Table of Contents

Advertisement

Quick Links

Be sure to read this instruction manual carefully and strictly observe the safety and

operation instructions herein, especially the warnings and cautions, so as to red ce the

possibilities of personnel injury, property loss, engine performance deterioration,

premature wear or damage.

Warnings in this manual mu t be observed strictly. Failure to do so can cause burns,

amputation, mutilation, asphyxiation, other personal injury or death. Cautions are

provided for the user to operate the engine in a proper way, so as to avoid damage to

engine parts and engine performance deterioration. Warnings and cautions in this

manual are not complete since Shanghai Diesel Engine Co., Ltd. (SDEC) has no

possibility and is not able to foresee all potential risks resulted from failures to follow the

safety cautions and operation instructions.

Repair, Technical Consultation, Complaint and Suggestion

For engine repair, technical consultation, complaints or suggestions, please contact

SDEC's after-sale service center: spare@sdecie.com.

Please provide the following information for product repair:

The engine model

The engine order number

The engine serial number

The date of the equipment procurement

The detailed description of the fault

The address and phone number of the contact person

Caution

Advertisement

Table of Contents

Summary of Contents for Shanghai Diesel Engine E Series

- Page 1 Warnings and cautions in this manual are not complete since Shanghai Diesel Engine Co., Ltd. (SDEC) has no possibility and is not able to foresee all potential risks resulted from failures to follow the safety cautions and operation instructions.

-

Page 2: Table Of Contents

Table of Contents 1 Introduction..........................1 1.1 To User and Operator..................... 1 1.2 Notices for Engine Quality Feedback................1 1.3 Safety Instructions ......................1 1.4 Engine Operation Instructions..................2 2 About the Engine ........................3 2.1 Engine Outline Diagrams ....................3 2.2 Engine Model Identification .................. -

Page 3: Introduction

Thank you for purchasing a product of Shanghai Diesel Engine Co., Ltd! The E series natural gas engine, available in two displacements of 10L and 12L, is a large-power four-valve electronic-controlled natural gas engine with four or six cylinders that is newly developed by SDEC. Featuring strong power and low gas consumption and with the emissions conforming to relevant national regulations, the E series natural gas engine is a perfect power for middle- and high-end vehicles and industrial equipment. -

Page 4: Engine Operation Instructions

Operation and Maintenance Manual E Series Natural Gas Engine gas in a bad ventilated room overnight or for a longer period of time. Keep or maintain the equipment in a large, well ventilated place instead. Cool down the engine first when filling coolant to avoid being hurt by the coolant steam. Open the pressure cap only when the coolant is lower than 50 , and then slowly loosen the cap to release the pressure of cooling system. -

Page 5: About The Engine

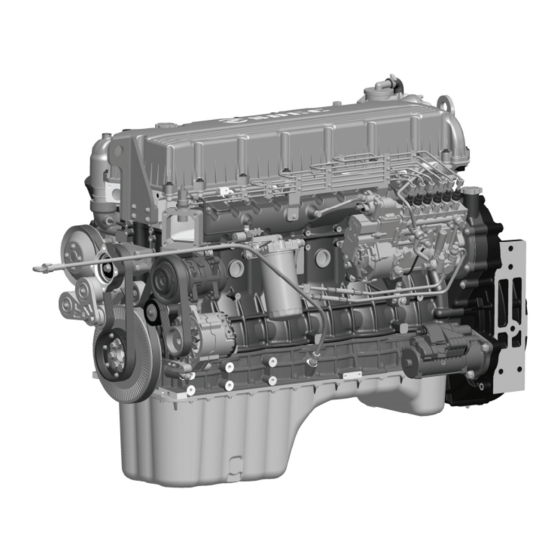

Operation and Maintenance Manual E Series Natural Gas Engine 2 About the Engine 2.1 Engine Outline Diagrams 2.1.1 SC10ET natural gas engine (10L) Intake Side 1 AC Compressor 2 Fan belt (Outer) 3 Fan belt (Inner) 4 Alternator 5 Oil dipstick... - Page 6 Operation and Maintenance Manual E Series Natural Gas Engine Exhaust Side 1 Oil separator 2 Oil separator gas outlet pipe 3 Oil separator oil return pipe 4 Air compressor 5 Oil filter (2 Pcs) 6 Oil drain plug 7 Oil pan...

