Monitor 1. Preventive Maintenance The complete monitor and control system should be inspected during each apparatus check. Careful inspection for damage to the monitor or nozzle is especially important after use in emergency operations. a) Operate each function (left-right, up-down, stream-fog, stow) with each of the transmitters. -

Page 22: Handheld Transmitter

DS5 Status Indicator LED (Indication VS. Meaning) Reference Indication Meaning Blinks 6 times rapidly during Visual indication that the controller is startup initializing - normal operation. Blinks 6 times rapidly during SW4 (Figure 10) in wrong position – must be startup then blinks at ¼... -

Page 23: Repair Parts

VIII. EPAIR ARTS See print 98291072 for repair parts. - Page 24 Elkhart Brass Mfg. Co., Inc. Mailing Address: P.O. Box 1127 Elkhart, IN 46515 USA Shipping Address: 1302 W. Beardsley Ave. Elkhart, IN 46514 USA Tel. 1-574-295-8330 Fax 1-574-293-9914 e-mail: info@elkhartbrass.com www.elkhartbrass.com 98291073 Rev. A...

Need help?

Do you have a question about the Scorpion RF 8294-07 and is the answer not in the manual?

Questions and answers