- Page 7 Operation and Maintenance Manual E Series Natural Gas Engine Front End 1 Water temperature sensor 2 Fan pulley 3 Water pump pulley 4 Fan belt tensioner (outer) 5 Alternator belt tensioner (inner) 6 Vibration damper 7 Alternator 8 Idler pulley...

- Page 8 Operation and Maintenance Manual E Series Natural Gas Engine Rear End 1 Speed sensor 2 Flywheel 3 Roller bearing...

- Page 9 Operation and Maintenance Manual E Series Natural Gas Engine 2.1.2 SC12ET natural gas engine (12L) Intake Side 1 AC Compressor 2 Fan belt (Outer) 3 Drive belt (Inner) 4 Alternator 5 Oil dipstick 6 Low pressure gas filter 7 Low pressure gas shut-off valve...

- Page 10 Operation and Maintenance Manual E Series Natural Gas Engine Exhaust Side 1 Rear lifting ring 2 Oil separator gas outlet pipe 3 Oil separator oil return pipe 4 Air compressor water inlet pipe (1) 5 Air compressor water outlet pipe (2)

- Page 11 Operation and Maintenance Manual E Series Natural Gas Engine Front End 1 Fan pulley 2 Water temperature sensor 3 Water pump pulley 4 Fan belt tensioner (outer) 5 Alternator belt tensioner (inner) 6 Vibration damper 7 Alternator 8 Idler pulley...

- Page 12 Operation and Maintenance Manual E Series Natural Gas Engine Rear End 1 Speed sensor 2 Flywheel 3 Roller bearing...

-

Page 13: Engine Model Identification

Shang Chai Power * Q stands for vehicle, G off-road equipment, D generator set. For example: SC12ET390Q5 stands for Shang Chai E series four-valve vehicle natural gas engine of 12 liters with power of 390 PS and compliant with China V 2.3 Engine Nameplate... -

Page 14: Specifications And Parameters

Operation and Maintenance Manual E Series Natural Gas Engine 2.4 Specifications and Parameters 2.4.1 Specifications Engine SC10ET SC12ET Total displacement/L 10.4 11.8 Type In-line, four-stroke, water-cooled, electronic-controlled Bore/mm Stroke/mm Number of Cylinders Number of valves of each cylinder Compression ratio 10.5:1... - Page 15 Operation and Maintenance Manual E Series Natural Gas Engine 2.4.2 Parameters Engine SC10ET SC12ET Lubricating System Oil pressure/kPa @ Idle speed (minimum allowance) @ Rated speed (minimum allowance) @ Rated speed (maximum allowance) Oil pan capacity/L 35-29 41-33 (Oil dipstick “high-low”)

-

Page 16: Engine Operation

Lube oil of good quality dedicated for natural gas engine should be used for the engine in all seasons. The quality grade of the oil is equivalent to CF 15W-40. It is recommended to use a dedicated lube oil of Shanghai Diesel Engine Co., Ltd. -

Page 17: Engine Operation

Operation and Maintenance Manual E Series Natural Gas Engine ignition systems or contact SDEC’s service center. The switch goes back to the position ON from the position START automatically after the engine has started up. Caution: The oil pressure gauge should show reading within 15 seconds after the engine has started up;... -

Page 18: Engine Shutdown

Operation and Maintenance Manual E Series Natural Gas Engine Engine vibrates abnormally; Engine sounds abnormal; Engine coolant temperature and oil pressure change abruptly; Engine power output is insufficient; Lubricating oil consumption is too much; Gas consumption is too much; There is leakage of oil, gas or/and coolant. -

Page 19: Engine Maintenance

Operation and Maintenance Manual E Series Natural Gas Engine 4 Engine Maintenance 4.1 Maintenance Plan The following table gives maintenance intervals and tasks. Make regular maintenance based on this table. If the engine frequently operates at the ambient temperature below -18°C or above 38°C, or in dusty environment or under a stop-and-go condition, the maintenance period should be shortened properly. -

Page 20: Maintenance Record

Operation and Maintenance Manual E Series Natural Gas Engine 4.2 Maintenance Record Make a regular maintenance record. You may make your own maintenance log by referring to the format of Maintenance Record below. Maintenance Record Engine Serial No. Engine Model & Order No. -

Page 21: Tasks And Methods Of Engine Maintenance

Operation and Maintenance Manual E Series Natural Gas Engine 4.3 Tasks and Methods of Engine Maintenance Checking engine periphery Check the periphery of the engine each time before starting: Check if the engine is in clean state and free from useless things on it. - Page 22 Operation and Maintenance Manual E Series Natural Gas Engine Checking coolant level Warning: Avoid skin or eye contact with coolant to prevent personal injury for coolant contains alkali. Warning: At operating temperature, engine coolant is hot and under pressure, and the steam can cause personal injury.

- Page 23 Operation and Maintenance Manual E Series Natural Gas Engine Checking cooling fan Perform visual check on the cooling fan for crack or any other defect. The fan should be installed reliably. Tighten the fastening bolts (55-65 N·m) or replace the damaged fan if necessary.

- Page 24 Operation and Maintenance Manual E Series Natural Gas Engine (1) Don’t stop the engine until the temperature of coolant reaches 60°C, then remove the oil drain plug, scrap the washer and drain the lubricating oil. Note: There are two oil drain plugs for some engine...

- Page 25 Operation and Maintenance Manual E Series Natural Gas Engine (8) Start the engine and keep it running at idle, and then check the oil filter and drain plug for oil leaks. (9) Shut off the engine, wait for about 10 minutes to provide enough time for the oil to flow back to the oil pan, and check the oil level.

- Page 26 Operation and Maintenance Manual E Series Natural Gas Engine Electrode Good Blackened Deposition consumed Electrode edge get round Carbon deposit at spark Overheated combustion due to electrode plug tip causes abnormal gas electrodepositing to consumed, which results arcing, scattered ignition, the spark plug is the in difficulty in ignition.

- Page 27 Operation and Maintenance Manual E Series Natural Gas Engine Removal (1) Remove a wire at the coil end (A), and then at the spark plug end (B). Note: To avoid confusion, only one high-voltage ignition wire shall be replaced at a time. When removing a wire from the coil and spark plug, pull up the wire back and forth.

- Page 28 Operation and Maintenance Manual E Series Natural Gas Engine (6) Tighten the housing with a proper tool (in the Aluminum direction showed) to 40 ± 7 N·m. head Aluminum casing Tightening direction (Right) (7) Open the main valve of the gas line and start the engine. Use soapy water to check the joints between the aluminum head and aluminum casing as well as the thread of the drain valve for gas leakage.

- Page 29 Operation and Maintenance Manual E Series Natural Gas Engine Replacing high and low pressure gas filter elements For the replacement of the low pressure gas filter element, refer to "Checking or replacing low pressure gas filter element". The replacement of the high pressure gas filter element is as follows: Unscrew the bowl suing a wrench, remove the element, and install a new one.

- Page 30 Operation and Maintenance Manual E Series Natural Gas Engine (5) Mark a sign on the damper and rotate the crankshaft for 360 degrees. Follow the same steps to check and adjust the rest intake and exhaust valve clearances. Checking/adjustment exhaust brake clearance (if equipped)

- Page 31 Operation and Maintenance Manual E Series Natural Gas Engine (3) Put an inspection lamp into the cleaned element to check it for broken holes or tears based on transmittance, and replace the element with a new one if any problem is found.

- Page 32 Operation and Maintenance Manual E Series Natural Gas Engine Checking air compressor Warning: Air pressure should be released from the air system before removing parts from the air compressor to avoid personal injury. Air outlet pipe Check the air outlet pipe and joints for carbon deposit.

- Page 33 Operation and Maintenance Manual E Series Natural Gas Engine Purge the air in the coolant system while adding the cleaning fluid. Pour the cleaning fluid slowly to avoid air block. Cleaning fluid should be added up to the bottom of the filler in the radiator and wait for about 3-5 minutes for a full purge of air.

-

Page 34: Engine System And Dedicated Components

Operation and Maintenance Manual E Series Natural Gas Engine 5 Engine System and Dedicated Components 5.1 Abbreviation Compressed natural gas Absolute pressure in intake manifold Electronic control module Natural gas pressure (sensor) Engine position sensor Natural gas temperature (sensor) FloTech... -

Page 35: Dedicated Components

Operation and Maintenance Manual E Series Natural Gas Engine Pressure Regulator Gas Filter Tanks Regulator Inter Coo ler PreThrottle Pressure Mixer FloTech Position F eedback Misc. Spark spare Control OH2.0 OH2.0 Compressed Air FPP, FPP2/IVS, Filter Filt er Engine Engine... - Page 36 Operation and Maintenance Manual E Series Natural Gas Engine 5.3.3 Fuel metering valve (FMV) A FMV includes natural gas nozzles, a natural gas Gas pressure and Gas outlet pressure sensor (NGP) and a natural gas temperature temperature sensor sensor (NGT).

- Page 37 Operation and Maintenance Manual E Series Natural Gas Engine Caution: Do not run the engine when the UEGO sensor is disconnected (not powered), because the sensor may be contaminated. During cold starting, the engine runs with slightly dense gas mixture to enhance engine stability and maintain the margin for not flaming out.

- Page 38 Operation and Maintenance Manual E Series Natural Gas Engine 5.3.8 Low-pressure gas shut-off valve The core of the low pressure gas shut-off valve is driven by coil and its state is controlled by ECM. It is closed when the engine is not in work. Its function is to stop or restore gas supply timely.

-

Page 39: Electronic Control Module Fault Code

Operation and Maintenance Manual E Series Natural Gas Engine 6 Electronic Control Module Fault Code 6.1 MIL and System Fault Code When the key switch is at "ON" position while the engine is in stop, the MIL comes on first and then dims after 2 seconds. -

Page 40: Fault Code

Operation and Maintenance Manual E Series Natural Gas Engine 6.3 Fault Code WOODWARD system Fault Fault Fault Description Fault Description code code SFC 133 UEGO Heater Voltage Low SFC 554 Low Flash Memory Available SFC 134 UEGO Heater Voltage High... - Page 41 Operation and Maintenance Manual E Series Natural Gas Engine Fault Fault Fault Description Fault Description code code SFC 371 PTP Higher Than Expected SFC 911 SmartCoil 1 Open Faults SFC 372 PTP Voltage Low SFC 912 SmartCoil 2 Open Faults...

-

Page 42: Troubleshooting Guidelines

Operation and Maintenance Manual E Series Natural Gas Engine 7 Troubleshooting Guidelines Some simple typical natural gas engine fault modes, possible causes and troubleshooting steps are listed in the tables below. If any one of modes occurs in engine operation, it is required to eliminate it by taking appropriate measures. - Page 43 Operation and Maintenance Manual E Series Natural Gas Engine Fault mode 4 Alternator refuses to charge or fails to charge enough Possible cause Correction The instrument or indicator lamp failure Check and replace the instrument or indicator lamp The battery connector(s) is loose or eroded...

- Page 44 Operation and Maintenance Manual E Series Natural Gas Engine Fault mode 7 Engine is difficult to start or takes long time to start Possible cause Correction Refer to the operating instruction manual of the vehicle Improper starting method or the equipment for proper starting method...

- Page 45 Operation and Maintenance Manual E Series Natural Gas Engine Fault mode 9 Rough running at idle speed Possible cause Correction The fault is shown by the fault code Refer to the fault code table in Chapter 6.3 for the cause...

- Page 46 Operation and Maintenance Manual E Series Natural Gas Engine Possible cause Correction The waste gate valve is stuck on open or close Check the boost pressure Problem of the ignition system or misfire Check the ignition coil connectors and wires for...

- Page 47 Operation and Maintenance Manual E Series Natural Gas Engine Fault mode 12 Engine cannot reach rated speed with load Possible cause Correction The fault is shown by the fault code Refer to the fault code table in Chapter 6.3 for the cause...

- Page 48 Operation and Maintenance Manual E Series Natural Gas Engine Possible cause Correction Wrong calibration of ECM Refer to the fault code table in Chapter 6.3 for the cause The high pressure gas shut-off valve is closed or Check the shut-off valve, or replace the gas filter element...

- Page 49 Operation and Maintenance Manual E Series Natural Gas Engine Possible cause Correction Pulleys or vibration damper bolts or nuts loose Check and tighten loose bolts or nuts The fan blades not in balance Remove the drive belt and operate the engine for a short time at the speed that the vibration was present.

- Page 50 Operation and Maintenance Manual E Series Natural Gas Engine Fault mode21 Oil consumption too much Possible cause Correction The engine runs at idle speed for too long time Shorten the time of the engine running at idle External oil leakage of the engine...

- Page 51 Operation and Maintenance Manual E Series Natural Gas Engine Possible cause Correction Fault of the pressure cap of the radiator or Check the function of the pressure cap pressure calibration is too low Fault of the thermometer Check the thermometer and replace it if necessary...

-

Page 52: Engine Storage

Operation and Maintenance Manual E Series Natural Gas Engine 8 Engine Storage If the engine is to be shutdown for a period of time (6 months at most), measures of cleaning and necessary oil seal should be taken for rust protection.

Need help?

Do you have a question about the E Series and is the answer not in the manual?

Questions and answers